Creators Wanted “Lends a Helping Hand” in S.C.

Last week was a milestone for the Creators Wanted Tour—it marked the first time the nationwide initiative returned to a community and got to see how perceptions of manufacturing had changed since its first visit.

Welcome back: The Creators Wanted Tour, a joint venture of the NAM and its workforce development and education partner, The Manufacturing Institute, returned to host and champion sponsor Nephron Pharmaceuticals Corporation in West Columbia, South Carolina, in the 11th stop of the roadshow, which took place Oct. 4–7.

Happy MFG Day! On MFG Day, Oct. 7, Creators Wanted campaign co-chair Lou Kennedy, president, CEO and owner of Nephron Pharmaceuticals Corporation, and her team hosted the tour stop’s premier event at its new Nephron Nitrile Glove Factory. The 426,000-square-foot facility is scheduled to open next month and will produce nitrile gloves used in hospitals and sterile rooms globally.

- The protective-glove shortage in the U.S. during the pandemic inspired Kennedy to build the factory, which is set to produce 2 million gloves a year at full capacity.

- South Carolina legislators from both sides of the political aisle were on hand for a tour of the site. House Democratic Majority Whip James Clyburn and Republican Reps. Joe Wilson and Jeff Duncan joined hundreds of local students, educators, community leaders and manufacturers to view and learn more about the campaign and its resources.

Ready for the “boom”: “There is a manufacturing boom taking place all over the country,” Majority Whip Clyburn said. “We’ve got to focus on getting these young people prepared” for manufacturing careers.

- As Rep. Wilson said, “The opportunities for manufacturing just can’t be better.”

- “401(k), great salary—average wage of 75 to 80K—clean and beautiful working conditions and hard work with a lot of fun,” Kennedy said of jobs at Nephron, while extolling opportunities at modern manufacturers across the state and in nearby communities.

- Major Creators Wanted supporters Honda and Trane Technologies also have operations in the Palmetto State, and several other campaign sponsors, including Chroma Color Corporation, are within a short distance of West Columbia.

More career guidance: Students seeking tailored advice about their professional futures got it from representatives of FactoryFix, official recruiting partner of Creators Wanted, who were on hand to meet and coach job seekers.

- South Carolina Chamber of Commerce President and CEO Bob Morgan, whose organization is a tour partner, was on site with his team to give students information on manufacturing opportunities in South Carolina.

- On Friday, Creators Wanted sponsor Autos Drive America had an exhibit showing attendees the types of vehicles being manufactured in South Carolina.

Women in manufacturing: During a “fireside chat” panel on the tour stop, Kennedy was joined by Autos Drive America President and CEO Jennifer Safavian and MI President Carolyn Lee to discuss the importance of advancing more women in manufacturing.

- “Growing up here in the deep south 20, 30 years ago, we were supposed to be teachers or … nurses; we weren’t supposed to be pharma CEOs,” Kennedy said. “And so, my goal is to help every young lady be what she wants to be, even if it’s the nontraditional career path. … If you want to be a super-genius chemist, you can do that. If you want to be a super-genius engineer, you can do that.”

- Echoed Safavian, “I think the message [of Creators Wanted] is, ‘Don’t be afraid to ask questions. Don’t be afraid to try something. For women especially, this is a terrific opportunity. … A lot of people think manufacturing is dark, dirty, dangerous. It is not. … it is the complete opposite.”

Calling all veterans: Modern manufacturing is also a natural fit for those who have been in the military, speakers told the audience during another panel discussion.

- “I started at Nephron as a senior system analyst, and throughout my career everything that I was faced with at Nephron I’d already seen in the military,” said Air Force veteran Eric Jackson, now a senior IT security analyst at Nephron. “So, I think the [military] training … is what prepared me for this job.”

The reach: The South Columbia 2022 tour stop, made possible by additional support from Dow, Honda and Nephron Pharmaceuticals, was a record breaker.

- More than 700 students from 13 schools—most located in traditionally underrepresented communities—participated in the tour stop’s events. Last year, those numbers were 500 and seven, respectively.

- This year’s West Columbia email signups—people wishing to learn more about manufacturing careers—brought Creators Wanted’s total signups to more than 520,000.

The last word: The tour stop may have been best summarized by one young student who attended the events. “Creators Wanted,” she said, “is a helping hand.”

MFG Day 2022 Kicks Off in North Carolina

The Manufacturing Institute, the NAM and SAS kicked off MFG Day 2022 at SAS world headquarters in Cary, North Carolina, where manufacturing, technology and political leaders highlighted the transformation in the industry and the promise of manufacturing careers.

The CEO: The session began with a welcome from SAS CEO Jim Goodnight, who spoke about manufacturing innovation and the way that cutting-edge technology is creating a more resilient industry and a more productive future.

- “We are committed to help teach and reskill the workforce for the demands of modern manufacturing, from data scientists and process engineers to robotic technicians,” said Goodnight. “There is great potential for growth in progress, especially when you bring analytics knowledge and tech experience to this critical sector.”

The governor: North Carolina Gov. Roy Cooper addressed the group and spoke about the value of workforce development.

- “When I talk with CEOs about coming to North Carolina or expanding in North Carolina, their top three issues right now are workforce, workforce and workforce,” said Gov. Cooper. “They know that they need this skilled, diverse help in their businesses.”

The NAM: NAM President and CEO Jay Timmons spoke about the skills gap in manufacturing and urged attendees—including students and young people—to see the opportunities for a rewarding career in the manufacturing industry.

- “If we don’t find the talent that we need to keep shop floors running and research and development moving, we’re going to lose out on productivity, on innovation, on growth,” said Timmons. “And this could cost America’s edge in global economic leadership. We cannot let that happen. We have to redouble our commitment to ensure that that does not happen.”

Transforming the workforce: The first panel of the day included a conversation with manufacturing leaders—moderated by Timmons and including experts from Deere & Company, Mack Trucks, SAS and Johnson Controls—discussing how technology and analytics continue to transform the industry and workforce. The conversation touched on:

- The way that companies are using advanced analytics to improve their products and processes in the modern age;

- The need for engagement programs and partnerships with professional organizations and school systems to help change perceptions of manufacturing; and

- The opportunity that manufacturing provides to solve big problems and make the world a better place.

Recruiting manufacturers: The day continued with a “creators” conversation moderated by MI President and Executive Director Carolyn Lee, which included panelists from SAS, ABB Inc. and Mack Trucks. The discussion covered:

- The dynamic nature of the industry—and how the sector innovated and adapted to new realities during the COVID-19 pandemic;

- The importance of networking, education and inclusive programming to attracting a diverse workforce; and

- The extraordinary range of careers in manufacturing—from sales, to operations, to HR and beyond—and the diverse set of skills and backgrounds needed to fill them.

The last word: “Manufacturing careers have a higher impact on local communities than any other sector in the economy,” said Lee. “So, manufacturing’s reach goes far and wide. But it’s not just the people on the plant floor; it’s all of the systems and all of the supports and all of the pieces that come together to support manufacturing.”

Learn more: For more information, and to check out video of the full event, click here.

An Army Vet Transfers His Skills to Manufacturing

For Christopher Wilf, joining the armed services is a family tradition.

“When I was growing up, my dad was in the military, his dad was in the military, and my mom’s side of the family had people in the military,” said Wilf. “When I was 16 and trying to plan out my future, my high school had a recruiting station with all four branches. I went in asking for information and went from there.”

Wilf had a four-year plan: to join the military, gain some skills and earn some money. But as he prepares to exit his role as a warrant officer in the U.S. Army more than 21 years later, it’s clear that the experience was a better and more long-lasting fit than he expected.

The next step: After two decades working in military aviation, Wilf wanted to try his hand at something else—and when he was introduced to the MI’s Heroes MAKE America program at Fort Stewart, outside Savannah, Georgia, he saw an opportunity for a new career.

- “Heroes gives you a whole range of opportunities, whether it’s within your existing specialty or not,” said Wilf. “If you’re looking for something new, they’ll provide you some references for that new area.”

- “We’re in Savannah, and logistics is huge here—lots of Fortune 500 companies that need logistics support. I understood logistics, but had no background in it, so the Heroes program I chose provided me with some of that training.”

The program: The MI designed Heroes MAKE America as an integrated certification and training program that helps prepare transitioning service members, veterans, National Guard members, reservists and military spouses for careers in the manufacturing and supply chain industries. It offers in-person and remote training options, as well as career guidance and placement support.

The results: Through the Heroes program, Wilf is working as a warehouse distribution manager at the Target distribution center in Midway, Georgia—and he credits Heroes with offering him the training to succeed.

- “As a guy coming in with no formal logistics knowledge, it gave me everything I needed,” said Wilf. “I’m currently working in the logistics field, and now I have some framework for how logistics works. When a concept comes up at work, I have a frame of reference—I can say, tell me about the specifics of this job, but I understand the general theme.”

Good advice: “Go into Heroes seriously, with a mindset of ‘I am doing this for myself and my career, to better myself and gain knowledge that makes me marketable in the civilian world,’” said Wilf.

- “For me, that was the most beneficial aspect of the course—that I became immediately marketable, even though it was only a two-month program. Employers know that I have some knowledge, and I’ve proven that I’m someone who can lead.”

The transition: It’s clear from Wilf’s experience that the skills he gained in the military make him a strong fit for manufacturing—and that the industry can provide him with a long-term career.

- “In just two months, I’ve already seen how my skills transfer,” said Wilf. “I’ve gone through a lot of interviews, and those characteristics of a military person—to be reliable, to be safety-conscious and to be a leader—that’s what people are looking for.”

- “Picking Heroes MAKE America provided me with the ability to stay on an upward trend and find a career, not just a job.”

A pitch for manufacturing: “If you’re looking for a field where you can get a job, with potential for upward growth, then manufacturing is it,” said Wilf. “From being at the warehouse level to working in management at headquarters, that potential for growth is real.”

“FAME Set the Path for My Entire Career”: a Manufacturing Success Story

Ellery Kring didn’t set out to begin a career in manufacturing. In fact, she wasn’t initially focused on a long-term career at all.

“I was pretty typical out of high school,” said Kring. “I needed some money and a job.”

The Kentucky native heard of a job opening at appliance manufacturer Bosch through someone she knew and secured an entry-level role that helped pay the bills. But when she learned about an apprenticeship opportunity through the Federation for Advanced Manufacturing Education (FAME) program, she saw a chance to build something more substantial.

someone she knew and secured an entry-level role that helped pay the bills. But when she learned about an apprenticeship opportunity through the Federation for Advanced Manufacturing Education (FAME) program, she saw a chance to build something more substantial.

The program: Founded in 2010 by Toyota and operated today by The Manufacturing Institute, FAME aims to help students become highly skilled, sought-after makers capable of meeting the unique needs and challenges of the modern manufacturing sector.

- It serves as a career pathway program for current and aspiring manufacturing workers, providing them with on-the-job training and classroom education, leading to an associate degree and the FAME Advanced Manufacturing Technician (AMT) certificate.

A “no-brainer”: “Bosch is a pretty big sponsor of FAME in northern Kentucky, and I heard about it through word of mouth on the plant floor,” said Kring. “I had a strong feeling that I liked being in industry, and when I heard that Bosch had a program that would train you in maintenance and pay for your school, it was a no-brainer.”

- “They allowed us to shadow other departments—quality, manufacturing, logistics,” Kring said. “And in addition to a technical degree, they also gave you the soft skills to help you make your own career.”

The path: After her FAME graduation four years ago, Kring served as a Manufacturing Engineering Systems (MES) application engineer, helping to digitize the shop floor and integrate solutions to improve efficiency in production lines. Kring describes the role as “production IT”—maintaining, troubleshooting and implementing new solutions.

- She has recently moved onward and upward—on Aug. 1, she began a new project role that will allow her to focus on building server infrastructure and communications.

The support: Kring credits the FAME program with her success and especially appreciates that it allowed her to keep working while furthering her education.

- “I definitely have that program to credit for where I am now,” said Kring. “They got me the associate degree, which was such a big deal—having an actual degree. Other employers had certification programs, but this got me a degree.”

- “Because it’s hands on, I got to shadow an engineer, and since I was an apprentice, I got my foot in the door in this department,” said Kring. “If it wasn’t for the FAME program, I wouldn’t have seen this department, or known that I would have been interested in such a job.”

The industry: Kring notes that the reality of advanced manufacturing is far different from the stereotypes she had in mind when she first began considering a career in the industry. She encourages other job seekers to give it a second look:

- “Manufacturing is versatile,” said Kring. “I would highly advise people to be aware of

- how diverse and advanced it is. You could be in logistics and planning, or IT, or purchasing, or marketing.”

- “It’s important to keep in mind that there’s no one thing in manufacturing. It’s constantly growing and expanding. . . . Once you get your foot in the door, you have limitless possibilities for the rest of your life.”

Kring also encourages other women to join the field and says that, while manufacturing may currently be a male-dominated industry, there are plenty of opportunities for women who are interested in making their mark.

- “Women are perfectly capable of doing anything that a man” can do, said Kring. “There are women in this field, and we need more. I would tell women not to have preconceived notions about the industry. Don’t be intimidated, and don’t let any preconceived ideas or stereotypes stop you from going after it.”

The last word: “FAME set the path for my entire career,” said Kring. “I can’t speak highly enough about it. You can’t go wrong—it’s only a year and a half long program. It pays for your school, you get hands-on work experience, and you come out of it debt-free. It’s a quick program that has a lifetime effect in a positive way.”

MFG Day 2022 Is Almost Here!

This Friday, Oct. 7, manufacturers across the country will open their doors in an epic celebration of manufacturing in America. Students, parents, teachers, local leaders and many others will be welcomed into factories, technical schools and similar venues to see what modern manufacturing is really about.

What it is: Led by The Manufacturing Institute—the NAM’s workforce development and education partner—MFG Day kicks off a monthlong series of events that provide an inside view of the industry and the exciting careers it offers.

This year’s events: MFG Day events include open houses, expos, job fairs, roundtable discussions and more across the United States, featuring many different types of manufacturing.

- This year, more than 500 companies and organizations are already on the national map of registered events, beating last year’s total.

- One of the flagship events will be hosted by SAS at its world headquarters in Cary, North Carolina, and include remarks from SAS CEO Jim Goodnight and Gov. Roy Cooper, as well as discussions with manufacturing leaders from Deere & Company, Mack Trucks, Johnson Controls and ABB. Experts from SAS and the MI will speak about technology, analytics and career paths in manufacturing, while manufacturing and technology exhibits will be open to visitors.

- In addition, the NAM and MI’s Creators Wanted mobile experience will stop at Nephron Nitrile’s new glove factory in West Columbia, South Carolina, giving visitors the chance to complete challenges that resemble real, creative manufacturing work.

Why it matters: The manufacturing industry will need to fill about 4 million jobs by 2030, and a lack of high-skilled workers threatens to leave more than half of those positions empty, according to a study by the MI and Deloitte. MFG Day is designed to increase awareness among the young people who could become the stars of tomorrow’s industry, showing them how much they stand to gain from choosing manufacturing as their career.

- Changing misconceptions: MFG Day helps the industry push back against misguided stereotypes, demonstrating that today’s industry is high skilled, high tech, clean, creative and welcoming to people of all backgrounds and talents.

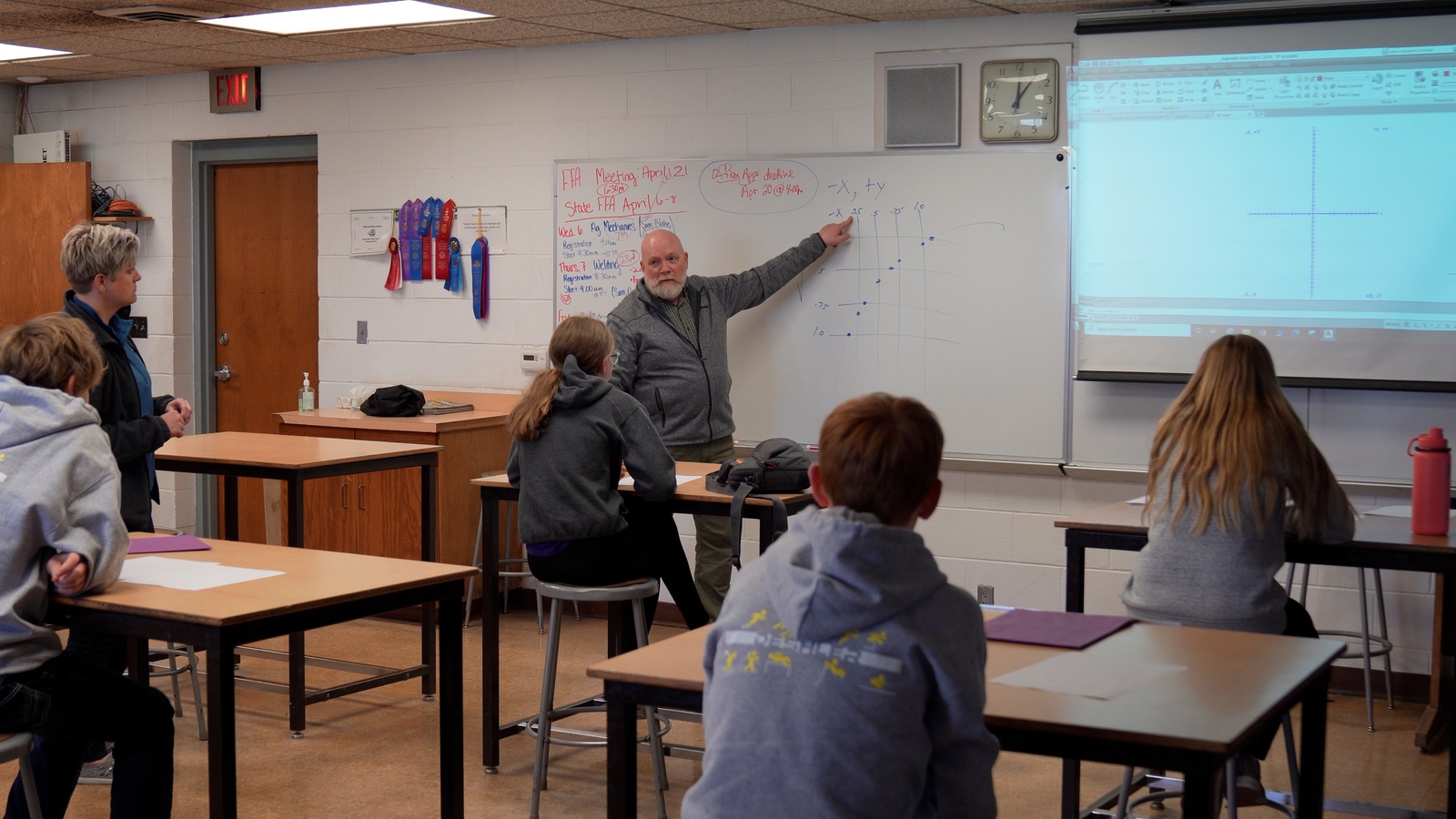

- Opening doors: MFG Day events are also excellent opportunities to demystify the industry and show young people (along with their parents and teachers) a vision of an exciting future. The coolness factor matters—taking students through a dynamic, high-tech factory floor can fire their imaginations and change the course of their lives.

Don’t forget: If your company or organization is already on board and planning an MFG Day event, register it so that the MI can keep track of the industry’s outreach and highlight the impact of MFG Day nationwide.

- Find more resources to help you with MFG Day planning here. And check out these useful tips for promoting and sharing MFG Day content on social media.

What we’re saying: “This is manufacturing’s biggest annual stage to inspire the next generation,” said MI Director of Student Engagement Jen White. “We hope anyone who cares about the industry’s future will use their social media platforms and amplify #MFGDay22, to showcase why manufacturers are saying ‘Creators Wanted.’”

Creators Wanted Inspires Students in Tennessee

If you’re a student or job seeker looking for tailored career guidance combined with some hands-on, immersive fun, White House, Tennessee, was the place for you to be last week.

National impact: The Creators Wanted Tour, a joint project by the NAM and MI, made its 10th national tour stop at White House Heritage High School on Sept. 27–29.

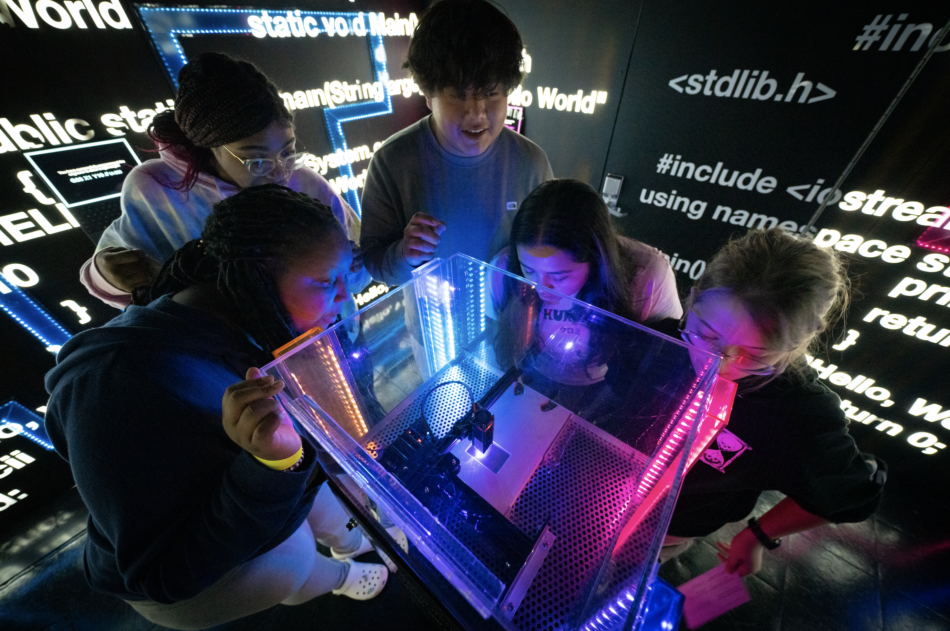

- There, more than 700 students from four schools in Tennessee’s Robertson County went through the Creators Wanted mobile immersive experience, the award-winning, manufacturing-themed escape room–like activity in which participants work together to solve challenges in a “race to the future.”

- They also got the opportunity to chat with on-site sponsor representatives from Electrolux, Schneider Electric and FactoryFix about the many rewarding, well-paying career paths available in the industry.

- Local partners, including the Robertson County Economic Development Board, the Tennessee Chamber of Commerce & Industry and the Tennessee Manufacturers Association, were also on hand to answer jobs- and manufacturing-related questions.

Calling all creators: During the Tennessee stop’s premier event, speakers underscored the need for more skilled workers to fill the millions of open manufacturing jobs in the U.S.

- “Here in Tennessee, our industry has more jobs to fill than there are people looking for them,” Tennessee Chamber of Commerce & Industry and Tennessee Manufacturers Association President and CEO Bradley Jackson said.

- Speaking from firsthand experience about the many benefits of choosing one of those jobs was Tony Fraley, a plant manager for Electrolux. “I’m living proof of the great career opportunities in the field of advanced manufacturing,” said Fraley, who started at the company “running a process that coats dishwasher racks.”

- “I grew up about two hours from here in a small town very similar to White House,” he continued. “I always liked math and science. … I hope that stories like [mine] inspire the next generation of workers to consider a career that’s not only been good to me, but also offers a strong opportunity to earn a family-sustaining wage in a high-demand field.”

The numbers: The Tennessee stop resulted in more than 52,000 email signups from people interested in learning more about manufacturing careers.

An eye-opener: Students had a great time at last week’s events—and were pleasantly surprised to learn just how many interesting options manufacturing could offer them.

- “Creators Wanted made me excited about my future,” said one student.

- Added another, “Creators Wanted made me think more about my future in manufacturing.”

The last word: It’s past time for manufacturing careers to get their due as the gratifying professions they are, according to the Creators Wanted Spotlight panelists (and manufacturing company employees).

- Manufacturing “is definitely very rewarding [from a salary standpoint] but also the lifestyle that you get to have,” said Schneider Electric Manufacturing Engineer Zoie McFarland. “I get to go boating every weekend. I get to go hiking. I travel a lot. … Also, I was able to buy a house at 25. So, I think that is one major benefit—the lifestyle [manufacturing] gives you and the benefits that come from it.”

Creators Wanted Kicks Off Fall 2022 in Tennessee

Robertson County, Tennessee, is a battleground—for companies vying for talent. With approximately 14,000 students in the school district, it’s a prime target for manufacturers looking to attract more young workers by shifting perceptions among parents, educators and students themselves.

What’s happening: The Creators Wanted Tour, the NAM and The Manufacturing Institute’s effort to build the workforce of the future, kicked off its fall 2022 tour yesterday in White House, Tennessee, just outside of Nashville. The stop’s premier event offered a glimpse of the advantage the tour gives manufacturers over other industries.

- “Our mission is to enable all students … to succeed … in a technologically advanced and culturally diverse society,” Dr. Chris Causey, director of schools for Robertson County, said at the kickoff event, calling Creators Wanted “a life-changing experience.”

- The stop was made possible by support from Dow and Honda, as well as more than 70 other manufacturing companies, including Tennessee stop hosts Electrolux and Schneider Electric.

The pitch and platform: Area manufacturing leaders held students’ attention as they spoke about the resilience of the industry and the reward of manufacturing careers.

- “Preliminary job numbers for August already show that Tennessee has reached its highest manufacturing employment level in over a decade—that’s over 360,000 Tennesseans,” said Bradley Jackson, president and CEO of the Tennessee Chamber of Commerce and Tennessee Manufacturers Association, the official NAM and MI affiliate organization in Tennessee and key partner in the tour’s first-ever stop in the state.

- Tony Fraley, the Electrolux plant manager in Springfield, didn’t just trumpet the company’s new, $250 million state-of-the-art manufacturing facility. He explained to students that robots and cobots are increasing the industry’s need for technical skills, which enables workers with these skills to make “family-sustaining wages in a high-demand field.”

- “We have a lot of job openings, really good jobs,” said Ken Engel, senior vice president, global supply chain – North America at Schneider Electric. He highlighted the company’s advanced development program, where students “fresh out of college have a rotational program” to get experience in supply chain, logistics, lean manufacturing, marketing, finance and other disciplines.

The Creators Wanted experience: “The skills and technology on display here will help change Tennesseans’ understanding of what a manufacturing team does and how they do it,” said MI President Carolyn Lee.

- “So, for those of you who’ve gone through our mobile experience—did you have fun?” asked NAM President and CEO Jay Timmons, causing students to nod in agreement.

- Hoping to spur more career exploration, he concluded with this: “Have you learned that you can make a lot of money in manufacturing, doing things you like to do? That’s just a taste of what our industry is about and what manufacturing teams do every day.”

Early returns: More than 200 attendees gathered for the premier event, including students from White House Heritage High School, East Robertson High School and Jo Byrns High School.

- During the two-and-a-half day stop, the NAM and MI expect more than 700 students to visit and more than 30,000 email signups by students and career mentors interested in manufacturing careers.

The last word: “To strengthen manufacturing’s competitiveness, we must shift perceptions among, and provide opportunities to, students, parents and educators,” said NAM Executive Vice President Erin Streeter. “This stop in Tennessee will provide them with an introduction to the technologies and careers that are defining the future.”

How One Manufacturer Is Reinvigorating a Small Nebraska Town

Deshler, Nebraska, has a population of 747. It has one grocery store and one gas station, and its local high school graduates approximately 18 seniors each spring. It’s also the global headquarters of international irrigation firm Reinke Manufacturing, which employs a large number (about 600) of the town’s residents.

A great job: Working at Reinke has many perks, including generous pay and benefits, but until recently, the company had a hiring challenge to overcome in one specific area: housing.

- “We are so rural that we were having difficulty getting people,” Reinke Manufacturing President Chris Roth said. “We could recruit them easily, but then it was like, ‘Well, where am I going to live?’”

A solution—with an added perk: Around 2012, Roth and other leaders at Reinke came up with a fix: The company would purchase a house for a new employee and rent it to him at a reasonable fee.

- After that, the firm was on a roll. “We started to buy up lots with homes that needed to be torn down, homes that have been vacant for years … and put up something else” in which employees could live, Roth said. The move has “improved the town, too,” he added.

- The first build was a fourplex with efficiency apartments. “There’s a bedroom in the back, a bathroom and a kitchenette. People like those; they’re really nice.”

Expanding a vision: The efficiencies are mostly for single people, however, and Reinke wanted to have options for prospective employees with families, too. So, it began thinking bigger.

- “Our second fourplex was a building with two duplexes,” Roth said. “These are two-bedroom units, and small families live there.”

- Soon the company began purchasing single-family homes, too. It currently rents out seven such houses—all available for sale to the employees.

Even bigger: In early 2021, Reinke made its biggest investment in affordable employee housing yet. It purchased an entire motel in nearby Hebron, Nebraska, and turned it into apartments.

- The building now houses 40 people, some of them families. “It was run down when we bought it, but all brick and had a newish roof, so we were able to save a lot of it,” Roth said.

- In addition, the company recently broke ground in Deshler on a two-story, eight-unit housing complex of two-bedroom apartments that will be ready in spring 2023.

Game changer: Since Reinke got in on the housing game, recruitment and retention of top employees “is easier now,” Roth said. “They’re willing to move because they know we’ll have housing. If you’re going to move several states, you want to know where you are going to live … There really isn’t anything on Apartments.com [in Deshler].”

- Another benefit for Reinke employees has been that their new landlord requires less up-front outlay. “A deposit and first and last months’ rent is a lot, and it can be a problem for a lot of folks,” Roth said. “We don’t necessarily need all that.”

- The program is so popular, Roth said, there’s currently a waiting list for the units.

Other efforts: In addition to employee housing, Reinke is increasing its presence and education efforts at the local schools in a bid to recruit talent sooner.

- The company started an employee-taught welding program at Deshler High School, which allowed the company to develop its own curriculum using American Welding Society Standards.

- “It gives us the opportunity to get in front of kids and teach them skills that we need,” Roth said. Reinke offers a similar program to adults through a cooperative effort at a community college.

- A Reinke-run middle school program helps students learn to use CNC machinery, with which the company manufactures parts. Through another program at the middle school, the company teaches a class on AutoCAD, software that allows users to create detailed two- and three-dimensional drawings, as well as courses on basic electrical and hydraulics skills.

The last word: Worker housing and manufacturing classes for young people will do more than create a top-notch workforce for the company, Roth said.

- “A lot of times kids will graduate and go to Omaha or Lincoln, and they don’t come back,” he said. “This is a way, hopefully, to keep people here in Deshler. They make very good money, have great benefits, so we hope they stay … and keep the town going.”

Manufacturers Call for Quick Resolution to Rail Negotiations

Timmons: Delays in concluding the rail negotiations will exacerbate the pain of inflation and supply chain disruptions, and failing to reach an agreem

Washington, D.C. – Following news that White House aides and Cabinet officials spent Tuesday reviewing contingency plans for a work stoppage, including outreach to shippers, truckers and air-freight lines to keep goods moving, National Association of Manufacturers President and CEO Jay Timmons released the following statement on the ongoing negotiations between Class I railroads and labor unions representing the freight rail workforce:

“For years now, America’s manufacturing workers have endured the effects of rapidly rising material costs and severe supply chain disruptions, and our member surveys have shown quarter after quarter that these are among the top challenges affecting manufacturing growth in America. Further delays in concluding the rail negotiations will exacerbate the pain of inflation and supply chain disruptions, and failing to reach an agreement before Friday’s deadline would devastate the movement of manufactured products that families depend on,” said Timmons. “The Presidential Emergency Board has announced reasonable recommendations that nearly all parties have accepted, so now is the time to resolve remaining issues. We appreciate the administration’s proactive approach, and Congress should be ready to act as a last resort. But manufacturers still believe that the parties have it within their power to resolve these talks before they inflict severe economic damage.”

Currently, the American freight rail network accounts for nearly 40% of total freight volume, and a strike or delay in finalizing a long-term contract would have devastating impacts across surface supply chain networks and economic output. The Association of American Railroads recently released a report that found a nationwide freight rail interruption could cost more than $2 billion per day in lost economic activity.

Background: On Monday, Sept. 12, the NAM sent a letter to congressional leaders reiterating support for the work of the Presidential Emergency Board, which has aided in the talks. The NAM also urged Congress to use its statutory authority to institute the PEB’s recommendations should it become necessary to intervene. The NAM supported President Biden’s selection of an independent and objective PEB and believes that the recommendations announced on Aug. 16 have provided an appropriate framework to avoid disruption to freight rail operations.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Pfizer’s Refugee Hiring Program Changes Lives

As Mona Babury tells it, Pfizer’s refugee hiring program was born out of the basic human need to connect during a time of shared anguish.

Wanting to help: Last August, Babury, the pharmaceutical company’s director of global diversity, equity and inclusion, was horrified by news coverage of the Taliban taking over Afghanistan and refugees fleeing.

- Babury’s husband had fled Afghanistan for the United States with his family at the age of 5, some 40 years before, so she had a personal connection to the events unfolding.

- She felt an urge to talk to someone who would understand, so she turned to Pfizer Executive Vice President and Chief People Experience Officer Payal Sahni, also a former Afghan refugee. In the course of their conversation, an idea popped into Babury’s head.

Lightbulb moment: “I said, ‘Why don’t we create a refugee hiring program? It will give [refugees] a glimmer of hope when they’re coming here with just the clothes on their backs,’” Babury recalled. “Within minutes, she responded, ‘Go for it.’”

Making it a reality: Pfizer, which had close to 1,000 job openings it was looking to fill, had never created a refugee hiring program before. “We didn’t have a playbook,” Babury said.

- The team decided to research similar initiatives, and in doing so contacted The Tent Partnership for Refugees, a nonprofit organization established by Chobani founder Hamdi Ulukaya to help businesses hire and train refugees.

- Thanks to Tent’s help, Pfizer’s Refugee Leadership Initiative was launched in mere days, with Babury named as its leader.

- Its goal? Hire a minimum of 100 refugees by the end of 2022 and provide mentorship opportunities to an additional 150—with 50 of these opportunities earmarked for LGBTQ+ refugees.

Following through: In less than a year, the initiative is well on its way to reaching its goal—having hired 68 refugees so far. The enthusiasm from Pfizer’s workforce has been immediate and widespread.

- After sending an email announcing the program globally, “we had 300 colleagues email back [within a few hours] saying they wanted to volunteer, to support us in any way they could,” said Babury.

- At Pfizer’s Kalamazoo, Michigan, facility, where the initiative has been most successful, “one [team] leader took this very personally,” hiring 18 Afghan refugees since the beginning of 2022, said Babury. In partnership with a local refugee agency, he has also made “a commitment to continue to further ramp up hiring efforts.” (Learn more here.)

Going above and beyond: Pfizer, which now works directly with the not-for-profit humanitarian organizations Tent for Refugees, Welcome.US, the International Rescue Committee and eight other resettlement agencies to source and hire refugees, does more than extend job offers.

- Though the new employees do not require sponsorship to work in the United States, owing to their refugee status, they do need help restarting their lives. Pfizer provides up-front bonuses to help cover the costs of transportation to and from work and to help them obtain driver’s licenses.

A winning formula: Seeking out refugees as employees can be an enormously rewarding sourcing strategy for a manufacturing company, Babury said.

- “The knowledge curve might be a little [steeper], but in the end, there’s so much data that shows refugee hiring pays off immensely,” she said. “They’re very hardworking, loyal and thankful for the opportunity to enter a new workforce.”

A proud moment: “I am so proud of the incredible progress we have made in support of this important and impactful initiative,” said Pfizer Chief Global Supply Officer Mike McDermott. Pfizer Global Supply, Pfizer’s manufacturing and supply organization, has hired the most refugees at Pfizer to date.

- “Our smart, talented and dedicated new colleagues are already making a difference. We welcome their fresh perspectives and have been motivated by their pride and passion,” he continued.

- “I’d also like to recognize our PGS colleagues for welcoming these new teammates with open arms, supporting them both professionally and personally,” he added. “Everyone deserves a fresh start, and we consider it an honor and a privilege to play a role in the new chapters for these refugees and their families.”

Success stories: The backgrounds of many of the recent hires are as impressive as they are diverse.

- The very first refugee hire, a man named Afzal Afzali, had been working for the U.S. embassy and the American University of Afghanistan when the Taliban seized control last summer. “He had to make a decision to escape within a few hours of the invasion,” according to Babury. “On his way out, he rescued four unaccompanied children protected by the U.S. government and reunited them with their mother in the United States.”

- Afzali, who now lives with his family in Texas and works at Pfizer in procurement, told the company the new job has led him to finding his “life’s purpose in serving others … likewise, Pfizer is all about breakthroughs that change patients’ lives.”

- Another new employee had previously worked with the Afghan president. She is now a senior associate on Babury’s team. She was recruited through the Pfizer Refugee Leadership Initiative Mentorship program.

The last word: Seeing the success of these new employees energizes those around them, said Babury.

- “The leader at our Kalamazoo site will speak to you with such a light in his eyes about how … once these hires have a job, they don’t consider themselves refugees anymore. They’re people with jobs. They have a way to take care of their families. There is a sense of pride among all our colleagues because of this program.”