Creators Wanted Gets Set for Fall Tour

Creators Wanted is gearing up for another season of bolstering positive perceptions of manufacturing careers and inspiring new manufacturers. Its schedule for this fall is now set—and we’re sharing it with you.

The nationwide tour, a joint project of the NAM and its workforce development and education partner The Manufacturing Institute, with significant legacy funding from Dow, Honda and Trane Technologies as well as contributions from more than 70 manufacturing companies, will stop in Nashville, Tennessee, on Sept. 27–29.

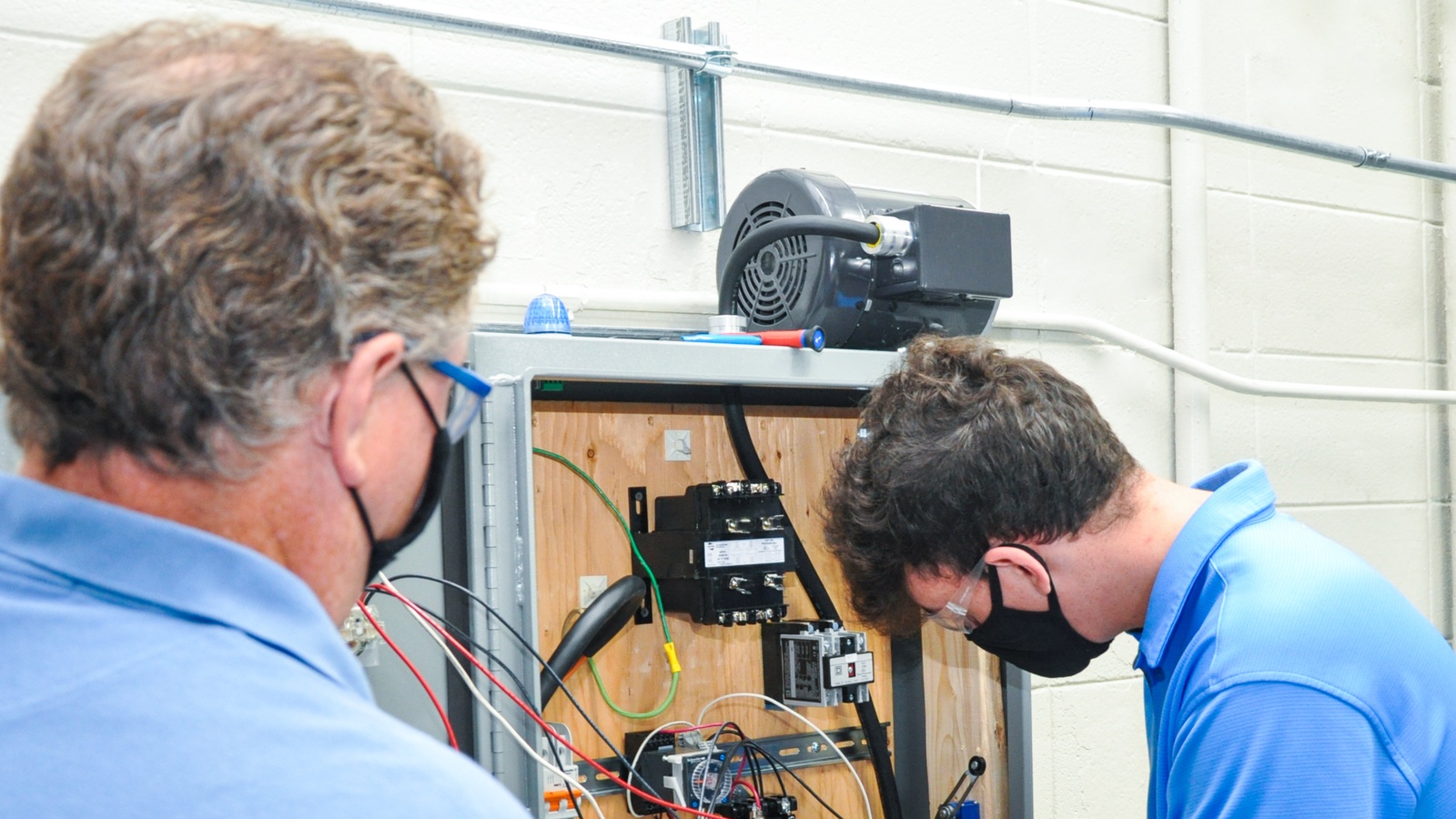

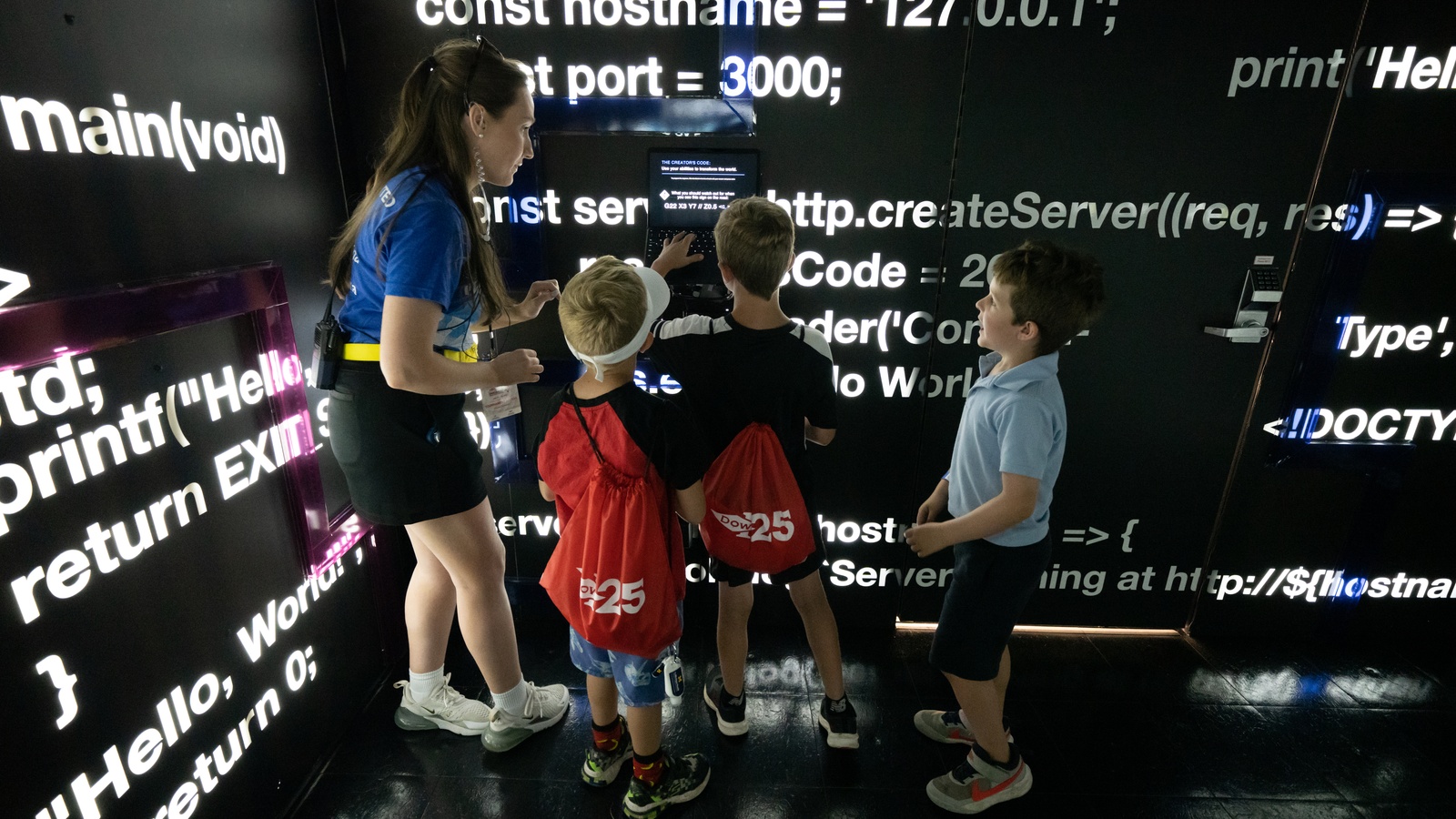

- The tour features an award-winning mobile immersive experience, to help students, emerging workers, parents and other career mentors learn and get excited about opportunities in modern manufacturing.

- Tour stop attendees will also meet local manufacturers, interact with hands-on technology, attend presentations by stars in the industry and access resources for training and job opportunities.

Building on big impact: The MI and Deloitte have already reported that positive perception of manufacturing careers has soared from 27% when the tour started to 40% today, just shy of the goal of 50% by 2025.

- The campaign has amassed—and maintained—an email network of more than 320,000 highly engaged students and career mentors.

Destination Tennessee: The Nashville stop will be the 10th since the tour began last year.

- Hosted by Electrolux and Schneider Electric and co-presented by Robertson County Economic Development, the Tennessee Chamber of Commerce and Tennessee Manufacturers Association and FactoryFix, the stop will take place at White House Heritage High School in the Nashville-adjacent town of White House, Tennessee.

- More than 500 students, parents, teachers and community leaders are slated to attend.

It’s good to be back! From Oct. 4 to 7, as manufacturers nationwide celebrate MFG Day 2022, Nephron Pharmaceuticals will host the second Creators Wanted tour stop this fall, in West Columbia, South Carolina. FactoryFix and the South Carolina Chamber of Commerce will also participate.

- The tour visited West Columbia and Nephron last October. This year’s encore visit to the city will take place at the Nephron Nitrile Factory.

- More than 20,000 students and career mentors are expected to sign up online to learn more about modern manufacturing careers.

College visit: Next, the tour will visit Decatur, Illinois, on Oct. 24–26, for a stop that will be hosted by Caterpillar and ADM and co-presented by Illinois Manufacturing and FactoryFix.

- The events will be held at Shilling Center at Richland Community College. This third fall tour stop is expected to draw many visitors from the local community and add more than 20,000 students and career mentors to our network in Illinois.

Windy City premiere: The last stop on the Creators Wanted fall tour will be at the Rockwell Automation Fair in Chicago, on Nov. 16-17. The Creators Wanted immersive experience will be a main feature on the showroom floor at this gathering of thousands of industrial automation leaders and experts.

Learn more: Tour organizers say that there is still time to join the fall tour stop events. Interested in supporting the cause and the MI’s sustained workforce solutions? Contact Barret Kedzior at [email protected].

Second Chance Hiring Works For Union Pacific

Finding and keeping a job can be challenging for people with criminal records. These jobseekers face exclusionary business practices and logistical obstacles, which result in an unemployment rate for this population that is five times higher than the general US public. To minimize this inequality, The Manufacturing Institute—the workforce development and education partner of the NAM—has joined with Union Pacific to expand candidate pools and bring more outstanding individuals into the manufacturing industry.

A second chance: Union Pacific began working on the second chance initiative last year, and the results have already proven fruitful.

- In 2022, the company launched a pilot program with local community organizations in Houston to eliminate barriers to employment for the formerly incarcerated and helped ensure the long-term success of these second chance candidates.

- In its first three months, the program brought in nearly 100 new applications and created positive relationships and support systems.

The steps to success: The Union Pacific team discovered that three components were critical to helping candidates find jobs and succeed:

- First, companies interested in hiring such candidates must update their own hiring practices and rethink potential barriers for otherwise qualified candidates—whether that means adjusting onerous required credentials or background checks.

- Second, partnerships and strong relationships with local community partners can help ensure that these candidates have the support they need to be successful. Tools like the MI’s Community Partnership Scorecard helped Union Pacific find partners that fit well with their goals.

- Third, establishing pilot initiatives in high-demand markets can help a company learn about best practices that can be replicated elsewhere. Plus, sharing experiences with other employers can help additional companies find success.

Expanding the program: Union Pacific’s current focus involves bringing the Second Chance initiative to new markets across the country to replicate the pilot program results.

- “Everyone I speak with about our success in Houston wants to know how we can take this model and multiply,” said Union Pacific Talent Acquisition Manager Ken Kawamura.

Leaders in the field: With the success of this initiative, Union Pacific has become an industry leader in establishing inclusionary hiring practices and building community partnerships. The company hopes to help establish second chance programs throughout the country.

- The Manufacturing Institute has been a critical partner in this work, providing information and resources necessary to its success.

- “The MI is committed to supporting members in the pursuit of effective Second Chance initiatives,” said MI Vice President of Workforce Solutions Gardner Carrick. “Our goal is to leverage those learnings and strategies across the manufacturing industry to expand talent and opportunity in the sector.”

The last word: Union Pacific’s primary goal in pioneering this initiative is to build a more equitable workforce for all employees.

- “In our eyes, once you are a part of Union Pacific, you are no different than any other employee, regardless of your background,” said Senior Director of Talent Acquisition Dan Culbertson.

Manufacturing Offers Many Debt-Free Careers

The manufacturing industry has had more than 2.6 million job openings nationally in 2022 already—a workforce shortage that shows little signs of slowing. Meanwhile, half of all those available jobs don’t require a four-year college degree or the debt that goes with it.

This week, President Biden announced new measures providing student debt relief to many eligible Americans. Yet the manufacturing industry helps young people avoid this problem in the first place, while also offering them salaries far above the national average.

Manufacturing Institute President Carolyn Lee weighed in on the advantages available to young people looking to make a strong entry into the workforce, instead of suffering under debt that makes it more difficult to start a family, purchase a first home and achieve other major life milestones. Here’s what she had to say.

How it works: Manufacturers often offer short-term certifications or other training programs that allow people to jump into high-paying careers quickly and without debt, Lee explains.

- “There are multiple pathways to career opportunities in manufacturing through skills training, ranging from short-term programs to more involved skills development and apprenticeship programs,” says Lee.

- For example, the Federation for Advanced Manufacturing Education (FAME) program (founded by Toyota and operated by the MI) offers current and aspiring manufacturing workers both on-the-job training and classroom education. The program leads to an associate degree and an Advanced Manufacturing Technician (AMT) certificate.

- Manufacturers work with FAME’s local chapters in part because they allow companies to use a global best system to train the skilled workforce they need to compete.

The numbers: The data show that manufacturing is a good choice for those inclined to avoid debt, Lee points out.

- As noted above, there have been more than 2.6 million manufacturing job openings so far in 2022, but just 47% of those job openings (about 1.2 million) require a bachelor’s degree or greater.

- Meanwhile, manufacturing workers in 2020 earned $92,832 on average (compared to an average of $77,181 for workers in all private nonfarm industries).

What can policymakers do? To ensure that manufacturing training programs continue to expand and succeed, policymakers should make certain changes, says Lee.

- For example, Pell Grants should be usable for high-quality training programs as short as eight weeks—often all that is needed to train a technician.

- Policymakers should also ensure that our education system focuses on skills attainment for career success, and that teachers and other influencers are aware of opportunities offered by pathways other than four-year degree programs.

#CreatorsWanted: The NAM and the MI have taken this message to communities across the country through the Creators Wanted campaign’s tour and mobile experience. Tens of thousands of students, parents, educators and local leaders have attended the tour stops, where they learned about the promise of manufacturing careers and were challenged to think like manufacturers in the interactive mobile experience.

- As Lee told students at the Creators Wanted stop in Freeport, Texas, “Without a steady stream of talented, bright young people … we can’t keep up the good work of continuously making our products. This is not a get-one-job-and-stay-there-for-40-years [situation]. This is a choose-your-own-adventure [career path] with continuing skills and challenges and opportunities and learning along the way.”

The last word: “We understand how oppressive student debt can be, especially when starting out in life,” said Lee. “More people should be able to get a rewarding and well-paying job that doesn’t require massive debt that takes a lifetime to pay off. This is one of the reasons we work so hard to make sure young people know about the variety of options available to them in manufacturing careers; it’s not just for the industry’s benefit, but for theirs as well.”

If you’d like to hear more about careers in manufacturing, come to one of the many MFG Day events happening this October.

An Aspiring Manufacturer Finds FAME

Aidan Bleser took to manufacturing early on.

“The concepts of manufacturing were part of my childhood,” says Bleser. “There was a lot of Lego-building, and stuff like that.”

Still, Bleser didn’t get a chance to hone his skills until high school, when he was accepted into a program that offered courses on manufacturing at a local college, St. Philip’s College in San Antonio, Texas. Near the end of his program, his professors at St. Philip’s encouraged him to take the next step by signing up for the FAME program’s local chapter in Alamo.

The program: The Federation for Advanced Manufacturing Education (FAME), which was created by Toyota and is now overseen by The Manufacturing Institute, is a career pathway program for current and aspiring manufacturing workers. It provides them with on-the-job training and classroom education, leading to an associate degree and the Advanced Manufacturing Technician (AMT) certificate.

The experience: Through the program, Bleser was offered a role at Toyota, where he spent two years doing hands-on work while also accruing college credit.

- “FAME was great,” said Bleser. “The two years went by fast, and I enjoyed getting the college credit while still working part time. It helped the learning experience, being able to work while going to school.”

The people: Bleser also enjoyed working with other program participants as part of a group, getting to know individuals who were interested in manufacturing and even advising and mentoring younger students after his time in the program was up.

- “I’ve stayed in touch with people in my cohort, and I have mentored people in the younger cohort,” said Bleser. “That group dynamic is a great opportunity, because you can learn skills yourself and then teach them to other people.”

The job: Bleser graduated in May and was offered a full-time position at Toyota in August. He is now employed as a maintenance officer at Adient, one of Toyota’s on-site suppliers—and credits the FAME program with giving him the tools he needed to be successful.

- “I would recommend FAME to anyone,” said Bleser. “It prepares you really well. By the time you’re hired, you’re not a new face, and you’re used to the culture.”

The road ahead: Bleser’s experiences in the FAME program and at Toyota have shown him that there are opportunities available in manufacturing for people with all sorts of different talents and interests. He has big plans for the future:

- “I’d like to look into system integration, maybe opening some sort of company myself one day,” said Bleser. “I’ve also gotten more into application development on the software side, so I’d like to continue doing that, and hopefully develop some software that can be used throughout manufacturing.”

The last word: “There are so many ways to work in manufacturing,” said Bleser. “From maintenance, to quality, to logistics, to management, there are a lot of different places you could find yourself. Anybody with any skill set could be valued.”

GE Appliances Sees Success in Hiring Afghan Refugees

It’s been almost a year, but the sights and sounds are never far from his thoughts: crowds of people surging toward departing planes, trampling those who stumble; gunshots ringing out; the explosion of a nearby bomb.

For Edris Akseer, now a bilingual recruiting coordinator at GE Appliances’ (GEA) Louisville headquarters, these memories are daily reminders of the horrors that he, his wife and his brothers endured in Afghanistan to get to the United States—and how different his situation is today.

- “That day [I left] was the worst day of my life,” recalled Akseer, a former translator for the U.S. Army in Afghanistan who was able to secure passage out through his U.S. military connections. “[But] I’m happy here. I really enjoy helping others and I find my job really interesting. … I saved enough to buy a car and I’m working on getting my driver’s license.”

Helping refugees: Akseer is one of more than 100 non-U.S.-born employees brought on in recent months by GEA in Louisville. About 50 are refugees from Afghanistan who came here last fall when the U.S. military exited the country. The other half are Spanish-speaking and hail from multiple nations.

- “In early 2022, we had a new production line–and we needed to hire over 1,300 people,” recalls GE Appliances Senior Manager Beth Mickle, who runs the production recruitment group at the company’s large campus in Kentucky.

- “Catholic Charities and Kentucky Refugee Ministries said they [were helping] a group of people from Afghanistan and said, ‘We think you would be a great employer for them. Would you be interested in taking a shot at this?’”

- GEA was interested—and opening the hiring process to refugees and other immigrants has been one of the best workforce decisions the company has made in recent memory, Mickle said.

Location, location: As a longtime U.S.-immigration entry point, Louisville has large populations of non-native-born people, said GE Appliances Workforce Development Recruiter Gabriela Salazar.

- These include people from the Democratic Republic of Congo, Cuba, Peru, Honduras, Venezuela and Mexico, said Salazar, who recently conducted a survey of languages spoken among GE Appliances employees. The findings: production staff at three factories communicate in a total of more than 40 languages.

- In a sense, working with charities to hire refugees is the next step in the company’s hiring practices. It “has helped us to tap into populations we might not have known how to tap into before,” Mickle said.

Learning as they go: GE Appliances now offers new-hire orientations in many languages, including Afghanistan’s official languages of Pashto and Dari, as well as Spanish and Swahili.

- The company also has a buddy system which pairs new employees with workers who have been at the facility for a while.

- “These are employees who volunteer to be points of contact, to help show people around,” Mickle said. “You know, ‘Where is the bathroom? ‘Where do I get my protective gear?’ We also translate all the new-hire documents [into native languages] because they won’t remember everything from their first day.”

- Recently GE Appliances hired an American Sign Language translator to help its deaf employees. “Where it started was different languages—and now we’re seeing a lot of new horizons,” Salazar said.

Onward and upward: Akseer has seen a lot of new horizons himself in the past few months.

- He was originally hired at GE Appliances as one of its much-needed production-line team members, but owing to his fluent English, compassion and constant willingness to help, Akseer was “always being pulled of the line to help translate” something for another new employee, according to Mickle.

- So when a translator role opened up on Mickle’s team mere months after his hiring, Akseer was in. “He was already doing the role of what we needed him to do. He’s just a natural teacher,” Mickle said.

- On top of the new country, the new company and the two new jobs in quick succession, Akseer underwent another major change: becoming a new father. His son was born shortly after the family came to the U.S.

Advice for other manufacturers: Hiring refugees and other immigrant workers has been a boon for GE Appliances, Mickle said, and other manufacturers should consider following suit if they can.

- “They are the first to raise their hands for overtime,” she said. “They work very, very hard. In [manufacturing], our jobs are not always the easiest. But they do it and they love it.”

The last word: “Manufacturers that bring on refugees see fewer turnovers and increased efficiency,” MI Vice President of Strategic Engagement and Inclusion AJ Jorgenson said. “They’re also helping to improve lives and communities. More inclusive workplaces strengthen manufacturing.”

From the Air Force to the Railroad: Tara Hogan’s Success Story

When Tara Hogan was growing up in Texas, she wanted to be a basketball coach—a career in freight rail wasn’t on her radar. But after high school and six years of service in the U.S. Air Force, she finished her college degree, took on a few different jobs and went looking for her next gig. She found Union Pacific Railroad on a list of companies looking to employ military veterans and landed a job as an operations management trainee in 2006.

More than 15 years later, after stints in Nebraska, Louisiana and Kansas, Hogan serves as a general manager at Union Pacific in Fort Worth, Texas, leading a team of 1,700 people as she runs the freight rail service in an active—and essential—area of the country.

Starting out: In many ways, Hogan found that her experience in the military gave her the tools to succeed at Union Pacific.

- “Union Pacific is a 24/7 operation that runs 365 days a year, as the military does,” said Hogan. “In the military, there’s a structure and a sense of certainty, and there’s comfort to that; at Union Pacific, there’s the same kind of certainty and structure. There’s a language in the military, and a language at Union Pacific.”

- “For me, it was the place I could go that felt the most familiar…. It’s got the structure of the military but the flexibility of the civilian environment.”

Paying it forward: Today, Hogan isn’t only an outstanding representative of the railroad industry in her own right; she’s also a role model for others who might be interested in a career in the sector—including individuals from communities that are currently underrepresented.

- Through Union Pacific’s UPLift program, which pairs underrepresented employees with executive sponsors, Hogan is sponsoring a woman in Fort Worth, offering career advice and networking support.

- “It’s not a one-and-done mentor situation,” said Hogan. “I’ll be with her throughout her career, and I’ll watch her grow. Hopefully, she’ll be my boss someday.”

A supportive environment: As a woman in freight rail, Hogan is generally in the minority, even as Union Pacific works to double the number of women employed at the railroad. Still, Hogan’s experience has been positive, and she has always felt encouraged to gain skills and rise in the company.

- “Everybody I have come across has wanted to see me succeed,” said Hogan. “If somebody is willing and wanting to learn, there are a ton of people here who want to teach you and see you be successful.”

- “I never thought I’d be in this position. I didn’t aspire to it. But the company saw something and kept challenging me to see what I can do. It’s been a great experience for me.”

The bigger picture: Hogan’s success at Union Pacific is part of the company’s ambitious efforts to advance women throughout its operations.

- Its Careers on Track program—in partnership with The Manufacturing Institute—aims to increase the number of women in the manufacturing and transportation, distribution and logistics industries.

- The program is designed to inspire women and youth to pursue modern industry careers through workforce development and career solutions.

The last word: “You can learn anything you want to learn here, depending on what your job is,” said Hogan. “Manufacturing has changed with the times and become better. All the opportunities to learn and grow have become better. If you’re a hard worker and willing to learn, there’s no glass ceiling anymore.”

An Army Vet Finds a New Mission in Manufacturing

Fernando Gonzalez grew up admiring his aunt because she served in the army—and when it came time for him to choose a career, he wanted to follow in her footsteps. He joined the U.S. Navy when he graduated from high school, working in navigation. But he still wanted to continue his education, so he eventually went to college, supporting himself by working as a security guard and later as a customer service representative for an auto company. At the same time, he joined the U.S. Army National Guard—giving him plenty to do all at once.

- “I was doing school, work and the National Guard,” said Gonzalez. “I suppose I’ve had a kaleidoscope kind of career—lots happening all at the same time.”

- Eventually, he decided to return to active duty and joined the U.S. Army as an industrial maintenance specialist. But when he completed his service, he found himself looking for a new kind of role.

A new path: As he was preparing to leave active duty, Gonzalez took advantage of the U.S. Department of Defense’s SkillBridge program through his local transition office. It was there that he learned about The Manufacturing Institute’s Heroes MAKE America initiative. He joined the logistics career skills training program at Fort Stewart near Savannah, Georgia—led by Heroes MAKE America and education partner Savannah Technical College—and got to work.

- Through an eight-week accelerated training program, he learned about manufacturing while also getting hands-on experience.

- After interviewing with a recruiter from Cargill, a global food corporation based in Wayzata, Minnesota, Gonzalez was offered a position. Today, he works at the company as an operations manager.

What is Heroes MAKE America? The MI—the workforce development and education partner of the NAM—designed Heroes MAKE America as an integrated certification and career-readiness training program that helps prepare transitioning service members, veterans, National Guard members, reservists and military spouses for careers in manufacturing. The initiative offers in-person training and remote training options, as well as career support and placement.

A positive experience: Gonzalez enjoyed the opportunity to learn about manufacturing and logistics and particularly appreciated being exposed to a wide array of careers in the industry.

- “Heroes was great,” said Gonzalez. “We toured some plants in the Savannah area, near where I was stationed in Fort Stewart. We saw a crew ship at port, we toured a steel mill, we learned about manufacturing and logistics.”

A smooth transition: Gonzalez found that his new career had plenty of similarities with his time in the military, making it a good match for the talents and work style he had honed there.

- “The soft skills correlate,” said Gonzalez. “You still deal with people; you still deal with some type of chain of command. You have goals for the day, the week, the quarter. In the military, we talk about missions, and that’s still what we do here. In the military we have this attitude of getting things done, figure it out. It doesn’t matter if you haven’t done it before—you figure it out and make it happen, and that’s been true here, too.”

A great job: Gonzalez has enjoyed learning new processes and applying his skills in new areas, working to maintain and operate equipment that receives, stores and loads commodities like corn and soybeans onto train cars for shipping. “Every day I learn something new,” he said.

The last word: “Manufacturing is a crucial industry,” said Gonzalez. “It has incredible opportunities at all skill levels. It’s vital to our country, to our security. And it’s not going away.”

How Manufacturers Can Attract and Retain LGBT+ Talent

Job openings in manufacturing remain high, with many manufacturers citing the shortage of skilled labor as a major business challenge. Increasingly, companies are taking a closer look at their internal cultures and asking themselves a crucial question: How can we make ourselves more attractive to new recruits from diverse backgrounds?

Seeking all willing workers: Panelists at the recent D&I Roundtable: Recruiting and Retaining LGBT+ Employees, hosted by The Manufacturing Institute, discussed the growing awareness among manufacturers of ensuring that their companies are LGBT+-friendly workplaces.

- “When you build a psychologically safe environment, all employees benefit from it because all employees will start to share their ideas without [fear of] retribution,” said Entegris Senior Manager of Talent Management & Development Phillip Spencer.

- “More generations identify as part of the LGBTQ+ community and want to work for companies that … support [them]. So, it really will benefit everyone and the bottom line of all of our companies” to be inclusive of the LGBT+ community.

Say no to “rainbow washing”: To recruit talent who identify as LGBT+, panelists agreed, manufacturers must genuinely create an accepting, open culture rather than just engage in “rainbow washing,”—i.e., adding a rainbow to company branding while offering few, if any, benefits to actual LGBT+ people.

- Make sure your company is “really aligning your policies and your practices and those unspoken rules in your organization to make sure that you are doing the things that you say that you believe in when you’re talking about supporting the [LGBT+] community,” said Senior Vice President of Human Resources at Georgia Power Company and Southern Company Sloane Drake.

- Entegris went back to basics with its inclusivity efforts, Spencer said, and it’s worked. “We started with a program talking about what does LGBTQ+ mean? And what does it mean in the workplace? Why are we talking about this in the workplace?”

- The company also rejiggered its employee retirement fund structure when it realized the old setup did not account for same-sex couples, Spencer added.

Seek out ambassadors, but don’t push: LGBT+ employees can act as ambassadors to help a company build trust among other LGBT+ workers and prospective new talent, speakers said. Companies should seek out such potential representatives, but without assuming they will want to take on the responsibility.

- “Nobody knows better what the experience is like than somebody who’s going through it,” said Goodyear Tire & Rubber Company Senior Engineer Arwen Kathke, who is also the community outreach chair for the Goodyear pride network. “Including those employees in your decision-making processes and having those conversations with them to understand what their experience is will go a long way.”

- “We’ve really spent a lot of time educating” our workforce, Drake said. “It’s not the responsibility of every LGBTQ+ employee in our organization to explain what [LGBT+] means. We’ve actually put some of our employees who were willing through storytelling training; they felt very comfortable being able to share and tell their stories in large meetings and on videos and podcasts, and that was very powerful. But [you don’t want] to make it feel like the one person in the room who [identifies as LGBT+] has to be the only one who can speak on that topic.”

Measuring success: How can manufacturers determine whether they’re reaching LGBT+ talent? There are various way, panelists said.

- “There’s one great metric that’s going to help any organization understand 100% if it’s inclusive: Do you allow people to self-identify?” Drake said.

- Another way is to review employee representation data, as well as the number of self-identifying people moving through leadership-development pipelines into leadership positions.

The last word: “If you create a supportive environment and have your internal development done,” said Kathke, “with employees who are starting to step up and really foster that environment, that’s going to work out a lot better in the long run.”

Shattering Records: Creators Wanted Has a Big Impact in Michigan

A record breaker. That’s the best way to describe the all-time high attendance rates, email subscriber numbers and other signs of surging interest in manufacturing careers brought about by the Creators Wanted Tour stop at the Dow Great Lakes Bay Invitational in Midland, Michigan, last week.

Family first: The nationwide tour, a joint initiative of the NAM and its workforce development and education partner, The Manufacturing Institute, marked its 10th stop July 13–16. This stop’s overarching theme: family, according to Dow Chairman and CEO and NAM Board Chair Jim Fitterling.

- Dow sponsored the golf invitational, the first LPGA event to achieve carbon neutrality, as well as the four-day Creators Wanted event. The company also recently more than doubled its commitment to the Creators Wanted campaign, to $2 million.

- “You’ll see many, many families out here,” Fitterling told the audience at the tour stop’s kickoff event. “The reason we’ve got the family focus here is that it’s not just about students; it’s also about parents. An awful lot of students say that they won’t consider going into manufacturing because they aren’t encouraged by their parents to go into that field.”

Shifting perceptions: One of the reasons that recent generations of parents haven’t encouraged their children to go into manufacturing? Misconceptions, explained Fitterling. But those are starting to change, he and other kickoff-event panelists said.

- “Sometimes [parents and students] have perceptions about manufacturing that just aren’t current,” Fitterling said. “Creators Wanted is about … [giving] them a hands-on experience to show them what’s going on in advanced manufacturing today.”

- MI President Carolyn Lee cited MI–Deloitte survey data showing significant recent growth in the percentage of parents who say they would encourage their children to enter manufacturing: 40%, up from 27% in 2017. “The good news is we are already making a dent on change,” Lee said.

Just plain fun: For many of the attendees at last week’s Midland tour stop, “racing to the future” in the Creators Wanted immersive experience/high-tech escape rooms, meeting creators at Dow, getting career coaching tips from FactoryFix, learning about opportunities in Michigan with the Michigan Manufacturers Association and participating in all the other family-friendly events was as much about having a good time as considering a new career path.

- “Having to use teamwork to exit the escape room and things like that, I find it really interesting,” said one student participant. “I take away that I could … have a career in manufacturing.”

- In addition to the immersive experience, there were activities and games in the STEM Center, where “kids, students and parents or other supervising adults [could] see how STEM relates to not only sports but other technologies that can help us ‘imagine better,’” such as 3D printing, said NAM Managing Vice President of Brand Strategy Chrys Kefalas.

- The next generation of manufacturers were also welcomed to take part in “Friction Hockey” and “Binary Bits” experiments, which let them see how surface friction affects object movement and translate computer code into phrases using LEGO blocks, respectively.

- There was also a fully stocked “Kid Zone” with miniature golf and a giant mural to which kids were encouraged to add their own artwork, as well as a “First Tee Junior Clinic,” hosted by the nonprofit First Tee, which aims to teach children life skills through golf.

Women in manufacturing: Midland was also the site of an important announcement from Lee during a fireside chat with Dow Senior Vice President of Operations, Manufacturing and Engineering John Sampson: Dow will provide a $500,000 grant over four years to support the MI’s Women MAKE America’s 35×30 campaign.

- The campaign’s goal: to increase the representation of women in the manufacturing workforce to 35% by 2030.

Major impact: The Dow GLBI tour stop generated a lot of interest.

- More than 47,000 email subscribers from Michigan signed up to learn more about modern manufacturing careers.

- More than 1,550 students, parents and/or attending adults went through the immersive experience.

- Ninety-six percent of surveyed immersive-experience participants reported an improved view of modern manufacturing, and 72% of respondents who had previously described manufacturing as “dirty,” “dangerous,” “old-fashioned,” “part of the past” or “traditional” described manufacturing as “modern,” “innovative,” “high tech” or “creative” in the latest survey.

Just some of the mentions: Many media outlets covered the event, including the following:

- Creators Wanted Experience encourages kids to explore manufacturing jobs (ABC News 12)

- Creators wanted — opportunity abounds in manufacturing, a joint op-ed by Fitterling and NAM President and CEO Jay Timmons (Crain’s Detroit Business)

- ‘Creators Wanted’ conveys urgency of manufacturing labor shortage (Midland Daily News)

- This is your chance to create the future, an op-ed by Michigan Manufacturers Association President John Walsh (Midland Daily News)

The last word: The Creators Wanted mobile experience encapsulates what modern manufacturing is all about, said Michigan Attorney General Dana Nessel, who toured it along with Solicitor General Fadwa Hammoud.

- The experience “showcased … new styles of recruiting & making the safety, inclusion, creativity & technology the new normal,” Nessel tweeted. “The Creators Wanted interactive experience was so cool!”

Watch now! See a video of tour-stop highlights here.

Husco Provides Jobs to Afghan Refugees

For Jason Schuetz, Husco’s vice president of global operations and advanced manufacturing, what started out as meeting a business need at his company has turned into something profoundly more fulfilling.

How it all started: The Waukesha, Wisconsin–based company, which specializes in hydraulic and electromechanical control systems, had open positions that needed to be filled—a challenge that many manufacturers face daily.

- “We were struggling for a long time to fill the positions that we had open. And we knew that if we continued to think in conventional ways, we would get conventional output and that was not much,” said Schuetz.

- “We were short a number of direct hire positions, similar to a lot of places in the area,” added Husco Director of Operations Mark Dreikosen. “We were looking for creative solutions to fill our staffing needs.”

An opportunity knocks: After months of minimal results in the hiring search, an opportunity was brought to Husco through Lutheran Social Services to help provide jobs for Afghan refugees who fled from the Taliban and relocated in Waukesha.

- After many internal conversations and external meetings with Lutheran Social Services and Manpower International, a global workforce solutions company, Husco moved forward in March.

- The result? Over the past several months, Husco has hired and welcomed 33 Afghan refugees.

- “It was needs based, really, for Husco,” said Dreikosen. “Fortunately for us, it wasn’t the first time we’ve done something like this. We’ve helped support groups who have emigrated from Myanmar, formerly Burma, under similar context where there’s political unrest.”

Adapting to change: Schuetz said that 2016 experience helped Husco prepare for some of the challenges the company faced with regard to documentation, language and some cultural differences, but new challenges surfaced as well.

- Schuetz said that being very fresh to the U.S. workforce, the refugees needed to be taught what the “professional expectations were in the U.S.”

- Work instructions needed to be translated into Pashto and reformatted to accommodate reading from right to left rather than left to right.

- “None of the individuals had licenses or had a means of getting to work,” said Schuetz. “So, we needed to quickly lean on and partner with Manpower—who has been vital in this—to help find and set up transportation.”

- To accommodate religious needs, Husco set up multi-faith meditation spaces so the new employees can pray throughout the day. In addition, for a facility-wide event during Ramadan, the company catered appropriate food so individuals could still participate and be part of the team while practicing their religious obligations.

Breaking the language barrier: To help the refugees’ English-speaking skills, Husco ensures there are translators available on every shift.

- Two employees, Hamza Jebran and Baitullah Jan—Afghan refugees themselves who studied English—serve as translators for their new colleagues. (Click here to watch an interview with Jebran.)

- “Another of our employees, Habib, couldn’t speak a word of English when we first met him a few months ago, and now we can have a conversation with him,” said Dreikosen. “Sometimes we will have one of our employees come up during a shift meeting and teach the rest of the crew some Pashto as they’re trying to learn some English and share their culture at the same time. It’s really cool to see.”

Eager to learn: For Dreikosen, the refugees’ motivation and eagerness to learn transcend the language and other cultural differences.

- “They’re as driven and motivated as any other employee who comes through Husco’s doors—and we caught on to that very quickly,” he said. “Their drive for success, given their situation, and how important it is to have a home and to feel welcomed, it’s inspiring.”

Strong foundation: Schuetz says that what has made Husco’s refugee program a success is the company’s strong foundation with its current employees.

- “It’s been successful for us because we have always made it a point to treat our people fairly and with respect,” he said. “The refugees have been welcomed by their fellow employees because they know that we treat everyone this way, and we would help anyone. There are many challenges, but this team decided they were going to make this work, and every obstacle that they encountered, they knocked it down and moved the ball forward.”

- The support from Husco has made the program a success: “It starts with our supervisors, our quality engineers, our technicians—they’re all in. They know there’s going to be bumps along the way, but they’ve bought in and know that this is the right thing to do,” said Dreikosen.

- Dreikosen notes that Husco is now receiving more referrals and inquiries from job seekers of all sorts of backgrounds. They’ve heard about the good the company does and how welcoming it is, and that attention has made the company more attractive in the eyes of job seekers.

The last word: “When this opportunity was brought to us through Lutheran Social Services, we grabbed onto it tightly and realized that with the challenges that we were going to encounter day to day, the end game was so much greater,” said Schuetz. “It’s been rewarding in so many ways.”

What the NAM says: “With more than 900,000 open jobs in manufacturing, we need to attract and hire from the widest talent pool possible,” said Manufacturing Institute President Carolyn Lee. “When manufacturers hire refugees, they see fewer turnovers and increased efficiencies, and at the same time, they’re helping improve the lives of refugees, their families and communities. Increasing diversity in the talent pool and developing more inclusive workplaces strengthens the competitive advantage of our industry and our workforce.”