Caterpillar Foundation Helps Veterans Find Manufacturing Careers

On Veterans Day, we honor the service members who safeguard our country, many of whom will go on to contribute their skills and experiences to civilian industries. Manufacturing is one beneficiary, with many veterans finding that the high-tech, mission-focused industry is an excellent home for their talents.

But how do transitioning service members and veterans find their new career paths? The Caterpillar Foundation is helping America’s heroes become tomorrow’s manufacturing leaders through its support of the Manufacturing Institute’s Heroes MAKE America initiative.

HMA provides integrated certification and career-readiness training in partnership with local community colleges to prepare transitioning service members, veterans, National Guard members, reservists and military spouses for rewarding careers in the manufacturing and supply chain industries.

Virtual training: The Caterpillar Foundation’s support began in 2021 and has helped HMA develop and launch its first 100% virtual training offering in partnership with Texas State Technical College—an exciting option for individuals across the country who might not be able to attend an in-person course.

- The program uses innovative solutions like virtual reality technology, provided by Transfr VR, in order to add a “hands-on” aspect to the students’ training for their Production Technician and OSHA 10 certifications.

- “Heroes MAKE America was great,” said Benjamin Novak, a graduate of Heroes MAKE America’s virtual training program. “The virtual self-paced program allowed me to balance class, transitioning and family life. Getting an opportunity to connect and speak with companies directly was a huge opportunity as well.”

New programs: Additionally, thanks to the foundation’s grant, Heroes MAKE America launched two new in-person training paths: a Mechatronics training program at Fort Hood, Texas, also in partnership with Texas State Technical College, and a Certified Logistics Technician training program at Fort Stewart/Hunter Army Airfield, Georgia, in partnership with Savannah Technical College.

partnership with Texas State Technical College, and a Certified Logistics Technician training program at Fort Stewart/Hunter Army Airfield, Georgia, in partnership with Savannah Technical College.

- Together, the three new training offerings (the two mentioned above and the virtual option) have graduated 133 participants as of November 2022, with another 40 participants expected to graduate in December.

- “Heroes MAKE America is a great program that wants to see veterans succeed,” said Anna Rabago, a graduate of the Mechatronics training at Fort Hood, Texas. “They helped mold me into a great candidate for manufacturing while earning seven manufacturing certifications. The instructors are subject-matter experts in their field and are willing to work early or late evenings to benefit the soldiers.”

An impressive year: The HMA program is on track to graduate 303 members of the military community across all 6 training sites in 2022, bringing the total number of graduates since the 2018 inception of HMA to 957. The training sites include Fort Hood, Texas; Fort Stewart/Hunter Army Airfield, Georgia; Fort Riley, Kansas; Fort Campbell, Kentucky; Fort Bragg, North Carolina; and the 100% virtual option.

The last word: “HMA provided me with all the tools that I needed to thrive as a civilian,” said Tillman Harris, a graduate of the Production Technician training at Fort Bragg, North Carolina. “They provided industry training, résumé assistance, interview prep and much more. Trust in yourself and have confidence in everything you do. HMA is a program that cares about us and wants us to succeed.”

Learn more: Find out more about Heroes MAKE America here.

How Managers Can Produce Top-Notch R&D

As innovation in manufacturing continues at breakneck speed, research and development is more important than ever—but it requires outstanding managers to make it all happen.

So how do these managers get the education and insights they need? The Innovation Research Interchange, a network of cross-industry innovators that the NAM combined with earlier this year, has an answer: an executive management course called Shaping Innovation Leaders.

The gist: Co-hosted by the Kellogg School of Management at Northwestern University, the course provides a forum for strategic thinking, education and networking for technology leaders from around the world.

- In 2023, it will take place on May 13–19 on the Northwestern campus in Evanston, Illinois.

The details: The goal of this seven-day program is to develop midlevel managers into leaders for their companies, by covering topics including:

- Evaluating financial results;

- Segmentation, targeting and positioning;

- Growing and defending your brand;

- Legal and strategic investments;

- Building a better network; and

- Negotiating skills and strategic alliances;

Who’s involved: To get a sense of this event’s caliber, look no further than the attendees from the 2022 course.

- They hailed from a wide range of companies, including manufacturers such as Mars, Procter & Gamble, John Deere, Hershey, NatureWorks, Air Liquide, Kimberly-Clark Corporation, Sherwin-Williams and many, many more.

The reviews are in: Participants in the 2022 course were enthusiastic about what they learned and experienced.

- “[I’m] really super impressed with the program, soup to nuts,” said John Deere Manager for Global Strategic Communications & Culture Jacqueline Kiple. “One of my favorite aspects of the program was really getting a chance to think about our business a little bit differently … to take a step back and think about the higher-level impacts that affect decision-making in our respective organizations.”

- “What I really enjoyed about this course was first and foremost the esteemed professors. … [The course] gives you a really big view of all the information you need to really understand business and understand the decisions that are getting made,” said Sherwin-Williams Associate R&D Director Tony Rook. “It gives you that top-level view of how you add value to [your] organization.”

Get involved: Registration is now open for the 2023 course. You can find additional information and register here.

Manufacturers Keep Pace with Technology Deployment

Manufacturers are staying on top of the tech game.

That was among the chief findings of a new polling conducted by the Manufacturing Leadership Council, the NAM’s digital transformation division. The annual Transformative Technologies in Manufacturing research survey aims to reveal data on current realities and expectations for manufacturing in the near future and in the years to come.

Rate of adoption: The most surprising data point was that 89% of respondents said they expect their company’s rate of adoption of disruptive technologies to increase over the next two years. That figure is up from 51% just one year ago.

Why disruptive technology? Reducing costs and improving operational efficiency were the most-cited reasons for investing in digital tech, with 83% of respondents identifying these as important motivations.

- Improving operational visibility and responsiveness came in second, at 61%.

- Other reasons include increasing digitization (40%), creating a competitive advantage (36%) and improving quality (30%).

Top near-future trends: Digital-twin modeling and simulation software, augmented and virtual reality, high-performance computing and further investments in supply chain management software will lead the next wave of investments during the coming year or two.

Not of interest: The survey found that quantum computing and blockchain technology are currently of the least interest to manufacturers.

The role of AI and ML: Artificial intelligence and machine learning usage continues to grow among manufacturers.

- Nearly 50% of respondents indicated that their companies have implemented AI, either on a single-project basis (40%) or in all factories (9%).

- About 75% said they are applying AI and ML to reduce costs and improve productivity and processes.

- Approximately 60% indicated they had used AI and ML for preventative/predictive maintenance or quality improvement.

Misunderstood metaverse: A new topic covered by this year’s survey, the manufacturing metaverse, was perhaps the least understood by respondents.

- About 38% said they were still trying to understand the technology and concept, 20% said they have no plans to adopt a manufacturing metaverse approach and 15% said they didn’t know how to respond to the question.

The last word: “Manufacturers are finding more use cases and business benefits for increasing their use of digital technology, and the pace of adoption is accelerating,” said MLC Co-Founder and Vice President and Executive Director David R. Brousell.

- “The research confirms that manufacturing is headed for an agile, connected and collaborative future driven by technology and fueled by innovation.”

How Adaptive Skills Can Play a Pivotal Role in Building the Manufacturing Sector of the Future

This new research from MI and EY on adaptive skills in the manufacturing workplace. What are adaptive skills? Simply put, they are skills or traits that enable individuals to transform their abilities as their demands and environment change. There is a need for broader and evolving skillsets in the manufacturing sector and for building a workforce motivated by opportunities for growth. Doing this will help manufacturers transition to workplaces to a point where forward-thinking, engaging, and digitally enabled work is the norm.

Future Skills Needs in Manufacturing: A Deep Dive

The Manufacturing Institute, in partnership with Rockwell Automation and PTC, released a forward-looking study on where the manufacturing sector will be headed over the next 5 to 10 years and how those changes will impact the necessary skills that will be required of employees. More advanced processes and innovations will necessitate enhanced data and technological skills. As a result, manufacturers will need to support or provide new elements of continuous learning for existing employees, and the skill sets of new employees will need to become increasingly more sophisticated. At the same time, soft skills will always be important. This need for advanced skills sets for modern manufacturers comes against a backdrop of a tight labor market, complicating the search and heightening the already fierce competition for talent.

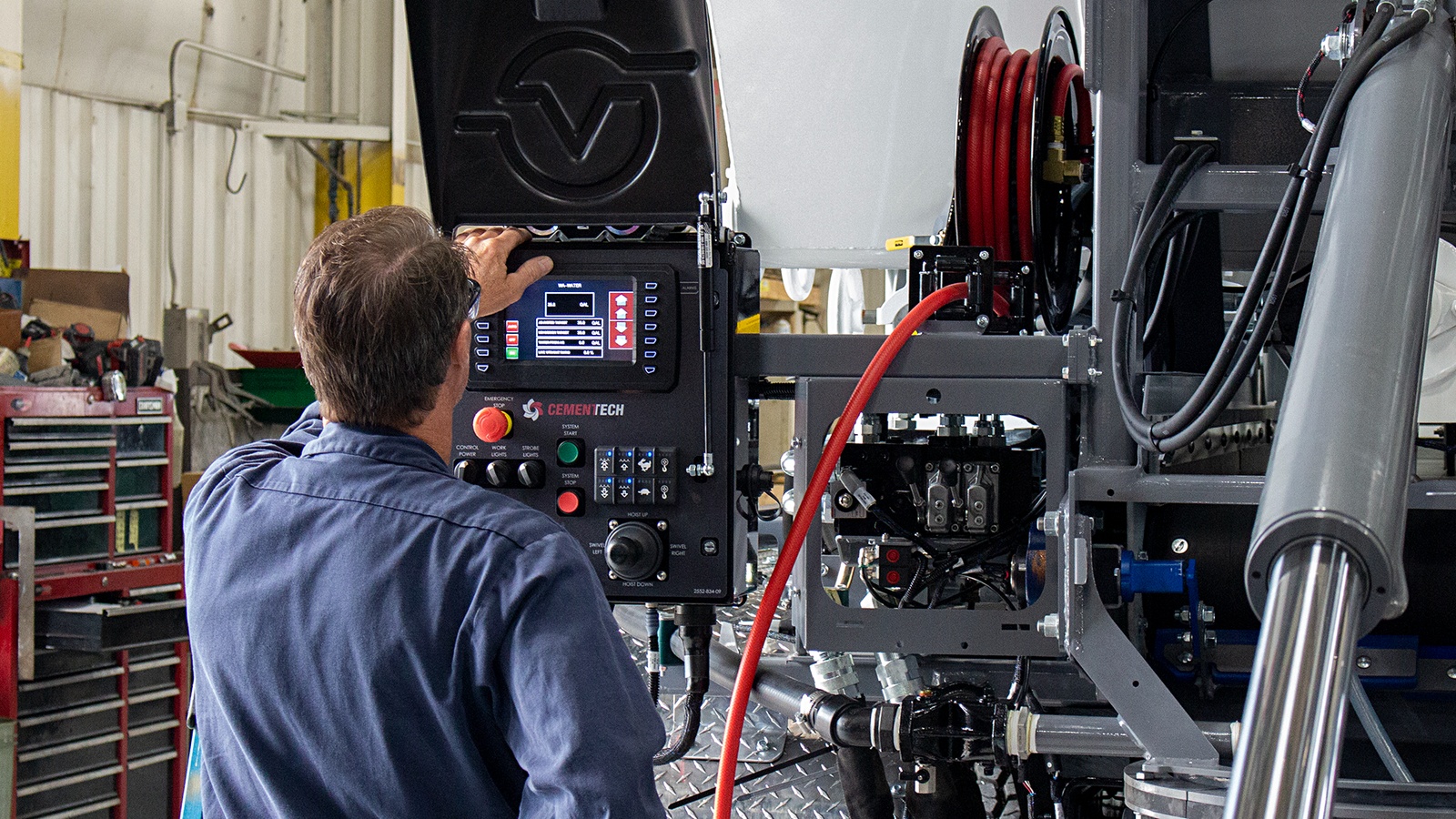

Concrete Mixer Maker Finds a Growth Formula

Even amid so much economic uncertainty, Cemen Tech is on track for a year of unprecedented growth. Leaders of the company, the world’s largest manufacturer of volumetric technology, attribute a good deal of its success to its loyal workforce.

Allegiance creator: Just what contributes to that worker loyalty? The answer may well be Cemen Tech’s unusual generosity.

- “We considered a number of new and different ways to continue to attract and retain good people,” Cemen Tech President and CEO Connor Deering said. “In September 2021, we made the decision to cover 100% of employee health insurance costs, the net effect of which is essentially our folks taking home more of the money they earn. That has really helped with retention.”

- The Indianola, Iowa–based company also raised wages across the board and began offering employees season tickets for local sports teams.

A new approach: Full health insurance coverage made a difference when it came to attracting and keeping workers, but the volumetric concrete mixer manufacturer was still hitting another roadblock when it came to employment: finding people with the right qualifications. So, it set out to solve the problem in house.

- As part of a planned facility expansion, the company is setting aside space for the new “Cemen Tech University,” an innovative answer to the question of how to develop employees with highly desired, specialized skills. Classes are tentatively set to start in January 2023.

- The company is also working with area high schools and technical schools to forge partnerships in which students work for Cemen Tech part time, while still pursuing their diplomas or degrees.

- “This way, we train applicants for immediate success on the job, helping to ensure a strong fit between the employee and the company from the start,” Deering said. “It also gives us an opportunity to teach new hires about our organizational culture. … I believe [our education efforts] will help support an educated team member who’s connected to our culture, resulting in a happier, better and more long-term employee.”

More incentives: Last March, Cemen Tech found a way to boost shift-worker attendance with a points-based rewards system.

- “We implemented an attendance bonus—if an employee stays within a certain number of points [for coming to work], they can earn an additional $90 a week,” said Cemen Tech Director of Human Resources Emily Lyons. “We have seen that help in terms of attracting and retaining employees and further incentivizing employees to achieve consistent attendance.”

- The company has also increased the referral bonus given to existing employees who bring in new hires, Lyons said.

Advice: Manufacturers looking to see similar growth to Cemen Tech, which is set to expand 65% this year, should consider implementing some of the firm’s ideas (if financially feasible). But companies should be prepared to incur some financial cost along the way.

- “Our growth has helped offset the profitability loss [from the increased benefits], but the reality is that our business is people,” Deering said. “If we don’t have people—good people—we’re not going anywhere. So, the fact that we’re little less profitable at the moment is OK, as long as we can continue to grow.”

MI Summit Advances Workforce Solutions

Last year, The Manufacturing Institute—the workforce development and education partner of the NAM—came to a realization: There were manufacturing conferences and there were workforce conferences, but neither addressed manufacturing-workforce challenges from a broad, national perspective. The MI wanted to change that.

And it did, just this month—with the inaugural, now-annual, MI Workforce Summit.

What it is: The summit, held this month in Cincinnati, Ohio, is a first-of-its-kind, multiday event that brought manufacturers, educators, community partners, association leaders and more together to network, attend workshops and hear talks from manufacturing and workforce leaders. All of them had the same goal: to build the manufacturing workforce of today and tomorrow to ensure the industry’s competitiveness.

- Made possible by sponsors including the Arconic Foundation, WestRock, FactoryFix, the Manufacturing Skill Standards Council and EY, and supported by the Ohio Manufacturers’ Association, the summit drew more than 300 participants.

- Half the attendees were manufacturing employers and half were from the MI’s leading partners.

- “Forging partnerships isn’t a theme, it’s an action item,” said Arconic Foundation President and Treasurer Ryan Kish. “Come up with concrete actions for your organization on how you’re going to go into the community and forge partnerships to tackle the manufacturing workforce challenge.”

What happened: The summit, with its theme of forging partnerships, resulted in the creation of more than 920 new connections among workforce stakeholders. It focused on three “areas of importance”: attracting, training and retaining quality employees and how partnerships enable success across all three. Specific events at the summit included:

- A plenary fire-side session on how partnerships helped Toyota and the entire manufacturing sector grow in northern Alabama;

- Breakout sessions focused on a range of key issues, including how parents and teachers help manufacturers attract talent, how the workforce can prepare for automation and how economic developers are now assisting in workforce development;

- Newly released research from the MI on adaptive skills and future skills needs;

- A plenary on the impact of culture on employee retention;

- Interactive Q&As on recruiting, training and retaining employees; and

- A session on how corporate and foundation grants can improve the manufacturing workforce ecosystem.

“Hidden” talent: A frequently untapped pool of potential workers—individuals with previous involvement in the criminal justice system—was another topic of discussion at the summit.

- One in four adults in the U.S. has a criminal record, according to the National Employment Law Project. Many companies have had success in hiring people with criminal records, which has led more manufacturers to begin recruiting “second chance” hires.

- A leader in these hiring practices is JBM Packaging, whose director of human capital and culture, Valerie Plis, spoke at the summit.

Hiring veterans: Military veterans are another group of promising potential hires, as speakers advised the attendees.

- More than 200,000 men and women transition out of the U.S. military and into civilian life every year, according to the Labor Department.

- The MI’s Heroes MAKE America program seeks to attract many of them to the manufacturing industry, by building connections between the military and veteran communities and companies seeking top talent.

Growing talent: The summit dove into another successful workforce solution model: the Federation for Advanced Manufacturing Education (FAME), created by Toyota in 2010 and transitioned to the MI in 2019.

- FAME, which recently wrapped up its own annual national conference, combines strong technical training and professional skills development with hands-on manufacturing work experience to create global best-in-class entry-level technicians. In just three years, it has spread across the U.S. and now has more than 400 manufacturer partners.

- From 2021 to 2022, the program saw an 18% increase in the number of participants, according to MI President Carolyn Lee.

The last word: In her remarks, Lee encapsulated the central idea behind the new summit: “When we pioneer solutions together, we’re stronger than when we work alone.”

Creators Wanted Moves the Needle in Decatur

While participants were having fun at this week’s Creators Wanted stop in Decatur, Illinois, the nationwide tour and its mobile experience were doing something, too: moving the needle on people’s perceptions of modern manufacturing.

What went on: Over the course of three days, more than 800 students from 13 area middle schools, high schools and community colleges poured into Richland Community College to learn about manufacturing careers. Also present were many educators and parents.

- Attendees “raced to the future” in the Creators Wanted mobile experience, solving various manufacturing-related challenges as they wound through the escape room.

- They heard panel talks from manufacturing leaders and team members and learned about some of the industry’s many perks, including great wages, flexible schedules, upward mobility, chances to earn and learn and more.

- Interactive activities, set up and run by manufacturers and the campaign’s recruiting partner, FactoryFix, were designed to garner interest—and display some of the real work done every day in modern manufacturing.

- This included virtual-reality paint and assembly training from Creators Wanted host sponsor Caterpillar, as well as a hazard-awareness simulator, a drink-making station and a laser-system exhibit from host sponsor ADM. Richland Community College took students on a tour through its state-of-the-art lab.

Generation inspired: Manufacturing leaders at ADM, Caterpillar and the Illinois Manufacturers’ Association, which together brought the tour to Decatur, got the chance to galvanize crowds.

- Said IMA President and CEO Mark Denzler: “Manufacturing makes the world a better place to live every day. Some of you are going to find the next cure for a disease. You’re going to build the next robot.”

- “For anyone who really is looking for a career that you can get into that is good-paying, that will provide you an opportunity to progress, consider manufacturing,” Caterpillar Group President of Resource Industries (and NAM Executive Committee member) Denise Johnson told the crowd.

- Following the event, students were indeed inspired. “It kind of changed my mind on what I want to do in the future,” one student

- “It was amazing,” said another. “I’d think about doing this for a career.”

Shoring up the shortage: The lack of skilled workers has been a pain point for manufacturers for several years now—and it’s a problem Creators Wanted aims to fix.

- “Programs like Creators Wanted are crucial in narrowing the workforce shortage in manufacturing and also showcasing the many opportunities within the manufacturing industry,” said ADM Senior Vice President of Global Operations and NAM board member Veronica Braker.

The impact: The tour stop made a splash in regional media, garnering overwhelmingly positive broadcast coverage and print mentions and placements (see here and here).

Meeting people where they are: “How do you get more young people interested in the field [of manufacturing]?” 25 News WEEK-TV anchor Erin Brown asked in a segment for the Peoria, Illinois, news station. “The answer could be more hands-on experiences with businesses like Caterpillar and ADM.”

Phoenix Closures Invests in Diversity and Inclusion

Manufacturers come from many different communities and backgrounds—and Phoenix Closures, a sixth-generation, family-owned business that makes packaging and closures, wants to make sure that all of them feel welcome in the industry. In the past few years, the company has created a D&I initiative that ensures their employees feel included in and excited about the place where they work.

Getting the ball rolling: The company began by installing a leader to oversee their D&I efforts and combine programming and support into one place. Vice President of Quality and Corporate Social Responsibility Meena Banasiak—a 2020 honoree at the Women MAKE Awards, formerly known as the STEP Ahead Awards—sees her role not only as that of a leader, but as proof of Phoenix’s commitment.

- “I’m part of our progress in terms of D&I at Phoenix,” said Banasiak. “This position I am in was created in order to have someone in the role to establish a framework for corporate social responsibility. This position had never previously existed.”

- “We knew as a business that we were in many ways doing a lot of things that would fall within a D&I program, but without that clear purpose and intention and definitive resources put behind it.”

- “So, in a very visible and important way, I had the opportunity to be in a position of leadership and join the executive staff as a woman of color and set the course for the nature of this work that we

’ve been pursuing.”

Developing programs: The company has created and implemented a range of initiatives that allow employees to connect and contribute.

CSR committee: Phoenix developed an employee resource group that is focused on corporate social responsibility and includes representation from all the company’s operating locations. Employees are encouraged to voice their ideas on the types of programs that could be offered to the workforce, and the group offers tools and resources to help members implement programs at their respective sites.

- “It’s great to have a way to give people that voice, to make the work environment something

that enables us to feel more included,” said Banasiak. “Yes, we’re here to do good work, but we might just be able to have fun while we’re doing it! We want our employees to feel comfortable bringing their whole selves to work if they want to and develop more profound relationships in the process.”

that enables us to feel more included,” said Banasiak. “Yes, we’re here to do good work, but we might just be able to have fun while we’re doing it! We want our employees to feel comfortable bringing their whole selves to work if they want to and develop more profound relationships in the process.”

Parental leave: The company has expanded its parental leave benefits. Today, all full-time employees are eligible for the program, and the benefit applies to the non-birthing parent as well—including in cases of adoption.

- “There are people who have been able to take advantage of it right away—and just hearing their personal story, and their sense of relief knowing they have this support from their company—it’s unfettered relief,” said Banasiak. “It goes a very long way toward cementing the relationship between employer and employee, when you feel like your employer is invested in you.”

Volunteer time off: Phoenix’s full-time employees are encouraged to take up to eight hours of paid time off per calendar year to volunteer with the charitable organization of their choice—either individually, or as part of a team.

- “There have been a few different events where a group of employees have gone together, so it simultaneously serves as a teambuilding exercise with a broader impact,” said Banasiak. “At the same time, we get to share the stories of these experiences and celebrate those organizations that our employees find meaningful to them. Excitement breeds further excitement.”

Pledge for Action: Phoenix was a signatory of the NAM’s Pledge for Action, which committed the manufacturing industry to taking 50,000 tangible actions to increase equity and parity for underrepresented communities, creating 300,000 pathways to job opportunities for Black people and all people of color, and reflecting the diversity of the overall U.S. workforce by 2030.

Starting small: According to Banasiak, it’s important to be sensitive to needs across the entire company, but also to create small forums where employees can feel comfortable discussing issues. By empowering employees to come forward with ideas, a company can unleash the creativity, energy and enthusiasm of a diverse workforce.

Building the habit: “At first you might be in a place that feels more performative rather than substantive, but it’s still a legitimate starting point,” said Banasiak.

- “We never before made an intentional effort to acknowledge Hispanic Heritage Month or Black History Month. By now, our employees are creating and hosting their own events—but before that, our first step was literally a single email to the organization.”

- “I’d argue that first step is every bit as necessary and valid on this journey. Just making that conscious effort—that’s going to be meaningful to someone. It’s necessary to build that habit in small ways to create an environment where ideas start to flow. The motivation builds upon itself, but you have to start somewhere.”

The bottom line: “Results are not instantaneous or something that one person can achieve,” said Banasiak. “It’s about slowly shifting the narrative.”

A Small Manufacturer on What Policymakers Can Do for Her Company

Courtney Silver runs a precision machining company that has been in business for 75 years, so she knows how fast the manufacturing industry evolves. The Ketchie, Inc., president, who serves as the vice chair of the NAM’s Small and Medium Manufacturers Group, has a clear message for policymakers and manufacturers alike.

- To stay competitive, “manufacturers must have policies that incentivize us to save for emergencies, like pandemics, and to use profits productively to invest in machines, technologies and people,” she says.

- “Small manufacturers know what to do, to invest our profits and grow”—and policymakers should let them get on with it.

We caught up with Silver earlier this fall and chatted about her plans for Ketchie, the policies that would support manufacturers’ competitiveness and more.

The history: Seventy-five years ago, her late husband’s grandfather came home from World War II to work in a local textile mill, Silver tells us.

- The former Air Force captain quickly observed that local manufacturers needed a “job shop” to provide precision machined solutions. In 1947, he founded the company.

- Since then, and through many upgrades in technology, the business has grown considerably. It now supports several industries, including “textile, rail, heavy machinery, agriculture and industrial equipment,” says Silver.

In the family: Silver joined the business in 2008, then took over as president after her husband passed away in 2014. Through all her years there, she says, “investing in the lives of the people I work with and providing them with opportunities to develop and grow their God-given talents has been what matters the most” to her.

- That dedication spills outward into the community. Silver and the company are deeply invested in their work with the North Carolina Manufacturing Institute, numerous local schools, the local Boys & Girls Club and the Cooperative Christian Ministries.

What do small manufacturers need? To help small manufacturers stay competitive and keep contributing to their communities, “we need a tax structure that works for us,” says Silver.

- The 2017 tax reform law benefited Ketchie by allowing large manufacturers to expand, meaning they had more orders for Ketchie. The company was able to hire more workers as well as provide raises and bonuses.

- However, small manufacturers need further support from policymakers, according to Silver. “Smaller manufacturers have access to less capital,” she explains, so they must often use their profits for crucial short-term investments, like new equipment.

- But they also need help from policymakers for longer-term efforts, such as saving for emergencies (including pandemics) and using their profits to aggressively attract and retain a high-quality workforce.

The absence of a tax structure that supports all these endeavors together “hinders innovation and growth and limits our ability to compete,” Silver points out.

A promising future: When asked how new technologies are helping small manufacturers innovate, Silver responds enthusiastically: “That’s why I love the industry so much—the machining technology is transformational for small businesses in our industry.”

- Ketchie has kept up with the latest innovations throughout its history. Back in the 1980s, that meant purchasing its first CNC (computer numerical control) machines for more efficient, precise machining.

- Today, it’s automation. The company’s first machine-tending collaborative robot will debut on the factory floor in November, taking over machinists’ “least favorite” part of the job—changing parts while the machines run. The robot will free up workers for more challenging and skilled work around the shop, as well as dramatically increase productivity by running unattended after shift hours, Silver says.

- Technology has “opened up” manufacturing, as she puts it. Automation, 3D printing, additive machining and more have “sped up the lifecycle from the idea to the finished part.”

People first: Technology may be evolving rapidly, but the need for a high-quality workforce remains the same. When asked about her plans for Ketchie’s future, Silver says that “the number-one challenge, again and again, is workforce.”

- Silver aspires to strengthen Ketchie’s community outreach by teaching semester-long classes in the shop for high school students, which will include mentorships and a character development curriculum along with job shadowing on the shop floor.

- Ketchie also plans to continue its leadership role in its community as an active member of the school program board, and by continuing to open its doors to tours, interns and apprentices.

- “Making these long-term investments in our youth, in our industry and in our team is foundational to who we are, and we are thankful for all of the opportunities to help shape our future workforce in manufacturing,” says Silver.

The next generation: For the president of a family company, this question must be inevitable: Will Silver’s children run the business, too?

- “Time will tell for sure. They both show strong leadership qualities and are interested in what we are accomplishing at Ketchie. My son has a lot of fun with a 3D printer at home, and my daughter already has excellent problem-solving skills. It’s going to be interesting to see!”

At the NAM: About her work at the NAM, Silver says, “I want to see a genuine opportunity for small and medium manufacturers to grow, thrive and successfully compete.”

- “Each SMM member should feel truly valued and know they have a place at the NAM. Their story, and what they do every day, matters to manufacturing in America.”