Hirebotics’ Co-Founders on Powering a Remote Team with PTC Onshape

The NAM’s Makers Series is an exclusive interview series featuring creators, innovators and trailblazers in the industry sharing their insights and advice. Meet Rob Goldiez and Matthew Bush, co-founders of Hirebotics. In this edition of the NAM’s Makers Series, Goldiez and Bush explain how Hirebotics uses PTC’s Onshape cloud-based CAD system to power its design teams.

How an Analytics Company Keeps Hospitals Running

Behind every hospital bed, doctor, ventilator, mask and the millions of other components that make up a hospital is the same thing: a prediction. How much will we need, and where, and when? Analytics make those predictions as precise as possible—and that’s never been more essential than during COVID-19.

Analytics software company SAS understood the problem better than almost anyone. And not long after the pandemic started, it partnered with the Cleveland Clinic to create an innovative dashboard that would help hospitals optimize their resources and keep saving lives.

How it started: On March 17, the Cleveland Clinic asked SAS to create models that could predict the spread of COVID-19. They wanted to understand the strain that COVID-19 might put on the hospital, and by extension, its resources—from ventilators to PPE to dialysis machines to their doctors’ time.

Why it’s different: While plenty of organizations around the world were building epidemiology curves to track the course of the virus, SAS and the Cleveland Clinic built a framework that offers more. The collaborative team came up with a range of scenarios based on varying inputs like virus transmissibility and social distancing. With SAS vetting the math behind the models, the Cleveland Clinic identified which curve it was on at a given time and developed action plans in advance.

How it worked: The models helped the Cleveland Clinic identify markers for potential surge scenarios and recognize when the actual severity of the outbreak would fall short of some projections. That means it did not have to cancel planned events like routine surgeries and treatments and was able to continue treating non-COVID-19 patients.

- “One of the challenges of this pandemic is the public health cost of dislodging patients with cancer or chronic disease to make room for COVID-19 patients,” said Dr. Steve Bennett, director of the global government practice at SAS. “These models can tell you that you may not need the surge capacity; you can keep doing the sorts of standard work that you’re doing. That has a valuable public health benefit.”

Sharing the wealth: SAS didn’t want to keep such a potentially valuable tool to themselves—so the team made their code publicly available on software development site GitHub. Other hospitals and public health agencies have adapted it, given feedback and made it their own, thus contributing to innovation and effective response.

- “Cleveland Clinic is very advanced in analytics—but at the same time, they really wanted to help smaller organizations and smaller clinic hospitals that may not have big data science teams,” said Natalia Summerville, senior manager at SAS. “That’s why they allowed us to make everything publicly available, which was amazing.”

What’s next: The technology has applications even beyond the current crisis. “SAS aspires to be the platform of the future,” said Dan Abramson, executive director of U.S. manufacturing at SAS (and an NAM board member). “It’s got capabilities in modeling and AI and data management and visualization. So, the knowledge we gain from projects like these can be a launching point for pretty much any business problem or challenge.”

The last word: “The collaboration worked,” said Andrew Williams, principal analytical solutions architect at SAS. “The analyst community has always spoken very highly of our technology and analytic capabilities in AI, machine learning and optimization—and I think what we’ve shown here is that we can apply them to critical use cases across the board and across industries.”

The Story Behind “This Is Our Shot”

The NAM and The Manufacturing Institute have launched a large-scale project to promote vaccination among manufacturing workers and communities, called “This Is Our Shot.”

As NAM President and CEO Jay Timmons describes it, “This project builds on our months of work advocating the use of face masks and other smart health measures to protect all Americans . . . . Now is our opportunity as a country to end this pandemic. Our future depends on all of us rolling up our sleeves and getting armed against COVID-19.”

So how did they make it happen? We recently talked to NAM Vice President of Brand Strategy Chrys Kefalas about the inside story.

Why: As Kefalas puts it, “We have a crisis. Depending on which study you look at, between 30% to 40% of Americans say they will not get a COVID-19 vaccine. We have to take direct aim now at vaccine hesitancy; otherwise, we’ll have safe and effective vaccines and not enough people willing to get them to reach heard immunity.”

Why the NAM and the MI? The NAM, along with its workforce development and education partner, the MI, has a “singular power” to leverage manufacturing’s unifying position as a trusted community resource, Kefalas explains.

How: In the spirit of manufacturers everywhere, let’s take a look at how this project got made.

- First, the research: “We’ve relied on a wide range of suggestions and guidance, from manufacturers of all sizes and all sectors. We’ve also sought recommendations from the Gates Foundation, the CDC and other public health leaders,” says Kefalas.

- Second, the reach: “We’re engaging company medical officers, local health care providers and community members who can change hearts and minds about COVID-19 vaccination.”

- Third, the sights: “It’s going to take videos, photos, flyers, posters, emails—and other very visible signs that others are getting armed against COVID-19.”

- Fourth, the psychology: Research shows that a sense of group loyalty or patriotism can boost vaccination numbers, Kefalas explains. To create that sense of solidarity (and social influence), the NAM and MI will distribute red and yellow ribbon pins for those who get vaccinated—and encourage people to put up red and yellow ribbons outside their homes once their whole households have received the vaccine.

What can you do? The initiative is providing manufacturers with communications materials to share with their teams. As Kefalas says, clear, consistent and direct communication from employers and peers really helps. “And when you are conveying medical information, rely on the experts like medical officers and direct people to their medical providers,” Kefalas suggests.

All we need is love: In case you missed it, the first video in this initiative dropped yesterday, a charming short called “I Love Frank.” Kefalas explains the idea: “Caring for others is really the one message that seemed to resonate across all demographic groups. Vaccinations should be really simple, because it comes down to one thing: we want to protect the people we love.” You can’t say it any better than that.

Manufacturing Associations Are Stronger Together

The NAM’s most effective allies aren’t just manufacturers themselves, but other manufacturing associations as well. And the strength of those alliances was on full display this month, as the NAM’s Council of Manufacturing Associations hosted its first virtual Winter Leadership Conference.

Despite the limitations of the pandemic, a record showing of association leaders turned out to discuss the future of the industry. Here’s a look at what they did.

The background: With a membership of 250 national manufacturing associations representing 130,000 companies worldwide, the CMA creates partnerships across the industry and amplifies manufacturers’ voices. It’s the place to be if you want to connect with association CEOs, senior staff executives, experts and decision makers of all kinds.

A meeting of leaders: Here are some of the highlights of the CMA conference, which showcased the incredible network of leaders that the NAM has built up.

- “Leading in the Midst of Uncertainty”: NAM President and CEO Jay Timmons spoke to Biotechnology Innovation Organization President and CEO Dr. Michelle McMurry-Heath about the pharmaceutical industry’s role in vaccine development during a year unlike any other.

- “The Changing Geopolitical Landscape”: Retired U.S. Army General Stanley McChrystal chatted with Steel Manufacturers Association President Philip Bell about how changes in foreign policy will alter the way manufacturers work.

- “Rising to the Occasion”: Timmons and Stephen Ubl, president and CEO of Pharmaceutical Research and Manufacturers of America (PhRMA), spoke about what manufacturers have done to combat COVID-19 and how they will protect the supply chain that is critical to vaccine delivery.

- “An Economic Forecast”: NAM Chief Economist Chad Moutray spoke about what manufacturers can expect in 2021, as well as what the “new normal” might look like.

The conference also featured smaller discussions among association executives on topics such as “Recruiting in a COVID-19 Environment”; “Planning, Promoting and Producing Online Experiences”; “The Digital Transformation”; and “Diversity, Equity and Inclusion.” In addition, leaders discussed how they can collaborate to advance manufacturers’ policy priorities with the new Congress and administration.

New leadership: The CMA announced new leadership at the conference as well. Robb MacKie, president and CEO of the American Bakers Association, will serve as the new CMA chair, and Bell will serve as CMA vice chair.

CMA Leadership Award: Every year, the CMA recognizes the association leader who has done the most to advance and expand this influential network. This year the award went to Steve Caldeira, president and CEO of the Household & Commercial Products Association.

- As Timmons said about Caldeira, “Steve has been a powerful force for CMA recruitment and retention. He’s convened his peers and colleagues in timely CMA discussions . . . [and has] been an indispensable voice for the CMA among the broader association community.”

The last word: As Timmons put it in his opening remarks, “Our country needs real leaders right now. It needs people who will speak truth and bring light into darkness. And the business community has to provide that leadership.”

How NAM Cyber Cover Helps Manufacturers

Cyberspace seems to get more dangerous every day. The latest scare comes from the likely Russian hack of tech company SolarWinds’ software, which affected several U.S. government agencies along with major corporations. But manufacturers can give themselves some peace of mind by investing proactively in security measures—such as cyber insurance.

One industry executive is very happy with his decision to buy cyber coverage from the NAM to protect his company. After its sister company was attacked in a cyber incident, Manitoba Corporation’s Partner and Vice President of Marketing Adam Shine shopped around for plans that would safeguard the family-run metal recycling business based in New York. After considering his options, Shine signed up with NAM Cyber Cover because it offered proactive protection in addition to coverage, tailored to manufacturers at a competitive price.

“I think the NAM has done a good job of providing value for money, so it’s not like you’re just writing a check for cyber insurance on an if-come basis,” said Shine. “You’re actually signing up for some user training and some tools that will help you mitigate that risk.”

What it is: NAM Cyber Cover is a cybersecurity and risk-mitigation program developed exclusively for the NAM’s member companies and organizations in partnership with AHT Insurance and Coalition, which specializes in underwriting cyber and technology insurance.

What it offers: Cyber Cover presents a range of benefits for manufacturers seeking to secure themselves against cyber intrusions, allowing them to:

- Manage risks through a free Cyber Risk Assessment, as well as gain access to threat monitoring and vulnerability alerts;

- Mitigate the severity of intrusions with training platforms and programs that help employees recognize issues, while also working with ethical hackers to identify vulnerabilities;

- Receive 24-hour-a-day coverage from Cyber Cover support; and

- Recover from an attack with instant support that helps manufacturers survive and rebuild after a breach.

The word from Manitoba: “Speaking from experience, don’t think it can’t happen to you,” said Shine. “[Cyber attackers are] targeting every company from every walk of life…. To know that you have coverage and a safety net is critical. I would highly advise everybody now to have cyber coverage.”

The word from the NAM: “Modern manufacturers are deploying advanced technologies that are transforming what we make and how we make it. This rapid digitization and the workplace disruptions created by the COVID-19 pandemic have created new and unprecedented risks for our members,” said NAM President and CEO Jay Timmons. “Our partnership with AHT and Coalition will help protect our industry from cyberattacks and ensure we can continue to lead our economic recovery and renewal.”

Watch this interview with Shine about his experience, and take a look at what Cyber Cover offers here.

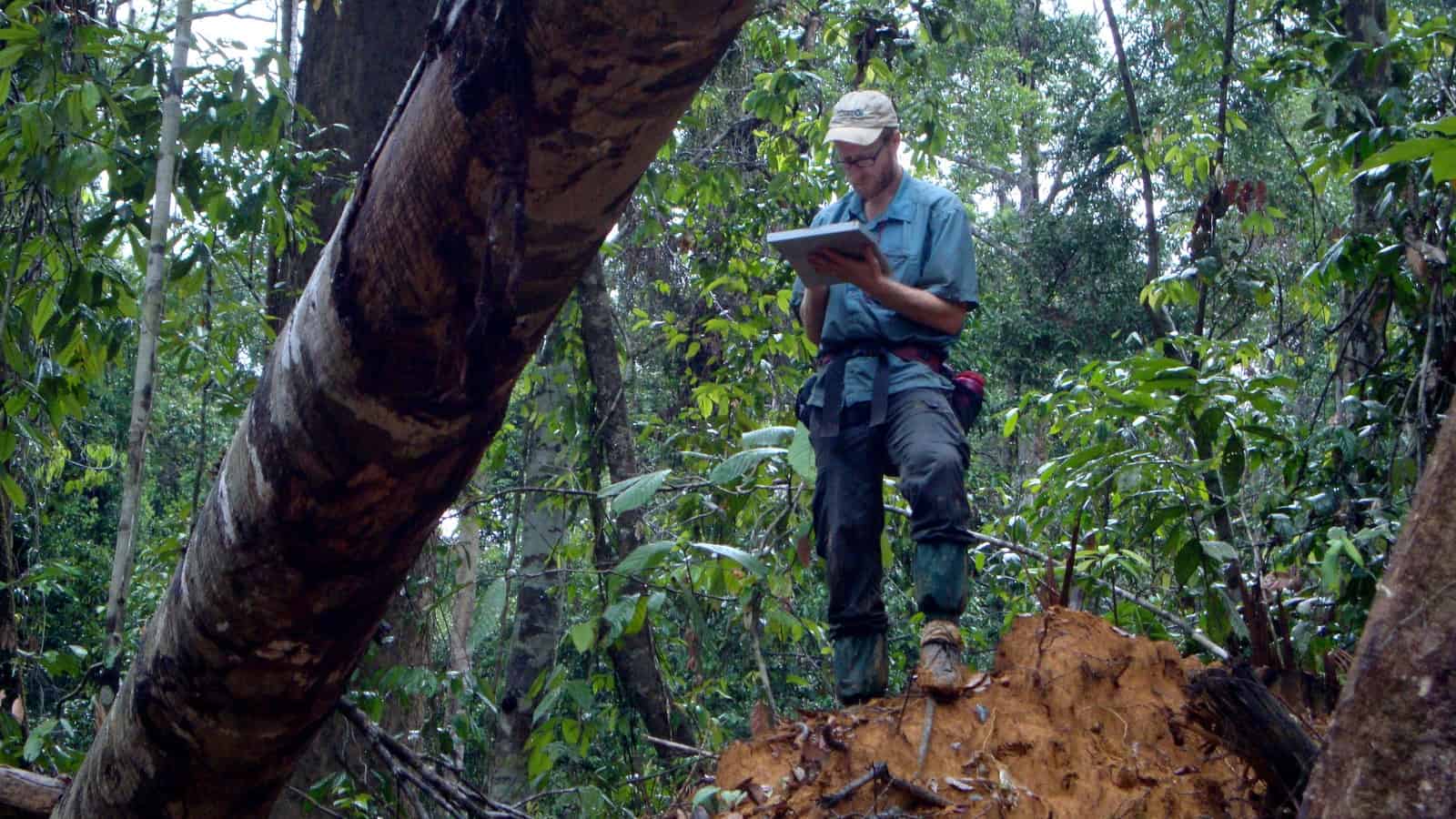

A Manufacturer Works to Keep Forests Safe

International Paper is acutely aware that forests are “the lungs of the landscape,” says Chief Sustainability Officer Sophie Beckham. That’s why the company, which serves 25,000 customers in 150 countries around the world, has developed a close partnership with The Nature Conservancy.

Beckham chatted with us recently about what the two organizations have done together. Here’s the condensed interview.

How it started: International Paper’s collaboration with TNC goes back decades, to the days when International Paper was the largest private forest landowner in the United States. About 15 years ago, when International Paper made the decision to divest of all of its land holdings, TNC acquired significant amounts of the company’s land. And in 2017, International Paper decided to go further—taking on an expansive effort to help others support forests and communities.

- “We wanted to look outside our own supply chains, and understand how might we contribute to knowledge on natural climate solutions and biodiversity,” said Beckham. “Working on projects that are more global in scope and more focused on natural climate solutions—that was the beginning of the relationship.”

Phase 1: First, International Paper partnered with TNC to reduce the carbon impact of logging in southeast Asia, including through cutting-edge methods like bioacoustics—a technique for measuring the biodiversity of forests by recording the animals and insects that live there. The company also employed reduced-impact logging methods to advance carbon sequestration.

Phase 2: Earlier this year, the partnership moved into a new phase, and today International Paper is bringing its expertise to North American forests. It partners with private local landowners to sequester more carbon, which reduces the impact of climate change while protecting the land’s commercial value.

- “We’ve learned from our experiences around the world that we have great opportunities to promote sustainability without compromising the economic value of the land for landowners—and now, we’re bringing those techniques to forests in North America,” says Beckham.

Good advice: For other companies interested in promoting sustainability, Beckham emphasizes the importance of strategic partnerships and collaboration.

“There was a time in which manufacturers felt a little bit in the defensive position with environmental stakeholders—but the turning point has already happened,” said Beckham.

The Timeline for the Vaccine Rollout

The counteroffensive against the pandemic entered its next phase earlier this week, when 90-year-old Maggie Keenan became the first Brit to receive the initial dose of the United Kingdom’s rollout of Pfizer’s COVID-19 vaccine. Meanwhile, the U.S. effort is also moving forward, with some big milestones coming up this month. Here’s what the timeline looks like.

Dec. 10: The Vaccine Advisory Board at the Food and Drug Administration will meet to consider emergency approval of Pfizer’s COVID-19 vaccine.

Dec. 11 or 12 is likely to see the beginning of U.S. inoculations for the Pfizer vaccine, since they are expected to begin 24–48 hours after FDA approval.

Dec. 17: The Vaccine Advisory Board is expected to consider Moderna’s COVID-19 vaccine.

Dec. 18 or 19: Moderna’s vaccine is set to reach patients.

End of December: 40 million doses of vaccine are expected to be delivered by Pfizer and Moderna, which will cover approximately 20 million people.

January or February 2021: Johnson & Johnson’s single-dose vaccine is expected to come online, offering additional options and capacity for COVID-19 vaccines, while deliveries of the Moderna and Pfizer vaccines are expected to multiply nationally. The goal is to have another 80 million people vaccinated during these two months.

By June 2021: 600 million vaccines in total are expected to be produced by a range of manufacturers, which means that everyone who wants a vaccine will have access to it at little to no cost.

How Pfizer Will Deliver Its Vaccines

Pfizer is working around the clock to ensure an efficient and speedy distribution of its potential COVID-19 vaccine, pending emergency use authorization in the United States. To do so, it has developed an innovative packaging and storage solution that just might help save the world.

The challenge: Beyond developing a vaccine in the shortest time frame ever attempted, researchers at Pfizer must ensure that hundreds of millions of vials of its potential COVID-19 vaccine are kept frozen at extreme temperatures (-70 degrees Celsius) as they are shipped across the globe.

The solution: Pfizer got to work designing, engineering and manufacturing temperature-controlled thermal shippers that use dry ice to maintain the required temperature until the point of vaccination.

Once in transit: Pfizer will monitor GPS-enabled thermal sensors in every thermal shipper from a control tower, which will track the location and temperature of each vaccine shipment along its preset route. That means Pfizer can prevent unwanted deviations before they happen.

Once on site: After arriving at the points of use, providers will have three options for storage:

- Ultralow temperature freezers, which are commercially available now and can extend shelf life for up to six months.

- Refrigeration units commonly available in hospitals, which can safely store the vaccine for up to five days at 2–8 degrees Celsius.

- The same Pfizer thermal shippers that carry doses during shipping; these can serve as temporary storage units for up to 15 days as long as they are refilled with dry ice.

The last words: “We have developed detailed logistical plans and innovative tools to support effective vaccine transport, storage and continuous temperature monitoring. Leveraging those resources and based on our track record, we are very confident in our ability to distribute large quantities of our potential COVID-19 vaccine to customers with different infrastructures in all parts of the country and all markets across the globe,” said Pfizer Vice President, BioPharma Global Supply Chain Tanya Alcorn.

“Pfizer is proving yet again that manufacturers’ ingenuity knows no bounds. The progress they have made on a vaccine alone is incredible, and the innovative way they have now addressed these distribution challenges is impressive. It shows manufacturers’ unwavering commitment to saving lives and helping to lead America out of this crisis,” said NAM President and CEO Jay Timmons.

How Hershey Makes Masks

Ever wonder how disposable face masks get made? Recently, NAM staff photographer David Bohrer visited a Hershey facility in Pennsylvania where workers are making masks for local schools, food banks, homeless shelters and more—producing about 60,000 per month for donation. They gave him the full tour, where he snapped these mask-makers in action.

Here’s how they do it. First, workers combine three layers of nonwoven fabric into one large piece. Why three? Because you need a layer on both sides of the electrostatic filter to protect it.

(The candy pattern adds style to safety.)

Then workers pleat the fabric and insert the nose bridge. The outer edges get folded and sonic welded. And only then do you cut out individual masks from the three-layer fabric.

After the individual masks are cut, workers inspect each mask by hand.

Next, they use a machine to sonic weld the ear loops to the masks. When Hershey started making masks, workers did this by hand, but it later purchased a machine that speeds this process up. In the middle of a pandemic, every second counts.

Lastly, the masks get sterilized, bagged, labeled with a date and lot code and sent on their way.

To date, Hershey has donated more than 440,000 masks to more than 65 community organizations and nearly two dozen public school districts in central Pennsylvania.

“PPE is critical to our daily operations, and when acquiring masks became challenging earlier this year, we quickly pivoted and made the decision to buy our own equipment to make masks,” Hershey Vice President of International Supply Chain & Manufacturing Will Bonifant says. “Sharing our masks with our employees’ families and the broader community was just a natural extension of how we’ve always supported the communities in which we live and work.”

Porta-King CEO Steve Schulte Talks Health Care

Steve Schulte began his career running Porta-King Building Systems, a portable building manufacturer, five decades ago. At the time, the Montgomery City, Missouri, business had just 10 employees—but as it grew, Schulte decided to offer health insurance to his employees to attract and retain a high-quality workforce.

Over time, Schulte became an advocate of providing benefits like health care to manufacturing employees—and when the NAM started developing NAM Health Care to extend affordable coverage to small manufacturers, Schulte wanted a seat at the table. Today, he serves as the chair of the NAM Health Care program’s governing committee.

“I thought it was very important for small businesses to be part of a larger group to help improve the cost of their health care,” said Schulte. “Knowing how expensive it is in today’s market—as a small manufacturer, it’s very difficult to get a competitive rate. Being a part of a larger group offers a tremendous opportunity for small businesses to get involved.”

How it works: NAM Health Care is an association health plan created by the NAM, Mercer and UnitedHealthcare. It allows manufacturers with fewer than 100 employees to band together to purchase affordable coverage that is usually available only to larger companies. Offering a range of benefits and savings, the program is tailored to manufacturers and provides tools that make the process of offering health benefits easy.

NAM Health Care is operated by the plan’s governing committee, which is made up of mostly small and medium-sized manufacturers. The committee manages the NAM’s medical, dental, vision and life plans with the support of Mercer and UnitedHealthcare.

The benefits: While Schulte’s company is too large to take advantage of NAM Health Care, he knows that the initiative still provides important benefits for his company. By helping his smaller suppliers attract and retain high-caliber employees, he can strengthen his own supply chain and the manufacturing workforce as a whole.

The last word: “As time goes on and it becomes more well known in the manufacturing community that the NAM has this offering, it will continue to grow,” said Schulte. “I’m a believer in the program. I’m delighted to be a part of the beginning stages and to be able to see the success we’ll continue to have.”

To learn more about the program, go here.