The NAM and PTC Launch the “Makers Series”

The NAM’s creative shop, always on the cutting edge, is bringing you something new: a collaboration with PTC to showcase the digital transformation in manufacturing. Today, the NAM and PTC are launching a series of co-branded videos to show both manufacturers and the public what the future will look like.

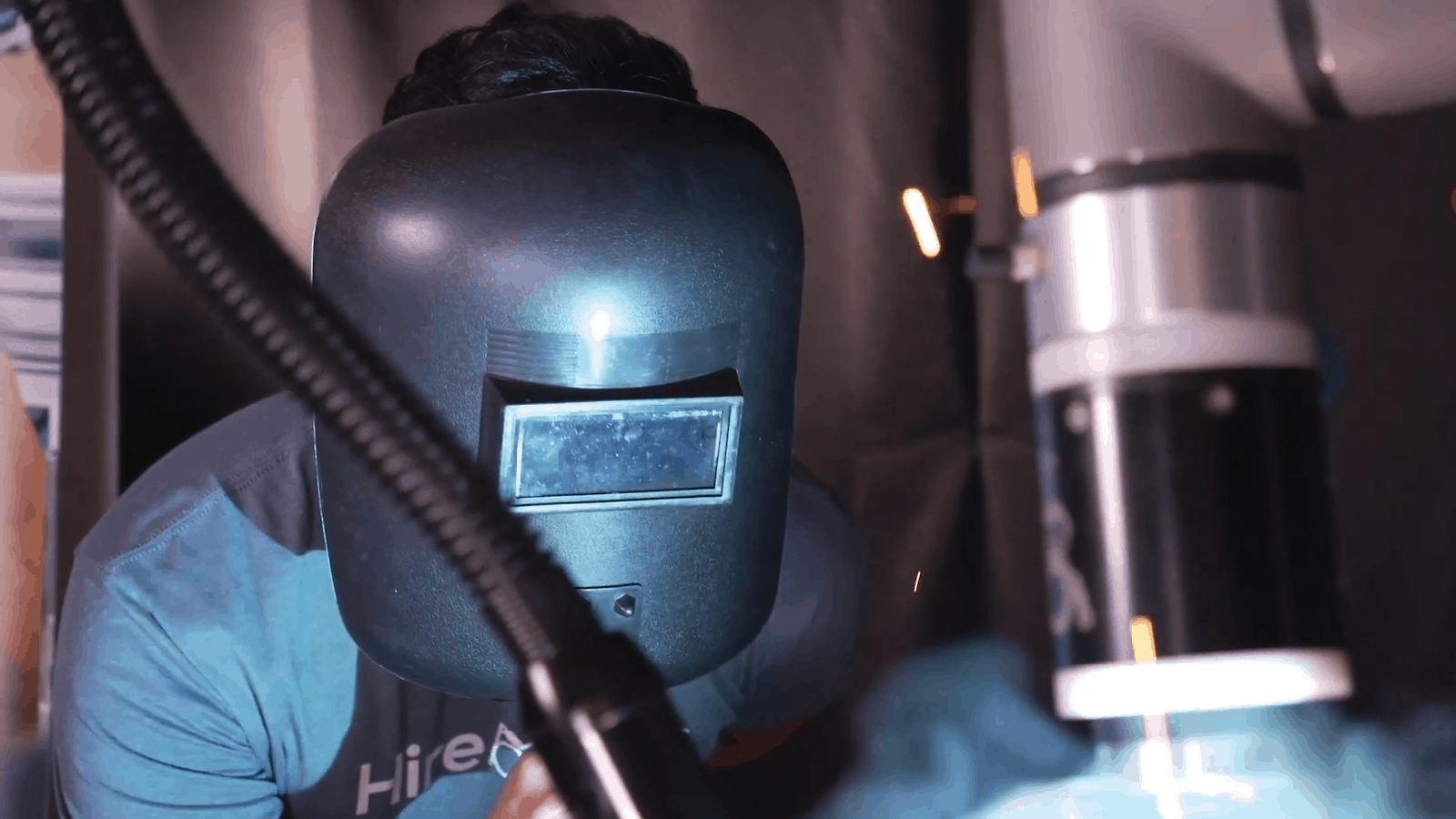

Watch: Before we go any further, take a few minutes to watch the first video in this series. In it, robotics company Hirebotics talks about how PTC’s Onshape cloud-based system allows it to design innovative welding robots that can be directed by a smartphone—and hired out to whatever company needs them.

The background: Over the past year, PTC has become a more visible presence to NAM members as a national sponsor of the association, expanding the NAM’s support of manufacturers in the United States and helping companies capitalize on digital technologies.

But the origins of this collaboration go back further than that. This sponsorship is a continuation of NAM President and CEO Jay Timmons’ “2020 Vision,” which he outlined back in 2015. Timmons envisioned turning the NAM into a “one-stop shop” for manufacturers—in advocacy, workforce development, legal action, news and more. Now, with PTC’s help, the NAM is giving voice (and visuals) to the industry’s future in more ways.

And there’s more . . . This series isn’t the only product of the collaboration—PTC President and CEO Jim Heppelmann has lent his expertise to the NAM’s board meetings and Leading Edge events, most recently giving a keynote address at the virtual Leading Edge Supply Chain Forum. Those of you interested in the business implications of the internet of things, augmented reality and the emergence of SaaS-based industrial solutions won’t want to miss his appearances in the future.

PTC says: Mike DiTullio, PTC’s president of SaaS business and an NAM board member, said of the partnership, “By partnering with the NAM on the Makers Series, we hope to inspire manufacturers with stories of how software is empowering manufacturers to transform and drive outcomes never thought imaginable. We are proud to be a member of the NAM, and even more proud to support the manufacturers of America.”

The NAM says: Timmons said of the partnership, “Through the Makers Series, PTC is providing powerful thought leadership, showcasing the incredible technologies that define modern manufacturing. We’re grateful that they are sharing their expertise and sponsoring this exciting initiative. They have created a model that demonstrates what the NAM is capable of producing alongside our members.”

Manufacturing Institute Partnership Enhances Railroad’s Hiring Reach

Union Pacific is seeking a more diverse workforce as it strives to continue “building America,” as it says. To do so, it is partnering with The Manufacturing Institute, the NAM’s workforce development and education partner, on a $3 million three-year joint initiative. Beth Whited, who serves as executive vice president and chief human resource officer at Union Pacific, recently told us more about these ambitious plans.

The details: The initiative, called Careers on Track, will work to inspire more women and youth to pursue modern industry careers. The funding supports workforce development and career solutions that will include:

- A new digital STEM curriculum;

- A virtual STEM experience—in which participants can “choose their own adventure” while exploring interactive 3D models of a real facility, locomotive and more;

- A STEM micro-grant program for young people; and

- A digital campaign showcasing industry career opportunities for underserved women in select regions.

Ultimately, Union Pacific intends to double the number of women in the UP workforce within the next 10 years.

Why partnerships matter: “These types of partnerships are important for us because they broaden our reach,” says Whited. “We run pilot programs of our own, but it’s difficult for us to make those available in every school in our served territory. With the MI’s broad reach and established programs, we can reach more women and youth than we could on our own.”

The scope: Whited likes to remind people that nearly everything in their homes moves by rail at some point, whether as a raw material or as a finished product. That also means there is a wide range of jobs involved, from skilled roles in transportation and manufacturing to civil, electrical and computer engineering—jobs that involve designing more fuel-efficient locomotives or building the freight cars of the future.

The tech: “People who don’t know much about railroads are always surprised by the level of high tech that’s employed,” says Whited. “Railroads have been around for 160 years plus, and so people think about it as old technology, but it absolutely isn’t.

- “You’ve got unbelievable signaling systems run everything safely, next-level optimization tools that determine how and when trains run, sophisticated technology in the 4,500 horsepower locomotives that we use to haul freight and so much more. The level of tech and advanced analytics and machine technology is usually quite startling to people.”

The pitch: Whited has advice for women who are unsure about working in a traditionally male-dominated field. “I would tell people to challenge their own thinking,” says Whited. “There aren’t jobs that are for men and jobs that are for women; there are jobs—and these are great jobs with great benefits that will help you fulfill your goals and give you a sense of pride. Come try it.”

The last word: As MI Executive Director Carolyn Lee said about this partnership, “There are nearly 500,000 job openings right now in manufacturing and millions more expected over the next decade. Closing the gender gap and building awareness with young people are critical to meeting this incredible need.”

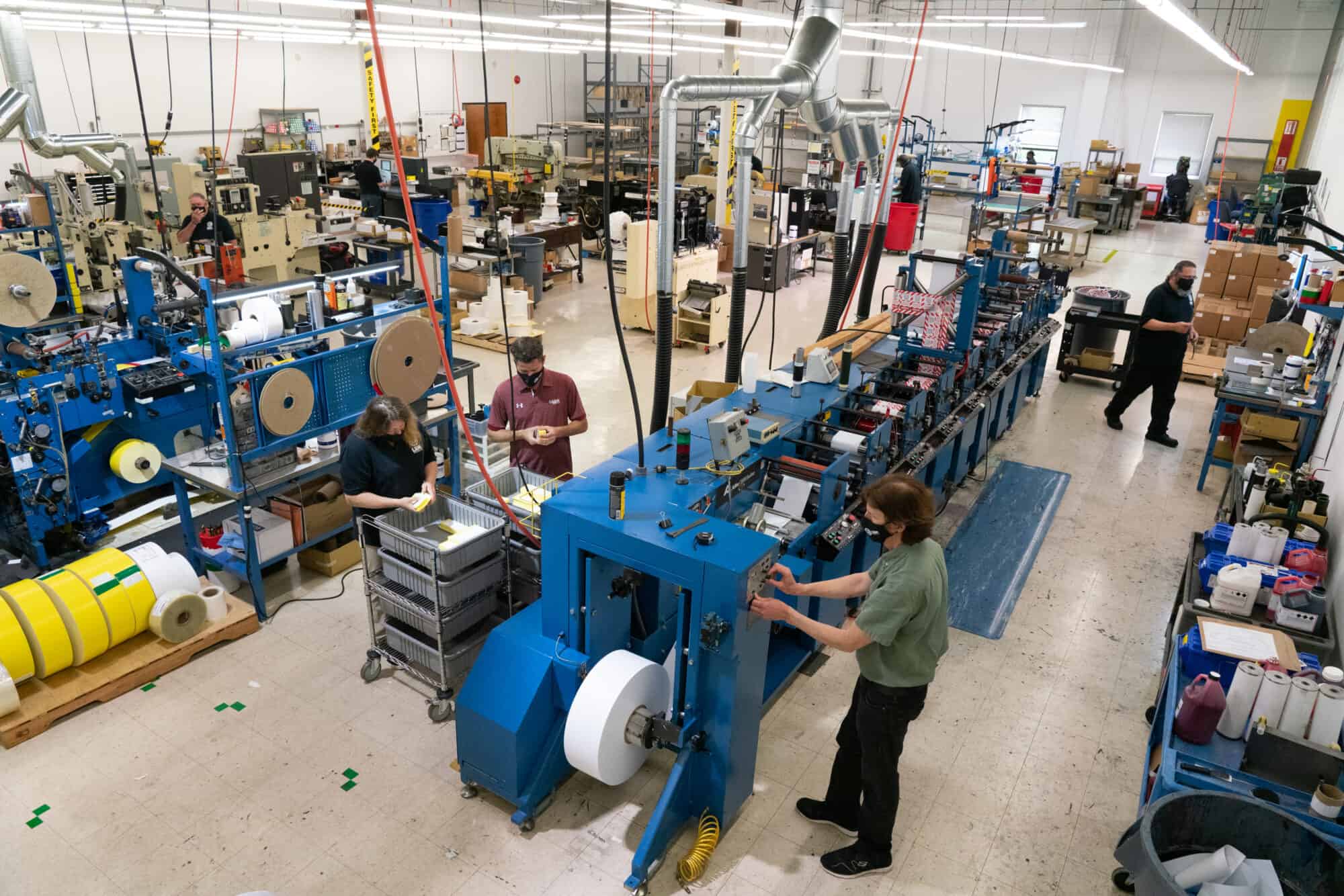

Creators Wanted Kicks Off Virtual Campaign

Creators Wanted, the pioneering workforce initiative from the NAM and MI, is adapting to the changing environment to continue its critical work to reduce the skills gap and end misperceptions about modern manufacturing.

What’s happening: We’ve gone virtual! The NAM and MI are still doing the Creators Wanted Tour, but they have exchanged in-person experiences for virtual ones (at least for now). The upside: these events will now be accessible to many more people.

What’s the plan: We’re kicking off our first virtual event on Tuesday, Feb. 2, at 10:00 a.m. EST. It will give you a sneak preview of what to expect during our Creators Wanted virtual events this year. (Click here for more information and to register.) After that, the NAM and MI will be making their way across the country, with virtual events aimed at different geographical areas.

What’s new and important:

- The NAM—with the MI’s support and leadership—has launched the Pledge for Action. It’s a commitment by manufacturers to take real, tangible steps to reflect the diversity of the U.S. workforce over the next decade. Taking the Pledge and supporting Creators Wanted are great ways for manufacturers to help close the opportunity gap.

- We’re collecting stories of creators around the country! Tell us about an amazing creator you know by visiting creatorswanted.org/shareyourstory.

Who’s it for: “Everyone! Well, we wouldn’t mind if everyone heard our message,” said NAM Vice President of Brand Strategy Chrys Kefalas. “But the NAM and MI specifically want to reach out to people who are ready to explore a career in manufacturing now. Maybe they’ve lost a job in the pandemic and are looking for a new career, or perhaps they’re already involved in manufacturing but want to gain the skills that will take them to the next level.”

- The NAM and MI also want to reach veterans and people who are underrepresented in manufacturing, including women, Black people and all communities of color.

- And, of course, the initiative intends to connect with young people, the next generation of creators.

Picking up where we left off: “The NAM and MI set big goals with Creators Wanted in 2020—to improve perceptions of manufacturing, reduce the skills gap and get more people into manufacturing career paths,” said Kefalas. “On Feb. 2, we will demonstrate that we can hit these goals with a new combination of virtual events, digital experiences and eventually in-person activations.”

But that’s not all… “The event will cover how we’re going to expand our impact, as well as exceed sponsor expectations. You won’t want to miss it.”

Final Manufacturing Survey of 2020 Finds Cautious Optimism to Close Out Turbulent Year

Washington, D.C. – The National Association of Manufacturers released its final Manufacturers’ Outlook Survey of the year, which showed optimism climbing from its low in the second quarter brought on by the COVID-19 pandemic. In the fourth quarter, 74.2% of manufacturers responding to the survey felt positive about their own company’s outlook, up from 66% last quarter. While encouraging, a wide gap remains between today’s numbers and the 90% average in 2019.

After two quarters with weaker domestic demand topping the list of primary business challenges, the inability to attract and retain talent lead the pack once again in the fourth quarter with 62.4% of respondents listing it as their primary current business challenge. Prior to COVID-19, workforce challenges had been the main concern for 10 consecutive quarters. According to the latest numbers from the Bureau of Labor Statistics, there were 525,000 job openings in manufacturing in October, a record high.

“There’s no question manufacturers have rebounded since the dramatic downturn in the spring, although a return to pre-pandemic optimism is still months away,” said NAM President and CEO Jay Timmons. “We were looking at levels of anxiety not seen since the Great Recession. The recent relief bill passed in Congress must be signed immediately. This, coupled with the manufacturing and distribution of vaccines, will help ensure we don’t go backward. But it’s clear that to keep moving forward in 2021, we’ll need to see more bold action that fosters growth and competitiveness for manufacturers in America and caution against any efforts that may undermine the fragile progress made in the closing months of 2020.

“It will surprise many to know that manufacturers have more than half a million jobs to fill right now. We’re hiring, and that’s why workforce challenges are once again the top concern in our survey. The pandemic delayed our Creators Wanted Tour, but we will be launching virtual tour events in 2021 and hitting the road when it’s safe. And we look forward to working with the new Congress and new administration to help more Americans take advantage of the great career opportunities in modern manufacturing.”

Read the full survey results here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.2 million men and women, contributes $2.35 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 62% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

A Hero Finds a Quality Career

Nicole Reyna’s professional journey—from college student to Army sergeant to senior quality assurance technologist at Smithfield Foods—wasn’t one she had planned. But thanks to The Manufacturing Institute’s Heroes MAKE America program, it’s one that has brought her where she wants to be. Initially, Reyna was interested in medicine and went to college to become a medical assistant. Shortly before graduation, however, she had an experience that changed her mind.

“I was two months from graduating that program, and I was working on removing stitches—and that’s when I realized I was not what you would call a ‘medically inclined person,’” Reyna said.

Instead, she spoke to recruiters at her local mall and ended up joining the U.S. Army, where she served for 12 years in logistics and quality assurance. When she left the military in 2019, she had only 90 days to find a job. And while she was enrolled in Department of Defense program that teaches veterans about resume building and job searching, she ran into a Heroes MAKE America program manager sitting outside the door, giving feedback on job candidates’ LinkedIn profiles and talking about a certified manufacturing program.

“It was a chance thing,” said Reyna. “But the Heroes program was fantastic. They walked through your resume; they help you write your resume; we’d do mock interviews. You go through The Manufacturing Institute’s certification process. And every week, we would go to manufacturing facilities and see what they look like—how robotics work, how generators are built, how food is manufactured. It was very comprehensive.”

The program managers were also highly engaged in ensuring Reyna found a role. When she was initially passed over for a position at a Smithfield distribution center, Reyna’s program manager called the company’s talent acquisition executive to make sure Reyna could receive an interview. After a conversation, Smithfield decided to find Reyna a role—and today, Reyna is one of three senior quality assurance technologists for one of Smithfield’s large distribution centers.

After her experience, Reyna has one piece of advice for people considering the Heroes program: Do it.

“The opportunities afforded to you are insane,” said Reyna. “When you don’t do these programs, you’re thrown to the wolves. At the Heroes program, you have resume assistance, you see facilities, you get to meet with people and speak with hiring managers. And if we put in a resume somewhere, we’d tell our program managers we applied and they’d call to follow up. It’s invaluable.”

Workers Without BAs Could Be Earning Much More

About 30 million American workers without four-year college degrees have the skills necessary for jobs that pay 70% more than their current roles, according to a new study cited by The New York Times (subscription).

The opportunity: “The findings point to the potential of upward mobility for millions of Americans, who might be able to climb from low-wage jobs to middle-income occupations or higher.”

- “Our research shows the same thing,” said Manufacturing Institute Vice President of Strategic Initiatives Gardner Carrick. “We know that less than half the people that earn a manufacturing certification go to work in manufacturing. Those people have the skills to work in manufacturing, but are not doing so. And we know that is costing them between $10K–$15K in earnings every year.”

The challenge: These workers may not know they have the skills for more lucrative careers, and potential employers may be on the lookout for particular certifications or degrees. Today, two-thirds of jobs require some postsecondary education or training—whether that involves a four-year college degree, or a specialized technical or nontechnical course that prepares a potential employee for their role.

A way forward: The Manufacturing Institute’s FAME program offers students the opportunity to earn a two-year associate degree while working in their sponsor’s manufacturing facility as an Advanced Manufacturing Technician (AMT).

The pitch: “The FAME program enables people to maximize their earnings, because we don’t just build skills—we teach individuals to be world-class manufacturing employees,” said Carrick. “A recent study by Opportunity America and the Brookings Institution showed that FAME students are more than twice as likely to complete school as students in other similar technical programs and will earn almost twice as much as those students in the five years after school.”

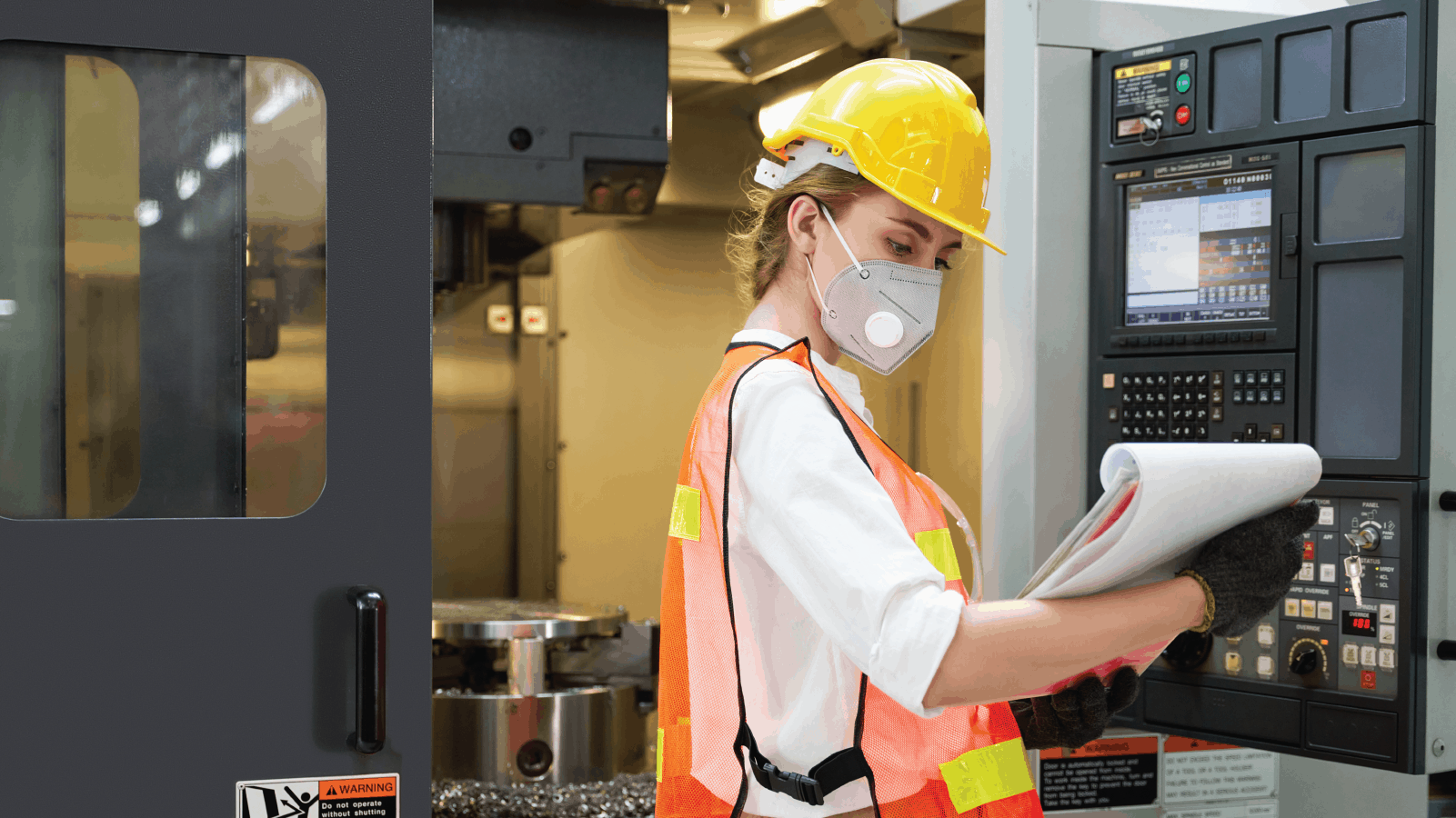

A Manufacturing Leader Shares What She’s Learned

As more women enter the manufacturing industry every day, they need guidance from those who have already succeeded. Luckily, BASF Corporation Senior Vice President of Chemical Intermediates North America Erika Peterman is happy and proud to show the way.

Peterman is the 2020 chair of The Manufacturing Institute’s STEP Ahead Awards, which recognize accomplished women in manufacturing from the shop floor to the C-suite. She also works with BASF to increase the number of female leaders within the company, recognizing that strong female leadership brings value to corporations, as a study from MSCI shows. BASF is also a proud sponsor of the STEP Ahead Awards and participates in many programs that encourage women and girls to enter this rewarding field.

So what does Peterman have to say to women who are just starting out? Here is her advice, courtesy of a recent email interview.

1. Don’t underestimate your abilities.

As a young engineer, I was once called in to solve a problem affecting distillation operations. After chatting with the control room technician, I asked her to run a little test, opening and closing various valves while also recording process flows and temperatures. It took only 20 minutes (enough time for a pleasant conversation about weekend plans), after which I shared the solution with my boss.

That 20-minute test had a big impact on my career. Later that afternoon, my boss told me that the team had struggled with this problem since before I took the job. Had I worried about how my solution measured up to previous ideas, I may never have solved it at all.

2. Be prepared to be tested, but stay calm and trust you belong.

Women have earned a seat at the table, but unfortunately, some people will challenge you anyway. Later in my career, when I worked in product management, my boss’s boss told me my salary was “much higher” than my counterparts’. I was thrown, but I knew my response would matter not only to me, but to other women who looked up to me as a role model.

I told myself to stay calm and responded that he should consider placing me in a higher-level role commensurate with my compensation. Of course, I’d done the market research and knew I wasn’t overpaid. I also knew this boss had a reputation for trying to catch people off guard—but this time, he was the one who didn’t know what to say! To this day, I’m proud of how I managed that conversation. I knew I had to defend myself, because if I didn’t, no one else would.

3. Learn to listen and become comfortable with not being the expert in the room.

I have so many examples for this that it’s hard to choose just one. Everyone has points in their career when they do not know all the answers, and that is okay. The key is to be confident in what you do know and comfortable going to others to ask for assistance.

Considering multiple perspectives and forging strong alliances within your organization are the keys to driving progress and innovation. Let go of your ego to allow for clarity of thought and action, and it will set you apart from others.

Check out the STEP Women’s Initiative and the STEP Ahead Awards here.

Merck CEO Ken Frazier Talks Diversity in Manufacturing

Merck Chairman and CEO Ken Frazier is one of the few African American CEOs of a Fortune 100 company and a passionate advocate of manufacturing’s diversity and inclusion efforts. Recently, Manufacturing Institute Executive Director Carolyn Lee asked him a few questions by email about Merck’s approach. The condensed interview is below.

What advice do you have for CEOs looking to improve their organizations’ diversity and culture of inclusion?

Well, first things first—you must understand your own environment. What does the data tell you about the diversity of your organization? Do your employees believe they can bring their most authentic selves to work each day? What are people telling you? You should be having courageous conversations with them.

Once you figure out what your employees think, you can work on changing that environment. You should also plan on integrating your solutions into all your internal and external policies.

From there, you need to monitor progress and make sure your leadership is modeling the changes for all employees. Those leaders must be held accountable for your D&I goals.

How have you implemented such an approach at Merck?

We work hard to make our culture as inclusive as possible, so that all our workers feel empowered to fulfill our mission of saving and improving lives. We’ve made sure that our talent processes take unconscious bias into account, from hiring to reviews to succession planning. We’ve also created employee business resource groups, which not only support people at work, but have a meaningful say in our business practices.

Meanwhile, we weave D&I efforts into our day-to-day business activities. We work to get diverse patients into clinical trials, ensure our business strategies are relevant to patients all around the world and prioritize diversity among our suppliers.

Diverse employees are also a major asset for a company serving a diverse patient base around the globe. We need employees to bring their knowledge and experience to work so they can teach us how to serve our patients better.

And lastly, I strongly believe that we must learn from and be a role model to others, both in manufacturing and beyond. We have joined coalitions and organizations such as The CEO Pledge for Diversity and Inclusion, Paradigm for Parity and The Valuable 500, all of which do excellent work in the D&I sphere.

How can D&I efforts complement the industry’s work to close the “skills gap”?

We know there were around 12 million unfilled jobs in this country before the pandemic, and there are 5 million inner-city and other African American kids who want access to the economy. They want to be participants. They want to be citizens. They want to be leaders. What they lack is the education and the opportunity—and we business leaders can fix that.

Following the industry’s June “Pledge for Action,” the National Association of Manufacturers brought industry leaders together to focus on recommending bold next steps to increase equity and parity in our sector and increase opportunities for underrepresented communities in America. Click here to add your company to manufacturers’ combined efforts to make a difference—and make a Pledge for Action Commitment.

And register here for the Manufacturing Institute’s Virtual D&I Summit on December 7 and 8, where you’ll learn more about advancing diversity and inclusion in the manufacturing workforce.

“The Superhero Generation”: Microsoft and York Exponential Collaborate on Upskilling

Residents of York, Pennsylvania, will proudly tell you about the role it played in the “Arsenal of Democracy” during World War II. Today, the town is drawing on that manufacturing heritage as it adapts to the digital age. And among the leaders of the transformation is the collaborative robotics startup York Exponential, which has partnered with Microsoft’s new skills initiative to help York residents get the education they need for high-tech manufacturing jobs.

The initiative: Microsoft’s global skills initiative is designed to help 25 million people worldwide gain digital skills by the end of the year. It is intended to offer rising and mid-career professionals the skills they need to succeed in a changing economy—both during and after COVID-19. The program also includes partnerships with local companies like York Exponential that seek to upskill workers.

“If there’s maximum digital transformation in the U.S. post-COVID, we believe there is capacity in the United States for the manufacturing sector to absorb more than a million new roles in technology,” said Microsoft Philanthropies General Manager of Digital Inclusion Naria Santa Lucia.

How it works: Microsoft uses LinkedIn data to identify jobs that are in demand, projected to grow in the future and accessible to applicants without a related degree. It offers free learning content to help people develop the skills those jobs require, including soft skills like virtual collaboration. The initiative also offers certifications and job-seeking tools to connect people with applicable jobs.

In practice: York Exponential is looking to add well-rounded employees—new workers proficient in digital skills as well as experienced workers who can gain new qualifications, said CEO John McElligott. The company is combining its own community outreach—including through its training school, the Fortress Academy—with Microsoft’s tools to help students and employees gain the qualifications they need to be successful.

Why partnerships matter: Partnerships like this one offer exponential benefits by joining large-scale training efforts and resources with local talent.

- From Microsoft: “The most important consideration is locally-based entities that are trusted by the community,” said Santa Lucia. “If we’re going to change this economy and who has access to it, it’s about the networks you’re introduced to and who is going to connect you where you need to go. The content is important, but it’s really about that personal connectivity. That’s how we get to jobs.”

- From York Exponential: “Communities like us are often overlooked,” said McElligott. “People go to major metropolitan areas and big cities. So the fact that we’re having these discussions with Microsoft means a lot—an initiative of this size could have an outsized impact on a community as small as us.”

The last word: “This generation growing up today is the superhero generation,” said McElligott. “They grew up watching the Avengers, in a world where everything is robotics and superpowers. They are primed to do amazing things with technology—and to build things for their families, their communities and their country.”

October is Manufacturing Month and a perfect time to check out the exciting careers and training opportunities available from companies like Microsoft and York Exponential. There are still many events left, including an October 28 capstone event presented by Microsoft and called “Creators Wanted: Empowering a Diverse and Sustainable Manufacturing Workforce.” You can find the list of events at creatorswanted.org.

FAME Is All It’s Cracked Up to Be

Would you believe that one apprenticeship program could add $45,000 to its graduates’ salaries? It sounds incredible, but that figure is from a new study by Opportunity America and the Brookings Institution. And the program in question is Kentucky FAME, part of the wider FAME program that was originally founded by Toyota before its stewardship was transitioned to The Manufacturing Institute. FAME is now operating in 14 states.

As regular Input readers know, FAME students earn a two-year associate degree while working in their sponsor’s manufacturing facility as an Advanced Manufacturing Technician (AMT). This new study shows how much the students—and by extension their employers—get out of the deal.

Here are some highlights:

- The need for apprenticeships: “Today, two-thirds of jobs require some postsecondary education or training—not necessarily a four-year college degree, but some more specialized technical or nontechnical preparation for the world of work.”

- FAME’s effectiveness: “FAME participants were significantly more likely than non-FAME participants to complete their program of study—roughly 80 percent of FAME students graduated, compared with 29 percent of non-FAME students.”

- The results: “Five years after completion, FAME graduates were earning nearly $98,000, compared to roughly $52,783 for non-FAME participants—a difference of more than $45,000 a year.”

- The seal of approval: “Graduates’ reviews of the FAME experience were overwhelmingly positive. A total of 97 percent said they felt that enrolling in FAME was the right decision for them, and all but 3 percent said they would recommend it to a close friend or relative.”

The MI says: MI Vice President of Strategic Initiatives Gardner Carrick said of the study, “The results are amazing and confirm that FAME is a global-best program. We hope manufacturers will join us in expanding FAME to their community and offering people across the country the chance to see similar success.”

Publicity alert: Check out a story about the report in The Wall Street Journal (subscription). Meanwhile, Opportunity America hosted a webinar about the study yesterday, featuring Carrick among other speakers.

. . . and more: The MI and FAME are hosting a “FAME Live!” virtual event tomorrow, Oct. 21. Manufacturers with open skilled maintenance positions are invited to tune in here.