Creators Wanted Gets an Endorsement

The NAM and The Manufacturing Institute’s Creators Wanted campaign got a resounding endorsement from The Dallas Morning News, which called the initiative “a smart approach that may be a harbinger of things to come” in a recent editorial (subscription).

Traveling attraction: “‘Creators Wanted’ . . . will visit schools and community gathering places around the country in coming months to attract future workers to that industry. Creators Wanted features a tractor-trailer-mounted escape room and ‘immersive experience’ designed to hold kids’ attention while also overcoming stereotypes that keep students from choosing careers in manufacturing.”

Filling a void: As the editorial notes, Creators Wanted “aims to reduce the skills gap in the U.S. by 600,000 workers by 2025, and increase the number of students enrolling in technical/vocational schools or reselling programs by 25%.”

- While the article focused on the activities of the campaign, the sustained initiatives of The Manufacturing Institute are also important to reaching these goals.

Sign of changing times: The NAM’s and MI’s focus on students is “smart,” says the editorial, in light of changing perceptions among youth about higher education. The pandemic and soaring tuition are causing young people to consider options besides college.

The last word: “Creators Wanted is a clever approach that teens will enjoy. We encourage parents and guidance counselors to consider it. But the larger point here is about the pipeline of workers needed to ensure our economy can continue to grow. NAM has taken the initiative to improve that pipeline, putting them ahead of the competition for now. We hope to see others join that race soon.”

Join in: Interested in supporting Creators Wanted? Contact Creators Wanted Finance Director Barret Kedzior at [email protected].

How Manufacturers Can Retain Employees

With manufacturers facing a skills gap that could result in 2.1 million unfilled jobs by 2030, retaining qualified and effective employees is critical. But how do manufacturing leaders keep great employees on staff? The Manufacturing Institute’s Center for Manufacturing Research and the American Psychological Association have some answers, collected in their recently published Manufacturing Engagement and Retention Study.

Why people stay: According to the study, the main reasons that employees remain at a company are enjoyment of the work (83%) and stability/job security (79%). Other contributors to satisfaction include the family friendliness of the employer and the way the job fits into their lifestyles outside of work.

- The next generation, however, has slightly different motives: “Although fewer survey respondents overall (42%) identified training and career opportunities as reasons for staying, around two-thirds of those under age 25 said these were motivating factors in their decision to remain with their current employer (69% and 65%, respectively).”

Feeling good: Employees who felt valued by their companies had significant more motivation and job satisfaction.

- Nearly all workers who said they felt valued by their employers (97%) described themselves as highly motivated and satisfied with their jobs. Nearly as many (96%) would recommend their company to others as a good place to work.

- Meanwhile, among employees who did not feel valued by their employers, those numbers dropped to 45% and 25%, respectively.

Fair treatment: Workers who felt that their employers treated them fairly were also less likely to be stressed out on a typical workday (at only 16%). But among workers who said they were treated unfairly, 68% felt stressed on a regular basis.

- Those who felt that they were treated fairly were also much less likely to say they intended to look for a new job within the next year—at just 2% versus 19% among those who felt they were treated unfairly.

Pandemic effects: The MI and APA conducted this study during the COVID-19 pandemic, which notably did not affect employees’ responses to a great degree. In fact, many felt more positive about their employers.

- A majority of employees (58%) said the pandemic and their company’s response to it had not changed their view, and more than one-third (37%) had a more positive view of the company, compared to just 5% who viewed their employer more negatively.

Find out more: Learn more about what motivates people to stay by reading the full study here.

A Second Chance in Manufacturing Pays Dividends

One of manufacturers’ top concerns is the insufficient number of skilled workers available to fill their open jobs. Yet right before us is an often-overlooked pool of millions of potentially strong employees: people with criminal records.

That’s why The Manufacturing Institute has partnered with Stand Together and the Charles Koch Institute to promote “second chance” hiring—to get these workers who need jobs into jobs that need them. Recently, the MI hosted its first webinar on the importance of this initiative and what manufacturers should know about it.

The data: One in three Americans has a criminal record, and yet this entire population is frequently discounted outright during employer job searches due to societal stigma and general misperceptions. During the webinar, the panelists shared some additional data:

- Of the approximately 19 million Americans with felony convictions on their records, some 1 million are incarcerated and some have aged out of the workforce, said Jeff Korzenik, author of “Untapped Talent: How Second Chance Hiring Works for Your Business and the Community” and chief investment strategist for Fifth Third Bank. “But millions are of working age, [and] virtually all of them are unable to participate to the fullest extent of their possibility, of their talents, because of barriers.”

Talent shortage: 814,000 manufacturing jobs were unfilled as of May, according to the Bureau of Labor Statistics.

- “Manufacturers continue to tell us that attracting and retaining workers remains one of their top challenges,” said MI Executive Director Carolyn Lee during the webinar.

- 2.1 million manufacturing jobs could go unfilled by the end of the decade if current trends continue, according to a recent MI and Deloitte study, and that “could mean the loss of up to $1 trillion in lost economic impact for the U.S.”

Worth the work: Employers who identify and support a strong candidate with a criminal record “get an employee who is on average more engaged and more loyal” than other workers, said Korzenik, who called this method of hiring the “second chance model.” This can lead to higher retention rates, saving an organization on turnover costs, he added.

- The model, which Korzenik developed, both identifies characteristics likely to lead to successful employment (strong character, soft and hard skills) and provides support processes (such as help with transportation to and from work) to help bridge gaps.

Living proof: Webinar panelist Cory Webb is a recent graduate of the Cuyahoga County, Ohio–based ACCESS to Manufacturing Careers, a program that trains both young people and people with criminal records for careers in manufacturing. He considers himself a testament to ACCESS’ success.

- “I started this program because I thought it would be a great opportunity for me to gain a career in manufacturing and machine operating,” said Webb, now an auxiliary operator for program participant Jergens Inc. The initiative “did a pretty good job as far as getting me prepared … for machine operating,” he said.

Learn more: The MI has released a host of resources for manufacturers interested in second chance hiring. You can find them here.

MI Announces 2021 STEP Honorees

The Manufacturing Institute has announced its newest cohort of extraordinary female leaders in manufacturing: the 130 Honorees of the 2021 STEP Ahead Awards. On Nov. 4, the MI will recognize their achievements at an in-person gala in Washington, D.C.

An industry-wide honor: These yearly awards, part of the MI’s STEP Women’s Initiative, recognize women in manufacturing who exemplify excellence from the factory floor to the C-suite.

- To date, the awards have honored 932 exceptional women, and the winners have made an impact—through mentoring, programs and events and more—on 300,000 people, from industry peers to kids in school.

The whole initiative: The STEP (science, technology, engineering and production) Women’s Initiative consists of the STEP Ahead Awards, a professional leadership-development program and regional STEP Forward events that take place throughout the year. It aims to boost women’s representation in manufacturing and support the next generation of female talent.

Why it matters: Women make up close to half the U.S. labor force, yet they account for less than one-third of the manufacturing workforce. Meanwhile, the biggest challenge for manufacturers has long been the lack of skilled workers available to fill open jobs. By employing 10% more women, manufacturers can bridge the skills gap by 50%.

What they’re saying: “Women in manufacturing proved themselves time and time again during the pandemic, driving innovation and progress, and they are now helping our industry build the next, post-pandemic world,” said MI Executive Director Carolyn Lee.

- “As an industry, we are always working to do more to bring more women into manufacturing and encourage their innovative ideas and transformative leadership,” added 2021 STEP Ahead Chair and Johnson & Johnson Executive Vice President and Chief Global Supply Chain Officer Kathy Wengel.

- “The creativity, commitment and passion displayed by each of these women leaders and rising stars drive innovation in our industry forward,” said 2021 STEP Ahead Vice Chair and 3M Senior Vice President and Chief Corporate Affairs Officer Denise Rutherford.

. . . and don’t forget, creators are wanted: The NAM and MI’s Creators Wanted project, which aims to close the skills gap and get many more people into manufacturing, will help fund the MI’s workforce-development efforts, including STEP. A full half of the funds raised (which will total millions of dollars) will go toward supporting the MI’s programs into 2025.

Interested in becoming a STEP Ahead sponsor? See opportunities here.

A FAME Graduate Finds a Fresh Start

When Kristy Willis moved to Louisiana, she wasn’t sure what she wanted to do next. Her 15-year marriage had ended in divorce, and she needed to find a way to support herself and her four children. She began by searching for a college where she could gain additional education and skills—and when she came across The Manufacturing Institute’s FAME program, she knew she had found the right place. In August 2019, she began her fresh start with GeauxFAME.

What it is: The Federation for Advanced Manufacturing Education (FAME), which was founded by Toyota and is now operated by The Manufacturing Institute, is a career pathway program for current and aspiring manufacturing workers. It provides them with on-the-job training and classroom education, leading to an associate degree and an Advanced Manufacturing Technician (AMT) certificate.

A critical role: Willis viewed manufacturing as a vital part of the American economy, and was excited about the opportunity to feel connected to it.

- “When I came into this program, I didn’t know anything about the manufacturing business—but I wanted to be a part of it,” said Willis. “I saw manufacturing as adding strength to the economy in the United States. Wherever you go, manufacturing is needed, and I wanted to be a part of that industry.”

Personal and professional growth: Willis was wary about returning to school after 10 years, but she was motivated by the need to provide for her children. Ultimately, spending time in the FAME program has changed the way Willis sees herself and her opportunities.

- “The experience has been humbling,” said Willis. “But it has helped build my confidence in myself and given me something to look forward to.”

Of course, Willis had to contend with a particularly challenging year as COVID-19 made traditional learning environments impossible. Still, she found the program and her experience rewarding.

- “The past year has been crazy,” said Willis. “Being a mom of four kids, when they got sent home from school, and I got sent home from school, and everyone was trying to study at the same time—our house was wild. But we grew as a family during all of this, through all these trials.”

Next up: Willis will graduate in July, and her sponsoring employer, Boise Cascade—an Idaho-based wood product manufacturer with a facility in Lena, Louisiana—has already offered her a full-time job and the opportunity to continue her education and pursue her bachelor’s degree. She’s excited about the road ahead.

Good advice: Willis also encourages people who are looking for a new career to give the FAME program a try—even if they have never considered a career in manufacturing before.

- “This program is perfect for that mindset,” said Willis. “If you want to try it out and see how it works, it gives you that opportunity. You get a big picture of the manufacturing process, as well as insights behind standard operating procedures—why these safety practices are performed, or why those machines are serviced the way they are—and then it’s up to you to continue on through the program.”

The last word: “If you’re questioning what to do with your life, stay strong and have courage,” said Willis. “You are strong and smart enough—you take those trials that have brought you down in this life, and use them to make yourself stronger.”

MI and NAM Honor Manufacturing Leader

Emily Stover DeRocco Put Public Focus on Manufacturing’s Critical Workforce Issues

Washington, D.C. – The Manufacturing Institute and the National Association of Manufacturers released a statement on the passing of Emily Stover DeRocco, former President of The Manufacturing Institute:

“Our industry has lost a true leader on workforce development,” said Manufacturing Institute Executive Director Carolyn Lee. “Under her leadership, the Institute developed a national portal of industry-recognized Manufacturing Skills Certifications that have influenced today’s secondary and post-secondary education efforts in 36 states. Emily’s efforts helped put a spotlight on the changing workforce needs in manufacturing and the policies needed to meet these greatest challenges. As we remember and honor her many contributions, our thoughts and prayers are with the DeRocco family.”

“Emily was a true champion to our nation’s workforce and was passionate about manufacturing,” said NAM President and CEO and Chair of the MI Board of Directors Jay Timmons. “She served former President George W. Bush and U.S. Secretary of Labor Elaine Chao as well as many other political leaders on workforce development initiatives where her voice and leadership helped usher in a renewed focus in this country on matching education programs with the skills needed to build the modern manufacturing workforce. Although Emily will be sorely missed, there is much to celebrate in the life she lived and the example she set. She is an inspiration to us and to the Manufacturing Institute and manufacturing community which she was proud to serve.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.3 million men and women, contributes $2.35 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org

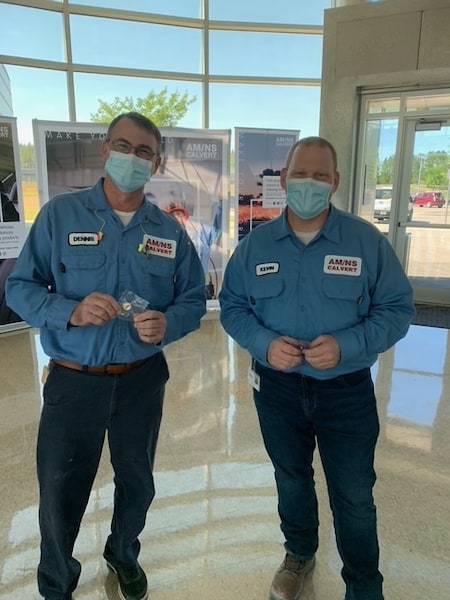

A Tour of Manufacturers’ Vaccine Clinics

What does it look like when manufacturers get vaccinated? For some people across the country, it was just another day at work.

Hundreds of manufacturers nationwide have hosted vaccination events for their own employees, sometimes including family and community members as well. NAM Director of Photography David Bohrer stopped by a few of these events to capture them, while other companies sent the NAM their own pictures. Here are some of those photos—a visual tour of manufacturers’ efforts to keep America safe and healthy.

Calvert, Alabama: Steel and mining company ArcelorMittal held an on-site vaccine clinic at its plant for team members and the local community. If you look closely, you’ll see that one of these employees is holding a pin from the NAM and The Manufacturing Institute’s Yellow and Red Ribbon initiative—a symbol of vaccination that you can wear to show you’ve done your part.

Fremont, California: Below, an employee of ALOM Technologies Corporation, which creates supply chain technology and solutions, gets his shot at the company’s facility. In the background, you can see a poster for This Is Our Shot, the NAM and MI’s effort to help manufacturers across the country get vaccinated.

Perryville, Missouri: More than 150 Gilster-Mary Lee Corporation employees were vaccinated at an on-site clinic set up at the company’s request by the local Perry County Health Department.

In our interview with Gilster-Mary Lee President and CEO Tom Welge back in April, he told us how the tragic death of his father (and former Gilster-Mary Lee CEO) Don Welge from COVID-19 reinforced the company’s commitment to vaccinations. Read more about the company’s efforts here.

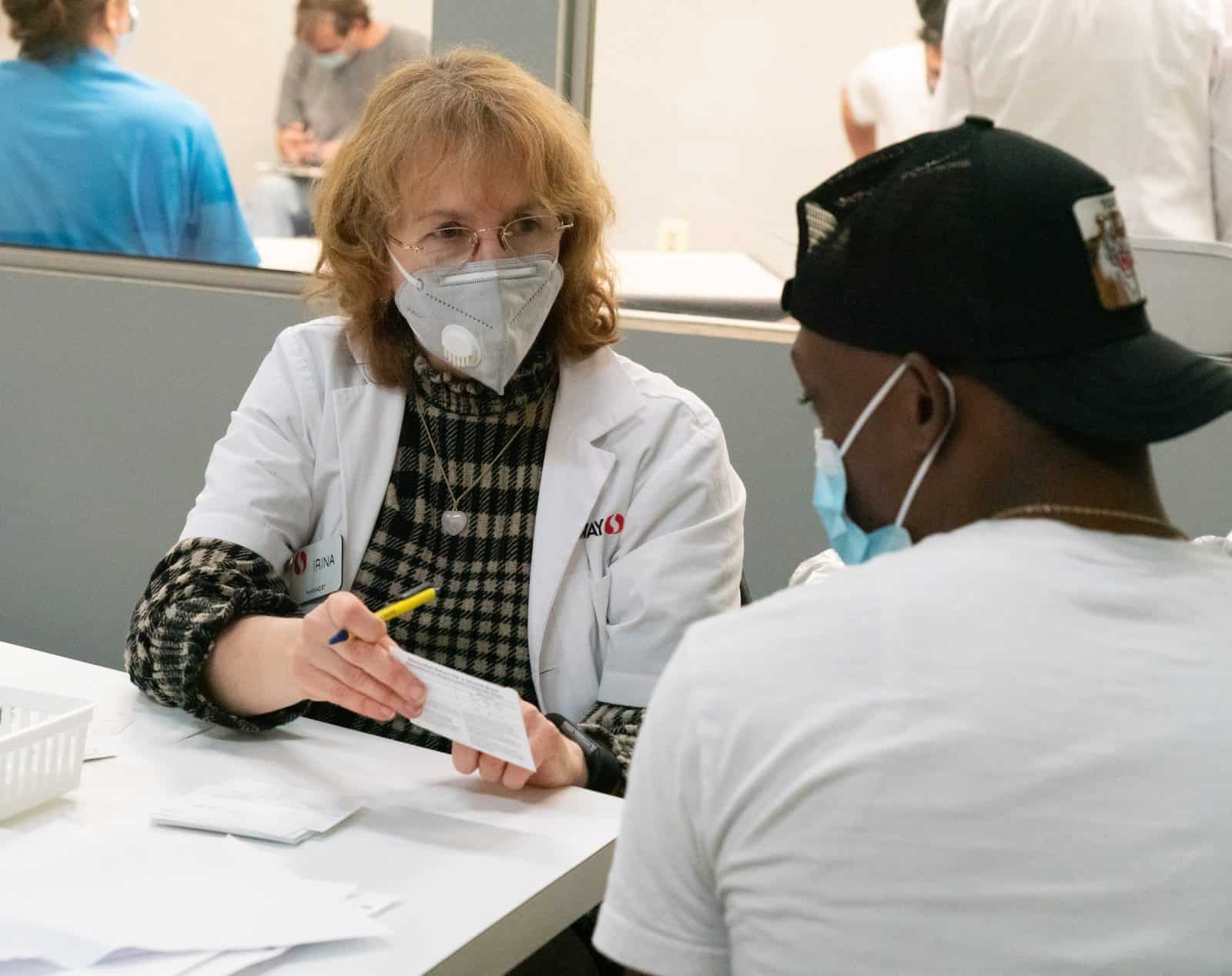

Baltimore, Maryland: Marlin Steel Wire Products led a coalition of 81 manufacturing companies in an effort to get vaccine doses for their workers. In the end, the coalition organized 17 events for more than 3,300 employees.

Here’s a photo from a March event for workers from Marlin Steel, Orlando Products and Arnold Packaging. It was hosted at Orlando’s facility, where a team from Safeway administered the shots.

We spoke to Marlin President and Owner Drew Greenblatt back in April about how he organized this effort. Check out the interview here.

Lafayette, Indiana: At Subaru of Indiana, more than 2,900 vaccinations were delivered across eight clinics held in the facility’s lobby. The clinic was open to all on-site personnel, including vendor and contractor representatives, along with associates’ spouses and eligible kids. Recently, the company transitioned to hosting a weekly vaccine clinic at its on-site Health and Wellness Center.

Join in: If you’re a manufacturer looking to encourage vaccinations among your employees or even host an event yourself, check out the many resources available through the NAM and the MI’s This Is Our Shot project. The most recent addition is an “on-site vaccination clinic toolkit” provided by the Department of Health and Human Services. And don’t forget to wear your yellow and red ribbon pin!

Manufacturing Leaders Get a Sneak Peek at Creators Wanted

The NAM and The Manufacturing Institute unveiled their Creators Wanted experience last week in Dallas, previewing it for the NAM’s Executive Committee as well as local business leaders, workforce development officials and the media. Visitors got an exclusive look at this “mobile manufacturing experience” that will soon embark on a tour around the country, showing Americans what modern manufacturing is all about.

As NAM President and CEO Jay Timmons said, “Creators Wanted will help a new generation of emerging and displaced workers see themselves in a modern manufacturing career, while also adding to the industry’s talent pipeline by engaging veterans, women and communities of color, all critical to expanding the workforce of tomorrow.”

What they saw: Below, ExxonMobil Senior Vice President Neil Chapman, Celanese Corporation Chairman, CEO and President Lori Ryerkerk, Toyota Executive Vice President of Product Support and Chief Quality Officer Chris Nielsen and Trane Technologies Chairman and CEO (and NAM Board chair and co-chair of the Creators Wanted campaign) Mike Lamach get a first look at this interactive, hands-on experience.

An online choose-your-own-adventure version of the mobile experience will be rolling out this summer to reach students, parental figures, teachers and emerging workers nationwide. Here, MI Executive Director Carolyn Lee previews the “Keys to Success” room, where participants will race to solve riddles that will help reinforce key attributes of manufacturing careers, such as teamwork, problem solving, imagination and communication.

Lee also gave a presentation on Creators Wanted to the visitors. As she said in a statement, “By 2030, manufacturers need to fill more than 4 million jobs—according to research from the MI and Deloitte—but without initiatives like Creators Wanted, more than half of those jobs could go unfilled. This mobile experience will excite audiences across the country, sparking an interest in modern manufacturing so that we can connect emerging and displaced workers with resources that educate and empower.”

The tour allows you to experience the creativity of manufacturing firsthand and up close. In the gamified experience, participants will work as a team to solve a series of immersive challenges, requiring their full attention to think and compete. As they move through each obstacle, teams will learn more about modern manufacturing careers, the skills required to be successful and how people and technology work together.

We can’t reveal all the surprises, but doesn’t he look excited?

In fact, all of the NAM’s Executive Committee members who toured the exhibition were impressed and amazed by what they saw. Here are some of their reactions:

- “I will admit, I didn’t quite appreciate the opportunity for our industry until I saw the experience in person,” said Chapman. “Seeing is believing in the capacity of this tool to excite the next generation, parents, guardians and teachers about modern manufacturing careers.”

- “It’s clear that Creators Wanted has exactly the message and tools to strengthen our industry’s recruitment for talent. At a time when so many young people seek careers where creativity is valued and prized, we have a chance with this campaign to really drive the best and brightest into our talent pipeline,” said Nielsen.

- “The mobile experience is astounding; it’s unlike anything we’ve done as an industry to reach the next generation and engage emerging and displaced workers. But what makes this campaign worthwhile is that the mobile experience is just one part of a comprehensive plan to create interest and then create opportunity by providing resources to help people launch or grow a career in manufacturing,” said Lamach.

Join in: Last but not least, you too can find out what all the excitement is about. Check out https://creatorswanted.org/ for information about the campaign.

An Army Vet Finds Military Values in Manufacturing

Hugo Hinojosa loved being in the military. He served 22 years in the U.S. Army, with time in eight different duty stations. His service gave him the opportunity to get a degree, travel the world, see different places and forge close-knit friendships that he says will last a lifetime. When it came time for him to transition out of the military, he was open to ideas—and during a career skills program briefing at Fort Hood’s Copeland Center, a presentation from Heroes MAKE America captured his attention.

Endless opportunities: After a career spent moving around the globe, Hinojosa was hoping to stay in his home state of Texas for the long term. During the presentation from a representative of Heroes MAKE America, he was struck by the breadth of roles the manufacturing industry offered.

- “When they came out and told me about opportunities and other jobs in the surrounding area, I said, wow, this might be for me,” said Hinojosa. “With the certifications the program offered, you could work anywhere in the industry. I wasn’t limiting myself to a certain, specific job. I could work anywhere, you name it. The opportunities are endless.”

A unique experience: Hinojosa began his time in the program in the midst of the COVID-19 pandemic, which meant that some elements had to be adjusted to fit the logistical reality. But participants still received plenty of engagement: classroom lessons were shifted to a virtual format, and students met with program managers two at a time for a few hours every week. While it required a fair amount of self-direction and motivation, Hinojosa said that the program supported him as he learned at his own pace.

A powerful network: Hinojosa found the networking aspect of the program to be especially valuable once he began looking for work.

- “Every time we would have potential employers in team meetings, I would search them on LinkedIn and connect with them,” said Hinojosa. “I said, I saw you today during class, I’d like to connect. I started building my own network from there.”

The right stuff: The work paid off. Hinojosa received several offers and ended up getting hired by WestRock Company through meetings that were set up by Heroes MAKE America. He began as a member of the company’s management trainee program and was quickly recruited to work as a business partner in the human resources department. He sees his new career as a natural extension of his time as a service member.

- “Everywhere I go, I’m a steward of the Army,” said Hinojosa. “I’m working in a place where the values are in line with what I was brought up with in the military—integrity, respect, accountability and excellence.”

Today, Hinojosa encourages other transitioning service members to see themselves in a manufacturing career—and most importantly, to recognize their own skills.

The last word: “Don’t sell yourself short,” said Hinojosa. “Believe in the skills the military has given you. You’ve been trained and given skills that will pay dividends out here in the manufacturing industry. And the work ethic that’s instilled from day one is going to show.”

Second Chance Hiring Strengthens Manufacturing

Helping people with criminal records find good jobs is not just the right thing to do, but a way to strengthen the manufacturing industry for years to come. That’s why The Manufacturing Institute—the workforce development and education partner of the NAM—is partnering with Stand Together and the Charles Koch Institute to help manufacturers recruit from this population and fill some of the thousands of job openings within the industry.

Brianna Nuhfer, director of criminal justice for the Stand Together philanthropic community, spoke to us recently about the importance of second chance hiring and the opportunities it offers for manufacturers.

Why it matters: A criminal record is often a significant barrier to employment, preventing people from finding new jobs and building better lives. Not all people with criminal records have been incarcerated, but for those who have been, second chance hiring also significantly increases the success of reentry.

- “The vast majority of incarcerated individuals—over 95% of people who are incarcerated—will be returning to our communities and our neighborhoods,” Nuhfer says. “We want to make sure that their return is as successful as possible, and we know that employment is one of the primary factors that helps people get back on track and avoid recidivism or returning to prison.”

Why it matters for manufacturers: Hiring Americans with criminal records is also important for the success of the manufacturing industry. Right now, manufacturers are facing a significant shortage of skilled workers; in fact, a recent study by Deloitte and the MI suggests that the skills gap could result in 2.1 million unfilled jobs by 2030. Manufacturers need workforce-ready employees, and many people with criminal records fit the bill.

Building a smart workforce: According to Nuhfer, research shows that workers with criminal records often have the lowest turnover rates of all employees. She cites several other key advantages:

- 82% of managers report that the value these workers bring to companies is just as high as—if not higher than—the value that their employees without criminal records provide.

- Many formerly incarcerated people received manufacturing-related training while they were in correctional facilities, preparing them for work in the modern industry.

Building partnerships: The partnership with the MI will increase awareness of second chance hiring opportunities and help manufacturers recruit, train and support these workers.

- “The NAM and The Manufacturing Institute have such an incredible reach across the country, and their leadership is undeniable,” said Nuhfer. “The resources you put out for the field are utilized and noticed—and so your involvement and your commitment to this issue is going to have an incredible ripple effect across the country, opening up thousands of employment opportunities for deserving individuals.”

Creating a culture: For company leaders interested in second chance hiring, Nuhfer has some simple advice: these hiring practices shouldn’t just be a matter of policy, but also a matter of culture. Leaders should demonstrate by example that their companies value smart, talented workers of all backgrounds.

The MI says: “Second chance hiring gives businesses an opportunity to welcome highly motivated, engaged, productive and loyal new team members who may otherwise be overlooked,” said MI Executive Director Carolyn Lee. “This is not only the right thing to do for our businesses, but it’s also the right thing to strengthen our communities.”

The last word: “All of us are more than our choices, good or bad,” said Nuhfer. “None of us wants to be defined by the worst decision we’ve ever made for the rest of our lives.”

To learn more about second chance hiring, register here for an upcoming webinar on June 10.