Manufacturers Talk Talent Development at the MI’s Workforce Summit

In an ever-changing world, collaboration is more necessary than ever for solving the challenges facing our manufacturing workforce. Last week, in Charlotte, North Carolina, the Manufacturing Institute’s annual Workforce Summit united more than 300 industry leaders to do just that, tackling workforce challenges while redefining what manufacturing represents for tomorrow.

The backdrop: MI Chief Program Officer Gardner Carrick opened the summit by highlighting a shift in public perception. Americans view manufacturing more positively now, and attitudes toward education and career pathways are evolving. As confidence in the value of a traditional four-year degree declines, new opportunities are emerging for skills-based careers in modern manufacturing.

- But, Carrick noted, the industry must stay on the offensive. “The next generation of workers doesn’t need convincing that technology is exciting; they live it,” he said.

- “The story isn’t that we’ve changed; it’s that we’re leading,” Carrick concluded. “And that’s what will inspire the next generation.”

Quick insight: Participants at the summit, who came from dozens of manufacturing sectors and many nonprofit and partner organizations, discussed practical, transformative solutions in every session. Here are some of the big takeaways:

- Rethink education: ABB’s Jason Green emphasized the need to get technology into the hands of students early and to reimagine career and technical education, including real-world learning and applications. Apprenticeships built on company needs can help create talent pipelines that are both practical and custom-fit.

- Invest in culture: Lisa Winton of Winton Machine explained why she views culture as a competitive advantage, especially for small manufacturers. Her team leverages local training resources and encourages multigenerational learning, where mentorship flows both ways.

- Design for flexibility: Amatrol’s Paul Perkins urged companies to mold jobs around people, not the other way around. By creating fluid career paths and removing unnecessary barriers, manufacturers can use mobility itself as an attraction strategy.

- Focus on skills: Walmart.org’s Sean Murphy and the MI’s Sytease Geib highlighted skills-based strategies that strengthen pipelines, accelerate and validate learning, enhance retention and unlock meaningful career growth.

- Empowering the frontline: Jerry Dolinsky, CEO of Dozuki, and Dr. Rebecca Powers Teeters of 3M highlighted how AI-driven digital tools can help frontline workers. Connected workers can bridge skills gaps, boost engagement and drive productivity, while practical AI applications create smarter workflows, enhance safety and foster continuous learning and innovation.

Parting words: “The momentum, the environment, the atmosphere surrounding what we do will continue to evolve, and we know that we can solve our problems if the industry is tackling them together,” said MI President and Executive Director Carolyn Lee. “The MI will continue to be here to support you.”

Couldn’t make it this time? The MI, the NAM’s 501(c)3 workforce development and education affiliate, works year-round to help companies strengthen their workforce and deliver innovative solutions to workforce challenges. Here are some ways to get involved:

- Sign up for updates to the MI’s Solutions Center for resources, best practices and opportunities to learn from peers through the Solutions Series. Explore our regularly scheduled virtual convenings as part of the Solutions Series to see how manufacturers across the country are addressing workforce challenges.

- Get updates directly from the MI on the latest workforce insights and be among the first to receive information about upcoming events and to register for next year’s Workforce Summit, taking place in Indianapolis, Indiana.

- Want more labor data and insights? Sign up for the MI’s comprehensive Workforce in Focus newsletter to stay up to date on the latest workforce trends.

GE Aerospace Foundation Partners with MI on Opportunities for Veterans

The GE Aerospace Foundation has made a $500,000 commitment to the Manufacturing Institute’s Heroes MAKE America initiative, which provides training and certifications for veterans and other members of the military community seeking new careers in manufacturing. (The MI is the NAM’s workforce development and education affiliate.)

The details: The grant will fund the creation of a new accelerated Federal Aviation Administration Airframe and Powerplant (A&P) Certification training program at Fort Bragg in North Carolina in collaboration with Fayetteville Technical Community College.

- The new A&P training program at Fort Bragg will launch in 2026 and will train transitioning servicemembers and veterans to earn the certifications they need to take in-demand jobs in the aerospace industry.

- Fort Bragg is already home to the HMA’s Department of Defense SkillBridge-approved logistics certification training course.

GE Aerospace says: “As we continue to advance the future of flight, it is critical that we invest in developing talent to help us build it and bring it to life,” said GE Aerospace Chief Human Resources Officer and GE Aerospace Foundation Chair Christian Meisner.

- “We look forward to working alongside our partners to reinforce North Carolina’s long-standing leadership as the first in flight and keystone of the aviation manufacturing industry.”

The MI says: “We are thrilled to join forces with the GE Aerospace Foundation to expand Heroes MAKE America and ensure our veterans have the skills needed to integrate into the manufacturing workforce,” added MI President and Executive Director Carolyn Lee.

- “We are committed to providing the resources and opportunities to empower today’s American heroes to become tomorrow’s manufacturing leaders.”

Manufacturing Job Training Gets Creative

This isn’t your grandfather’s workforce development training (Manufacturing Dive).

What’s going on: “Emerging programs are increasingly going beyond simple vocational training by targeting students early or in underserved communities, offering direct pathways to employment and exposing trainees to advanced tech skills.”

- The changes are a direct response to the longtime shortfall of manufacturing workers, which could reach 1.9 million if current trends persist, according to a Manufacturing Institute–Deloitte study cited by the article.

- The MI is the NAM’s 501(c)3 workforce development and education affiliate.

How it’s happening: Thanks to federal and state-level funding and private-company innovation, “prospective workers can now opt into a manufacturing career via multiple training paths.”

- Events such as those hosted by manufacturers during Manufacturing Month in October are allowing companies to get prospective workers in the door.

- At the events, manufacturers reinforce “that this is a sector where you can make a real impact and build a fulfilling career,” Laura Phillips, vice president of engineering and procurement for Pella Corporation, told the publication. “We get to tell our story, challenge outdated perceptions and spotlight the career pathways that exist in this industry.”

What else they’re doing: Pella uses a “multifaceted” approach to attracting talent, pairing interns with mentors and forming partnerships with schools to host plant tours and job shadows so students can see what modern manufacturing is really about.

- “Many of the students we have met through these interactions have joined the Pella team,” Phillips said.

The automation factor: Pella uses automation to supplement, not replace, human workers.

- The technology “make[s] tough jobs easier and equip[s] younger team members with tools that help them upskill and work hand in hand with technology,” Phillips added.

The MI says: “Manufacturers have long recognized the need to better engage the next generation of workers,” said MI President and Executive Director Carolyn Lee.

- “That’s why MFG Day matters and is so powerful—especially when it’s connected to onboarding and training. Pella’s approach works and is a great model for our industry.”

- “From Manufacturing Month and Manufacturing Day events that bring in prospective team members to pay-as-you-learn training, the industry is igniting interest in students and job seekers everywhere.”

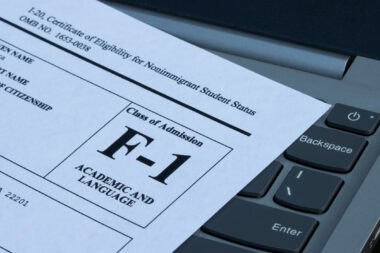

DHS Should Reconsider Proposed F-1 Visa Changes

With nearly 400,000 jobs open across the sector, the manufacturing industry in the U.S. needs ongoing access to a robust pipeline of skilled workers—but changes proposed to the F-1 student visa by the Department of Homeland Security threaten to reduce the talent in that pipeline, the NAM said recently.

What’s going on: “The F-1 visa … through its Curricular Practical Training (“CPT”) and Optional Practical Training (“OPT”) and STEM OPT options is a major source of high-skilled talent for the manufacturing industry in the U.S.,” the NAM told DHS in response to the agency’s draft reforms to the visa program.

- “[T]he proposed rule would impose changes that risk diminishing the appeal of an American education, making it harder for students to transition into careers that strengthen U.S. manufacturing. This would have a negative impact on the growth and international competitiveness of manufacturing in the United States, which is at odds with President Trump’s objective to bolster the domestic industry.”

What’s at stake: The primary change under consideration “is the switch of F-1 student visas from a duration of status (“D/S”) that remains in effect for as long as the student is enrolled in an academic program to a fixed time period that corresponds to the program’s length but cannot exceed four years.”

- “This would significantly diminish the attractiveness of U.S. universities for prospective international students, because it is at odds with the length of time that many if not most students take … to actually earn their degrees.”

- That change would also make it harder for international students to secure OPT or STEM OPT extensions, in turn inhibiting their “transition into the U.S. manufacturing workforce.”

Why it matters: “These proposed changes … would weaken manufacturers’ access to a plentiful pool of elite global talent upon which we depend to fulfill President Trump’s vision for a manufacturing renaissance in America,” the NAM concluded.

MFG Day 2025 Kicks Off with Novonesis Event

MFG Day 2025 started with a bang yesterday, thanks to Novonesis, a global leader in biosolutions manufacturing. Partnering with the Manufacturing Institute—the workforce development and education affiliate of the NAM—the company invited more than 300 high school students, education partners and community leaders to its flagship MFG Day 2025 event at its North American headquarters in Franklinton, North Carolina.

The big tour: Team leaders from Novonesis, which leverages the power of biology across more than 30 industries—including food, health, agriculture and energy—led local students through its facility to see advanced biomanufacturing up close and meet the people shaping the U.S. bioeconomy.

- Students saw production facilities, stepped into advanced biotechnology labs and participated in interactive STEM demonstrations designed to showcase the integration of science and manufacturing.

All the sights: The students took rotating immersive tours featuring Novonesis’ origin story, research and development and the role of biosolutions in daily life. Then they made their way to the fermentation shop floor and control room, where they engaged with workforce development and community college programs. On the tour, students were able to see the full array of opportunities available to them in modern manufacturing.

- “When students walk through our doors, they see that manufacturing today is about innovation, sustainability and meaningful careers,” said Novonesis North America President Tue Micheelsen. “It opens their eyes to possibilities they may never have imagined.”

The bigger picture: Access to talent continues to be a challenge for manufacturing companies.

- According to research from the MI and Deloitte, manufacturers will need to fill nearly 3.8 million manufacturing roles by 2033. Nearly 1.9 million of those are expected to go unfilled due to the lack of skilled talent necessary to fill these jobs.

Why MFG Day matters: Events like the Novonesis tour and other MFG Day activities help the industry alleviate—and hopefully even reverse—this workforce crisis.

- By giving students a firsthand look at all the exciting careers on offer in the industry, not to mention the world-changing innovations it puts forth, manufacturers can attract more young people into the industry—and put them on the path toward high-paying lifelong careers.

- The average manufacturing employee earns $102,000 a year, often with generous benefits and employer-sponsored health insurance in addition.

The NAM says: The NAM “is proud to work for the success of the 13 million men and women who make things in America. On MFGDay25, we look to inspire the next generation of creators so we can build a bright manufacturing future,” said NAM President and CEO Jay Timmons.

The last word: “People can’t be what they can’t see,” said MI President and Executive Director Carolyn Lee.

- “Today, students got to see first-hand the many career opportunities available in modern manufacturing. We’re so grateful to Novonesis for helping expose local students to all that our industry has to offer.”

Learn more here about MFG Day and the events taking place across the country throughout the month of October.

FAME USA Partners with Amatrol

The Manufacturing Institute, the 501(c)3 workforce development and education affiliate of the National Association of Manufacturers, announced that Amatrol will be an official sponsor of the Federation for Advanced Manufacturing Education USA.

The Manufacturing Institute, the 501(c)3 workforce development and education affiliate of the National Association of Manufacturers, announced that Amatrol will be an official sponsor of the Federation for Advanced Manufacturing Education USA.

The background: FAME USA, an initiative founded by Toyota and now run by the MI, is the premier American model of manufacturing skills training, developing highly skilled, professional and sought-after talent to meet the unique needs and challenges of modern manufacturing.

- Amatrol is a globally recognized leader in technical education, providing critical certification, training equipment and continuing education materials to educational institutions and manufacturers.

The partnership: Amatrol is now the exclusive FAME training equipment and content sponsor for the advanced manufacturing, industrial maintenance and smart manufacturing space.

- Together, the two institutions will advance workforce readiness and upskilling as the sector embraces artificial intelligence and the Manufacturing 4.0 revolution.

- Amatrol will continue its Diamond Sponsorship of the FAME National Conference while extending its support to the MI’s Workforce Summit as a Gold Sponsor.

The MI says: “The Manufacturing Institute’s mission is building and strengthening the manufacturing workforce, and FAME USA is a key part of fulfilling that mission. Manufacturers will need to fill 3.8 million jobs by 2033, and half of those are expected to go unfilled because we don’t have the people with the right skills,” said MI President and Executive Director Carolyn Lee.

- “Through the partnership with Amatrol, we’re creating a clear pathway for FAME USA chapters to access top-tier training resources—whether ensuring new chapters start with great equipment from day one, or giving existing chapters the opportunity to strengthen and expand their training programs as needs evolve.”

“Most importantly, this will allow us to work more cohesively with instructors throughout the FAME initiative and help them be more successful,” said Amatrol President Paul Perkins.

How a Manufacturing Leader Worked Her Way Up

Howmet Aerospace Vice President of Procurement Gina Govojdean never doubted that she would have a career in manufacturing.

- “I was always interested in manufacturing, because I was drawn to the idea of making things that matter,” she said.

Govojdean’s breadth of experience within the industry has shaped the leader she is today—from her first internship at what was then Alcoa Inc. to more than a decade of leadership in procurement, internal audit, operations and plant management.

The beginning: Govojdean’s early career in procurement gave her a chance to hone her negotiation skills. But it wasn’t long before she asked herself: how do I compete with colleagues who have decades more experience? Her answer: diversify. After four years working in procurement, she moved into an internal audit role—a position traditionally held by accountants.

- “I saw it as an opportunity,” said Govojdean. “The internal audit team travels, and that was the first lens for me that showed I could get closer to the plants that make things. I’d see all these processes and all these operations. I decided to diversify my skill set—and that became a key theme for me.”

Learning on the job: Govojdean has held 13 roles in 13 years—each one helping her grow and get closer to the action on the factory floor.

- “Stepping away and diversifying what I was able to experience really made me a much better leader,” said Govojdean.

Lots of opportunity: Her experiences in different areas demonstrate the wide range of opportunities that are available in manufacturing, and she’s enthusiastic about encouraging others to join the industry.

- “There are so many different functions and so many important people when it comes to making something—there’s something for everyone,” said Govojdean. “It’s something that’s special about manufacturing, and something that should draw in the kind of people who chase opportunities and want different experiences. It’s there. Sometimes you just have to raise your hand and say ‘yes.’”

Leading the field: Govojdean is grateful to the mentors who have encouraged her throughout her career—and as a leader in manufacturing herself, she’s enthusiastic about mentoring others.

- “It’s a fast-paced environment, and things really need to go right when you’re serving such a critical customer base—but being tough and kind is not mutually exclusive,” said Govojdean. “You can lead with grit while also being kind.”

- “Really believing in people and empowering them—that’s one of the most rewarding things about being in manufacturing leadership.”

Gaining recognition: Thanks to her passion for manufacturing, her dedication to mentorship and her relentless pursuit of excellence, Govojdean was named a 2025 Women MAKE Awards (now STEP Ahead Awards) Honoree by the Manufacturing Institute. The awards honor 130 individuals who have achieved excellence in the manufacturing industry, everywhere from the shop floor to the C-suite, helping the next generation see themselves in modern manufacturing careers.

Filling a need: At a time when manufacturing faces a significant employment gap—with an estimated 3.8 million positions needing to be filled by 2033—Govojdean sees the breadth of opportunity as the industry’s strong suit.

- “I see every day as an opportunity to challenge outdated perceptions around the manufacturing workforce and open doors to others,” said Govojdean. “This field thrives when diverse voices are part of the conversation.”

Looking to the future: As manufacturing continues to evolve, leaders like Govojdean show what’s possible when talent meets opportunity. Her journey is a reminder that this industry doesn’t just build products; it builds careers, leaders and futures. And as the next generation looks to make an impact, manufacturing is ready for them.

Get involved: Do you know someone like Govojdean who is making an outsized impact on the manufacturing industry? If so, you can nominate your peer or colleague for the 2026 STEP Ahead Awards here.

Heroes MAKE America’s Impact Highlighted at Fort Bragg

The Manufacturing Institute’s recent Heroes MAKE America ‘Military to Manufacturing’ Career Fair at Fort Bragg in North Carolina highlighted Johnson & Johnson’s commitment to helping our nation’s heroes.

What’s going on: The day’s event, which also comprised an employer spotlight and was held last Thursday on the 107-year-old military base, delivered on HMA’s mission: connecting military members seeking jobs with national and regional manufacturers looking for talent. More than 20 employers attended, hoping to recruit top talent.

- Since launching in 2018, Heroes MAKE America—an initiative of the NAM’s 501(c)3 workforce development and education affiliate, the Manufacturing Institute—has exposed nearly 50,000 participants searching for their next manufacturing careers through training and events.

- Johnson & Johnson Chief Technical Operations and Risk Officer and NAM Board chair and MI board member Kathy Wengel was on hand to give remarks to the audience, which consisted of HMA alumni, future class participants, active duty and transitioning military members, veterans, military spouses and state and military leadership.

- Wengel was joined by MI President and Executive Director Carolyn Lee, NAM President and CEO Jay Timmons, who serves as Chair of the MI’s Board, Johnson & Johnson Wilson plant manager and U.S. Army veteran Pete Goodridge, and North Carolina Department of Military and Veterans Affairs General Counsel Jimmie Bellamy.

Manufacturing needs you: A common theme among the manufacturing leaders’ remarks was the still-high number of open (and rewarding) jobs in the industry—currently at about 400,000.

- “We want even more people from across the nation to join this industry,” Lee told the crowd. “The skills you bring as transitioning service members—leadership, discipline, problem-solving, teamwork, technical expertise and more—are exactly what manufacturers are looking for. That’s what today is all about: connecting you with companies eager to meet you and that value your experience.”

Investing in the state—and the military: Timmons talked about the groundbreaking earlier this year of J&J’s new biologics facility in Wilson, North Carolina, as well as the health company’s announcement of its intention to invest $55 billion in U.S. manufacturing over the next four years.

- “That investment sends a powerful signal about the opportunities in store for those considering this career path,” Timmons added.

- Added Wengel, “In addition to our partnership with Heroes MAKE America, we have several initiatives at J&J to support military hires and the military community as a whole.”

- Through the Veteran’s Leadership Council, the group gives its workforce access to mentors and volunteers, leadership and development opportunities. It also has a strong military leave policy, which provides full pay and benefits to activated employees for up to three years. J&J partners with leading veterans service organizations to offer a wide range of services to veterans and their families.

Why Heroes? Heroes MAKE America—which has a Skillbridge Certified Logistics Technician course in partnership with Fayetteville Technical Community College, near Fort Bragg also offers in-person and virtual training programs nationwide to assist veterans and transitioning military members in earning industry recognized certifications and skills needed in modern manufacturing.

- These include courses in manufacturing operations, industrial system maintenance, automation and robotics, and aviation maintenance.

- “These programs don’t just train you,” Lee told the audience. “They open doors.”

- More than 500 companies in 49 states have hired HMA graduates at salaries exceeding $72,000. The program has a 96% graduation rate and a 92% placement rate.

Dive deeper: Learn more about how your company can get involved with Heroes MAKE America here.

More People Are Staying Unemployed Longer

More than one in five unemployed Americans have been out of work for more than half a year, a post-pandemic high (The Washington Post, subscription).

What’s going on: “In all, more than 1.9 million Americans had been unemployed ‘long term’ in August, meaning they have been out of work for 27 weeks or more, a critical cliff when it comes to finding a job. That’s nearly double the 1 million people who were in a similar position in early 2023.”

- While the likelihood of losing one’s job has not increased substantially, the probability of remaining unemployed in the event of a job loss has risen, according to the Post.

- The past two months have shown job market cooling, with weaker-than-anticipated jobs numbers leading “policymakers to voice concerns that the labor market could continue deteriorating.”

- Recent weekly unemployment insurance claims were at their highest in nearly three years.

Why it’s significant: “Six months of unemployment often signals a turning point in a person’s job search, according to economists. They’ve probably run out of unemployment insurance benefits and severance payments by then, leaving them on shakier financial ground. People who have been unemployed for more than six months are also more likely to become discouraged and stop looking for work altogether.”

- Although the unemployment rate is near historic lows, many employers have paused hiring as they wait to see the effect of tariffs and other trade-related policies.

Confidence tanks: Now, for the first time in four years, there are more unemployed people in the U.S. than there are open jobs—and job-seeker confidence is crashing.

- In a recent Federal Reserve Bank of New York survey, respondents gave themselves less than a 45% chance of finding work in the next three months in the event they were to lose their current jobs. That’s the lowest reading in more than 12 years.

- Finding work has been especially difficult for recent college graduates, as there are fewer entry-level positions available.

An economist’s view: “As reflected in the previous four months of job losses, the manufacturing industry has faced challenges,” said NAM Chief Economist Victoria Bloom. “We’re now seeing that weakness spread to other industries and through the broader economy, a cautionary signal.’”

FAME Brews Up a Partnership with ShopFloor Coffee

The Manufacturing Institute, the NAM’s workforce development and education affiliate, announced a new partnership between the Federation for Advanced Manufacturing Education (FAME USA), the premier American model of manufacturing skills training, and ShopFloor Coffee, a mission-driven coffee brand that supports skilled trades and manufacturing education nationwide.

How it works: ShopFloor Coffee will donate 20% of proceeds directly to workforce development programs across the country, including FAME USA, Robotics Education & Competition Foundation and All Within My Hands, Metallica’s foundation supporting skilled trades.

- “FAME USA is proud to partner with ShopFloor Coffee to support our shared mission of growing and sustaining a highly skilled manufacturing workforce,” said FAME USA National Director Tony Davis. “It’s about creating opportunities for students, celebrating those already in the field and building a pipeline of talent for the future.”

- “We’re honored to fuel the future of manufacturing through this partnership,” said ShopFloor Coffee Co-Founder Mike Franz. “This isn’t just about better coffee in breakrooms. It’s about waking people up to the power of American manufacturing and the programs, like FAME USA, that keep it strong.”

FAME: FAME offers a cutting-edge earn-and-learn model, in which students earn associate degrees while also working at manufacturing facilities. Students across the country have gone on to many high-paying careers at major manufacturing firms.

What’s next: Together, FAME USA and ShopFloor Coffee will shine a spotlight on the stories of students, apprentices and employers shaping the future, while rallying communities to invest in workforce development in new and creative ways.