What It Takes to Manufacture a Vaccine

You may not know it, but one company has the capacity to manufacture bulk drug substance for more than a billion doses of COVID-19 vaccines annually: Emergent BioSolutions, a global supplier for the Johnson & Johnson vaccine and U.S. supplier for the AstraZeneca vaccine. Emergent Executive Vice President of Manufacturing and Technical Operations Sean Kirk spoke with us recently to explain what goes into the heroic production of all these doses—in other words, what it takes to help defeat COVID-19.

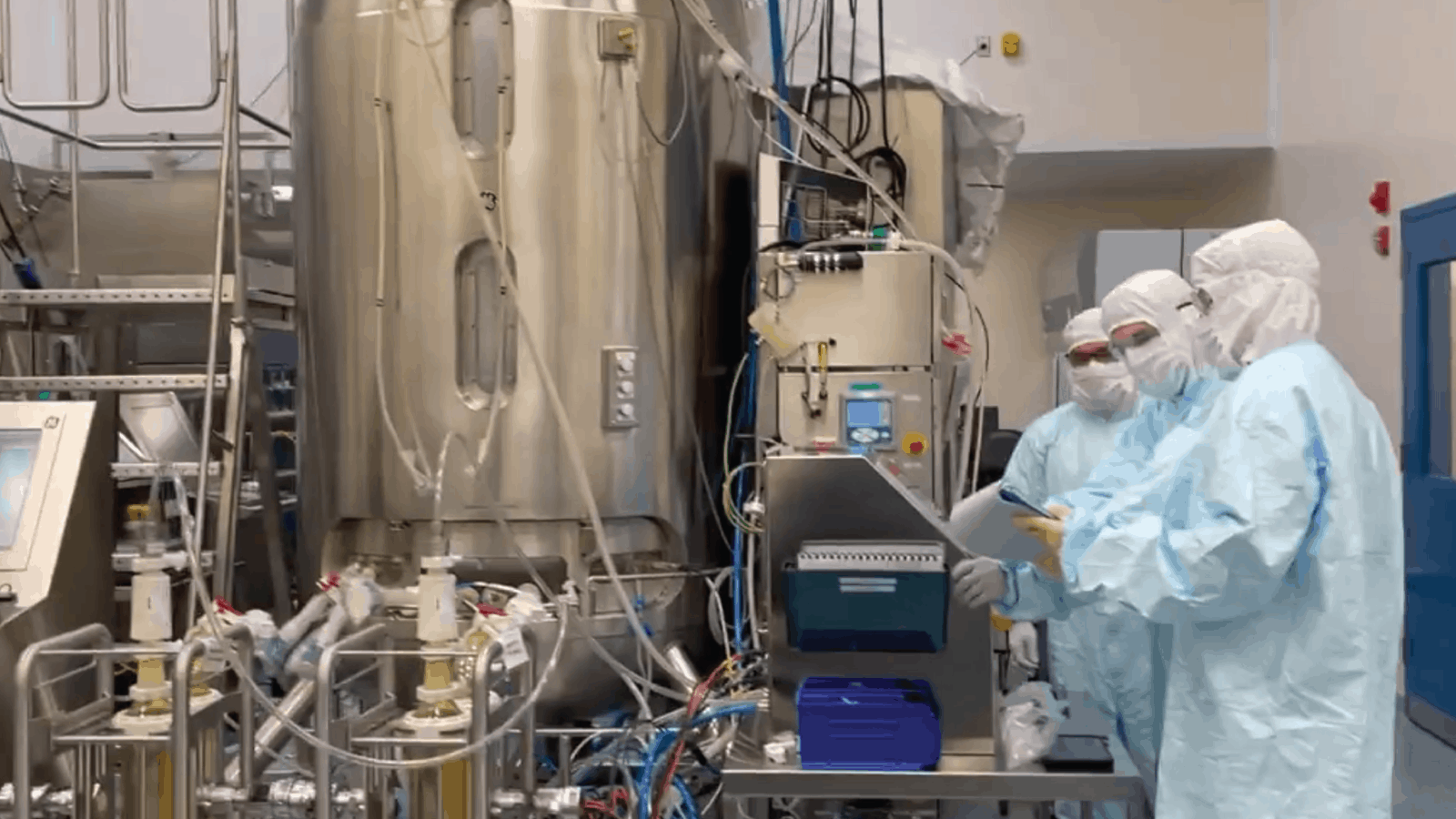

How the vaccine works: The complexity begins with the vaccines themselves, which are amazing feats of bioengineering. The two vaccines have broadly similar structures, though they are made by separate, quarantined production lines in the Emergent facility. (As Kirk says, you can’t even take a wrench from one production suite to the other.)

You can think of this type of vaccine as a sort of beneficial Trojan Horse:

- Particles of a virus called an adenovirus, which usually causes cold and flu-like symptoms, are engineered to hold the DNA of SARS-CoV-2 (the official name of the coronavirus)—and to not be infectious themselves.

- Those adenovirus particles enter your cells and program them to produce a component of SARS-CoV-2 called a spike protein.

- That process provokes an immune response, teaching your system how to defeat the real COVID-19.

So how do you make it? As you might guess, making such a precise vaccine is itself a complicated and delicate process.

- You need to make a lot of modified adenovirus particles very fast, while ensuring they aren’t infectious and can deliver their payload of SARS-CoV-2 DNA.

- To cut a long story very short, the production process involves “infecting living cells [with the modified adenovirus] and turning them into virus factories,” as science writer Derek Lowe says.

Where Emergent comes in: Emergent handles the manufacturing process, which results in something called “bulk drug substance,” Kirk explains.

- “Our facility produces the high concentration active pharmaceutical ingredients, the viral vectors themselves,” he says. “Then we freeze them down and ship them out to what’s called a fill/finish facility, which dilutes the concentrate and fills vials or syringes with it.”

The numbers: That concentrate will eventually become part of the 100 million Johnson & Johnson doses and 300 million AstraZeneca doses purchased by the U.S. government.

What it takes: Kirk gave us a glimpse of just how much effort went into getting ready for a new vaccine.

- 6 or 7 months: That’s all Emergent had, for a process that normally takes years. Consider how much goes into it, Kirk says: ordering equipment, getting that equipment to work correctly and comply with regulations, “working out the kinks from the complex biological manufacturing process”—and then scaling it up and optimizing it to make large quantities of vaccines as quickly and safely as possible.

- 800 new jobs: Emergent had to increase hiring, adding approximately 800 new jobs in 2020, many of which were dedicated to COVID-19 response across three Maryland sites.

- Group effort: Emergent works incredibly closely with Johnson & Johnson and AstraZeneca, along with the U.S. government and the company’s own suppliers. “We have leveraged U.S. government rated orders to get access to critical raw materials and equipment. We’ve depended upon certain suppliers, who were likewise rallying to the cause, to really step up and ramp up their overall capability and capacity,” says Kirk.

Why can’t you go faster? Kirk says he gets this question all the time and wants to impress upon readers that these are very complex biologic manufacturing processes.

- “They are highly regulated, highly technical and have to be highly reproducible,” he continued. “We are growing living cells and then we are infecting them with these viral vectors.”

- Furthermore, everything that Emergent produces must have the same characteristics of the product used in the clinical trials—“that’s the essence of biologic vaccine development,” Kirk says. “That’s the only way you can ensure safety and efficacy.”

The last word: Kirk tells us what he tells his employees: “It’s unbelievably difficult, more difficult than anything I’ve done in my entire career. But I can’t think of a more awesome opportunity to leave an indelible mark on the course of human history. We are going to help return a degree of normalcy to society. We’re going to help reunite families, open up economies and put a smile on children’s faces when they go back to school. And that’s an honorable and amazing thing.”

This article is the first in an exclusive four-part series on Emergent’s accelerated production efforts.