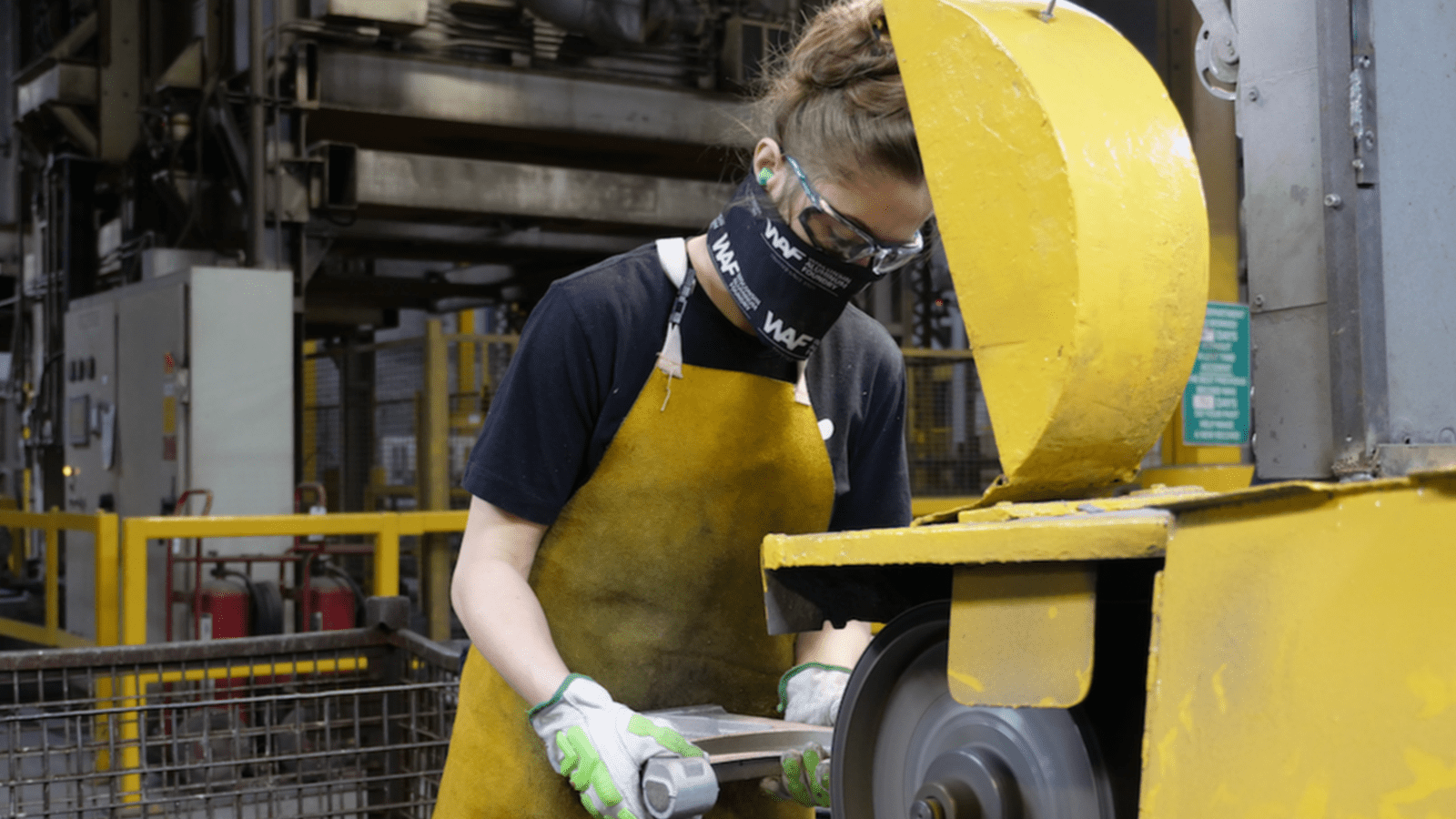

WAFCO Seeks a Child Care Solution to the Labor Shortage

It all started with a conversation in a parking lot.

Wisconsin Aluminum Foundry CEO Sachin Shivaram was chatting with a second-shift employee outside the WAFCO building one evening last summer when he happened to glance into the man’s car.

- “[I notice] he’s got a car seat in there, so I ask him, ‘What do you do for child care?’” Shivaram recalled. “He said he’s a single dad of a 4-year-old daughter, and he takes her to a different [caretaker’s] house every night. I thought, ‘That can’t be a good environment for her.’ It got me thinking, ‘How can we help this man get better care?’”

Oasis needed: Shivaram aims to find out. While the top executive of a century-old aluminum casting and molding manufacturer may seem an unlikely advocate for affordable child care, helping employees care for their kids has practically become a business imperative for WAFCO.

- “When the frenzy of the labor shortage got going, we connected” child care and the inability to fill jobs, Shivaram said, adding that the Manitowoc area is a “child care desert” with few available spots in centers. “One day we had no women on second shift, [yet] women are 50% of the population. [That’s because,] unfortunately, the burden of caring for children falls primarily on women. We realized, ‘If we’re going to make a dent in the labor shortage, we have to fix this.’”

Lending a hand: So, the company started trying to do just that. On Shivaram’s watch, it began giving employees $400 a month in child care reimbursement, on top of its $27-an-hour median wage, health care benefits and double pay for overtime.

- WAFCO has also purchased spots, when available, at a high-quality local day care center owned by the wife of a company associate and subsidized the cost of those spots for employee children.

Doing even more: Then Shivaram learned about the state’s Workforce Innovation Grant Program, the aim of which is “to help the regions of Wisconsin solve their most pressing workforce challenges by financially supporting collaborative, sustainable and innovative pandemic-recovery plans developed by regional organizations.”

- In addition to setting aside $1 million of its own capital for the creation of a child care center, WAFCO applied for $5 million of grant money last year in the program’s first round. While the company didn’t get the funds then, Shivaram plans to redouble the firm’s efforts and apply for round two this year.

The response: “Employees love it,” Shivaram said of the child care subsidy. Of WAFCO’s approximately 580 employees, about 80 make use of the funds. “Even those employees who don’t have children of child care age say this is really helpful.”

What’s next: WAFCO has identified a site for the planned center, a former adult day care facility. It is also working with KinderCare Learning Centers, the Oregon-based childhood-education company, to decide on an operating model.

- “There will be a strong emphasis on early learning for 0-to-5-year-olds,” Shivaram said. “We’re not just going to have check-the-box child care. And we are committed to paying [child care workers] more than a living wage.”

Advice for other manufacturers: Manufacturers looking to offer child care help to their employees should chiefly remember one thing as they start to plan: You can’t go it alone.

- “This does take a coalition,” Shivaram said. “This is really businesses coming together to help a need in society that, if we don’t resolve it, is only going to make us less successful. This is not going to happen with one business [working] alone.”

Industry-wide efforts: WAFCO’s initiative is part of a larger wave of manufacturers offering increasingly competitive benefits—including child care—for their teams.

- The Iowa-based Vermeer Corp. has full onsite child care facilities for the children of its employees.

- Rockwell Automation, headquartered in Wisconsin, has a generous “caregiver leave” policy to allow workers to take paid time off to look after dependents.

- When schools were closed at the beginning of the pandemic, the Pennsylvania-based i2M employed teachers to host onsite learning “pods” for the children of employees. The company is now working on a similar setup for after-school care.

The NAM says: “As we look to close the skills gap and resolve ongoing talent shortages, manufacturers continue to outperform other industries when it comes to pay and benefits packages they offer,” said Manufacturing Institute President Carolyn Lee. The MI is the NAM’s workforce development and education partner.

- “Manufacturers are constantly finding innovative ways to provide quality-of-life-improving services, such as child care, health care options, leave and retirement savings, that will motivate and empower millions of manufacturing team members nationwide and make our industry more equitable and inclusive.”