PALIoT Takes on Supply Chain Challenges

Supply chain problems, PALIoT Solutions is coming for you.

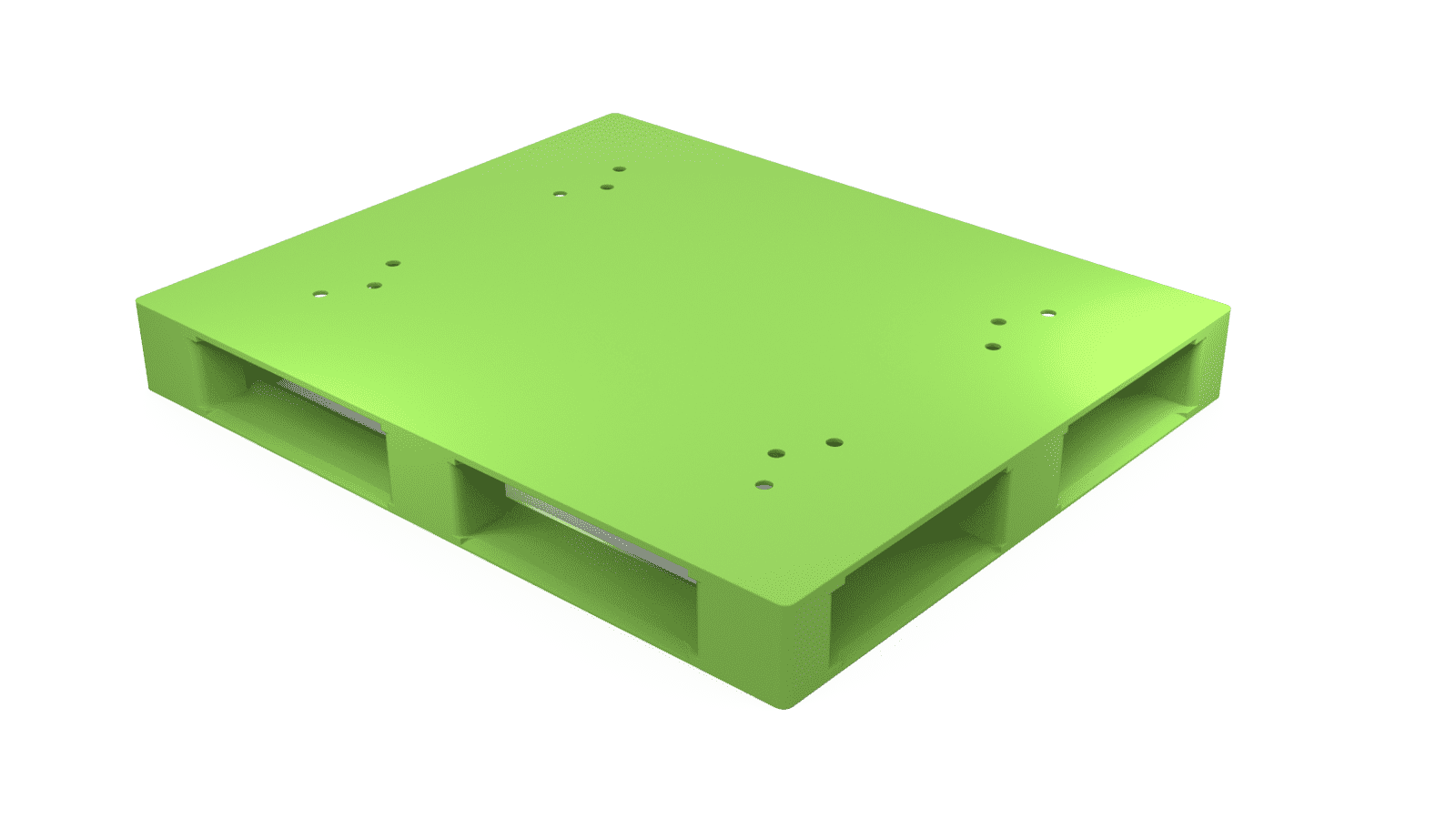

This fall, the New-York-state-based startup, whose name derives from a combination of “pallet” and “IoT,” will begin production of its smart shipping pallets. According to company leaders, these products will do nothing less than revolutionize the way food and goods are transported.

From vision to reality: PALIoT cofounders Paul Barry and Richard MacDonald envisioned pallets “whose positive impact on the environment keeps increasing as more of them are manufactured and deployed,” according to the firm’s website.

- To accomplish this feat, the pallets had to be both far lighter and more durable than typical pallets, which are made of wood and nails.

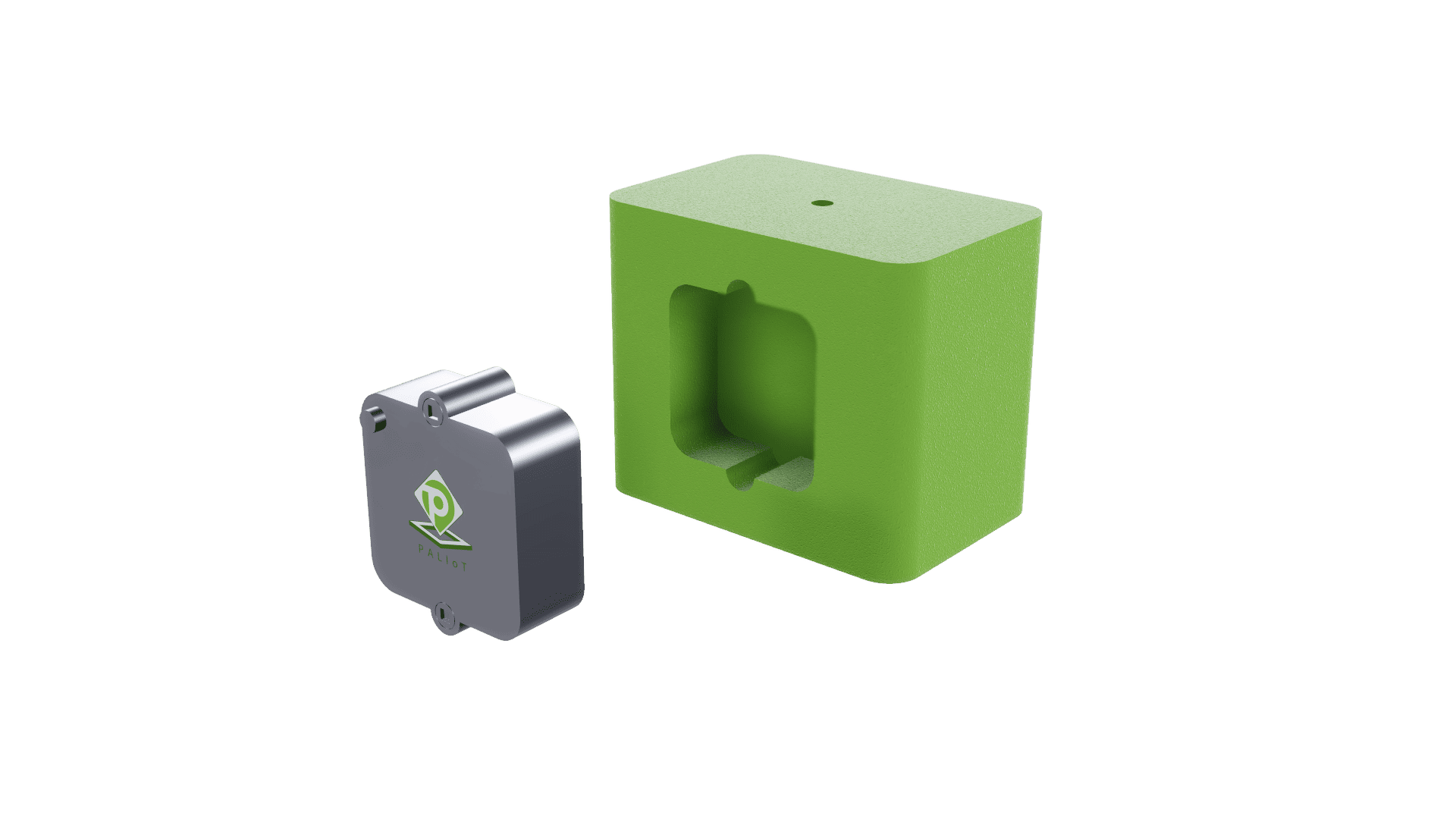

- After significant research and development, Barry and MacDonald came up with the solution: a polyurea-coated, engineered-plywood pallet that was 20 pounds lighter than its traditional peers and contained a proprietary sensor capable of instant communication with the cloud, making inventory tracking a cinch.

The “secret sauce”: “The ‘secret sauce’ is essentially a smart mesh network,” said Barry, who hails from Ireland and has an electrical engineering and investment banking background. “The PALIoT pallets in a shipment will all talk to each other, say, ‘Hey, I’m here.’ And [after shipping,] because they know they’ve been on a truck, they know they have to report all that valuable inventory and environmental data back to the cloud.”

- PALIoT, which will rent its pallets to customers using a per-pallet, pooling model (with an optional subscription service), acquired exclusive global use of the mist® Mesh Networking protocol. This ensures that communication is highly secure and battery sensitive at all times.

- The company estimates it will initially produce between 650,000 and 700,000 pallets a year in the first phase of the launch.

Savings for all: PALIoT’s groundbreaking sensors promise to save buyers both resources and money.

- “Food producers see tens of millions of dollars a year in food waste,” Barry said. With PALIoT technology, those producers will be able to track their perishable food shipments’ temperature and humidity conditions, viewing that information in the cloud so handlers can take swift action to cut down on spoilage.

- And because real-time asset protection is a PALIoT priority, the pallets will help companies cut down on theft and losses. As Barry put it, “If a pallet gets stolen, we will know where and when.”

A “smart” solution: Typical asset-embedded IoT sensors fail long before the assets themselves, making them impractical for longer-term use. Not so with PALIoT’s pallets, which can be used for a decade before they will need to be “retired and recycled,” according to Barry.

- “How can you justify having an expensive piece of hardware with a battery that needs replacing every few years?” he continued. “Using a combination of communications technologies, we’ve been able to solve the key problems of battery life and cost for large-scale asset-pooling companies.”

What’s next: Having recently relocated its manufacturing operations from Colorado to just outside Rochester, New York, PALIoT has its sights set on doing business with the dairy farms of the Northeast. It also plans to expand its manufacturing footprint across the U.S.

- “Demand is not the issue,” Barry told us. ”People just want a better solution, and we think this is it.”