Nexteer Displays Advanced Manufacturing in Action

Would you like to see the latest advanced technologies exhibited and explained for your benefit, all without leaving your office? The NAM’s Manufacturing Leadership Council’s virtual plant tours provide just such an opportunity, taking you inside cutting-edge processes and complex systems at manufacturing facilities across the country. Most recently, the MLC dropped in on Nexteer Automotive, where tour participants got to see its innovative Digital Trace Manufacturing™ (DTM) System in action.

Who they are: Nexteer specializes in electric and hydraulic power steering systems, steering columns and driveline systems, as well as advanced driver assistance systems and automated driving-enabling technologies. The company serves more than 60 customers around the world, including BMW, Ford, GM, Toyota and Volkswagen.

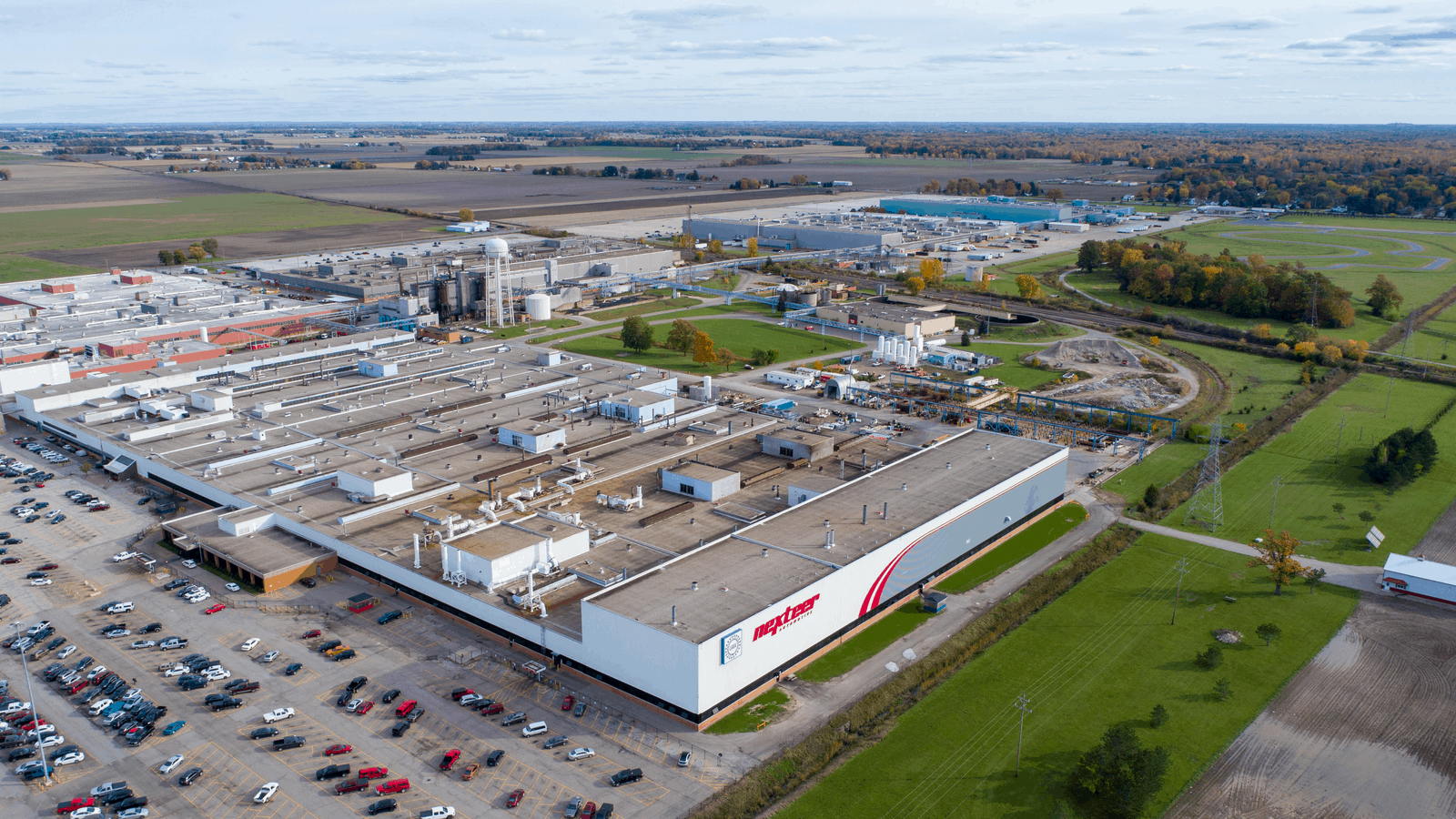

What is DTM? Nexteer’s DTM System connects and standardizes the company’s entire operations—including thousands of data-production components in 27 manufacturing plants around the world. To showcase the system’s capabilities, Nexteer took tour participants inside its Saginaw, Michigan, site, which includes six manufacturing plants comprising 3.1 million square feet of manufacturing floor space.

Tour highlights: Participants learned about the complexities of running a large-scale automotive component manufacturing plant, as well as how Nexteer uses the DTM System to maximize efficiency.

- Nexteer team members explained how they design and program machines for data processing, showing how they determine where data will be sent and how they use barcode scanners and other methods to track components’ serial numbers.

- Participants also got a virtual walk-through of Nexteer’s tracking system, which follows material from receiving and shipping through the production line with single-box precision. They also learned how Nexteer uses its Center of Analysis to correct any issues that arise.

Why it matters: It’s one thing to have a large system collecting data, and it’s another to be able to use that data effectively. The Nexteer virtual plant tour provided participants with practical takeaways, which will help them adopt similar innovations at their own facilities—for the benefit of employees, customers and shareholders alike.

Coming soon: Don’t miss the MLC’s upcoming tour of Johnson & Johnson’s facility on Wednesday, Dec. 1, from 11:00 a.m. to 1:00 p.m. EST. You will see how Johnson & Johnson uses mobility tools, advanced robotics and material handling and adaptive process controls to improve its operations. After the tour, stay for the panel discussion on how to scale advanced manufacturing technologies to create a sustainable, reliable and adaptable product supply. Sign up here.