Innovation Takes Center Stage as Manufacturers Launch NAM State of Manufacturing Tour from the Rock & Roll Hall of Fame

CLEVELAND – The National Association of Manufacturers today kicked off its annual NAM State of Manufacturing Tour, a cross-country sprint spotlighting the vital role that manufacturing plays in supporting the nation’s economy. On the first leg of the tour, NAM President and CEO Jay Timmons and other leaders underscored the state’s industrial momentum while calling on our nation’s leaders to pursue a comprehensive manufacturing strategy—building on permanent, pro-growth tax reform manufacturers secured last summer.

“Innovation Built America. Manufacturing Wins the Future” is the theme of this year’s tour, and framed a series of events in Cleveland, bringing together industry leaders, students and policymakers to spotlight Ohio’s nearly 700,000 manufacturing employees—about 12% of the state’s workforce.

“There’s no better place to start a road tour than the Rock & Roll Hall of Fame,” said Timmons, an Ohio native, at the iconic Rock & Roll Hall of Fame, where he delivered his 13th NAM State of Manufacturing Address. “Like rock ‘n’ roll, manufacturing is everywhere. We are hitting the road to showcase the world-leading innovation happening across the country and how we make the next 250 years even greater. Manufacturers are ready to invest—and we need certainty, like the tax bill delivered last year. Permanent tax reform gave manufacturers the rocket fuel. Now we need clear skies. That’s energy dominance, permitting reform, trade certainty, investing in the manufacturing workforce and smart AI policy.

Timmons was joined by Rockwell Automation Chairman and CEO and NAM Board Chair Blake Moret, Cleveland Mayor Justin Bibb, EQT Corporation President and CEO and NAM board member Toby Z. Rice, The Ohio Manufacturers’ Association President Ryan Augsburger and NAM Executive Vice President Erin Streeter. Following the address, Timmons and Moret hosted a student reception at the Hall of Fame, where they engaged with the next generation of creators. The tour then moved to the Rock Hall’s “Jam Garage” for a unique filming opportunity showcasing the intersection of culture and industry. The setting provided a compelling backdrop for discussions about the connection between manufacturing and rock ‘n’ roll—two distinctly American traditions that involve bold ideas, creative risk-taking embracing technological change and the ability to shape global culture.

“The innovation we’ve seen Ohio manufacturers embrace over time is exactly why this tour is so vital,” said Moret. “At Rockwell, we see every day how automation and AI are redefining what’s possible on the factory floor. By visiting places like Cleveland State University and seeing the talent being cultivated here, it’s clear that Ohio manufacturers are moving at the speed of business. Now, we must ensure the federal government keeps up with that pace.”

The afternoon featured an in-depth tour and lunch at EY-Nottingham Spirk Innovation Hub followed by a final stop at Cleveland State University to discuss the critical intersection of higher education and industrial workforce development.

“Ohio’s manufacturers are the backbone of our state’s economy, and having the national tour stop here in Cleveland underscores the importance of our mission,” said Augsburger. “We are proud to stand with the NAM to advocate for the policies that will keep our nearly 700,000 manufacturing workers at the forefront of global competition.”

From Cleveland, the 2026 NAM State of Manufacturing Tour will go on to Philadelphia, Pennsylvania; Charlotte, North Carolina; Milwaukee, Wisconsin; Dallas and Houston, Texas; and Phoenix, Arizona. Throughout the tour, the NAM will continue meeting with policymakers, manufacturers of all sizes, students and business leaders, advocating for the people and policies that will ensure the United States is the best place in the world to do business. To learn more about the tour and the NAM’s mission, visit www.nam.org.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.95 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Treasury Clears Path for Greater Manufacturing Investment with Tax Proposal on CAMT

Washington, D.C. – Following the release of a new proposal from the Department of the Treasury reforming key aspects of the Corporate Alternative Minimum Tax guidance and addressing the interaction between the immediate expensing of R&D costs and the CAMT, National Association of Manufacturers Managing Vice President of Policy Charles Crain released the following statement:

“Congress and the Trump administration passed a once-in-a-generation tax law last summer, and now Treasury is building on that win.

“The Corporate Alternative Minimum Tax has threatened manufacturers’ ability to raise wages, hire workers and invest in their communities since it was enacted in 2022. With today’s proposal, Treasury has taken a step toward fixing this fundamentally unworkable regime.

“In particular, the proposed changes to protect H.R. 1’s restoration of immediate expensing for R&D costs will ensure manufacturers are not penalized for their commitment to making investments that drive innovation. Manufacturers conduct 52% of private-sector research—investments that will continue to drive the industry and the economy given that 80% of manufacturers say AI innovation will be essential to grow or maintain their business by 2030.

“The Trump administration is meeting the moment by taking urgent action to supercharge private-sector R&D. Manufacturers called for this critical change, and we thank Treasury for taking this important step to support manufacturing innovation and ensure the continued success of H.R. 1 for our industry.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.95 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Existing Home Sales Drop in January as Inventory Tightens and Time on Market Rises

Existing home sales fell 8.4% in January, the largest monthly decline in nearly four years, and 4.4% over the year. Housing inventory moved down to 1.22 million units, reflecting a 0.8% drop from December but a 3.4% increase from last year. The median existing home price was $396,800, up 0.9% from last year. The Northeast, South, Midwest and West all posted monthly decreases in existing home sales in January.

Single-family home sales fell 9.0% from December and 4.3% from January 2025, with the median price increasing 0.6% from last year to $400,300. Condo and co-op sales decreased 2.6% over the month and 5.0% over the year to 380,000 units in January. Meanwhile, the median price for condos and co-ops rose 3.8% from the prior year to $364,600.

Homes were typically on the market for 46 days in January, up from 39 days in December and 41 days in January 2025. First-time buyers made up 31% of sales in January, up from 29% in December and 28% in January 2025.

Small Business Optimism Holds Near 52-Year Average in January

The NFIB Small Business Optimism Index edged down 0.2 points to 99.3 in January, remaining slightly above the 52-year average of 98. January’s increase was due primarily to the rise in those expecting better real sales volume. Of the 10 components included in the index, three increased and seven decreased. Meanwhile, the Uncertainty Index jumped 7 points to 91, remaining well above the 51-year average (68) and above the average since 2016 (80).

Small business owners again cited taxes as their top concern, with 18% reporting it as the most important problem, down 2 points from December. The share of business owners reporting labor quality as their top problem fell 3 points from December to 16%, with 31% struggling to fill open jobs and 50% reporting hiring or trying to hire in January. Meanwhile, the cost or availability of insurance was third on the list of concerns, with 13% reporting it as a top problem, up 4 points from the prior month and the highest level since December 2018.

A net 32% of small business owners reported raising compensation, up 1 point in January after rising 5 points in December. Meanwhile, 22% of business owners plan to raise compensation in the next three months, down 2 points from December. Pressure on profitability strengthened in January, with positive profit trends decreasing 1 point from December to a net negative 21%. Among owners reporting lower profits, 34% blamed weaker sales, 14% mentioned usual seasonal changes and 10% noted labor costs. Meanwhile, 3% reported their last loan was harder to get than previous attempts, down 2 points from December, and a net negative 6% of owners cited paying a higher interest rate on their most recent loan, down 3 points from the prior month.

The outlook for general business conditions fell 3 points to 21%. Furthermore, expectations for better business conditions are 26 points below the same month a year ago. On the other hand, 15% reported that it is a good time to expand their business, up 2 points from December but a rather weak reading compared to times of economic expansion. Despite overall growth running hot, small business owners feel like economic conditions are more moderated, with investment-led growth not hitting all sectors equally.

Manufacturing Adds Jobs After a Yearlong Slide

Nonfarm payroll employment rose by 130,000 in January, coming in above expectations. At the same time, the unemployment rate edged down 0.1 percentage point from December to 4.3% in January, while the labor force participation rate ticked up 0.1 percentage point to 62.5%. In addition, the establishment employment survey was revised as a result of the Bureau of Labor Statistics’ annual benchmarking process and the updating of seasonal adjustment factors. As a result of the annual benchmark revision, the employment levels from April 2024 to March 2025 were revised downward by 898,000 nonfarm jobs and 98,000 manufacturing jobs.

Manufacturing employment increased by 5,000 in January after 13 consecutive months of declines. On the other hand, the collective job losses in November and December of 10,000 were revised downward by 8,000 jobs to a decrease of 18,000 jobs. Manufacturing employment is down 82,000 over the year. Durable goods manufacturing employment rose by 9,000 in January, while nondurable goods employment fell by 4,000. The most significant gain in manufacturing in January occurred in transportation equipment manufacturing, which added 4,800 jobs over the month. Meanwhile, the most significant losses occurred in apparel manufacturing and chemical manufacturing, which shed 1,800 jobs each over the month.

The employment-population ratio inched up 0.1 percentage point from December to 59.8% in January but is down 0.3 percentage points from a year ago. Employed persons who are part-time workers for economic reasons declined by 453,000 from December to 4.89 million in January but are up from 4.48 million in January 2025. Native-born employment is down 1,195,000 from December but up 840,000 over the year. Meanwhile, foreign-born employment is up 565,000 over the month but down 97,000 over the year. At the same time, the native-born unemployment rate is up 0.4 percentage points over the year to 4.7% in January, while the foreign-born unemployment rate is down 0.1 percentage point to 4.5%.

Average hourly earnings for all private nonfarm payroll employees rose 0.4%, or 15 cents, reaching $37.17. Over the past year, earnings have grown 3.7%. The average workweek for all employees edged up 0.1 hour to 34.3 hours and by the same to 40.1 hours for manufacturing employees.

Inflation Cools in January: Energy Prices Ease and Core Slows

In January, consumer prices increased 0.2% from December and 2.4% over the year, down from the 2.7% annual rise in December and less than the anticipated 2.5% hike. Core CPI, which excludes more volatile energy and food prices, rose 0.3% from December and 2.5% over the year, down from the 2.6% 12-month increase in December and the slowest pace since March 2021.

Energy costs edged down 0.1% over the year in January, after rising 2.3% year-over-year in December. Within the energy index, gasoline prices declined 7.5% over the year, while fuel oil prices fell 4.2%. Meanwhile, electricity prices increased 6.3% year-over-year, and natural gas prices surged 9.8%.

In January, food prices grew 2.9% over the year, after increasing 3.1% year-over-year in December, while prices for food at home advanced 2.1%. Meanwhile, prices for food away from home climbed 4.0% from January 2025, down from the 4.1% year-over-year increase in December. Of the different food groups, beef and veal and coffee continue to rise at the fastest pace, soaring 15.0% and 18.3% over the year, respectively.

The shelter index grew 0.2% from December and 3.0% over the year, the greatest factor in the all-items monthly increase but down from the 3.2% annual gain in December. Meanwhile, prices for used cars and trucks decreased 1.8% over the month and 2.0% over the year, while new vehicle prices inched up 0.1% over the month and 0.4% from January 2025. Relatedly, prices for motor vehicle maintenance and repair jumped 4.9% year-over-year.

Although the headline inflation rate is still above the Federal Reserve’s target of 2.0%, it has moderated back closer to 2025 lows. Federal Reserve officials held their interest rate target steady at their January meeting, and markets anticipate that the Federal Open Market Committee will keep its interest rate target unchanged again at next month’s meeting. Risks to the Federal Reserve’s employment and inflation mandates remain elevated but appear to be easing.

Manufacturers: America Wins with Strong Infrastructure

NAM Launches “Building to Win” Campaign Ahead of Surface Transportation Reauthorization

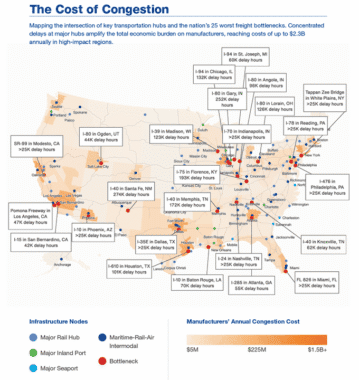

Washington, D.C. – The National Association of Manufacturers today launched “Building to Win,” a six-figure campaign urging Congress to pass robust infrastructure investments and reauthorize critical federal highway programs before they expire on Sept. 30. As part of the launch, the NAM unveiled a new infrastructure policy roadmap, including original analysis on the economic costs of congestion on manufacturers and a set of core infrastructure policy pillars. The NAM also debuted a new ad underscoring the importance of infrastructure investment and permitting reform to manufacturing competitiveness.

“Manufacturers need modern, reliable infrastructure to create more jobs, grow our economy and keep America competitive,” said NAM President and CEO Jay Timmons. “From roads and bridges to ports and airports, from highways to runways and waterways, 21st-century infrastructure means supply chains that deliver, commutes that work and communities that thrive. That’s why policymakers must act with urgency this year to invest in robust American infrastructure by passing a strong surface transportation reauthorization bill and commonsense, comprehensive permitting reform.”

Manufacturers’ Infrastructure Policy Pillars:

The NAM’s policy roadmap outlines four pillars for a robust surface transportation reauthorization:

- Continuing robust investment levels for federal infrastructure, including by developing long-term solutions for Highway Trust Fund solvency

- Strengthening supply chains across transportation modes

- Investing in water infrastructure that will support manufacturing growth and public health

- Reforming burdensome permitting laws and regulations to ensure federal infrastructure investments are made efficiently and responsibly

Original Analysis from the NAM:

- The NAM’s analysis shows that highway congestion costs manufacturers more than $25 billion annually and results in over 65 million hours of delays in freight carrying finished goods and critical inputs each year.

- The analysis also visualizes, through a new map, key logistics nodes intersecting with the nation’s 25 worst freight bottlenecks, revealing more than 2 million hours of annual delays incurred and faced by manufacturers.

- In addition, the NAM estimates that congestion at container and bulk ports cost manufacturers more than $13 billion annually in carrying costs and demurrage charges.

Top 10 Most Congested Regions for Manufacturing Freight

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.90 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

S&P Global PMI Rises in January as Output Accelerates and Inflation Pressures Persist

The S&P Global Manufacturing PMI was 52.4 in January, up from the December reading of 51.8. New orders rose in January, though growth was modest and below the survey average. However, exports declined for the seventh consecutive month, as tariffs were noted to have driven up costs and hurt demand. Meanwhile, prices on inputs increased, with vendors raising charges in response, and selling price inflation rose to its highest level since August. In sum, the rate of inflation remained elevated from a historical context in January.

Production rose at the strongest rate since last August, and combined with weak sales, allowed stocks of finished goods to increase for the sixth consecutive month. In anticipation of future production, employment grew modestly in January. Backlogs of orders increased in January due to the rise in new orders, following four months of decline. Meanwhile, delivery times continued to lengthen, a result of difficulty sourcing inputs and resource constraints for suppliers.

Potential for growth from lowered interest rates and reduced import competition held business confidence steady in January. At the same time, output continuing to outpace sales presents the risk of a production slowdown and negative effects on employment unless demand improves.

Global Manufacturing Hits a Three-Month High in January as Output, Orders and Optimism Improve

In January, growth in global manufacturing activity strengthened from December, rising from 50.4 to 50.9, a three-month high. Output and new orders both expanded as manufacturers saw the strongest rise in new work in almost a year. New export orders contracted in January for the 10th consecutive month but at their slowest pace during this downturn. Meanwhile, lead times continued to slow, lengthening for the 20th consecutive month. Employment grew for the first time in three months as job gains in the U.S., China and Japan contrasted job losses across the Eurozone.

India, Greece, the Philippines and Thailand had the highest PMI readings in January. On the other hand, Brazil, Germany, Russia and Italy were some of the larger nations to register declines in activity. The upturn in manufacturing occurred across consumer, intermediate and investment goods in January, with the fastest growth seen in consumer goods.

Meanwhile, input and output price pressures rose at the quickest rates in three years in January, with the jump largely driven by the U.S. Despite this, forward-looking indicators remained positive, with business optimism hitting a 10-month high but remaining below long-run averages.

Manufacturing Job Openings Rise as Hiring and Separations Remain Low

Job openings for manufacturing increased by 34,000 to 433,000 in December. On the other hand, the November job openings level of 399,000 was revised downward from 403,000 in the previous report. Nondurable goods job openings in December rose by 11,000 to 139,000, while durable goods job openings climbed by 23,000 to 294,000. The manufacturing job openings rate ticked up to 3.3% from 3.0% in November but stayed the same from 3.3% the previous year. The rate for nondurable goods manufacturing advanced 0.2 percentage points to 2.8% and 0.3 percentage points to 3.6% for durable goods manufacturing.

In the larger economy, the number of job openings dropped to 6.5 million, a decline of 386,000 from November and 966,000 from the previous year. The job openings rate fell to 3.9% from 4.2% in November and from 4.5% in December 2024. This data reflects an overall labor market that has eased back to pre-pandemic levels, but remains relatively tight from a historical perspective.

The number of hires in the overall economy increased 172,000 to 5.3 million in December but decreased 81,000 from the previous year. The hires rate for the overall economy edged up 0.1 percentage point in December to 3.3%. Meanwhile, the hires rate for manufacturing similarly ticked up 0.1 percentage point to 2.3%, down from 2.4% in December 2024. The hires rate for durable goods stayed the same at 2.0%, while the hires rate for nondurable goods inched up 0.1 percentage point to 2.7%.

In the larger economy, total separations, which include quits, layoffs, discharges and other separations, rose 107,000 from November to 5.3 million and 169,000 from the previous year. The total separations rate ticked up 0.1 percentage point to 3.3% for the overall economy but stayed the same for manufacturing at 2.4%, down from 2.5% from the year prior. Within that rate, layoffs and discharges increased by 7,000 in December for manufacturing, while quits ticked up by 2,000. The quit and layoff rates continue to remain lower for manufacturing than the total nonfarm sector.