J&J: Price Controls, PBMs Problematic

Drug price controls will “chill” critical innovation in pharmaceutical manufacturing and do nothing to address the underlying causes of high medication costs, Johnson & Johnson leaders said recently.

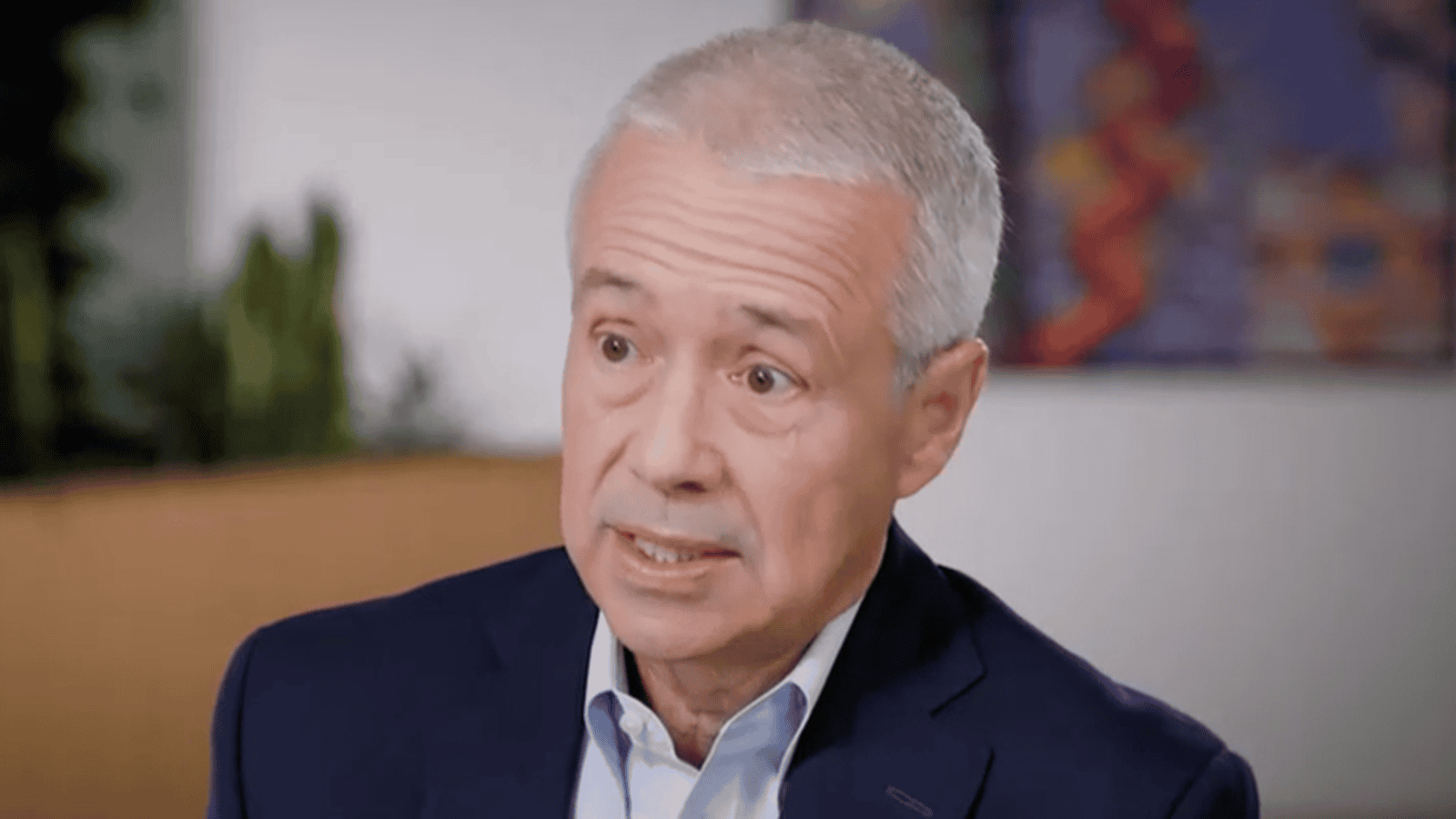

What’s going on: J&J Chairman and CEO Joaquin Duato and Executive Vice President and Chief Financial Officer Joseph Wolk told Bloomberg TV earlier this month that the pharmaceutical price controls mandated by the 2022 Inflation Reduction Act do a disservice to patients everywhere.

- “[T]he Inflation Reduction Act … is something that is misguided, and it’s going to chill innovation,” Duato told Bloomberg’s David Gura earlier this month. “When you chill innovation on investment in [research and development], then you have [fewer] cures.”

- The IRA gave the federal government authority to set prices for certain prescription medications in Medicare. In August, the Biden administration released the first 10 Medicare prescription drugs subject to those price controls, which go into effect in 2026.

- “I’d like to see a much more fact-based dialogue around the topic of drug pricing,” Wolk added. “About six years ago, Johnson & Johnson … was paying about 25% in discounts and rebates off [the] list price [of medications]. Today, that [figure is] 60%, yet the patients aren’t receiving the benefit of those discounts.”

The background: Pharmacy benefit managers are supposed to pass the manufacturer discounts they receive on to health plans and patients—but instead, they frequently pocket the discounts, the NAM has told Congress on several occasions.

- That’s one of several problematic business practices Congress must end by enacting comprehensive PBM reform, the NAM has said.

- Such legislation would do far more to benefit consumers than capping drug prices.

Cause and effect: The result of price controls will be fewer breakthrough cures and treatments for patients suffering from various illnesses, J&J told Bloomberg TV.

- “The number of medicines that will be there will be [lower], just because [fewer] investors would be putting money into developing new medicines,” Duato continued. “It’s going to be less attractive for investors to put money there.”

- And as Wolk said in another Bloomberg segment: “Investing in R&D, prioritizing R&D years in advance for [a drug] that may happen 10 years down the road is critically important.”

What should be done: If Congress truly wants to help patients with the cost of medications, it must focus on “the middlemen who are really driving up prices: pharmacy benefit managers,” NAM President and CEO Jay Timmons said recently.

Existing Home Sales Falls 4.2% YoY in August

Existing home sales dipped 2.5% in August and fell 4.2% from August 2023. Housing inventory rose to 1.35 million units, reflecting a 0.7% increase from July and a 22.7% boost from last year. The median existing home price was $416,700, up 3.1% from last year, with all four U.S. regions reporting price increases.

Single-family home sales decreased 2.8% from July, with the median price increasing 2.9% from August 2023 to $422,100. Condo and co-op sales held steady month-over-month but declined 11.6% from the previous year, with the median price up 3.5% from the prior year to $354,200.

Homes were typically on the market for 26 days in August, up from July’s 24 days and 20 days in August 2023. First-time buyers made up 26% of sales, matching the all-time low from November 2021 and down from 29% in both July and a year ago. All-cash sales accounted for 26% of transactions in August, while investor purchases represented 19%. Distressed sales remained steady at 1%.

In the Northeast, existing home sales dropped 2.0% from July, with a median price of $503,200, up 7.7% from last year. The Midwest saw no change in sales month-over-month, but the median price rose to $315,400, a 3.8% increase from August 2023. In the South, sales fell 3.9% from July, with a median price of $367,000, reflecting a 1.6% year-over-year rise. The West reported a 2.7% sales decline from July and a 1.4% decrease from the previous year, with a median price of $622,500, up 2.2% from a year ago. The housing market remained sluggish with sales dipping across the country.

Congressional Tax Writers Join NAM to Talk Tax Reform

As part of its “Manufacturing Wins” campaign to preserve pro-manufacturing tax provisions, the NAM hosted a roundtable this week with Reps. Carol Miller (R-WV) and David Kustoff (R-TN)—respectively the chair and a member of the Ways and Means Committee Supply Chain Tax Team.

Preparing for 2025: The Supply Chain Tax Team has jurisdiction over the corporate income tax rate. Tax reform reduced the corporate rate to 21%, spurring the creation of thousands of new manufacturing jobs—and the NAM is working with Congress to ensure the U.S. maintains a competitive corporate rate as policymakers debate next year’s “tax Armageddon.”

Understanding the benefits: Rep. Miller emphasized that the dollars saved due to tax reform’s lower corporate rate have supported job creation, higher wages and the flourishing of local communities.

- As a business owner herself, she said she believes it’s important for members of Congress in charge of tax policy to understand the risks businesses take, the communities they support and the certainty they need to be successful.

Measuring the impact: Rep. Kustoff emphasized the importance of real-world data on the benefits of the lower corporate tax rate—from the number of jobs created to the work businesses have done to provide their employees with bonuses and higher wages.

- According to Rep. Kustoff, real-world metrics are important for educating policymakers about the need for action, as crucial, pro-manufacturing tax provisions are set to expire at the end of 2025.

Recognizing the ripples: The discussion also touched on the wider impact of tax increases on global supply chains and the broader U.S. economy.

- Participants noted that a higher corporate income tax rate’s ripple effects would hurt companies throughout the economy—even when those companies are pass-throughs and not explicitly affected by the corporate income tax rate.

- That’s because these small businesses often sell to and partner with larger corporations that would have less capital available under a higher corporate rate.

Our take: “Prior to 2017 tax reform, the U.S. had the highest corporate tax rate among the more than three dozen countries in the Organisation for Economic Cooperation and Development and the third highest in the entire world,” said NAM Vice President of Economic Policy Charles Crain.

- “That put manufacturers in America at an alarming disadvantage. A competitive tax rate helps business compete in the global economy, leads to job creation, investments and purchases of new equipment and allows manufacturers to give back to their communities.”

- “If Congress were to raise the corporate rate, it would force America to take a step back on the global stage—at a time when other countries around the world are implementing more competitive tax agendas.”

A Veteran and His Spouse Forge New Careers in Manufacturing

Finding a civilian job after serving in the military can be daunting. For former Army cavalry scout Jose Gallegos, the task was even more complicated because his spouse, Aleksandra Balinska-Gallegos, also needed a new position. Through Heroes MAKE America—a Manufacturing Institute program that builds connections between the military community and the manufacturing industry—both Gallegos and Balinska-Gallegos found rewarding roles in Pennsylvania with food and industrial manufacturer Cargill.

The program: Heroes MAKE America provides integrated certification and career-readiness training in partnership with local community colleges to prepare transitioning service members, veterans, National Guard members, reservists and military spouses for rewarding careers in the manufacturing and supply chain industries.

- “The program not only introduces you to the manufacturing world—it prepares you for everything that is around it,” said Balinska-Gallegos. “How to correctly write your resume, how to match a military background with civilian life, how to translate military vocabulary to civilian vocabulary. And from writing a resume to emailing with potential employers and preparing for interviews—it was a little bit of everything.”

The benefit: The program helped both spouses at the same time—a huge benefit for Gallegos, who was looking for opportunities in the civilian world, and for Balinska-Gallegos, who had arrived with Gallegos from Lithuania and was worried about navigating the U.S. job market.

- “I was a completely new fresh military spouse,” said Balinska-Gallegos. “When Jose told me that there was an opportunity not only for him to go to the manufacturing program, but to also take his spouse—I was over the moon.”

Working nearby: Although they work in different plants—Gallegos as an operations and management associate at a meat production plant, and Balinska-Gallegos as an administrative assistant at a plant producing chocolate—their mentors at Heroes MAKE America helped ensure that the couple would work at the same company and in the same location.

- “He’s at a meat plant, and he loves beef. I’m at a chocolate plant, and I love chocolate,” said Balinska-Gallegos. “It’s perfect.”

Finding success: Although Gallegos’ work in the Army was very different from his role at Cargill, his supervisors have already noticed his leadership skills. While the approximately 60 other associates recruited this year are all college graduates, it’s Gallegos who has been called to take on bigger tasks.

- “After my first month, they started giving me supervisor responsibilities,” said Gallegos. “I’m shadowing managers and superintendents so I can learn from them, so … I can be in different areas of the plant.”

The last word: “I would have been very scared to start working in the U.S. without this kind of background, and I’m not sure what [Jose] would have done after leaving the Army if he didn’t go through the Heroes MAKE America program,” said Balinska-Gallegos. “That course prepared us immensely for this new life.”

Learn more: Find out more about Heroes MAKE America and the Manufacturing Institute, the workforce development and education affiliate of the NAM, here.

Photo: Jose Gallegos and Aleksandra Balinska-Gallegos with MI Director of Heroes Program Execution Rachelle Wolford (left).

NAM-Supported Bills Clear House Committee

The NAM this week advocated the passage of two pieces of manufacturing-critical legislation, successfully driving the agenda of a Wednesday House Energy and Commerce Committee markup.

What’s going on: The committee—with the NAM’s strong support—approved two bills that address longstanding manufacturing priorities:

- A congressional resolution disapproving of the Environmental Protection Agency’s harmful PM2.5 rule

- A bill instituting important pharmacy benefit manager reforms

Reversing an unworkable PM2.5 standard: The EPA announced a new, more restrictive particulate matter standard in February, reducing allowable levels from 12 micrograms per cubic meter of air to 9 micrograms—despite a standard of 9 being “essentially background levels in some of the country,” as the NAM has pointed out.

- “Manufacturers have sharply reduced particulate matter emissions, or PM2.5; as a result, industry in the United States has some of the cleanest and most efficient operations in the world,” NAM Vice President of Domestic Policy Chris Phalen told the committee.

- “Now, the vast majority of emissions are from sources well outside of our control, with fires, dirt roads and other nonpoint sources accounting for 84% of PM2.5 emissions,” Phalen continued. “[T]he EPA’s rule will make it more difficult for states to issue permits for the construction of new facilities or expansions of existing factories.”

- The committee’s PM2.5 resolution, offered under the Congressional Review Act, seeks to overturn the EPA’s unworkable standard.

Reforming PBMs: PBMs are unregulated middlemen whose business practices drive up health care costs for manufacturers and manufacturing workers.

- “By applying upward pressure to list prices that dictate what patients pay at the pharmacy counter, pocketing manufacturer rebates and failing to provide an appropriate level of transparency about their business practices, PBMs increase health care costs at the expense of all patients in America,” NAM Vice President of Domestic Policy Charles Crain said.

- Provisions in the NAM-supported Telehealth Modernization Act would increase transparency into PBMs’ business practices and delink their compensation from medicines’ list prices.

The last word: “Manufacturers commend the Energy and Commerce Committee for approving these important bills, which will reduce costs and enhance growth at manufacturers across the country—allowing our industry to continue to create jobs here at home and drive U.S. competitiveness on the world stage,” said NAM Managing Vice President of Policy Chris Netram.

Mapping the Impact of a Port Strike

Building permits rose 4.9% in August but are 6.5% lower than August 2023. Permits for single-family homes were 2.8% higher than July but were down 0.5% in the past year. Permits for buildings with five or more units surged 8.4% from July but are down a significant 16.8% in the past year. In August, housing starts increased 9.6% over the month and 3.9% over the year. Starts for single-family homes were up 15.8% from July and 5.2% from August 2023. On the other hand, starts for buildings with five or more units declined 6.7% from July and were down 6.2% from August 2023. Housing completions in August were up 9.2% from July and a significant 30.2% higher than August 2023. Single-family home completions were down 5.6% from July to 1,029,000 but up 8.4% over the year. Completions for buildings with five or more units rose 36.5% and were 79.2% higher than August 2023. In September, Philadelphia’s regional manufacturing activity was mixed. The index for current general business activity turned positive, rising from -7.0 to 1.7. Nearly 22% of firms reported increased activity this month, while 20% reported decreases and nearly 51% reported no change. On the other hand, the indexes for new orders and shipments declined and turned negative. Firms reported an increase in employment after declining last month, with the employment index rising back into positive territory at 10.7. Firms also provided forecasts on production levels, with a higher share of firms reporting an increase in production (nearly 38%) than those reporting a decrease (28%). Price indexes moved higher, with firms continuing to report overall increases in prices. The prices paid index rose to its highest reading since December 2022, reflecting the notable portion of firms experiencing higher input costs. The prices received index also rose, undoing the previous month’s decrease. Looking ahead, most future indicators increased. The index for future general business activity rose slightly to 15.8, indicating growing optimism among firms. A higher proportion of firms still expected increases in activity. Additionally, the new orders, shipments and future employment indexes also rose. Although the future prices paid index increased, the future prices received rose by a larger margin. Meanwhile, the future capital expenditures index moved up to its highest reading since March 2022. Manufacturing activity in New York state grew in September for the first time in nearly a year, with the headline general business conditions index rising 16 points to 11.5. The new orders index climbed 17 points to 9.4, a multiyear high, while the shipments index rose 18 points to 17.9, its highest level in a year and a half. Unfilled orders increased slightly, while inventories rose 11 points to zero, indicating inventories are now level after two months of declines. Delivery times were little changed, and supply availability was the same reading (-2.1) as August. Employment continued to shrink modestly, with the index for the number of employees coming in at -5.7. The average employee workweek recovered some after a steep drop the prior month, signaling a slight increase in hours worked. Input and selling prices were little changed, as reflected in the prices paid index at 23.2 and the prices received index at 7.4. Manufacturers continued to face rising costs while operating in a weakened pricing environment. Firms were more optimistic about the future. The future business activity index rose eight points to 30.6, with nearly 45% of respondents expecting conditions to improve over the next six months. However, the capital spending index fell 11 points, dipping below zero for the first time since 2020. Industrial production rose 0.8% in August after falling 0.9% in July. The decline in July was influenced by shutdowns due to Hurricane Beryl. Manufacturing output increased 0.9%, in part, due to a recovery in motor vehicles and parts production, which jumped nearly 10% in August. Meanwhile, manufacturing output excluding motor vehicles and parts production increased 0.3%. At 103.1% of its 2017 average, total industrial production in August was unchanged from the same month last year. Capacity utilization moved up to 78%, 1.7 percentage points below its long-term average from 1972 to 2023. In August, the majority of major market groups saw gains. The consumer goods index rose 0.7%, with a 10.5% increase in automotive products making up for its loss in the previous month. The materials index grew 0.9%, with gains in all its subcomponents. Defense and space equipment posted a modest increase of 0.5%. The business equipment index rose 1.4%, supported by a 6.6% gain in the transit equipment index. Durable goods manufacturing increased 2.1%. Apart from the large rebound in motor vehicles and parts, there were gains in primary metals (up 3.2%), electrical equipment, appliances and components (up 2.0%) and aerospace and miscellaneous transportation equipment (up 1.2%). Nondurable goods manufacturing, on the other hand, decreased 0.2% in August, with the largest losses in petroleum and coal products (down 2.3%) and apparel and leather (down 1.6%). Manufacturing capacity utilization increased 0.6% to 77.2%, which is 1.1 percentage points below the long-term average.Signs of a Rebound for Residential Construction

Philadelphia Fed Manufacturing Survey Turns Positive in September

NY State Manufacturing Activity Grows for the first time in 2024

Industrial production bounces back in August