Manufacturers Share Immediate Impacts Under Latest Tariffs

As three of the largest U.S. retailers—Walmart, Home Depot and Target—this week warned President Trump that his tariff policy could empty store shelves within weeks, upend supply chains and raise consumer prices, the tariffs already in place on imported goods are having effects on those who make things in America.

Speaking up: Manufacturers in the U.S. are sharing their stories of increased cost pressures and uncertainty, both the result of new tariffs. Makers of everything from machinery to bicycles to food service equipment are reporting ill effects.

- For Craig Souser, president and CEO of robotic packaging solutions manufacturer JLS Automation in York, Pennsylvania, steel tariffs in particular have had a big—and negative—effect on business.

- “[W]e’re seeing increased costs [in steel] that will eventually get passed along to the customer,” Souser told the York Dispatch (subscription).

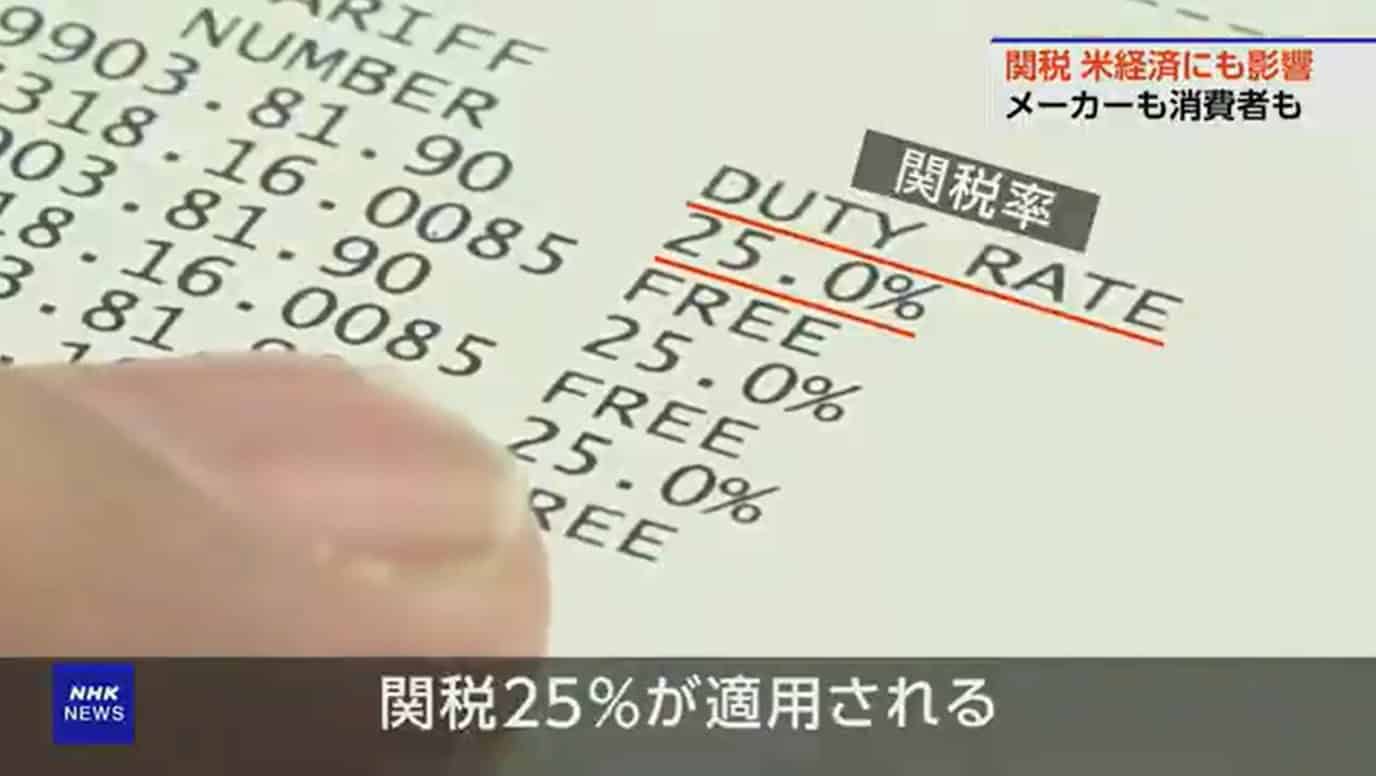

“Writing the checks”: Chuck Dardas, president and chief operating officer of Michigan automotive parts manufacturer AlphaUSA, told NHK News recently that his small business and others like it are the ones “writing the checks for” the new tariffs—and it’s not something they can keep up.

- “To absorb 25% or 50% in tariffs, it’s a task that we cannot in the long term endure,” Dardas said. “It’ll cause our company and many other companies our size to probably go out of existence.”

The unknown: Perhaps the hardest part about the new tariffs: the uncertainty they bring, NAM board member Lisa Winton, CEO and co-owner of Georgia-based machinery maker Winton Machine Company, told NPR earlier this month.

- “We just noticed our first invoice that had a tariff line on it,” she said. “There’s just so much unknown right now, and I think that’s the most difficult thing—to make decisions for your company financially when you just don’t know all the pieces to the puzzle.”

No time: Arnold Kamler, chairman of Kent International, a New Jersey bicycle manufacturer, told Fox Business last week that while his business was already moving overseas production to the U.S. when tariffs hit, it has yet to complete the move—and that’s been a problem for his small outfit.

- “We’ve managed to move almost half of our production out of China already, but that’s only [almost] half,” he said. “We need more time. … [W]e’re a small company.”

- During the pandemic, “[e]verybody bought a bicycle”—but “things got very slow after that. … All the money we made during the pandemic is all gone, plus a lot more. Then we have these tariffs. [If the Trump administration had said], ‘Look … in nine months, 10 months, this will be the tariff,’” that might have been doable, he went on. “But we g[ot] two weeks’ notice. It’s impossible to run a company to plan for” that.

Passing on the costs: In Ohio, Wasserstrom Company President Brad Wasserstrom told 10 WBNS that his Columbus-based food service and supply company will most likely have to raise customer prices to pay for the new tariffs.

- “[W]e’re negotiating with suppliers when we can, if there’s any flexibility in what they’re passing on to us,” Wasserstrom said. “Some have been able to do something to help us out. They’re not passing through maybe the full tariff. But very few have said they’re going to pass on nothing.”