The Innovators Quest Gets Students Excited About Manufacturing

Manufacturers have a new opportunity to connect with students and encourage them to explore careers in manufacturing. The Manufacturing Institute (the NAM’s workforce development and education affiliate) has developed a gamified experience called Innovators Quest, specially designed to introduce students to manufacturing-related skills in a fun-filled format.

The experience is made up of four realms in a board game format with hands-on building challenges. As they seek to recover the “Crystal of Innovation,” students in grades 4 through 9 can try their hands at 3D printing, robotics and other crucial skills. Manufacturers can sponsor Innovators Quest sets, which they can take to schools, afterschool programs, local community events, Boys and Girls Clubs and more.

The quest: The conceit of the game is that the aforementioned crystal has fractured, and the students must fix it by completing four challenges in whichever order they choose.

- While the students play collaboratively, completing challenges together, they all take on the role of different innovator characters who have different mixes of manufacturing-related strengths, including “analytical, visual, intuitive, strategic and extroverted.”

- “We want all students to see themselves in at least one of these characters,” MI Director of Student Engagement Jen White explained to us.

The challenges: The four challenges ingeniously explore manufacturing concepts while still entertaining the participants, as the writer of this article can vouch.

- One challenge instructs students to build paper airplanes. But the lesson isn’t just about building—it’s about perfecting and testing your products. The players must make 10 airplanes following two separate designs, then put together an electric plane launcher. Finally, they test their airplanes to see if they sail the necessary 6 feet to “fly away” with a handful of the crystal fragments. Skills and concepts learned: collaboration, iteration, precision, electromechanical building, aerodynamics, following directions and testing.

- A second challenge draws on the principles of additive manufacturing. Players are asked to use 3D pens (which dispense a line of malleable plastic that can be made into shapes or figures) to construct the pieces of a bridge over which the crystal fragments must be transported. Skills and concepts learned: additive manufacturing, precision, following a blueprint, welding parts together, collaborating on different pieces and structural integrity.

We won’t spoil the other two realms, but they involve a similar blend of fun challenges and manufacturing skills exploration—including the construction of a small robotic toy and a test of deductive reasoning.

The bottom line: “Innovators Quest was developed based on proven approaches to empower manufacturing employers to engage students early and often,” said MI President and Executive Director Carolyn Lee. “By sparking their interest in skills needed in modern manufacturing, this student engagement tool illustrates the limitless possibilities of the many careers in our industry. The time to invest in our future workforce is now.”

- “Innovators Quest is an important initiative that will provide students with early knowledge about the variety of opportunities for a career in manufacturing and highlights the value of teamwork, collaboration and communication in the production environment,” said American Honda Motor Co. Executive Vice President Bob Nelson. “We’re proud to continue our partnership with the Manufacturing Institute to build that future workforce.”

Learn more: Learn more about Innovators Quest and how your company can sponsor a kit to build manufacturing career awareness in your community. To secure a sponsorship before the 2025–2026 school year begins, contact [email protected].

Women MAKE Awards to Honor Outstanding Women in Manufacturing

The Manufacturing Institute—the workforce development and education affiliate of the NAM—has announced the recipients of the 2025 Women MAKE Awards, honoring some of the most impressive and inspiring women in the manufacturing industry today.

The awards, which will take place in Washington, D.C., on April 24, will highlight 130 individuals who have demonstrated excellence and leadership in their careers across all levels of the manufacturing industry.

The challenge: The manufacturing industry faces a significant talent gap—with more than 400,000 job openings and an estimated 3.8 million positions needing to be filled by 2033.

- Women make up about half of the U.S. labor force, but less than one-third of the manufacturing workforce. Boosting the numbers of women who choose a career in modern manufacturing is essential to closing this gap—and the honorees of the Women MAKE Awards are leading the way.

The initiative: The MI’s Women MAKE America Initiative strengthens the modern manufacturing workforce by elevating and highlighting the women leading the industry at every level—from the shop floor to the C-suite—in order to inspire the next generation and help close the talent gap in the industry.

The awards: Each year, 100 Honorees and 30 Emerging Leaders are chosen from the thousands of nominations submitted to the MI by their peers for making significant contributions to their companies, communities and efforts to cultivate the next generation of skilled talent. Since its inception, the Women MAKE Awards have recognized about 1,700 outstanding individuals.

The MI says: “Every year, more women are finding opportunity and breaking barriers in manufacturing,” said MI President and Executive Director Carolyn Lee. “By elevating these outstanding women for their success, we are showing young women—and everyone else—that manufacturing is a rewarding industry with unlimited potential.”

- “At a time when there is such high demand for talent in our sector, these extraordinary women demonstrate the impactful careers that are available. By elevating role models who are paying it forward, the Women MAKE Awards strengthen the future of the industry by inspiring the next generation.”

Manufacturing leaders say: “With hundreds of thousands of open jobs in manufacturing, it has never been more critical to attract and retain top talent,” said Toyota Senior Vice President of Electric Vehicle Supply Susan Elkington.

- “This year’s Women MAKE Honorees and Emerging Leaders are breaking barriers, leading with innovation and proving there is no limit to what they can achieve in our industry. By amplifying their stories and accomplishments, we inspire others to step into manufacturing and shape its future.”

Learn more: Read about the awardees and learn more about the awards gala.

Lawmakers on Taxes, CHIPS, Trade and Workforce

A day after President Donald Trump’s first address to Congress in his second term, the industry remains on edge amid the growing uncertainty of what’s being called a trade war by some in Washington.

What Congress is saying: We’re starting to see public comments from members of Congress on various topics in the president’s speech on Tuesday. Here’s what they’re saying.

Tax reform: House Ways and Means Committee Chairman Jason Smith (R-MO) committed yesterday to delivering a comprehensive tax bill to President Trump by Memorial Day, according to MarketWatch. Echoing NAM President and CEO Jay Timmons’ repeated calls for a swift tax deal, Chairman Smith emphasized the urgency of providing certainty to small businesses and working families, stating, “Failure is not an option.”

- “[W]e have to move this one big, beautiful bill as quickly as possible,” he said.

- In recent weeks, Timmons has leveraged the NAM’s public platform extensively—including through the NAM State of Manufacturing Address, television and radio interviews across the country, social media and op-eds in Ohio and Florida—to press Congress to act now and make the 2017 tax reforms permanent.

CHIPS: New Sen. Jon Husted (R-OH), the former lieutenant governor of the state, expressed support for the CHIPS and Science Act, emphasizing its bipartisan backing and importance of national security. “For the economic and national security of America, we need to make chips in the USA—I believe this is part of an America First agenda,” he wrote in a statement provided to The Columbus Dispatch.

- House Speaker Mike Johnson (R-LA) indicated to Punchbowl that nothing would be discussed on the CHIPS and Science Act until the president’s FY 26 budget.

- Sen. Todd Young (R-IN) said that the president’s mention of the act in his speech was “not consistent with the extensive conversations we’ve had with the administration about the many successes and future of the CHIPS program and how it helps with our shared goal of creating a robust domestic chips supply.”

Trade and workforce: “As I’ve said, tariffs are a tool in the toolbox, but they must be strategic and support American jobs—not create uncertainty that undercuts our domestic manufacturing,” Rep. Debbie Dingell (R-MI) told the Detroit Free Press. “The domestic auto industry currently relies on an integrated North American supply chain, and our trade policies need to reflect that.”

- Sen. Thom Tillis (R-NC) zeroed in on implementation of any tariffs. “If you’re talking about tariffs that are going to be inflationary, causing all kinds of retaliation and disrupting the markets, I’m almost certainly against them,” he said in an interview with CQ Roll Call. “However, if you’re talking about tariffs that are used surgically … to be used judiciously and to build the economy, then I’m all for it.”

- For Sen. Kevin Cramer (R-ND), according to The Wall Street Journal (subscription), “It comes down to how long [the tariffs] would last.” He said you “can’t simply turn on and off an inflationary switch” or flip a switch to build manufacturing facilities in the U.S., “or even harder yet, get the workforce to fill those jobs that would be created, particularly at the same time as you’re shirking immigration.”

Big picture: “Manufacturers are already planning for 2026, and they need the certainty to invest and grow now. We’re seeing bipartisan interest in these priorities, and the NAM is building consensus to achieve exactly that and have even stronger champions for manufacturers in Congress to reinforce what we need to compete and win,” said NAM Executive Vice President Erin Streeter.

The State of the Manufacturing Workforce in 2025

The NAM kept up a breakneck pace on the third day of its 2025 Competing to Win Tour, with the Manufacturing Institute delivering the first-ever State of the Manufacturing Workforce Address at Drake State Community and Technical College in Huntsville, Alabama, before an audience of students, faculty, manufacturers and local and state officials.

Opportunity—for all: Taking the stage to give the MI’s assessment of the manufacturing worker base in 2025, Carolyn Lee, president of the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate, homed in on the theme of opportunity.

- “Manufacturing is not just about innovation and economic growth; it’s about opportunity. It’s about ensuring that every community, every aspiring maker, builder and creator—no matter their background—can have access to the skills, training and careers that will define the future.”

- But because the industry stands at a crossroads, part of that opportunity today is to help manufacturing maintain its momentum, Lee said, echoing a theme of NAM President and CEO Jay Timmons’ 2025 State of Manufacturing Address on Tuesday.

Finest hours ahead: Lee was joined at the event by Rep. Dale Strong (R-AL), who spoke about the strength of Alabama’s manufacturing sector.

- “I think we’ve proven here in Alabama, and North Alabama especially, advanced manufacturing is part of our DNA,” he said. “You look at the jobs that we’ve brought in the last 10 or 15 years. You start with GE Aviation, Polaris, Toyota Motor Manufacturing, Mazda Toyota. We’ve proven that the Alabama workforce has the ability. I think our finest hours are still ahead.”

A world-changing job: Timmons echoed that sentiment. “You’re stepping into one of the most important and innovative fields in the world,” he told the Drake State students.

- “The products, the materials, the technologies that you will help create, they won’t just be used in your hometown or even all across our country. They’re going to help change economies … They’re going to strengthen the very foundation of America’s security and prosperity.”

A shortfall: But manufacturing today faces an immense challenge, Lee told the crowd: “a structural workforce deficit.”

- “[I]f we don’t act boldly, the U.S. faces a shortfall of 1.9 million manufacturing workers by 2033; 3.8 million positions will open up, but nearly half could go unfilled. That’s not just a workforce issue—it’s an economic and national security issue.”

- That’s despite the average annual earnings—including pay and benefits—for a manufacturing employee coming in at more than $102,000.

- The dearth of workers in the sector is driven by both retirements and growth.

How to overcome it: “[W]e have to inspire more Americans to see themselves in manufacturing,” Lee said. “That starts early, with programs that spark curiosity and excitement for careers in our industry. And when I say early, I mean as young as 9 or 10 years old—because today’s 4th graders will graduate in 2033 and may be our future team members.”

- To this end, the MI partners each year with manufacturers on MFG Day, which kicks off a full month of events at which companies show young people, students and job seekers what a modern manufacturing career looks like.

- The MI, with the support of Honda, has also created a new interactive experience to interest youngsters in the industry: “Innovators Quest,” which combines elements of board games and popular fantasy and storytelling activities.

The FAME factor: Under the MI’s auspices, the Federation for Advanced Manufacturing Education USA, a workforce program started by Toyota in 2010 and entrusted to the MI in 2019, has grown considerably. (Drake State is home to one of the public–private partnership’s newest chapters.)

- FAME participants attend classes and earn while they learn in hands-on apprenticeships with manufacturers.

- The program—in which a participant can easily earn more than $30,000 over two years—has become “the gold standard for how employers, educators and communities should work together” on manufacturing workforce training, Lee said.

Other efforts: The MI helps manufacturers actively recruit groups often overlooked in manufacturing hiring initiatives: veterans, women and previously incarcerated individuals.

- The Heroes MAKE America program helps connect former members of the military with manufacturing jobs. Walmart provides crucial funding to the program; in 2022, it gave a six-figure grant to fund the development of a model that translates skills acquired in the military to ones recognized by manufacturing employers.

- The Women MAKE America Initiative is the nation’s premier program aimed at closing the gender gap in the sector.

- “The MI is helping manufacturers develop second chance hiring strategies, recognizing that talent is talent—and potential shouldn’t be wasted,” Lee said to the audience.

Working together: “As we look ahead, manufacturers, educators and policymakers must work together to strengthen our talent pipeline,” Lee and Drake State Community and Technical College President Dr. Patricia G. Sims wrote in a Thursday op-ed for the Alabama Political Reporter.

Manufacturing in Alabama: On Thursday afternoon, the NAM and MI contingent continued its manufacturing-facility tour, visiting Toyota Motor Manufacturing Alabama and Bruderer Machinery—both in Huntsville—and Milo’s Tea Company in Bessemer.

- “I plan on making my career here,” said Drew, a 2024 FAME graduate, during a discussion before a tour of the shop floor. Drew is now working as a maintenance team member at Toyota Alabama. The talk focused on how the FAME program prepared participants for a rewarding career in auto manufacturing. Toyota Alabama—2,400-plus team members strong—has created 10,000 jobs in the state.

- Lee visited Bruderer Machinery, a leading manufacturer of high-precision stamping presses that provides solutions for the automotive, aerospace and electronics industries. Bruderer is also a key supporter of the FAME apprenticeship model.

- Timmons and the rest of the NAM team finished the day at Milo’s Tea, the fastest-growing tea company in America. The family-owned business, founded by CEO Tricia Wallwork’s grandparents Milo and Bea Carlton, has won 40% of the refrigerated iced tea market share in the U.S. “This reminded me of my grandmother’s iced tea,” said Timmons. “You could see how special Milo’s is by just walking the shop floor and seeing the smiles and camaraderie.”

Timmons: Tax Reform Paramount for Manufacturing Growth

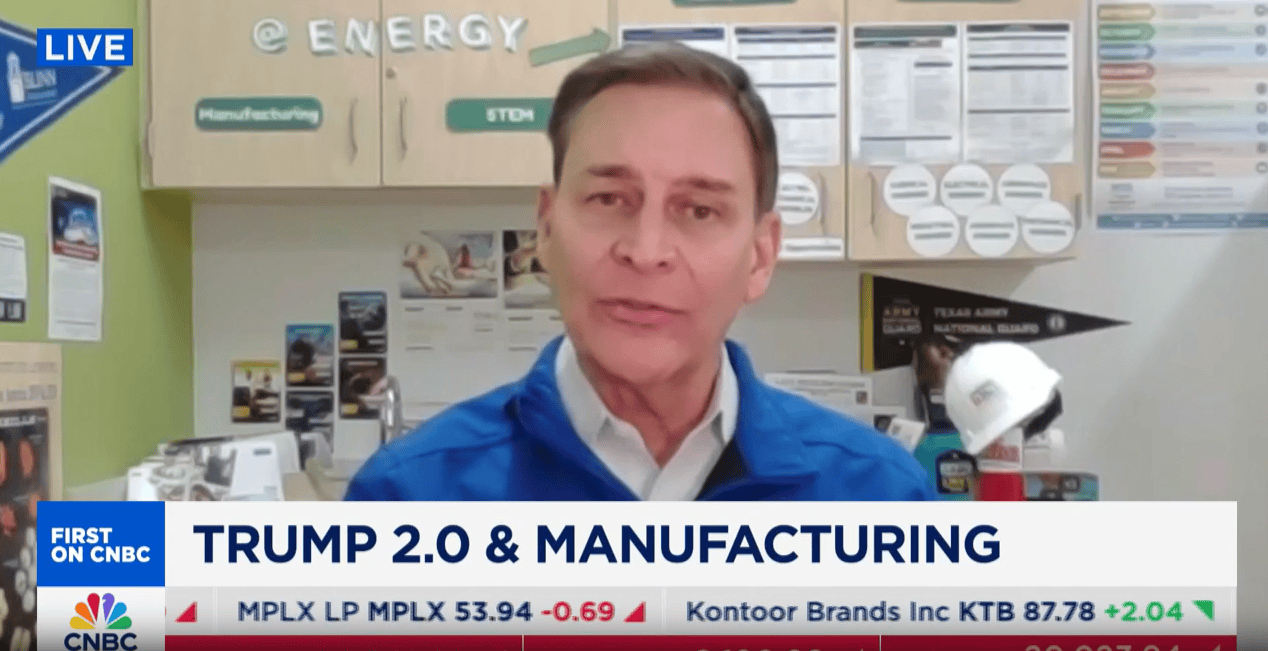

Manufacturers need an integrated, comprehensive strategy for expanding their sector, and a large part of that is preserving and bringing back tax reforms, NAM President and CEO Jay Timmons said on CNBC’s “The Exchange” Wednesday.

What’s going on: Timmons spoke to the news channel from a teacher workroom at the Energy Institute High School in Houston, Texas, a stop on the first leg of the NAM’s 2025 Competing to Win Tour. He told show host Kelly Evans that any plans to bolster manufacturing in the U.S. must “start with renewing those tax reforms from 2017.”

- “A smart strategy is going to involve reducing the cost of doing business for manufacturers here in the United States,” he said, praising Republican House leadership for being “able to move” forward a House budget bill “that’s going to set the framework for those tax rates to be set, hopefully, permanently in stone.”

- The 665-student Energy Institute High School, led by Principal Lori Lambropoulos, is the first high school in the U.S. dedicated to preparing students for careers in the energy industry.

What else is needed: Timmons echoed some of the major themes from the NAM State of Manufacturing Address, which he gave Tuesday in Ohio.

- “We also are looking at regulatory reform,” he told Evans. “We’re looking at expanding our energy dominance. We’re looking at workforce policy … and then, of course, we have to have a sensible trade policy as well.”

But back to taxes: Bringing back expired provisions from the 2017 Tax Cuts and Jobs Act, and making them and other, scheduled-to-expire provisions from the legislation permanent, is critical to manufacturing’s future success, Timmons continued.

- “Ninety percent of my 14,000 members are small and medium manufacturers. Most of them benefit from the pass-through deduction that expires this year. And I don’t think what you want to see is a huge tax increase that will cost 6 million jobs in the economy happen if we don’t renew those reforms,” he said, citing data from a recent NAM study on the effects of a congressional failure to act on tax reforms.

- “That’s why the Speaker’s actions in the last day or so have been so incredibly important to get this thing moving forward. President Trump actually endorsed that bill—the ‘one big, beautiful bill,’ as he calls it—and that will help make America great again for manufacturing.”

Energy dominance: Also critical to the success of manufacturing and the U.S. economy as a whole: the right energy policies, Timmons said. Promising to “unleash the energy sector,” President Trump lifted the previous administration’s ban on liquefied natural gas exports on his first day in office.

- Yesterday, the NAM got to see first-hand some of the effects of that kept promise, when the team visited Freeport LNG’s liquefaction facilities near Houston.

- More than 9,000 construction jobs were created during the construction of those facilities, which now directly employ about 400 people. Their operations have an estimated total positive economic impact on the U.S. economy of more than $5 billion a year.

- “Energy is … a critical national security component,” Timmons said on CNBC.

Emphasis point: The tour also stopped at Bray International, a global leader in flow control and automation solutions, supporting U.S. energy dominance, LNG exports and high-tech manufacturing.

- The visit helped underscore why policies that support manufacturing investment and provide certainty to manufacturers are essential to America’s economic future.

Up next: Today, the NAM is in Alabama, where this morning Manufacturing Institute President and Executive Director Carolyn Lee gave the Manufacturing Institute’s State of the U.S. Manufacturing Workforce Address at Drake State Community & Technical College in Huntsville. (The MI is the NAM’s 501(c)3 workforce development and education affiliate.) The theme: building the workforce of the future.

- This afternoon, the team will tour Toyota Motor Manufacturing Alabama in Huntsville, the manufacturing facilities of Bruderer Machinery in Huntsville and Milo’s Tea Company in Bessemer.

State of Manufacturing 2025: When Manufacturing Wins, America Wins

“Manufacturing in the U.S. has momentum”—and to keep it going, manufacturers will need to push, NAM President and CEO Jay Timmons said Tuesday in the NAM’s annual State of Manufacturing Address.

What’s going on: Speaking to an audience of manufacturers and congressional and state officials at Armstrong World Industries in Hilliard, Ohio, Timmons, who was joined by NAM Board Chair and Johnson & Johnson Executive Vice President and Chief Technical Operations & Risk Officer Kathy Wengel, emphasized the “defining moment” for the industry and said that for manufacturing, “what happens next really matters.”

- “Uncertainty is the enemy of investment,” he told the crowd. “Manufacturing is a capital-intensive industry. We make decisions months and years in advance. … That’s why we need certainty. We need a clear, actionable, multistep strategy from our government—one that says, ‘We want you to invest here, hire here and succeed here.’”

- Timmons’ annual speech kicked off the NAM’s 2025 Competing to Win Tour, starting with a whirlwind four-states-in-four-days tour of manufacturing facilities, schools, government offices and more.

- “In Ohio, manufacturers have thrived because our leaders have taken decisive actions to keep our industry competitive,” Ohio Manufacturers’ Association President Ryan Augsburger said at the kickoff event. But now, “manufacturers across Ohio and the nation are facing critical challenges, from tax uncertainty, project delays and workforce shortages to supply chain vulnerabilities and price pressures that threaten our ability to grow. … These issues cannot wait.”

What manufacturing needs: Certainty from the federal government should come in several forms, Timmons said, including the following:

- Preserving tax reform: The 2017 tax reforms were “rocket fuel” for manufacturing in America—but key provisions have expired and others are scheduled to sunset. Congress must bring them back and improve and extend the package. “Every day that Congress delays because of process and politics, manufacturers face rising uncertainty, delayed investments and fewer jobs,” said Timmons.

- Regulatory clarity and consistency: Manufacturers today spend a total of $350 billion just to comply with regulations. “Commonsense regulation is critical to American manufacturers to continue to innovate, to compete against foreign manufacturers and to improve the lives of American citizens,” Austin So, general counsel, head of government relations and chief sustainability officer for Armstrong World Industries, told the crowd.

- Permitting reform: President Trump’s lifting of the liquefied natural gas export permit ban was a start, but to reach our full potential as energy leader, we must require “federal agencies to make faster decisions and reduc[e] baseless litigation,” said Timmons.

- Energy dominance: “America should be the undisputed leader in energy production and innovation. But … we are seeing opportunities for energy dominance fade in the face of a permitting process that takes 80% longer than other major, developed nations,” Timmons said, adding that we must cut red tape, require federal agencies to make faster decisions and reduce meritless litigation.

- Workforce strategy: By 2033, manufacturing faces a shortfall of 1.9 million manufacturing employees, Timmons said. To fill those positions, the sector needs a “real workforce strategy,” one that includes apprenticeships, training programs and public–private partnerships.

- Commonsense trade policy: If President Trump continues to use tariffs, “we need a commonsense policy … that provides manufacturers with the certainty to invest” and “a clear runway to adjust,” according to Timmons.

State of manufacturing: “Manufacturing in the United States is moving forward,” Timmons said. “Like a press at full speed, like a production line firing on all cylinders, like the workers who show up before dawn and leave long after the job is done—manufacturing in the United States is driving us forward.” And Timmons added that now it’s time “to make America Great for Manufacturing Again.”

On the move: Following the speech, Timmons, Wengel and Augsburger joined state lawmakers, including state Sens. Kristina Roegner and Andrew Brenner, and local business leaders for a visit to the Ohio Statehouse for an event focused on the importance of tax reform for Ohio and its manufacturing sector.

- A recent NAM study found that, if key provisions of tax reform are allowed to expire, Ohio would risk losing 208,000 jobs and $18.9 billion in wages.

What’s at stake: Tax reform was transformational for Humtown Products, the Columbiana, Ohio–based family-owned sand cores and molds manufacturer, President and CEO Mark Lamoncha told the audience at the Ohio Statehouse tax event.

- “We have been at the forefront of 3D-printed manufacturing for years and have invested significantly in the machinery and equipment required, including the purchase of 3D printers—one of which can easily cost over $1 million,” he said.

- “Since the 2017 tax reform, Humtown has invested over $9 million in capital expenditures related to 3D printing and averages around $100,000 annually in R&D costs. Under the 2017 tax reform, we were able to deduct 100% of those costs, generating around $1.6 million in accelerated tax savings.”

- “That amount alone allowed us to purchase another 3D printer, fueling continued growth. That’s what tax certainty allowed us to do. But right now, that certainty is slipping away. As these provisions begin to expire, our tax burden is increasing.”

Creators Wanted: The group also fit in a stop at Columbus State Community College, which serves approximately 41,000 students, to visit with students in the semiconductor and mechanical drive classes.

The last word: The NAM recently “stood shoulder-to-shoulder with congressional leaders—delivering a clear, urgent message on tax reform” and is “driving the agenda on regulatory certainty, on energy dominance, on permitting reform, health care and workforce development,” Wengel told the audience. “The NAM is not waiting for Washington to act; we are making sure Washington acts for you, for manufacturers.”

- Added NAM Executive Vice President Erin Streeter: “The NAM is on [these issues], and we’re going to keep fighting, as we do every day with the right leaders, the right strategies and the right vision for the future.”

Manufacturers: AI Regulations Should Support Innovation and U.S. Leadership

The introduction of artificial intelligence has been a boon to manufacturing, and the technology will continue to have a positive impact—as long as regulations are “right-sized,” manufacturers told Congress this week.

What’s going on: “Manufacturers are utilizing AI in myriad ways on the shop floor and throughout their operations,” the NAM told the House Subcommittee on Commerce, Manufacturing and Trade in a statement for the record at Wednesday’s hearing, where data was cited.

- “The diverse use-cases of AI in manufacturing suggest a need for a cautious regulatory approach to this groundbreaking technology: one that supports innovation and U.S. leadership in AI while providing context-specific, risk-based, right-sized rules of the road for manufacturers,” the NAM said.

- Giving testimony at the hearing, Siemens USA President and CEO and NAM Board Member Barbara Humpton discussed the many benefits of using AI in manufacturing and emphasized the need to ensure that AI regulations include “targeted” rather than “overly broad” definitions.

Industrial vs. consumer-focused AI: First, it’s important to distinguish between industrial and consumer-facing AI, Humpton told the subcommittee members.

- “Industrial AI is different from consumer AI,” she said. “Industrial AI uses controlled data from the manufacturing environment to help manufacturers create business value. Think better products, more efficient operations, a more prepared workforce. … AI will enable all companies—from startups to small and medium enterprises to industrial giants—to thrive in this new era of American manufacturing.”

- In written testimony, she added that “the core distinction of industrial AI is that it is trained on highly monitored data from sensors and machines, providing a more reliable foundation for training AI models.”

Simple, singular and targeted: Regulation of AI should be undertaken with a light touch and following a full accounting of on-the-books laws to prevent duplicative and/or contradictory rules, the NAM said.

- “[P]olicymakers should always review existing laws and regulations before enacting new ones, because most uses of AI correspond to tasks and objectives that industry has faced for a long time and that are thus highly likely to have already been addressed by existing laws and regulations,” said the NAM, which also referenced its first-of-its-kind AI report, “Working Smarter: How Manufacturers Are Using Artificial Intelligence,” released last May.

- “Similarly, policymakers must right-size any compliance burden associated with AI regulation,” the NAM continued. “The ubiquitous use of AI throughout modern manufacturing, as well as manufacturing’s dependence on innovation, underscore the need for rules that enable rather than hinder manufacturers’ development and adoption of AI systems.”

Protect without hindering: Congress “must advance industrial AI by prioritizing strong rules for digital trade, especially to include strong protections for source code and algorithms,” Humpton went on in her written testimony. “We encourage policymakers to build upon the success of previous U.S.-led efforts to protect intellectual property.”

- Legislators must also safeguard privacy and protect against baseless legal claims, the NAM said. “[I]t is … crucial that Congress take steps to maintain the privacy of personal data when utilized in AI contexts. … A federal standard should avoid a patchwork of state-level rules by fully preempting state privacy laws; it also should protect manufacturers from frivolous litigation.”

The last word: “The range and importance of uses of AI—transforming every aspect of the core of manufacturers’ operations—make it clear that AI has become integral to manufacturing,” said the NAM. “With the right federal policies, manufacturers in the U.S. will continue to devise new and exciting ways to leverage AI to lead and innovate and stay ahead of their global competitors.”

Manufacturer Sentiment Declines

Manufacturer sentiment fell in the third quarter of this year, according to the NAM’s Q3 2024 Manufacturers’ Outlook Survey, out Wednesday.

What’s going on: Results of the survey, which was conducted Sept. 5–20, reflect “preelection uncertainty,” NAM President and CEO Jay Timmons said—but also larger economic concerns.

- “The good news is that there is something we can do about it,” said Timmons. “We will work with lawmakers from both parties to halt the looming tax increases in 2025; address the risk of higher tariffs; restore balance to regulations; achieve permitting and energy security; and ease labor shortages and supply chain disruptions.”

Key findings: Notable data points from the survey include the following:

- Some 62.9% of respondents reported feeling either somewhat or very positive about their business’s outlook, a decline from 71.9% in Q2.

- A weaker domestic economy was the top business challenge for those surveyed, with 68.4% of respondents citing it.

- Nearly nine out of 10 manufacturers surveyed agreed that Congress should act before the end of 2025 to prevent scheduled tax increases on manufacturers.

- The overwhelming majority—92.3%—said the corporate tax rate should remain at or below 21%, with more than 71% saying a higher rate would have a negative impact on their businesses.

- More than 72% said they support congressional action to lower health care costs through the reform of pharmacy benefit managers.

The last word: “When policymakers take action to create a more competitive business climate for manufacturers, we can sustain America’s manufacturing resurgence—and strengthen our can-do spirit,” Timmons said.

- “This administration and Congress—and the next administration and Congress—should take this to heart, put aside politics, personality and process and focus on the right policies to strengthen the foundation of the American economy.”

Solving the Talent Equation at the MI’s Workforce Summit

More than 300 leaders and experts gathered in Minneapolis last week to discuss the industry’s talent challenges, from hiring to training and retaining. The Manufacturing Institute’s annual Workforce Summit convened manufacturers, partners from education and training groups, philanthropy leaders and representatives from community-based organizations to share insights and brainstorm solutions.

The backdrop: With more than 500,000 open jobs in the industry, manufacturing leaders are intent on solving the talent equation.

- MI Chief Program Officer Gardner Carrick provided context for attendees. “For the last 7+ years, manufacturers have told the MI that the single biggest challenge they face is finding the right people to employ,” he said. “It is the crisis right in front of us.”

- Carrick urged attendees to “act now, because the system needs help.” However, he also noted that this crisis will take time to fix, saying that manufacturers should “be patient, but be committed.”

Quick insights: The participants brought many new ideas and fresh perspectives to the gathering. Here are some of the highlights:

- Recruitment and hiring: NTT DATA led a session on artificial intelligence technologies that can help with talent attraction, while other sessions focused on changing Americans’ perceptions of the industry and demonstrating that manufacturing is a “cool” field to work in.

- Retention: Mark Rayfield, CEO of Saint-Gobain North America and CertainTeed, highlighted the importance of culture as a retention tool, saying, “Culture is everything. Employees want to work for a place where they are respected.” In a separate session, Jill Wyant, president and CEO of Madison Air, shared why their cultural value of frontline obsession guides how they attract and retain their frontline employees.

- Training: One session focused on training frontline supervisors in methods that boost retention of frontline workers. Other sessions focused on using the FAME USA model (of combined accreditation and training) to cultivate talent for manufacturing facilities.

- Preparing the next generation: Ketchie Inc.’s Andy Silver spoke about the company’s Opportunity Knocks program, an unpaid internship program for high school students that offers real-world learning experience and mentorship. Programs like these can transform young people’s perceptions of the manufacturing industry and set them on rewarding career paths, as Silver noted.

Did you miss it? Don’t worry! There are plenty of ways to get involved in the solutions being driven by the MI, the NAM’s 501(c)3 workforce development and education affiliate.

- Check out the MI’s Solutions Center, a new initiative that will provide manufacturers innovative resources and opportunities to access solutions and best practices on how to tackle the challenges of recruiting, training and retaining talent in today’s competitive landscape. Attendees got a first look, but now we’re sharing it with everyone.

- Get updates directly from the MI on the latest workforce insights and receive information about registering for next year’s Workforce Summit in Charlotte, North Carolina, taking place Oct. 20–22, 2025.

- Want more labor data and insights? Sign up for the MI’s comprehensive Workforce in Focus newsletter to stay up to date on the latest workforce trends.

The last word: “The MI and manufacturers across the country are changing the narrative, raising awareness and finding new ways to get people in the door and retain them,” said MI President and Executive Director Carolyn Lee. “As we face workforce shortages and retention challenges, events like the MI’s Workforce Summit are necessary to help the industry share important insights and ensure the readiness of the future manufacturing workforce.”

Manufacturers Help Those Affected by Hurricane Helene

Within days of Hurricane Helene’s landfall, manufacturers were reaching out to help those who had been affected.

What’s going on: Companies from an array of industries are volunteering their resources, time and energy to getting storm victims essential items. Helene, which made landfall in Florida last Thursday, has killed at least 189 people and left more than 1.2 million customers without power (ABC News).

- Toyota is matching donation contributions made by its U.S.-based employees to the American Red Cross, disaster relief organization SBP and other nonprofits. The auto manufacturer is also offering payment relief options to those affected.

- Norfolk Southern Corp. has donated $100,000 to the American Red Cross, which is undertaking relief work across multiple states, including North Carolina, Florida, Georgia and Tennessee. The company’s Employee Disaster Relief Program is also giving employees affected by the storm grants for qualified expenses and losses.

- DENSO North America Foundation, the philanthropic group of global automotive components manufacturer DENSO, is donating $200,000 to the American Red Cross in support of disaster relief across southeastern states.

- Procter & Gamble’s Disaster Relief is partnering with Walmart and Matthew 25: Ministries, an international aid organization, in their recovery efforts in the hard-hit Florida cities of Perry and St. Petersburg. P&G resources will go toward a Tide Loads of Hope Mobile Laundry Unit, powered by Matthew 25: Ministries, to offer free, full-service laundry to responders and affected residents. Shower trailers with hot water will also be provided.

Additional resources: SBP and Good360 offer manufacturers disaster preparedness resources and training when natural disasters hit.

- “Hurricane Helene has been devastating, leaving many without access to power and vital resources,” NAM President and CEO Jay Timmons wrote in a social post Wednesday. “Manufacturers looking for recovery resources or looking to provide supplies can connect with SBP via sbpusa.org and Good360 via good360.org.”

Share your stories: Are you helping those affected by Helene? Tell us how by emailing [email protected].