Solving the Talent Equation at the MI’s Workforce Summit

More than 300 leaders and experts gathered in Minneapolis last week to discuss the industry’s talent challenges, from hiring to training and retaining. The Manufacturing Institute’s annual Workforce Summit convened manufacturers, partners from education and training groups, philanthropy leaders and representatives from community-based organizations to share insights and brainstorm solutions.

The backdrop: With more than 500,000 open jobs in the industry, manufacturing leaders are intent on solving the talent equation.

- MI Chief Program Officer Gardner Carrick provided context for attendees. “For the last 7+ years, manufacturers have told the MI that the single biggest challenge they face is finding the right people to employ,” he said. “It is the crisis right in front of us.”

- Carrick urged attendees to “act now, because the system needs help.” However, he also noted that this crisis will take time to fix, saying that manufacturers should “be patient, but be committed.”

Quick insights: The participants brought many new ideas and fresh perspectives to the gathering. Here are some of the highlights:

- Recruitment and hiring: NTT DATA led a session on artificial intelligence technologies that can help with talent attraction, while other sessions focused on changing Americans’ perceptions of the industry and demonstrating that manufacturing is a “cool” field to work in.

- Retention: Mark Rayfield, CEO of Saint-Gobain North America and CertainTeed, highlighted the importance of culture as a retention tool, saying, “Culture is everything. Employees want to work for a place where they are respected.” In a separate session, Jill Wyant, president and CEO of Madison Air, shared why their cultural value of frontline obsession guides how they attract and retain their frontline employees.

- Training: One session focused on training frontline supervisors in methods that boost retention of frontline workers. Other sessions focused on using the FAME USA model (of combined accreditation and training) to cultivate talent for manufacturing facilities.

- Preparing the next generation: Ketchie Inc.’s Andy Silver spoke about the company’s Opportunity Knocks program, an unpaid internship program for high school students that offers real-world learning experience and mentorship. Programs like these can transform young people’s perceptions of the manufacturing industry and set them on rewarding career paths, as Silver noted.

Did you miss it? Don’t worry! There are plenty of ways to get involved in the solutions being driven by the MI, the NAM’s 501(c)3 workforce development and education affiliate.

- Check out the MI’s Solutions Center, a new initiative that will provide manufacturers innovative resources and opportunities to access solutions and best practices on how to tackle the challenges of recruiting, training and retaining talent in today’s competitive landscape. Attendees got a first look, but now we’re sharing it with everyone.

- Get updates directly from the MI on the latest workforce insights and receive information about registering for next year’s Workforce Summit in Charlotte, North Carolina, taking place Oct. 20–22, 2025.

- Want more labor data and insights? Sign up for the MI’s comprehensive Workforce in Focus newsletter to stay up to date on the latest workforce trends.

The last word: “The MI and manufacturers across the country are changing the narrative, raising awareness and finding new ways to get people in the door and retain them,” said MI President and Executive Director Carolyn Lee. “As we face workforce shortages and retention challenges, events like the MI’s Workforce Summit are necessary to help the industry share important insights and ensure the readiness of the future manufacturing workforce.”

Manufacturers Help Those Affected by Hurricane Helene

Within days of Hurricane Helene’s landfall, manufacturers were reaching out to help those who had been affected.

What’s going on: Companies from an array of industries are volunteering their resources, time and energy to getting storm victims essential items. Helene, which made landfall in Florida last Thursday, has killed at least 189 people and left more than 1.2 million customers without power (ABC News).

- Toyota is matching donation contributions made by its U.S.-based employees to the American Red Cross, disaster relief organization SBP and other nonprofits. The auto manufacturer is also offering payment relief options to those affected.

- Norfolk Southern Corp. has donated $100,000 to the American Red Cross, which is undertaking relief work across multiple states, including North Carolina, Florida, Georgia and Tennessee. The company’s Employee Disaster Relief Program is also giving employees affected by the storm grants for qualified expenses and losses.

- DENSO North America Foundation, the philanthropic group of global automotive components manufacturer DENSO, is donating $200,000 to the American Red Cross in support of disaster relief across southeastern states.

- Procter & Gamble’s Disaster Relief is partnering with Walmart and Matthew 25: Ministries, an international aid organization, in their recovery efforts in the hard-hit Florida cities of Perry and St. Petersburg. P&G resources will go toward a Tide Loads of Hope Mobile Laundry Unit, powered by Matthew 25: Ministries, to offer free, full-service laundry to responders and affected residents. Shower trailers with hot water will also be provided.

Additional resources: SBP and Good360 offer manufacturers disaster preparedness resources and training when natural disasters hit.

- “Hurricane Helene has been devastating, leaving many without access to power and vital resources,” NAM President and CEO Jay Timmons wrote in a social post Wednesday. “Manufacturers looking for recovery resources or looking to provide supplies can connect with SBP via sbpusa.org and Good360 via good360.org.”

Share your stories: Are you helping those affected by Helene? Tell us how by emailing [email protected].

A Navy Vet Finds a New Mission

Many people imagine that a job in manufacturing requires working on a shop floor to create products. Joseph Fields—a human resources professional at MGX Equipment Services—knows that isn’t the case.

“Working in MGX, there’s cranes and welding and engineering—but there’s also HR, and finance, and payroll, and employee health and safety,” said Fields. “There are lots of opportunities you can lean into.”

The background: Fields spent eight years as a yeoman in the U.S. Navy before he transitioned into a civilian role in 2000. Over the course of the next two decades, he worked in human resources at a variety of companies. However, he was laid off in October 2023 after a six-year stint when his employer downsized.

- A few days later, he attended a virtual career fair sponsored by Heroes MAKE America—a Manufacturing Institute program that builds connections between the military community and the manufacturing industry—and found his new role.

- “I wasn’t planning to go to the HMA career fair, because I had zero experience with manufacturing,” said Fields. “But I saw it on LinkedIn, and at the time, I hadn’t interviewed with anyone in six years. I figured this would be a good opportunity to talk about myself and get some feedback.”

The result: Fields didn’t just get feedback, he was offered a job with MGX, one of the manufacturers in attendance.

- “I met with lots of great companies, including a manager at MGX, and we had a great conversation,”

said Fields. “She called me the next day and asked if I was interested in an HR position. They offered it to me the week after Thanksgiving.”

said Fields. “She called me the next day and asked if I was interested in an HR position. They offered it to me the week after Thanksgiving.” - “We are very thankful we found Joseph through Heroes Make America. He attended our virtual career fair and visited our breakout room. After listening to our presentation a few times, he still stayed in our room,” said MGX Director of HR Ashley Barkdoll. “I could tell he would be a great fit for our team after having a few conversations with him.”

The program: Heroes MAKE America provides integrated certification, career-readiness training and job-searching support in partnership with local technical and community colleges to prepare transitioning service members, veterans, National Guard members, reservists and military spouses for rewarding careers in the manufacturing and supply chain industries.

- Heroes also offers virtual and on-site career fairs—like the one where Fields found his new position—for members of the broader military community.

The other side: Today, Fields is paying it forward by working with Heroes MAKE America to find veterans and others with military affiliations to interview with MGX. He’s especially grateful for the support that Heroes gives to graduates and other job seekers throughout the hiring process.

- “I like that Heroes MAKE America not only promotes organizations that focus on veteran hiring, but also that they do the follow-up to make sure people get hired,” said Fields.

Advice to veterans: Fields wants other veterans to know that manufacturing offers a broad range of opportunities, with something for everyone—and that Heroes MAKE America can help them find it.

- “It’s not about finding a manufacturing job; it’s about finding a job in a manufacturing company,” said Fields. “There are so many different kinds of roles and opportunities.”

- “If you’re unsure about finding a job in manufacturing, attending the virtual career fair is a great option to meet with companies to see what they have to offer, even if you think this industry isn’t something that you would normally consider,” added Barkdoll.

Advice to manufacturers: Fields encourages other employers to connect with the Heroes MAKE America program and see everything that a veteran brings to the table.

- “Some of us may not have hands-on experience for the position you’re trying to fill, but we’re trainable,” said Fields. “So ask yourself: Can I train up for this position?”

The last word: “Take a chance on a veteran,” said Fields. “You’ll get a great employee out of it.”

Heroes MAKE America Draws a Crowd

Nearly 100 veterans attended a manufacturing career fair at Fort Riley, Kansas, last week, including many who had prepared for their new careers via the Heroes MAKE America program (Kansas Biz News).

What’s going on: “The career fair and other events held by Heroes MAKE America and Manufacturing Institute [the NAM’s 501(c)3 workforce development and education affiliate] aim to grow the manufacturing industry’s workers for the advancement of modern manufacturing and offer programs, including informational sessions, career fairs, networking, career readiness, placement support and manufacturing tours.”

- More than 30 regional and national manufacturers had booths at the event.

How it helps: HMA—an MI program with a 90% graduate placement rate—offers career help to job seekers transitioning out of the military and into the civilian workforce. The aid is in the form of training and introductions to manufacturing leaders seeking employees.

- One military member who attended the fair said “she’s received help with resume writing, interviewing for jobs and how to translate military experience into tools you can use in the civilian world.”

- HMA, which hosts virtual career fairs throughout the year, also offers resources to employers. These include online training, courses and access to the research of the Society of Human Resource Management Foundation.

Why it’s important: The industry could create about 3.8 million new manufacturing jobs on net between this year and 2033, according to a new study by Deloitte and the MI.

- However, if the current manufacturing employee deficit is not shored up, approximately half of these jobs—or 1.9 million—could go unfilled.

What’s next: Interested employers can participate in an information session to be held later this month, where they can learn more about attracting, hiring and retaining military talent through upcoming career fairs and virtual hiring events.

The last word: “Members of the military community often possess valuable skills and qualities—such as discipline, teamwork, leadership and problem-solving abilities—that are in demand for manufacturing careers,” said MI President and Executive Director Carolyn Lee.

- “That’s why manufacturers are increasingly connecting with this top talent through an array of resources provided by the MI’s Heroes MAKE America initiative.”

In Search for Workers, One Manufacturer Pulls Out the Stops

Marvin, a window and door manufacturer based in Warroad, Minnesota, is looking thousands of miles south to fill job openings (The Wall Street Journal, subscription).

What’s going on: Marvin employs about 700 people at its Warroad location. With older-generation workers retiring at the rate of about one employee a week and a town population that hasn’t grown in decades, the company “came up with a recruitment plan called ‘The Path North,’ which aims to find workers in Puerto Rico and Florida willing to uproot their families and settle in a cold northern town”—but it’s proving a difficult sell, even with generous relocation bonuses and temporary housing.

- Unemployment in Puerto Rico and Florida is low, so Marvin is fishing for talent in relatively sparsely populated ponds.

- Of the 115 workers who came from Puerto Rico in the past eight or nine months, just 63 remain at the company.

- Marvin has 10 other locations throughout North America.

Why it’s important: Marvin’s challenge is emblematic of “manufacturing in America today. The U.S. population is barely growing, baby boomers are exiting the workforce,” many young people are unaware of the many advantages of working in manufacturing and “[t]here is little political will for lasting immigration reform that could fill workforce gaps.”

- If current trends continue, the U.S. will have 2.1 million open manufacturing positions by 2030, according to a joint study by Deloitte and the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate.

Well worth it: Still, for those who come to Marvin, the rewards are significant.

- The company helps employees find permanent housing and is even an investor in a local apartment complex.

- There is job security, too. When orders slowed at one of its factories a few years ago, the company offered cash bonuses to employees willing to relocate to Warroad.

- Marvin has also helped Warroad schools hire Spanish-language translators to assist the children of new hires.

The final say: “Tapping into new talent pools is especially critical in rural areas, whether it’s done via relocation support, engaging second chance populations or participating in initiatives such as the Manufacturing Institute’s Heroes MAKE America program, which is building connections between the military community and the manufacturing industry by bringing in new workers,” said MI President and Executive Director Carolyn Lee. “We need to engage all talent pools to fill the 500,000 jobs in manufacturing today.”

Manufacturing Employment Stays the Same

Employment in manufacturing remained essentially the same in April as it was in March, according to data out today from the U.S. Bureau of Labor Statistics.

- Overall employment increased by 175,000.

What’s going on: Manufacturing employed a seasonally adjusted 12,961,000 workers in April, up just marginally from 12,953,000 in March and 12,957,000 in February.

- The number of people employed in manufacturing was also up only slightly from April 2023, when it was a seasonally adjusted 12,941,000.

Durable goods vs. nondurable: There were a seasonally adjusted 8,144,000 workers in durable goods manufacturing in April, flat from March’s number.

- Nondurable goods had a seasonally adjusted 4,817,000 employees, also essentially unchanged from the prior month.

Workweek: The average workweek in the manufacturing industry was unchanged from March, at 40.0 hours.

- In the larger economy, the workweek for all nonfarm employees inched down by 0.1 hour in April, to 34.3 hours.

Earnings: Average earnings in manufacturing were also little changed from March to April, coming in at $33.61 an hour in the latest reading, down only slightly from $33.65, but up from February’s $33.44.

U.S. Birthrate Falls

The U.S. fertility rate is at record lows (The Wall Street Journal, subscription).

What’s going on: “The total fertility rate fell to 1.62 births per woman in 2023, a 2% decline from a year earlier, federal data released Thursday showed. It is the lowest rate recorded since the government began tracking it in the 1930s.”

- The data reflect a continuing trend: American women, across ethnic groups, are delaying or foregoing having children.

- In 2023, the number of U.S. births was the lowest in 44 years.

Why it’s happening: “A confluence of factors are at play. American women are having fewer children, later in life. Women are establishing fulfilling careers and have more access to contraception.”

- As a group, they are also increasingly uncertain about their futures “and spending more of their income on homeownership, student debt and child care.”

The details: From 2022 to 2023, birthrates declined more among younger women.

- “Women in their mid-to-late 30s are having children at similar rates to those in their early to mid-20s. Birthrates for women 35–39 fell to 54.7 births per 1,000 women—closer to the rates for women 20–24, which dropped 4% to 55.4 births per 1,000 women in 2023.”

- Birthrates among women in their 40s stayed the same.

Why it’s important: Fewer U.S. births could reshape the economy and “other facets of American life.”

- However, “[a]n influx of people immigrating to the U.S. could offset the impact of lower birthrates on the U.S. population’s size,” said Brady Hamilton, a co-author of the Centers for Disease Control and Prevention report that includes the data findings. “Immigration has risen in recent years, easing labor shortages and expanding the population of big metropolitan areas.”

Read more: For a comprehensive blueprint on U.S. immigration reform, download “A Way Forward,” the NAM’s recommendations to Congress on the subject.

New Overtime Rule Will Cost Employers and Workers

A new final overtime rule from the U.S. Department of Labor will reduce flexibility for employees and could force manufacturers to make difficult choices about their workforces, the NAM said Tuesday.

What’s going on: The new regulation “changes the salary threshold used to determine whether a worker is exempt from overtime pay” so that, beginning Jan. 1, 2025, most employees earning less than $58,656 will be owed time-and-a-half wages for hours worked over 40 in a single workweek (Bloomberg Law, subscription).

- The current salary threshold is $35,568.

- The new rule will go into effect July 1, following publication in the Federal Register.

Why it’s problematic: The change promises to present significant challenges to employers and employees alike.

- “Quarter after quarter, manufacturers cite workforce issues, such as attracting and retaining skilled employees, as their biggest business challenge,” said NAM Managing Vice President of Policy Chris Netram. The “rule places new constraints on employers, reduces flexibility for the workers who will be reclassified and may force companies to make painful choices that limit both job creation and growth opportunities available to employees.”

What’s next: The NAM is weighing all actions to protect manufacturers across the country.

Manufacturers: DOL Overtime Rule Will Exacerbate Workforce Crisis

Washington, D.C. – Following the release of the Department of Labor’s Wage and Hour Division rule concerning updates to the overtime regulations, National Association of Manufacturers Managing Vice President of Policy Chris Netram released the following statement:

“Quarter after quarter, manufacturers cite workforce issues, such as attracting and retaining skilled employees, as their biggest business challenge. Yet today’s rule places new constraints on employers, reduces flexibility for the workers who will be reclassified and may force companies to make painful choices that limit both job creation and growth opportunities available to employees. In addition, this latest regulatory hurdle will complicate manufacturers’ efforts to fill the millions of jobs our industry is projected to create within a decade.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.89 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

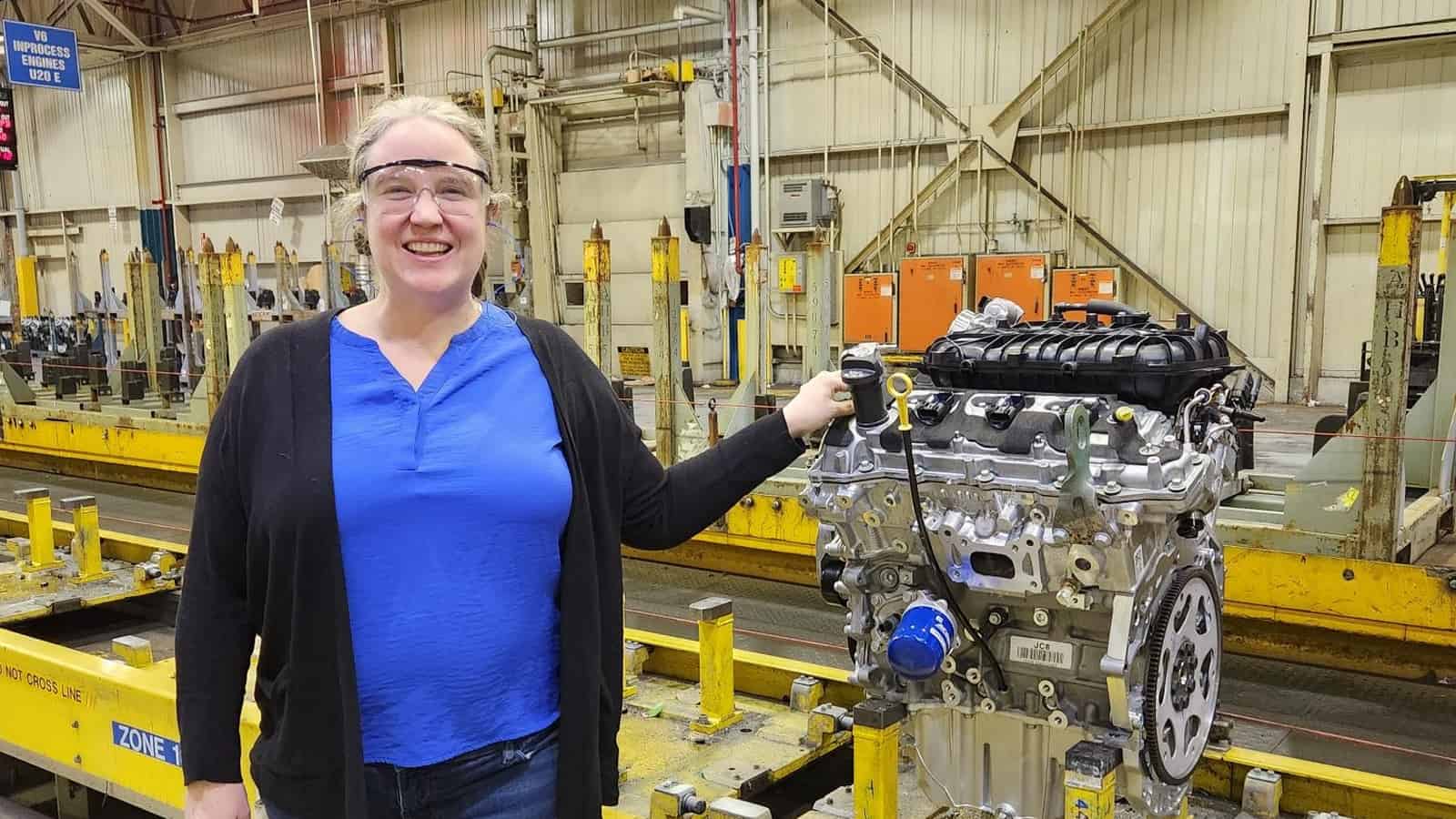

“Why Inclusion Matters”: GM’s Stephanie Thompson on STEM, Women in Manufacturing

Stephanie Thompson may not have always intended to go into manufacturing, but she’s very glad she did.

The path taken: “You don’t necessarily plan your journey, but sometimes you can look back and see how those paths presented themselves,” and you’re thankful they did, said the engineering manager at General Motors’ facility just outside St. Catharines, Ontario, Canada.

- “My career in manufacturing started in internships in university. I worked for a food manufacturer, for a company that made above-ground swimming pools … It was a great chance to try out different businesses, and I [realized that I] love the buzz and excitement that manufacturing has.”

Award nominee: Thompson is a 2024 Honoree of the Women MAKE Awards, honors given annually to 130 women making a difference in manufacturing by the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate.

- Thompson—who started working for GM full time right after university and has held multiple positions in her 23 years there—was the first woman to become an engineering manager in her time at her site.

- Women MAKE Award winners will be celebrated April 18 at the 2024 Women MAKE Awards Gala in Washington, D.C.

Always improving: An Ottawa native and graduate of the University of Waterloo, Thompson sums up her very complex job as “a manufacturing assembly specialist [who] makes sure people can do their jobs safely—and do it over and over again.”

- She oversees the assembly of whole powertrain lines. For one particular engine, “I was there for the first one made, and I was here for the last—we made over 5 million,” she said of a recently retired line.

- “We are always looking to make improvements, to make things more cost effective, to make things simpler,” she said. “The problem-solver part of me really enjoys making those incremental differences every day. [In manufacturing,] you get that sense of satisfaction from making stuff and ultimately giving a customer what they want.”

Women in STEM: Thompson, who has been recognized several times in her native Can

ada for her commitment to women’s education in science, technology, engineering and math, somehow found the time a few years ago to launch STEMbySteph.com, a STEM-focused website that includes a workshop series for women in the fields.

- She is also a mentor for FIRST Canada, which aims to interest kids in science and technology, and a regular speaker on related topics.

- “There are so many great women coming up through the ranks” in manufacturing today, she told us. “I want them to know there isn’t a limit to what they can do. I want to put myself out there as a technical role model, so women who apply [for manufacturing and STEM jobs] see themselves on the interview panel. They should know there’s a space for them in manufacturing.”

Work in progress: And while she’s had “nothing but great experiences with the men in manufacturing,” Thompson said the industry as a whole could benefit from “having some conversations” to make sure women feel welcome.

- “I don’t think it’s malicious,” she said, of the relatively low number of women in manufacturing (they make up about 30% of the

manufacturing workforce). “But one of the things you have to do as a leader is create intentionality and create environments where conflict is positive, where you can all create ideas to [fix] the problem and where individuals feel safe being themselves.”