Why Manufacturers Can’t Fill Their Job Openings

Manufacturers struggle to fill all available jobs, Manufacturing Institute President and Executive Director Carolyn Lee told NPR’s “Planet Money” this week. The program held an in-depth discussion with Lee and other experts about the industry’s workforce challenges and prospects for change.

The problem: “Last year, the Manufacturing Institute [the NAM’s workforce development and education affiliate] and Deloitte, a consultancy firm, surveyed more than 200 manufacturing companies. More than 65% of the firms said recruiting and retaining workers was their No. 1 business challenge,” NPR noted.

- “The Manufacturing Institute and Deloitte projected that the industry will need 3.8 million additional workers by 2033 and that as many as ‘1.9 million of these jobs could go unfilled if workforce challenges are not addressed.’”

Changing perceptions: Lee underlined the importance of changing Americans’ perceptions of the manufacturing industry and showing them that it is not dirty, boring and repetitive but modern and high tech.

- Manufacturing jobs are “clean and bright and full of technology,” Lee told NPR.

Skills shortage: Another problem facing the industry is a lack of people with specific, highly needed skills.

- “The hardest skills to find are the ones that maintain and fix equipment,” Lee says. “Every company we speak with is trying to hire technicians—every single one. The challenge is that there is no one walking around on the street with these skills, and it takes one to two years to teach those skills and another one to two years to contextualize those skills to the specific plant environment.”

The fix: Lee said that manufacturers have the most success in strengthening their workforces when they think local.

- “The very best models of workforce development that we see and that we engage in at the Manufacturing Institute are locally and regionally led public–private partnerships, where manufacturers come to the table—and with the support of the community college system and the local business community—they build the talent pipelines that they need,” she told the news outlet.

Finding FAME: The MI is also contributing directly to solving the skills shortage, including through the expansion of FAME, an earn-and-learn initiative originally founded by Toyota and now led by the MI that combines hands-on job training with classroom education.

- “[A]t the end of the 21 months [in the program], students come out with, in most cases, no college debt,” Lee said. They are also well set up for a lifetime of high-paying, in-demand work.

- A Brookings Institution and Opportunity America study cited by NPR found that “five years after completion, FAME graduates were earning nearly $98,000, compared to roughly $52,783 for non-FAME participants—a difference of more than $45,000 a year.”

Read the whole thing: You can find the whole NPR article here.

Anheuser-Busch Partners with the Manufacturing Institute on Workforce, Veterans’ Careers

Anheuser-Busch, the maker of Budweiser and Bud Light among other products, is investing more than $300 million in local communities and facilities in 2025, including in efforts to upskill its workforce and help veterans find new careers at the company (Anheuser-Busch).

- This investment is a continuation of the more than $2 billion Anheuser-Busch has poured into 100 facilities across America over the past five years.

Heroes MAKE America: To support veterans in their new careers, Anheuser-Busch is partnering with the Manufacturing Institute—the NAM’s workforce development and education affiliate—to become the first manufacturer in the U.S. to adopt the MI’s new digital credentialing system for veterans.

- This system, overseen by the MI’s Heroes MAKE America initiative, translates military experience into skills needed for manufacturing careers, making veterans’ backgrounds more comprehensible to hiring managers.

- Anheuser-Busch will also train its workforce on the credentialing system, so that they understand the important skills that veterans will bring to the company and can evaluate the thousands of applications it will receive using the system.

Workforce training: Anheuser-Busch is also expanding its Technical Excellence Center model across the country, following its great success in St. Louis. The first new center will be its Columbus, Ohio, Regional Excellence Center, where it “will upskill its entire regional technical workforce over the next three years,” according to the company.

- The MI has a role in this expansion as well. Anheuser-Busch will partner with the MI and local trade schools so that trade school students and educators can benefit from the St. Louis and Columbus Technical Excellence Centers.

Anheuser-Busch says: “This new $300 million investment in our manufacturing facilities across the U.S. is the latest example of Anheuser-Busch’s commitment to strengthening our local communities by creating and sustaining jobs and driving economic prosperity,” said Anheuser-Busch CEO Brendan Whitworth. “Investing in our people and in new technologies and capabilities to drive industry and economic growth is core to who we are.”

From the MI: “Anheuser-Busch’s $300 million investment is more than a commitment to manufacturing in America—it’s a commitment to America’s future,” said NAM President and CEO and MI Chairman of the Board Jay Timmons.

- “By expanding technical training and strengthening our industrial base in Columbus, and with their support of the Manufacturing Institute’s Heroes MAKE America initiative, they are opening doors of opportunity for manufacturing workers across this country.”

- “This investment will help fuel our economy, lift up communities and secure the promise of manufacturing in America for generations to come.”

On the ground: The announcement of Brewing Futures took place in Columbus, Ohio, with Whitworth, Secretary of Labor Lori Chavez-DeRemer, Ohio Gov. Mike DeWine and Sens. Jon Husted and Bernie Moreno. Marking the significance of the announcement, MI President and Executive Director Carolyn Lee and NAM Executive Vice President Erin Streeter also attended the event.

- “It was great being on the ground in Columbus, Ohio, for this announcement with Brendan Whitworth and Secretary Chavez-DeRemer highlighting Anheuser-Busch’s commitment to supporting veterans and advancing our workforce,” said Lee.

- “Through our Heroes MAKE America initiative, we’re proud to partner with forward-thinking manufacturing leaders like Anheuser-Busch who are proactively building supportive communities of veterans within their organizations. By adopting tools like our Manufacturing Readiness Badge program, they are not just investing in people; they are helping shape the future of manufacturing.”

- “This investment will help fuel our economy, lift up communities and secure the promise of manufacturing in America for generations to come.”

How a Small Manufacturer Offers Big Retirement Benefits

401(k) fees are a hot topic of conversation if you are an HR leader. When Miltec UV Human Resources Director Karen McKernan was discussing 401(k)s with an old friend, she discovered that Miltec, a small manufacturer, paid much more in fees than her friend’s larger employer. She was aghast, but what could Miltec do about it? The company did not have the purchasing power of a large firm, and so its options seemed limited.

Not so fast. Soon after that conversation, McKernan started receiving emails from the NAM about its new multiple employer plan, the Manufacturers Retirement & 401(k) Savings Plan, which allows many companies to participate in one 401(k) plan. Not only does the larger number of participants lower the fees, but the plan offers administrative and compliance oversight, as well as other benefits.

After doing her research, McKernan was convinced. By mid-2022, she was working with the NAM, the plan administrator, and recordkeeper and service provider Principal to make the switch. On Nov. 1, 2022, the new plan went live for Miltec employees. Today, McKernan says, she would never go back.

The benefits: Once McKernan laid out all the advantages for Miltec’s owners and 401(k) trustees, NAM 401(k) was an “easy sell,” she told us.

- Not only did the fee reduction seem like a “no-brainer,” but the new plan would lift a considerable administrative burden that had fallen entirely on McKernan. It would also offer benefits to employees that Miltec, as a small company, could not add on its own without creating even more administrative tasks.

- Furthermore, the NAM 401(k) comes with an independent 3 (38) investment fiduciary, One Digital, which reviews the funds’ performance regularly and issues reports on a quarterly basis, ensuring low-performing funds are “watched” and subsequently removed and replaced when needed. By delegating investment decisions under this arrangement, a company significantly reduces its potential liability for poor investment decisions.

- Additionally, any plan with more than 100 participants must undergo an annual audit, which is time consuming and expensive. Under NAM 401(k), the plan coordinates and manages the audit for participating companies.

What she doesn’t miss: McKernan listed all the duties she used to perform for Miltec’s own 401(k), which have now been taken over entirely by the NAM’s plan. She doesn’t miss:

- Monitoring enrollment, which Miltec’s employees can now undertake directly on Principal’s website;

- Sending out many required annual notices;

- Compliance testing and 5500 filings (which ensures the plan meets the IRS’s requirements for retirement plans, so that employees can receive tax benefits);

- Sending out summary annual financial reports and quarterly statements; and

- Handling employees’ questions and all communications about the plan.

In contrast, McKernan now only provides information to Principal through an automated payroll report and keeps an eye on how things are going, just in case. There have been few problems, she told us, and those were fixed with alacrity by Principal and the NAM.

Implementation: The entire timeline, from learning about NAM 401(k) to finalizing the switchover, took no more than a few months, McKernan said.

- Principal oversaw the transition, with weekly check-ins, a dedicated project manager and a schedule that included clear deadlines. While transitioning 401(k) plans is “a project,” McKernan said, Principal “managed it very well, including all required communications, and finishing right on time.”

- A word of advice: “If I had to do it all over again, I would have moved the plan over on Jan. 1 instead of Nov. 1,” said McKernan. Having two different plans in one year proved to be more of a headache than she expected, as it forced Miltec to do compliance testing on both plans in 2022.

The reception: “The company’s employees and owners are very pleased with the new NAM plan,” McKernan said.

- Aside from the savings in time and money, NAM 401(k) offers a host of other features that manufacturers can customize. One new feature that has proved popular with Miltec’s employees is loans, noted McKernan.

- In addition, Miltec’s previous plan had a 12-month waiting period before employees could participate, but NAM 401(k) reduced the wait to six months—which is far more appealing to new hires, she added.

- Ultimately, Miltec’s leaders and employees understood and appreciated the logic of joining a multiple employer plan, said McKernan. “They recognize the more participants you have, the more buying power you have. They are seeing the positive results of having access to a robust fund lineup and how that translates to lower fees every time they receive a quarterly statement.”

The bottom line: “I honestly don’t see how a small manufacturing company wouldn’t benefit from joining the NAM 401(k),” said McKernan.

- “I’ve been in HR for a very long time, and when we talk to job candidates about benefits, the 401(k) plan always comes up. It’s a benefit that is necessary to attract talent, as well as help your employees meet their retirement goals,” she added.

- “I wouldn’t hesitate to recommend this plan to any small, medium or large manufacturer.”

Rethink 2025 Is Coming Up Fast

Get ready! Manufacturing’s leading annual event on accelerating digital transformation is right around the corner.

What’s going on: Rethink—held by the Manufacturing Leadership Council on Marco Island, Florida, each June—is a must-attend conference for anyone interested in Manufacturing 4.0 and where it’s headed (The MLC is the digital transformation division of the NAM.)

- This year’s event takes place June 15–18 at the JW Marriott Marco Island Beach Resort.

Why you should go: Rethink attendees will get an inside look at the cutting-edge processes and technologies transforming manufacturing today—directly from those creating and implementing them. They’ll also get a chance to:

- Consult with peers on manufacturing’s most critical initiatives, including smart factories and digital production, resilient supply networks and analytics and data mastery;

- Participate in real-time discussions and one-on-one meetings to help them understand how various solutions can solve their business problems;

- Hear from industry leaders and experts during panel discussions, executive interviews and more;

- Interact and collaborate with peers during interactive “think tank” sessions; and

- Hear from the MLC’s event partners during Rethink’s exclusive VIP Tour.

Who will be there: Scheduled speakers include Siemens USA President and CEO Barbara Humpton, Eaton Vice President of Industry 4.0 Craig Sutton, Hershey Company Vice President of Manufacturing, Operations Technology and Supply Chain Strategy Will Bonifant, Rockwell Automation Senior Vice President of Intelligent Devices Tessa Myers and many more.

The gala: Closing out the packed three-day event is the Manufacturing Leadership Awards Gala, at which the MLC will recognize award finalists and winners of the Future of Manufacturing Award, the Manufacturing Leader of the Year, the Small/Medium Enterprise Manufacturer of the Year and the Large Enterprise Manufacturer of the Year. The gala will take place on the evening of June 18.

Attend: Register online here for Rethink 2025. (NAM members get a discount at checkout.) Questions? Send them to [email protected].

The Innovators Quest Gets Students Excited About Manufacturing

Manufacturers have a new opportunity to connect with students and encourage them to explore careers in manufacturing. The Manufacturing Institute (the NAM’s workforce development and education affiliate) has developed a gamified experience called Innovators Quest, specially designed to introduce students to manufacturing-related skills in a fun-filled format.

The experience is made up of four realms in a board game format with hands-on building challenges. As they seek to recover the “Crystal of Innovation,” students in grades 4 through 9 can try their hands at 3D printing, robotics and other crucial skills. Manufacturers can sponsor Innovators Quest sets, which they can take to schools, afterschool programs, local community events, Boys and Girls Clubs and more.

The quest: The conceit of the game is that the aforementioned crystal has fractured, and the students must fix it by completing four challenges in whichever order they choose.

- While the students play collaboratively, completing challenges together, they all take on the role of different innovator characters who have different mixes of manufacturing-related strengths, including “analytical, visual, intuitive, strategic and extroverted.”

- “We want all students to see themselves in at least one of these characters,” MI Director of Student Engagement Jen White explained to us.

The challenges: The four challenges ingeniously explore manufacturing concepts while still entertaining the participants, as the writer of this article can vouch.

- One challenge instructs students to build paper airplanes. But the lesson isn’t just about building—it’s about perfecting and testing your products. The players must make 10 airplanes following two separate designs, then put together an electric plane launcher. Finally, they test their airplanes to see if they sail the necessary 6 feet to “fly away” with a handful of the crystal fragments. Skills and concepts learned: collaboration, iteration, precision, electromechanical building, aerodynamics, following directions and testing.

- A second challenge draws on the principles of additive manufacturing. Players are asked to use 3D pens (which dispense a line of malleable plastic that can be made into shapes or figures) to construct the pieces of a bridge over which the crystal fragments must be transported. Skills and concepts learned: additive manufacturing, precision, following a blueprint, welding parts together, collaborating on different pieces and structural integrity.

We won’t spoil the other two realms, but they involve a similar blend of fun challenges and manufacturing skills exploration—including the construction of a small robotic toy and a test of deductive reasoning.

The bottom line: “Innovators Quest was developed based on proven approaches to empower manufacturing employers to engage students early and often,” said MI President and Executive Director Carolyn Lee. “By sparking their interest in skills needed in modern manufacturing, this student engagement tool illustrates the limitless possibilities of the many careers in our industry. The time to invest in our future workforce is now.”

- “Innovators Quest is an important initiative that will provide students with early knowledge about the variety of opportunities for a career in manufacturing and highlights the value of teamwork, collaboration and communication in the production environment,” said American Honda Motor Co. Executive Vice President Bob Nelson. “We’re proud to continue our partnership with the Manufacturing Institute to build that future workforce.”

Learn more: Learn more about Innovators Quest and how your company can sponsor a kit to build manufacturing career awareness in your community. To secure a sponsorship before the 2025–2026 school year begins, contact [email protected].

Lawmakers on Taxes, CHIPS, Trade and Workforce

A day after President Donald Trump’s first address to Congress in his second term, the industry remains on edge amid the growing uncertainty of what’s being called a trade war by some in Washington.

What Congress is saying: We’re starting to see public comments from members of Congress on various topics in the president’s speech on Tuesday. Here’s what they’re saying.

Tax reform: House Ways and Means Committee Chairman Jason Smith (R-MO) committed yesterday to delivering a comprehensive tax bill to President Trump by Memorial Day, according to MarketWatch. Echoing NAM President and CEO Jay Timmons’ repeated calls for a swift tax deal, Chairman Smith emphasized the urgency of providing certainty to small businesses and working families, stating, “Failure is not an option.”

- “[W]e have to move this one big, beautiful bill as quickly as possible,” he said.

- In recent weeks, Timmons has leveraged the NAM’s public platform extensively—including through the NAM State of Manufacturing Address, television and radio interviews across the country, social media and op-eds in Ohio and Florida—to press Congress to act now and make the 2017 tax reforms permanent.

CHIPS: New Sen. Jon Husted (R-OH), the former lieutenant governor of the state, expressed support for the CHIPS and Science Act, emphasizing its bipartisan backing and importance of national security. “For the economic and national security of America, we need to make chips in the USA—I believe this is part of an America First agenda,” he wrote in a statement provided to The Columbus Dispatch.

- House Speaker Mike Johnson (R-LA) indicated to Punchbowl that nothing would be discussed on the CHIPS and Science Act until the president’s FY 26 budget.

- Sen. Todd Young (R-IN) said that the president’s mention of the act in his speech was “not consistent with the extensive conversations we’ve had with the administration about the many successes and future of the CHIPS program and how it helps with our shared goal of creating a robust domestic chips supply.”

Trade and workforce: “As I’ve said, tariffs are a tool in the toolbox, but they must be strategic and support American jobs—not create uncertainty that undercuts our domestic manufacturing,” Rep. Debbie Dingell (R-MI) told the Detroit Free Press. “The domestic auto industry currently relies on an integrated North American supply chain, and our trade policies need to reflect that.”

- Sen. Thom Tillis (R-NC) zeroed in on implementation of any tariffs. “If you’re talking about tariffs that are going to be inflationary, causing all kinds of retaliation and disrupting the markets, I’m almost certainly against them,” he said in an interview with CQ Roll Call. “However, if you’re talking about tariffs that are used surgically … to be used judiciously and to build the economy, then I’m all for it.”

- For Sen. Kevin Cramer (R-ND), according to The Wall Street Journal (subscription), “It comes down to how long [the tariffs] would last.” He said you “can’t simply turn on and off an inflationary switch” or flip a switch to build manufacturing facilities in the U.S., “or even harder yet, get the workforce to fill those jobs that would be created, particularly at the same time as you’re shirking immigration.”

Big picture: “Manufacturers are already planning for 2026, and they need the certainty to invest and grow now. We’re seeing bipartisan interest in these priorities, and the NAM is building consensus to achieve exactly that and have even stronger champions for manufacturers in Congress to reinforce what we need to compete and win,” said NAM Executive Vice President Erin Streeter.

Women MAKE Awards to Honor Outstanding Women in Manufacturing

The Manufacturing Institute—the workforce development and education affiliate of the NAM—has announced the recipients of the 2025 Women MAKE Awards, honoring some of the most impressive and inspiring women in the manufacturing industry today.

The awards, which will take place in Washington, D.C., on April 24, will highlight 130 individuals who have demonstrated excellence and leadership in their careers across all levels of the manufacturing industry.

The challenge: The manufacturing industry faces a significant talent gap—with more than 400,000 job openings and an estimated 3.8 million positions needing to be filled by 2033.

- Women make up about half of the U.S. labor force, but less than one-third of the manufacturing workforce. Boosting the numbers of women who choose a career in modern manufacturing is essential to closing this gap—and the honorees of the Women MAKE Awards are leading the way.

The initiative: The MI’s Women MAKE America Initiative strengthens the modern manufacturing workforce by elevating and highlighting the women leading the industry at every level—from the shop floor to the C-suite—in order to inspire the next generation and help close the talent gap in the industry.

The awards: Each year, 100 Honorees and 30 Emerging Leaders are chosen from the thousands of nominations submitted to the MI by their peers for making significant contributions to their companies, communities and efforts to cultivate the next generation of skilled talent. Since its inception, the Women MAKE Awards have recognized about 1,700 outstanding individuals.

The MI says: “Every year, more women are finding opportunity and breaking barriers in manufacturing,” said MI President and Executive Director Carolyn Lee. “By elevating these outstanding women for their success, we are showing young women—and everyone else—that manufacturing is a rewarding industry with unlimited potential.”

- “At a time when there is such high demand for talent in our sector, these extraordinary women demonstrate the impactful careers that are available. By elevating role models who are paying it forward, the Women MAKE Awards strengthen the future of the industry by inspiring the next generation.”

Manufacturing leaders say: “With hundreds of thousands of open jobs in manufacturing, it has never been more critical to attract and retain top talent,” said Toyota Senior Vice President of Electric Vehicle Supply Susan Elkington.

- “This year’s Women MAKE Honorees and Emerging Leaders are breaking barriers, leading with innovation and proving there is no limit to what they can achieve in our industry. By amplifying their stories and accomplishments, we inspire others to step into manufacturing and shape its future.”

Learn more: Read about the awardees and learn more about the awards gala.

The State of the Manufacturing Workforce in 2025

The NAM kept up a breakneck pace on the third day of its 2025 Competing to Win Tour, with the Manufacturing Institute delivering the first-ever State of the Manufacturing Workforce Address at Drake State Community and Technical College in Huntsville, Alabama, before an audience of students, faculty, manufacturers and local and state officials.

Opportunity—for all: Taking the stage to give the MI’s assessment of the manufacturing worker base in 2025, Carolyn Lee, president of the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate, homed in on the theme of opportunity.

- “Manufacturing is not just about innovation and economic growth; it’s about opportunity. It’s about ensuring that every community, every aspiring maker, builder and creator—no matter their background—can have access to the skills, training and careers that will define the future.”

- But because the industry stands at a crossroads, part of that opportunity today is to help manufacturing maintain its momentum, Lee said, echoing a theme of NAM President and CEO Jay Timmons’ 2025 State of Manufacturing Address on Tuesday.

Finest hours ahead: Lee was joined at the event by Rep. Dale Strong (R-AL), who spoke about the strength of Alabama’s manufacturing sector.

- “I think we’ve proven here in Alabama, and North Alabama especially, advanced manufacturing is part of our DNA,” he said. “You look at the jobs that we’ve brought in the last 10 or 15 years. You start with GE Aviation, Polaris, Toyota Motor Manufacturing, Mazda Toyota. We’ve proven that the Alabama workforce has the ability. I think our finest hours are still ahead.”

A world-changing job: Timmons echoed that sentiment. “You’re stepping into one of the most important and innovative fields in the world,” he told the Drake State students.

- “The products, the materials, the technologies that you will help create, they won’t just be used in your hometown or even all across our country. They’re going to help change economies … They’re going to strengthen the very foundation of America’s security and prosperity.”

A shortfall: But manufacturing today faces an immense challenge, Lee told the crowd: “a structural workforce deficit.”

- “[I]f we don’t act boldly, the U.S. faces a shortfall of 1.9 million manufacturing workers by 2033; 3.8 million positions will open up, but nearly half could go unfilled. That’s not just a workforce issue—it’s an economic and national security issue.”

- That’s despite the average annual earnings—including pay and benefits—for a manufacturing employee coming in at more than $102,000.

- The dearth of workers in the sector is driven by both retirements and growth.

How to overcome it: “[W]e have to inspire more Americans to see themselves in manufacturing,” Lee said. “That starts early, with programs that spark curiosity and excitement for careers in our industry. And when I say early, I mean as young as 9 or 10 years old—because today’s 4th graders will graduate in 2033 and may be our future team members.”

- To this end, the MI partners each year with manufacturers on MFG Day, which kicks off a full month of events at which companies show young people, students and job seekers what a modern manufacturing career looks like.

- The MI, with the support of Honda, has also created a new interactive experience to interest youngsters in the industry: “Innovators Quest,” which combines elements of board games and popular fantasy and storytelling activities.

The FAME factor: Under the MI’s auspices, the Federation for Advanced Manufacturing Education USA, a workforce program started by Toyota in 2010 and entrusted to the MI in 2019, has grown considerably. (Drake State is home to one of the public–private partnership’s newest chapters.)

- FAME participants attend classes and earn while they learn in hands-on apprenticeships with manufacturers.

- The program—in which a participant can easily earn more than $30,000 over two years—has become “the gold standard for how employers, educators and communities should work together” on manufacturing workforce training, Lee said.

Other efforts: The MI helps manufacturers actively recruit groups often overlooked in manufacturing hiring initiatives: veterans, women and previously incarcerated individuals.

- The Heroes MAKE America program helps connect former members of the military with manufacturing jobs. Walmart provides crucial funding to the program; in 2022, it gave a six-figure grant to fund the development of a model that translates skills acquired in the military to ones recognized by manufacturing employers.

- The Women MAKE America Initiative is the nation’s premier program aimed at closing the gender gap in the sector.

- “The MI is helping manufacturers develop second chance hiring strategies, recognizing that talent is talent—and potential shouldn’t be wasted,” Lee said to the audience.

Working together: “As we look ahead, manufacturers, educators and policymakers must work together to strengthen our talent pipeline,” Lee and Drake State Community and Technical College President Dr. Patricia G. Sims wrote in a Thursday op-ed for the Alabama Political Reporter.

Manufacturing in Alabama: On Thursday afternoon, the NAM and MI contingent continued its manufacturing-facility tour, visiting Toyota Motor Manufacturing Alabama and Bruderer Machinery—both in Huntsville—and Milo’s Tea Company in Bessemer.

- “I plan on making my career here,” said Drew, a 2024 FAME graduate, during a discussion before a tour of the shop floor. Drew is now working as a maintenance team member at Toyota Alabama. The talk focused on how the FAME program prepared participants for a rewarding career in auto manufacturing. Toyota Alabama—2,400-plus team members strong—has created 10,000 jobs in the state.

- Lee visited Bruderer Machinery, a leading manufacturer of high-precision stamping presses that provides solutions for the automotive, aerospace and electronics industries. Bruderer is also a key supporter of the FAME apprenticeship model.

- Timmons and the rest of the NAM team finished the day at Milo’s Tea, the fastest-growing tea company in America. The family-owned business, founded by CEO Tricia Wallwork’s grandparents Milo and Bea Carlton, has won 40% of the refrigerated iced tea market share in the U.S. “This reminded me of my grandmother’s iced tea,” said Timmons. “You could see how special Milo’s is by just walking the shop floor and seeing the smiles and camaraderie.”

Timmons: Tax Reform Paramount for Manufacturing Growth

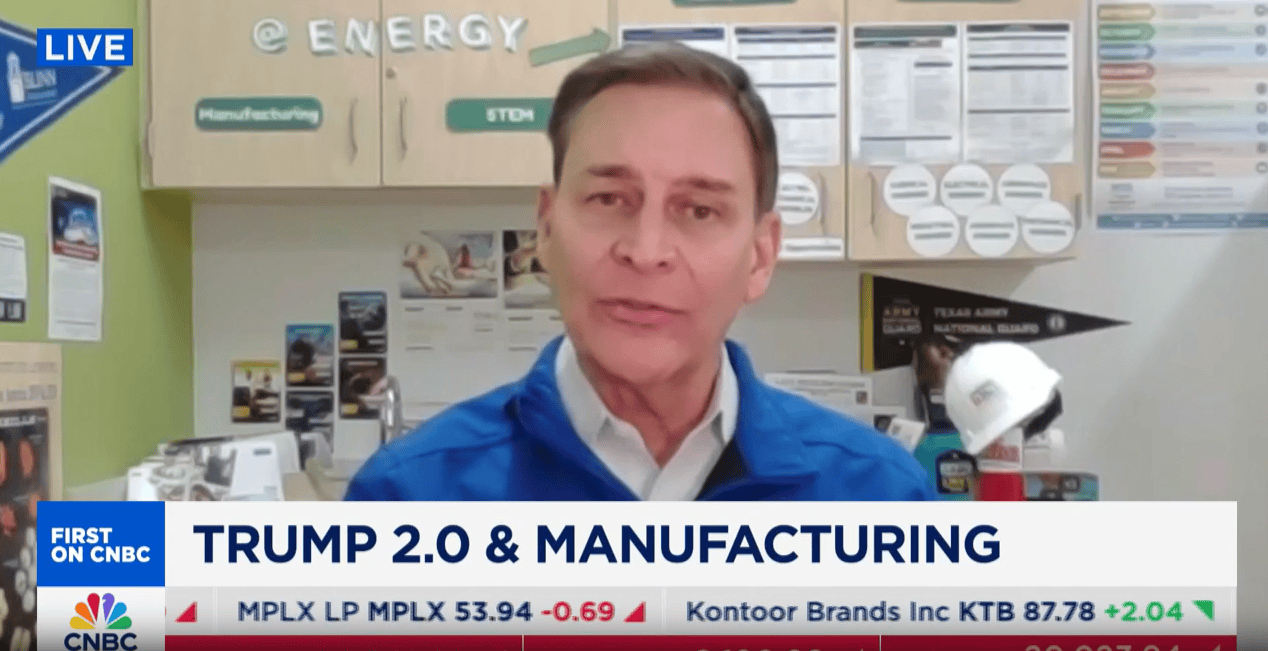

Manufacturers need an integrated, comprehensive strategy for expanding their sector, and a large part of that is preserving and bringing back tax reforms, NAM President and CEO Jay Timmons said on CNBC’s “The Exchange” Wednesday.

What’s going on: Timmons spoke to the news channel from a teacher workroom at the Energy Institute High School in Houston, Texas, a stop on the first leg of the NAM’s 2025 Competing to Win Tour. He told show host Kelly Evans that any plans to bolster manufacturing in the U.S. must “start with renewing those tax reforms from 2017.”

- “A smart strategy is going to involve reducing the cost of doing business for manufacturers here in the United States,” he said, praising Republican House leadership for being “able to move” forward a House budget bill “that’s going to set the framework for those tax rates to be set, hopefully, permanently in stone.”

- The 665-student Energy Institute High School, led by Principal Lori Lambropoulos, is the first high school in the U.S. dedicated to preparing students for careers in the energy industry.

What else is needed: Timmons echoed some of the major themes from the NAM State of Manufacturing Address, which he gave Tuesday in Ohio.

- “We also are looking at regulatory reform,” he told Evans. “We’re looking at expanding our energy dominance. We’re looking at workforce policy … and then, of course, we have to have a sensible trade policy as well.”

But back to taxes: Bringing back expired provisions from the 2017 Tax Cuts and Jobs Act, and making them and other, scheduled-to-expire provisions from the legislation permanent, is critical to manufacturing’s future success, Timmons continued.

- “Ninety percent of my 14,000 members are small and medium manufacturers. Most of them benefit from the pass-through deduction that expires this year. And I don’t think what you want to see is a huge tax increase that will cost 6 million jobs in the economy happen if we don’t renew those reforms,” he said, citing data from a recent NAM study on the effects of a congressional failure to act on tax reforms.

- “That’s why the Speaker’s actions in the last day or so have been so incredibly important to get this thing moving forward. President Trump actually endorsed that bill—the ‘one big, beautiful bill,’ as he calls it—and that will help make America great again for manufacturing.”

Energy dominance: Also critical to the success of manufacturing and the U.S. economy as a whole: the right energy policies, Timmons said. Promising to “unleash the energy sector,” President Trump lifted the previous administration’s ban on liquefied natural gas exports on his first day in office.

- Yesterday, the NAM got to see first-hand some of the effects of that kept promise, when the team visited Freeport LNG’s liquefaction facilities near Houston.

- More than 9,000 construction jobs were created during the construction of those facilities, which now directly employ about 400 people. Their operations have an estimated total positive economic impact on the U.S. economy of more than $5 billion a year.

- “Energy is … a critical national security component,” Timmons said on CNBC.

Emphasis point: The tour also stopped at Bray International, a global leader in flow control and automation solutions, supporting U.S. energy dominance, LNG exports and high-tech manufacturing.

- The visit helped underscore why policies that support manufacturing investment and provide certainty to manufacturers are essential to America’s economic future.

Up next: Today, the NAM is in Alabama, where this morning Manufacturing Institute President and Executive Director Carolyn Lee gave the Manufacturing Institute’s State of the U.S. Manufacturing Workforce Address at Drake State Community & Technical College in Huntsville. (The MI is the NAM’s 501(c)3 workforce development and education affiliate.) The theme: building the workforce of the future.

- This afternoon, the team will tour Toyota Motor Manufacturing Alabama in Huntsville, the manufacturing facilities of Bruderer Machinery in Huntsville and Milo’s Tea Company in Bessemer.

State of Manufacturing 2025: When Manufacturing Wins, America Wins

“Manufacturing in the U.S. has momentum”—and to keep it going, manufacturers will need to push, NAM President and CEO Jay Timmons said Tuesday in the NAM’s annual State of Manufacturing Address.

What’s going on: Speaking to an audience of manufacturers and congressional and state officials at Armstrong World Industries in Hilliard, Ohio, Timmons, who was joined by NAM Board Chair and Johnson & Johnson Executive Vice President and Chief Technical Operations & Risk Officer Kathy Wengel, emphasized the “defining moment” for the industry and said that for manufacturing, “what happens next really matters.”

- “Uncertainty is the enemy of investment,” he told the crowd. “Manufacturing is a capital-intensive industry. We make decisions months and years in advance. … That’s why we need certainty. We need a clear, actionable, multistep strategy from our government—one that says, ‘We want you to invest here, hire here and succeed here.’”

- Timmons’ annual speech kicked off the NAM’s 2025 Competing to Win Tour, starting with a whirlwind four-states-in-four-days tour of manufacturing facilities, schools, government offices and more.

- “In Ohio, manufacturers have thrived because our leaders have taken decisive actions to keep our industry competitive,” Ohio Manufacturers’ Association President Ryan Augsburger said at the kickoff event. But now, “manufacturers across Ohio and the nation are facing critical challenges, from tax uncertainty, project delays and workforce shortages to supply chain vulnerabilities and price pressures that threaten our ability to grow. … These issues cannot wait.”

What manufacturing needs: Certainty from the federal government should come in several forms, Timmons said, including the following:

- Preserving tax reform: The 2017 tax reforms were “rocket fuel” for manufacturing in America—but key provisions have expired and others are scheduled to sunset. Congress must bring them back and improve and extend the package. “Every day that Congress delays because of process and politics, manufacturers face rising uncertainty, delayed investments and fewer jobs,” said Timmons.

- Regulatory clarity and consistency: Manufacturers today spend a total of $350 billion just to comply with regulations. “Commonsense regulation is critical to American manufacturers to continue to innovate, to compete against foreign manufacturers and to improve the lives of American citizens,” Austin So, general counsel, head of government relations and chief sustainability officer for Armstrong World Industries, told the crowd.

- Permitting reform: President Trump’s lifting of the liquefied natural gas export permit ban was a start, but to reach our full potential as energy leader, we must require “federal agencies to make faster decisions and reduc[e] baseless litigation,” said Timmons.

- Energy dominance: “America should be the undisputed leader in energy production and innovation. But … we are seeing opportunities for energy dominance fade in the face of a permitting process that takes 80% longer than other major, developed nations,” Timmons said, adding that we must cut red tape, require federal agencies to make faster decisions and reduce meritless litigation.

- Workforce strategy: By 2033, manufacturing faces a shortfall of 1.9 million manufacturing employees, Timmons said. To fill those positions, the sector needs a “real workforce strategy,” one that includes apprenticeships, training programs and public–private partnerships.

- Commonsense trade policy: If President Trump continues to use tariffs, “we need a commonsense policy … that provides manufacturers with the certainty to invest” and “a clear runway to adjust,” according to Timmons.

State of manufacturing: “Manufacturing in the United States is moving forward,” Timmons said. “Like a press at full speed, like a production line firing on all cylinders, like the workers who show up before dawn and leave long after the job is done—manufacturing in the United States is driving us forward.” And Timmons added that now it’s time “to make America Great for Manufacturing Again.”

On the move: Following the speech, Timmons, Wengel and Augsburger joined state lawmakers, including state Sens. Kristina Roegner and Andrew Brenner, and local business leaders for a visit to the Ohio Statehouse for an event focused on the importance of tax reform for Ohio and its manufacturing sector.

- A recent NAM study found that, if key provisions of tax reform are allowed to expire, Ohio would risk losing 208,000 jobs and $18.9 billion in wages.

What’s at stake: Tax reform was transformational for Humtown Products, the Columbiana, Ohio–based family-owned sand cores and molds manufacturer, President and CEO Mark Lamoncha told the audience at the Ohio Statehouse tax event.

- “We have been at the forefront of 3D-printed manufacturing for years and have invested significantly in the machinery and equipment required, including the purchase of 3D printers—one of which can easily cost over $1 million,” he said.

- “Since the 2017 tax reform, Humtown has invested over $9 million in capital expenditures related to 3D printing and averages around $100,000 annually in R&D costs. Under the 2017 tax reform, we were able to deduct 100% of those costs, generating around $1.6 million in accelerated tax savings.”

- “That amount alone allowed us to purchase another 3D printer, fueling continued growth. That’s what tax certainty allowed us to do. But right now, that certainty is slipping away. As these provisions begin to expire, our tax burden is increasing.”

Creators Wanted: The group also fit in a stop at Columbus State Community College, which serves approximately 41,000 students, to visit with students in the semiconductor and mechanical drive classes.

The last word: The NAM recently “stood shoulder-to-shoulder with congressional leaders—delivering a clear, urgent message on tax reform” and is “driving the agenda on regulatory certainty, on energy dominance, on permitting reform, health care and workforce development,” Wengel told the audience. “The NAM is not waiting for Washington to act; we are making sure Washington acts for you, for manufacturers.”

- Added NAM Executive Vice President Erin Streeter: “The NAM is on [these issues], and we’re going to keep fighting, as we do every day with the right leaders, the right strategies and the right vision for the future.”