New Hiring Pipeline Highlight: Pfizer’s Refugee Hiring Program

In 2021, Pfizer launched a company-wide Refugee Hiring Program, with the goal to hire a minimum of 100 refugees by the end of 2022 and provide mentorship opportunities to an additional 150 — with 50 of these opportunities earmarked for LGBTQ+ refugees. In less than a year, the initiative is well on its way to reaching its goal — having hired 68 refugees so far — and garnering widespread enthusiasm from Pfizer’s workforce.

“The knowledge curve might be a little [steeper], but in the end, there’s so much data that shows refugee hiring pays off immensely,” said Mona Babury, one of the creators of the program at Pfizer. “They’re very hardworking, loyal and thankful for the opportunity to enter a new workforce.” Read more about the program details and success here.

Interested in learning how to start your own program? Check out these webinars from the MI team on hiring refugee talent:

Dr. Ashish Jha on the Next Phase of Pandemic Response

This winter, we might be facing both a difficult flu season and another surge of COVID-19. How can manufacturers help protect workers and all Americans from illness, hospitalization or worse? Dr. Ashish Jha, the White House COVID-19 response coordinator, gave a comprehensive answer at an NAM gathering of manufacturing leaders last week. Here’s what he had to say.

The situation today: Though both COVID-19 infections and deaths are down, Jha noted that if we keep steady at today’s numbers, we’ll be seeing 100,000 to 150,000 deaths per year—three to five times worse than the average flu season.

- However, “almost every one of those deaths is preventable,” he emphasized. In fact, we are better able to fight COVID-19 than the flu, as we have more effective treatments for the former.

- If we take some proactive measures, Jha added, we can “drive the death number down 90%.”

What to expect: The near future is rather worrying, according to Jha. The combination of COVID-19 and flu stands to hit us hard this winter.

- We’ve had two seasons in a row with “little to no flu”—in large part thanks to COVID-19 mitigation measures like masking and avoiding large gatherings.

- This year, however, people have largely stopped masking and are back to congregating in person. And there is reason to expect a COVID-19 wave anyway, as infections spiked during both the past two winters.

- Meanwhile, there are alarming indications that this flu season will be harsh. Jha noted that public health officials watch the southern hemisphere during our summer (their winter) to see what our flu season may be like—and this year, the southern hemisphere had an “early and robust flu season.”

- In addition, the health care workforce is truly exhausted after more than two years of the pandemic. “There’s no question that this is potentially challenging,” Jha concluded.

What to do: As alarming as the situation might be, Jha says there is “good news” as well. “We can actually control and prevent a large chunk of what might be coming down the path,” he said, as long as we focus on three key measures.

Vaccines: This is the big one. Getting people vaccinated against COVID-19 and flu is essential, said Jha, and the new BA.5-specific COVID-19 shots will make a big difference.

- The U.S. is the first country to authorize such a shot, and that means we now have a “vaccine that exactly matches the dominant variant” and that offers much better protection for today’s environment than the original vaccines.

- Jha praised manufacturers’ and the NAM’s efforts to encourage workers to get vaccinated and urged manufacturers to continue their efforts this season, including by offering paid time off for workers getting vaccinated.

Treatment: The second essential element is treatment. As Jha explained, we have very effective treatments for COVID-19, including antivirals and monoclonal antibodies. We must make sure that people have easy access to them, via test-and-treat sites and telehealth, for example. Employers can also help workers get these lifesaving treatments, he added.

- These medicines not only prevent hospitalizations and deaths, but also help people “clear the infection faster, so they feel better faster.”

- “There is some preliminary evidence that they also prevent long-term complications like long COVID as well,” Jha added.

Air quality: Last, Jha cited the importance of improving air quality to combat all respiratory infections, whether COVID-19, influenza or RSV (a common respiratory virus).

- Most Americans spend 90% of their time indoors, but don’t really think about the quality of the air they’re breathing, he noted.

- Yet, that air quality helps determine your likelihood of getting sick, and even “makes a difference to your cognition,” he pointed out. Research shows that improving air quality raised students’ test scores in schools and reduced worker absences.

- We can improve indoor air quality by upgrading filters, improving air exchanges with the outdoors or using air purifiers, he advised.

The long term: “The virus will continue evolving, and that means we need a long-term strategy for building people’s immunity,” said Jha.

- The next generation of vaccines—including nasal vaccines that block transmission and “variant-proof” vaccines—will truly put COVID-19 behind us. And we need to develop these vaccines fast, via a partnership between the government and private sector, he said.

- Improving indoor air quality will also have a huge long-term impact, he added, as the economy loses tens of millions of dollars from worker absences due to illness.

- “We should use this moment, with all that we have learned from this pandemic, to build a healthier society,” he said.

The last word: In conclusion, Jha said, “Let me wrap up by saying thank you for the incredible leadership so many of you have shown in bringing our country as far forward as it has come.”

- “This next set of challenges is every bit as big as the original,” he warned. Yet, when the public and private sector work together, they “can accomplish enormous things,” like the development and deployment of the COVID-19 vaccines.

- “My hope is that we can continue doing that work together. And if we do, we can certainly get through this fall and winter without disruption, without a lot more sickness . . . and get our country to a much better, healthier and more productive place.”

How One Manufacturer Is Reinvigorating a Small Nebraska Town

Deshler, Nebraska, has a population of 747. It has one grocery store and one gas station, and its local high school graduates approximately 18 seniors each spring. It’s also the global headquarters of international irrigation firm Reinke Manufacturing, which employs a large number (about 600) of the town’s residents.

A great job: Working at Reinke has many perks, including generous pay and benefits, but until recently, the company had a hiring challenge to overcome in one specific area: housing.

- “We are so rural that we were having difficulty getting people,” Reinke Manufacturing President Chris Roth said. “We could recruit them easily, but then it was like, ‘Well, where am I going to live?’”

A solution—with an added perk: Around 2012, Roth and other leaders at Reinke came up with a fix: The company would purchase a house for a new employee and rent it to him at a reasonable fee.

- After that, the firm was on a roll. “We started to buy up lots with homes that needed to be torn down, homes that have been vacant for years … and put up something else” in which employees could live, Roth said. The move has “improved the town, too,” he added.

- The first build was a fourplex with efficiency apartments. “There’s a bedroom in the back, a bathroom and a kitchenette. People like those; they’re really nice.”

Expanding a vision: The efficiencies are mostly for single people, however, and Reinke wanted to have options for prospective employees with families, too. So, it began thinking bigger.

- “Our second fourplex was a building with two duplexes,” Roth said. “These are two-bedroom units, and small families live there.”

- Soon the company began purchasing single-family homes, too. It currently rents out seven such houses—all available for sale to the employees.

Even bigger: In early 2021, Reinke made its biggest investment in affordable employee housing yet. It purchased an entire motel in nearby Hebron, Nebraska, and turned it into apartments.

- The building now houses 40 people, some of them families. “It was run down when we bought it, but all brick and had a newish roof, so we were able to save a lot of it,” Roth said.

- In addition, the company recently broke ground in Deshler on a two-story, eight-unit housing complex of two-bedroom apartments that will be ready in spring 2023.

Game changer: Since Reinke got in on the housing game, recruitment and retention of top employees “is easier now,” Roth said. “They’re willing to move because they know we’ll have housing. If you’re going to move several states, you want to know where you are going to live … There really isn’t anything on Apartments.com [in Deshler].”

- Another benefit for Reinke employees has been that their new landlord requires less up-front outlay. “A deposit and first and last months’ rent is a lot, and it can be a problem for a lot of folks,” Roth said. “We don’t necessarily need all that.”

- The program is so popular, Roth said, there’s currently a waiting list for the units.

Other efforts: In addition to employee housing, Reinke is increasing its presence and education efforts at the local schools in a bid to recruit talent sooner.

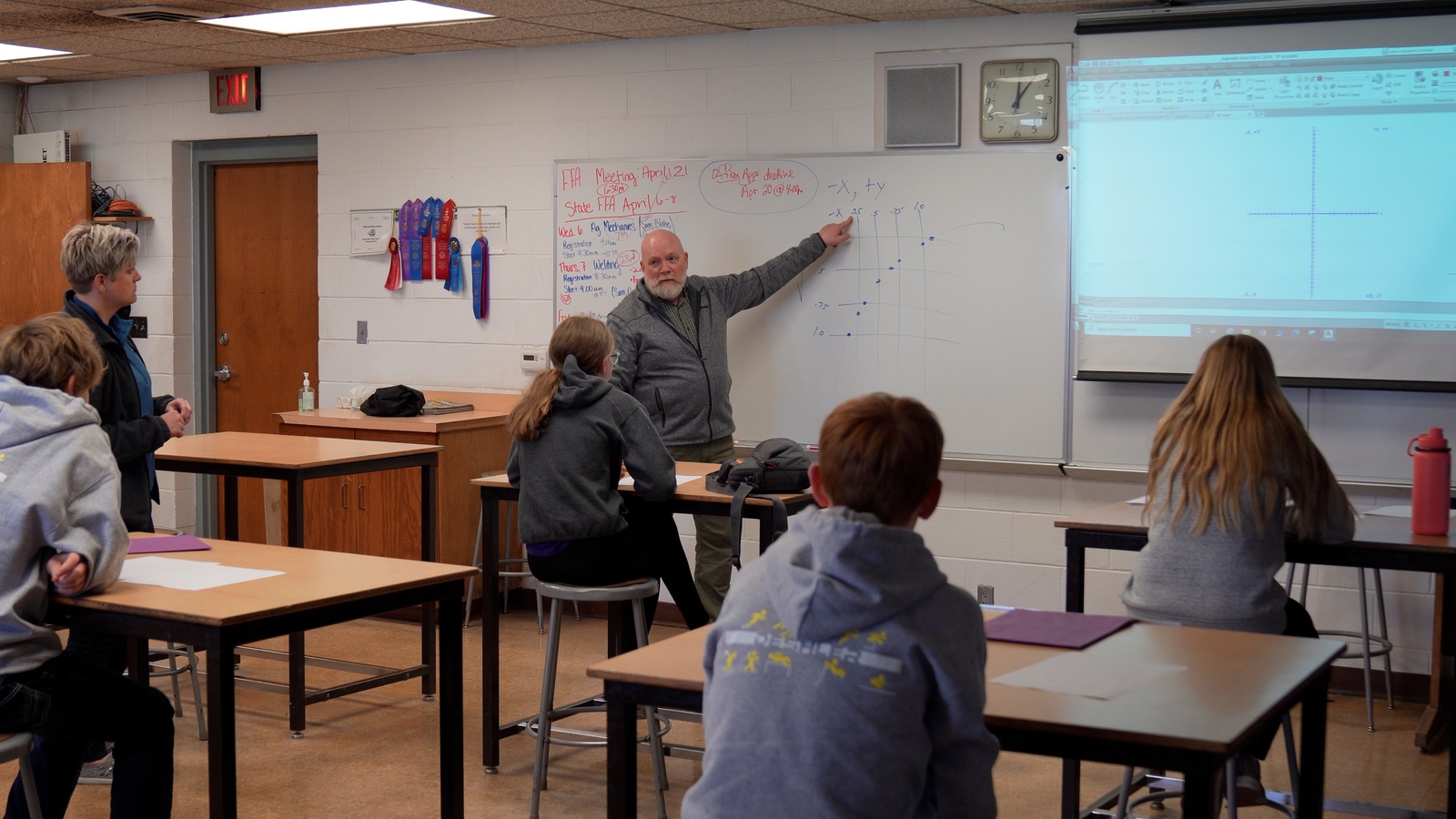

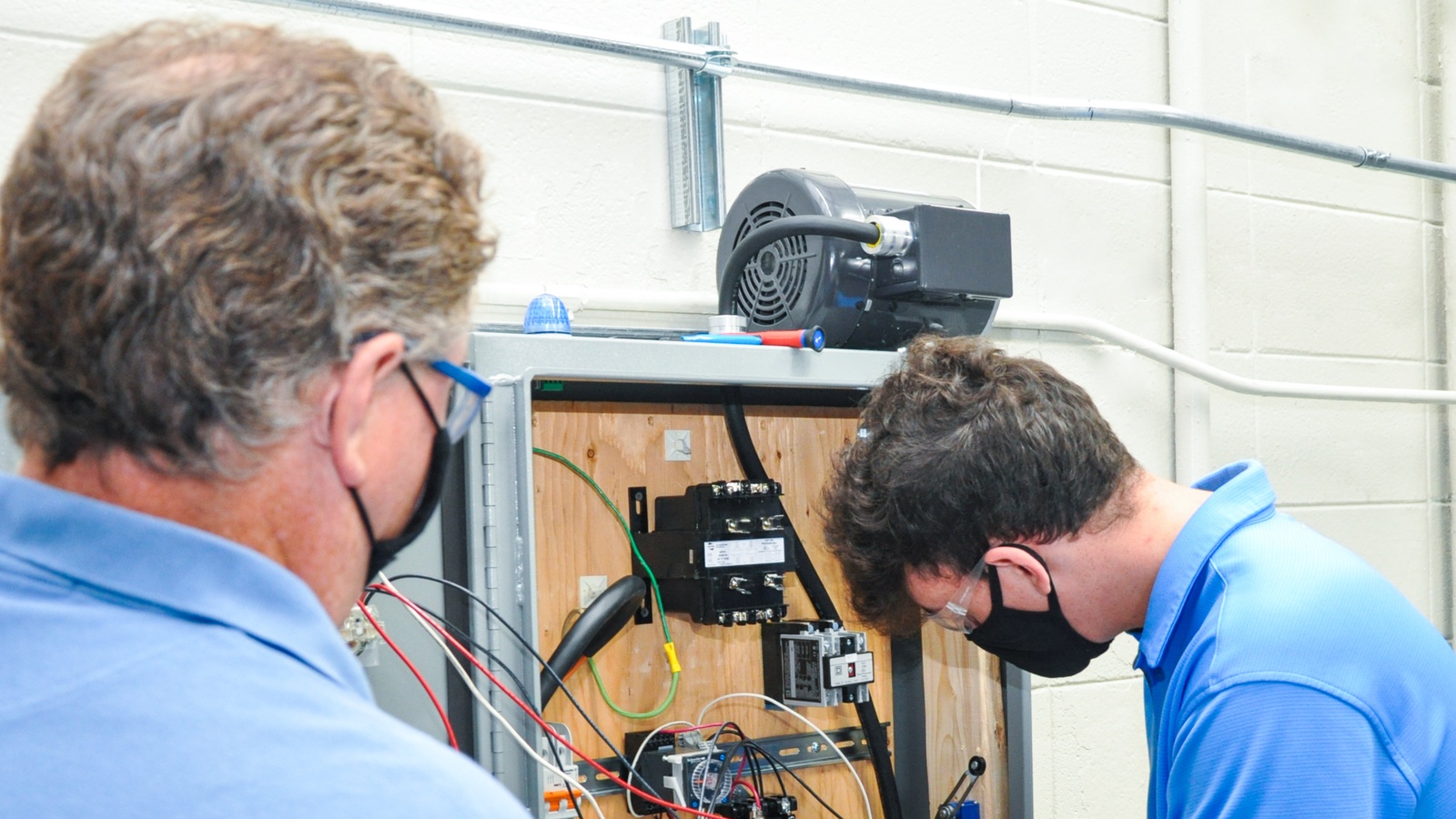

- The company started an employee-taught welding program at Deshler High School, which allowed the company to develop its own curriculum using American Welding Society Standards.

- “It gives us the opportunity to get in front of kids and teach them skills that we need,” Roth said. Reinke offers a similar program to adults through a cooperative effort at a community college.

- A Reinke-run middle school program helps students learn to use CNC machinery, with which the company manufactures parts. Through another program at the middle school, the company teaches a class on AutoCAD, software that allows users to create detailed two- and three-dimensional drawings, as well as courses on basic electrical and hydraulics skills.

The last word: Worker housing and manufacturing classes for young people will do more than create a top-notch workforce for the company, Roth said.

- “A lot of times kids will graduate and go to Omaha or Lincoln, and they don’t come back,” he said. “This is a way, hopefully, to keep people here in Deshler. They make very good money, have great benefits, so we hope they stay … and keep the town going.”

Pfizer’s Refugee Hiring Program Changes Lives

As Mona Babury tells it, Pfizer’s refugee hiring program was born out of the basic human need to connect during a time of shared anguish.

Wanting to help: Last August, Babury, the pharmaceutical company’s director of global diversity, equity and inclusion, was horrified by news coverage of the Taliban taking over Afghanistan and refugees fleeing.

- Babury’s husband had fled Afghanistan for the United States with his family at the age of 5, some 40 years before, so she had a personal connection to the events unfolding.

- She felt an urge to talk to someone who would understand, so she turned to Pfizer Executive Vice President and Chief People Experience Officer Payal Sahni, also a former Afghan refugee. In the course of their conversation, an idea popped into Babury’s head.

Lightbulb moment: “I said, ‘Why don’t we create a refugee hiring program? It will give [refugees] a glimmer of hope when they’re coming here with just the clothes on their backs,’” Babury recalled. “Within minutes, she responded, ‘Go for it.’”

Making it a reality: Pfizer, which had close to 1,000 job openings it was looking to fill, had never created a refugee hiring program before. “We didn’t have a playbook,” Babury said.

- The team decided to research similar initiatives, and in doing so contacted The Tent Partnership for Refugees, a nonprofit organization established by Chobani founder Hamdi Ulukaya to help businesses hire and train refugees.

- Thanks to Tent’s help, Pfizer’s Refugee Leadership Initiative was launched in mere days, with Babury named as its leader.

- Its goal? Hire a minimum of 100 refugees by the end of 2022 and provide mentorship opportunities to an additional 150—with 50 of these opportunities earmarked for LGBTQ+ refugees.

Following through: In less than a year, the initiative is well on its way to reaching its goal—having hired 68 refugees so far. The enthusiasm from Pfizer’s workforce has been immediate and widespread.

- After sending an email announcing the program globally, “we had 300 colleagues email back [within a few hours] saying they wanted to volunteer, to support us in any way they could,” said Babury.

- At Pfizer’s Kalamazoo, Michigan, facility, where the initiative has been most successful, “one [team] leader took this very personally,” hiring 18 Afghan refugees since the beginning of 2022, said Babury. In partnership with a local refugee agency, he has also made “a commitment to continue to further ramp up hiring efforts.” (Learn more here.)

Going above and beyond: Pfizer, which now works directly with the not-for-profit humanitarian organizations Tent for Refugees, Welcome.US, the International Rescue Committee and eight other resettlement agencies to source and hire refugees, does more than extend job offers.

- Though the new employees do not require sponsorship to work in the United States, owing to their refugee status, they do need help restarting their lives. Pfizer provides up-front bonuses to help cover the costs of transportation to and from work and to help them obtain driver’s licenses.

A winning formula: Seeking out refugees as employees can be an enormously rewarding sourcing strategy for a manufacturing company, Babury said.

- “The knowledge curve might be a little [steeper], but in the end, there’s so much data that shows refugee hiring pays off immensely,” she said. “They’re very hardworking, loyal and thankful for the opportunity to enter a new workforce.”

A proud moment: “I am so proud of the incredible progress we have made in support of this important and impactful initiative,” said Pfizer Chief Global Supply Officer Mike McDermott. Pfizer Global Supply, Pfizer’s manufacturing and supply organization, has hired the most refugees at Pfizer to date.

- “Our smart, talented and dedicated new colleagues are already making a difference. We welcome their fresh perspectives and have been motivated by their pride and passion,” he continued.

- “I’d also like to recognize our PGS colleagues for welcoming these new teammates with open arms, supporting them both professionally and personally,” he added. “Everyone deserves a fresh start, and we consider it an honor and a privilege to play a role in the new chapters for these refugees and their families.”

Success stories: The backgrounds of many of the recent hires are as impressive as they are diverse.

- The very first refugee hire, a man named Afzal Afzali, had been working for the U.S. embassy and the American University of Afghanistan when the Taliban seized control last summer. “He had to make a decision to escape within a few hours of the invasion,” according to Babury. “On his way out, he rescued four unaccompanied children protected by the U.S. government and reunited them with their mother in the United States.”

- Afzali, who now lives with his family in Texas and works at Pfizer in procurement, told the company the new job has led him to finding his “life’s purpose in serving others … likewise, Pfizer is all about breakthroughs that change patients’ lives.”

- Another new employee had previously worked with the Afghan president. She is now a senior associate on Babury’s team. She was recruited through the Pfizer Refugee Leadership Initiative Mentorship program.

The last word: Seeing the success of these new employees energizes those around them, said Babury.

- “The leader at our Kalamazoo site will speak to you with such a light in his eyes about how … once these hires have a job, they don’t consider themselves refugees anymore. They’re people with jobs. They have a way to take care of their families. There is a sense of pride among all our colleagues because of this program.”

Creators Wanted Gets Set for Fall Tour

Creators Wanted is gearing up for another season of bolstering positive perceptions of manufacturing careers and inspiring new manufacturers. Its schedule for this fall is now set—and we’re sharing it with you.

The nationwide tour, a joint project of the NAM and its workforce development and education partner The Manufacturing Institute, with significant legacy funding from Dow, Honda and Trane Technologies as well as contributions from more than 70 manufacturing companies, will stop in Nashville, Tennessee, on Sept. 27–29.

- The tour features an award-winning mobile immersive experience, to help students, emerging workers, parents and other career mentors learn and get excited about opportunities in modern manufacturing.

- Tour stop attendees will also meet local manufacturers, interact with hands-on technology, attend presentations by stars in the industry and access resources for training and job opportunities.

Building on big impact: The MI and Deloitte have already reported that positive perception of manufacturing careers has soared from 27% when the tour started to 40% today, just shy of the goal of 50% by 2025.

- The campaign has amassed—and maintained—an email network of more than 320,000 highly engaged students and career mentors.

Destination Tennessee: The Nashville stop will be the 10th since the tour began last year.

- Hosted by Electrolux and Schneider Electric and co-presented by Robertson County Economic Development, the Tennessee Chamber of Commerce and Tennessee Manufacturers Association and FactoryFix, the stop will take place at White House Heritage High School in the Nashville-adjacent town of White House, Tennessee.

- More than 500 students, parents, teachers and community leaders are slated to attend.

It’s good to be back! From Oct. 4 to 7, as manufacturers nationwide celebrate MFG Day 2022, Nephron Pharmaceuticals will host the second Creators Wanted tour stop this fall, in West Columbia, South Carolina. FactoryFix and the South Carolina Chamber of Commerce will also participate.

- The tour visited West Columbia and Nephron last October. This year’s encore visit to the city will take place at the Nephron Nitrile Factory.

- More than 20,000 students and career mentors are expected to sign up online to learn more about modern manufacturing careers.

College visit: Next, the tour will visit Decatur, Illinois, on Oct. 24–26, for a stop that will be hosted by Caterpillar and ADM and co-presented by Illinois Manufacturing and FactoryFix.

- The events will be held at Shilling Center at Richland Community College. This third fall tour stop is expected to draw many visitors from the local community and add more than 20,000 students and career mentors to our network in Illinois.

Windy City premiere: The last stop on the Creators Wanted fall tour will be at the Rockwell Automation Fair in Chicago, on Nov. 16-17. The Creators Wanted immersive experience will be a main feature on the showroom floor at this gathering of thousands of industrial automation leaders and experts.

Learn more: Tour organizers say that there is still time to join the fall tour stop events. Interested in supporting the cause and the MI’s sustained workforce solutions? Contact Barret Kedzior at [email protected].

Second Chance Hiring Works For Union Pacific

Finding and keeping a job can be challenging for people with criminal records. These jobseekers face exclusionary business practices and logistical obstacles, which result in an unemployment rate for this population that is five times higher than the general US public. To minimize this inequality, The Manufacturing Institute—the workforce development and education partner of the NAM—has joined with Union Pacific to expand candidate pools and bring more outstanding individuals into the manufacturing industry.

A second chance: Union Pacific began working on the second chance initiative last year, and the results have already proven fruitful.

- In 2022, the company launched a pilot program with local community organizations in Houston to eliminate barriers to employment for the formerly incarcerated and helped ensure the long-term success of these second chance candidates.

- In its first three months, the program brought in nearly 100 new applications and created positive relationships and support systems.

The steps to success: The Union Pacific team discovered that three components were critical to helping candidates find jobs and succeed:

- First, companies interested in hiring such candidates must update their own hiring practices and rethink potential barriers for otherwise qualified candidates—whether that means adjusting onerous required credentials or background checks.

- Second, partnerships and strong relationships with local community partners can help ensure that these candidates have the support they need to be successful. Tools like the MI’s Community Partnership Scorecard helped Union Pacific find partners that fit well with their goals.

- Third, establishing pilot initiatives in high-demand markets can help a company learn about best practices that can be replicated elsewhere. Plus, sharing experiences with other employers can help additional companies find success.

Expanding the program: Union Pacific’s current focus involves bringing the Second Chance initiative to new markets across the country to replicate the pilot program results.

- “Everyone I speak with about our success in Houston wants to know how we can take this model and multiply,” said Union Pacific Talent Acquisition Manager Ken Kawamura.

Leaders in the field: With the success of this initiative, Union Pacific has become an industry leader in establishing inclusionary hiring practices and building community partnerships. The company hopes to help establish second chance programs throughout the country.

- The Manufacturing Institute has been a critical partner in this work, providing information and resources necessary to its success.

- “The MI is committed to supporting members in the pursuit of effective Second Chance initiatives,” said MI Vice President of Workforce Solutions Gardner Carrick. “Our goal is to leverage those learnings and strategies across the manufacturing industry to expand talent and opportunity in the sector.”

The last word: Union Pacific’s primary goal in pioneering this initiative is to build a more equitable workforce for all employees.

- “In our eyes, once you are a part of Union Pacific, you are no different than any other employee, regardless of your background,” said Senior Director of Talent Acquisition Dan Culbertson.

Case Study: The Building Blocks of a Successful Second Chance Hiring Initiative

In early 2021, The Manufacturing Institute began collaborating with Union Pacific to build a Second Chance hiring initiative to expand candidate pools to be more inclusive of those with criminal records. Union Pacific Chairman, President and CEO Lance Fritz made expanding his company’s talent pipelines a priority and considers Union Pacific’s commitment to Second Chance employment an important part of that strategy.

To help design and implement Union Pacific’s Second Chance initiative, the MI partnered with Envoy Advisory via its Envoy initiative to make use of its expertise in inclusive hiring policies and practices and build partnerships with high-performing reentry and workforce organizations in Houston, Texas.

Assessing and adapting Union Pacific’s existing hiring policies and practices allowed for a deeper understanding of the candidate journey and illuminated potential barriers and support gaps for candidates from this population. While the pilot program was aimed specifically at candidates with criminal records, many of the identified employment barriers applied to a broad range of candidates from vulnerable backgrounds. Our case study outlines the three essential components of a successful Second Chance hiring initiative. Read the full case study here.

Manufacturing Offers Many Debt-Free Careers

The manufacturing industry has had more than 2.6 million job openings nationally in 2022 already—a workforce shortage that shows little signs of slowing. Meanwhile, half of all those available jobs don’t require a four-year college degree or the debt that goes with it.

This week, President Biden announced new measures providing student debt relief to many eligible Americans. Yet the manufacturing industry helps young people avoid this problem in the first place, while also offering them salaries far above the national average.

Manufacturing Institute President Carolyn Lee weighed in on the advantages available to young people looking to make a strong entry into the workforce, instead of suffering under debt that makes it more difficult to start a family, purchase a first home and achieve other major life milestones. Here’s what she had to say.

How it works: Manufacturers often offer short-term certifications or other training programs that allow people to jump into high-paying careers quickly and without debt, Lee explains.

- “There are multiple pathways to career opportunities in manufacturing through skills training, ranging from short-term programs to more involved skills development and apprenticeship programs,” says Lee.

- For example, the Federation for Advanced Manufacturing Education (FAME) program (founded by Toyota and operated by the MI) offers current and aspiring manufacturing workers both on-the-job training and classroom education. The program leads to an associate degree and an Advanced Manufacturing Technician (AMT) certificate.

- Manufacturers work with FAME’s local chapters in part because they allow companies to use a global best system to train the skilled workforce they need to compete.

The numbers: The data show that manufacturing is a good choice for those inclined to avoid debt, Lee points out.

- As noted above, there have been more than 2.6 million manufacturing job openings so far in 2022, but just 47% of those job openings (about 1.2 million) require a bachelor’s degree or greater.

- Meanwhile, manufacturing workers in 2020 earned $92,832 on average (compared to an average of $77,181 for workers in all private nonfarm industries).

What can policymakers do? To ensure that manufacturing training programs continue to expand and succeed, policymakers should make certain changes, says Lee.

- For example, Pell Grants should be usable for high-quality training programs as short as eight weeks—often all that is needed to train a technician.

- Policymakers should also ensure that our education system focuses on skills attainment for career success, and that teachers and other influencers are aware of opportunities offered by pathways other than four-year degree programs.

#CreatorsWanted: The NAM and the MI have taken this message to communities across the country through the Creators Wanted campaign’s tour and mobile experience. Tens of thousands of students, parents, educators and local leaders have attended the tour stops, where they learned about the promise of manufacturing careers and were challenged to think like manufacturers in the interactive mobile experience.

- As Lee told students at the Creators Wanted stop in Freeport, Texas, “Without a steady stream of talented, bright young people … we can’t keep up the good work of continuously making our products. This is not a get-one-job-and-stay-there-for-40-years [situation]. This is a choose-your-own-adventure [career path] with continuing skills and challenges and opportunities and learning along the way.”

The last word: “We understand how oppressive student debt can be, especially when starting out in life,” said Lee. “More people should be able to get a rewarding and well-paying job that doesn’t require massive debt that takes a lifetime to pay off. This is one of the reasons we work so hard to make sure young people know about the variety of options available to them in manufacturing careers; it’s not just for the industry’s benefit, but for theirs as well.”

If you’d like to hear more about careers in manufacturing, come to one of the many MFG Day events happening this October.

An Aspiring Manufacturer Finds FAME

Aidan Bleser took to manufacturing early on.

“The concepts of manufacturing were part of my childhood,” says Bleser. “There was a lot of Lego-building, and stuff like that.”

Still, Bleser didn’t get a chance to hone his skills until high school, when he was accepted into a program that offered courses on manufacturing at a local college, St. Philip’s College in San Antonio, Texas. Near the end of his program, his professors at St. Philip’s encouraged him to take the next step by signing up for the FAME program’s local chapter in Alamo.

The program: The Federation for Advanced Manufacturing Education (FAME), which was created by Toyota and is now overseen by The Manufacturing Institute, is a career pathway program for current and aspiring manufacturing workers. It provides them with on-the-job training and classroom education, leading to an associate degree and the Advanced Manufacturing Technician (AMT) certificate.

The experience: Through the program, Bleser was offered a role at Toyota, where he spent two years doing hands-on work while also accruing college credit.

- “FAME was great,” said Bleser. “The two years went by fast, and I enjoyed getting the college credit while still working part time. It helped the learning experience, being able to work while going to school.”

The people: Bleser also enjoyed working with other program participants as part of a group, getting to know individuals who were interested in manufacturing and even advising and mentoring younger students after his time in the program was up.

- “I’ve stayed in touch with people in my cohort, and I have mentored people in the younger cohort,” said Bleser. “That group dynamic is a great opportunity, because you can learn skills yourself and then teach them to other people.”

The job: Bleser graduated in May and was offered a full-time position at Toyota in August. He is now employed as a maintenance officer at Adient, one of Toyota’s on-site suppliers—and credits the FAME program with giving him the tools he needed to be successful.

- “I would recommend FAME to anyone,” said Bleser. “It prepares you really well. By the time you’re hired, you’re not a new face, and you’re used to the culture.”

The road ahead: Bleser’s experiences in the FAME program and at Toyota have shown him that there are opportunities available in manufacturing for people with all sorts of different talents and interests. He has big plans for the future:

- “I’d like to look into system integration, maybe opening some sort of company myself one day,” said Bleser. “I’ve also gotten more into application development on the software side, so I’d like to continue doing that, and hopefully develop some software that can be used throughout manufacturing.”

The last word: “There are so many ways to work in manufacturing,” said Bleser. “From maintenance, to quality, to logistics, to management, there are a lot of different places you could find yourself. Anybody with any skill set could be valued.”

GE Appliances Sees Success in Hiring Afghan Refugees

It’s been almost a year, but the sights and sounds are never far from his thoughts: crowds of people surging toward departing planes, trampling those who stumble; gunshots ringing out; the explosion of a nearby bomb.

For Edris Akseer, now a bilingual recruiting coordinator at GE Appliances’ (GEA) Louisville headquarters, these memories are daily reminders of the horrors that he, his wife and his brothers endured in Afghanistan to get to the United States—and how different his situation is today.

- “That day [I left] was the worst day of my life,” recalled Akseer, a former translator for the U.S. Army in Afghanistan who was able to secure passage out through his U.S. military connections. “[But] I’m happy here. I really enjoy helping others and I find my job really interesting. … I saved enough to buy a car and I’m working on getting my driver’s license.”

Helping refugees: Akseer is one of more than 100 non-U.S.-born employees brought on in recent months by GEA in Louisville. About 50 are refugees from Afghanistan who came here last fall when the U.S. military exited the country. The other half are Spanish-speaking and hail from multiple nations.

- “In early 2022, we had a new production line–and we needed to hire over 1,300 people,” recalls GE Appliances Senior Manager Beth Mickle, who runs the production recruitment group at the company’s large campus in Kentucky.

- “Catholic Charities and Kentucky Refugee Ministries said they [were helping] a group of people from Afghanistan and said, ‘We think you would be a great employer for them. Would you be interested in taking a shot at this?’”

- GEA was interested—and opening the hiring process to refugees and other immigrants has been one of the best workforce decisions the company has made in recent memory, Mickle said.

Location, location: As a longtime U.S.-immigration entry point, Louisville has large populations of non-native-born people, said GE Appliances Workforce Development Recruiter Gabriela Salazar.

- These include people from the Democratic Republic of Congo, Cuba, Peru, Honduras, Venezuela and Mexico, said Salazar, who recently conducted a survey of languages spoken among GE Appliances employees. The findings: production staff at three factories communicate in a total of more than 40 languages.

- In a sense, working with charities to hire refugees is the next step in the company’s hiring practices. It “has helped us to tap into populations we might not have known how to tap into before,” Mickle said.

Learning as they go: GE Appliances now offers new-hire orientations in many languages, including Afghanistan’s official languages of Pashto and Dari, as well as Spanish and Swahili.

- The company also has a buddy system which pairs new employees with workers who have been at the facility for a while.

- “These are employees who volunteer to be points of contact, to help show people around,” Mickle said. “You know, ‘Where is the bathroom? ‘Where do I get my protective gear?’ We also translate all the new-hire documents [into native languages] because they won’t remember everything from their first day.”

- Recently GE Appliances hired an American Sign Language translator to help its deaf employees. “Where it started was different languages—and now we’re seeing a lot of new horizons,” Salazar said.

Onward and upward: Akseer has seen a lot of new horizons himself in the past few months.

- He was originally hired at GE Appliances as one of its much-needed production-line team members, but owing to his fluent English, compassion and constant willingness to help, Akseer was “always being pulled of the line to help translate” something for another new employee, according to Mickle.

- So when a translator role opened up on Mickle’s team mere months after his hiring, Akseer was in. “He was already doing the role of what we needed him to do. He’s just a natural teacher,” Mickle said.

- On top of the new country, the new company and the two new jobs in quick succession, Akseer underwent another major change: becoming a new father. His son was born shortly after the family came to the U.S.

Advice for other manufacturers: Hiring refugees and other immigrant workers has been a boon for GE Appliances, Mickle said, and other manufacturers should consider following suit if they can.

- “They are the first to raise their hands for overtime,” she said. “They work very, very hard. In [manufacturing], our jobs are not always the easiest. But they do it and they love it.”

The last word: “Manufacturers that bring on refugees see fewer turnovers and increased efficiency,” MI Vice President of Strategic Engagement and Inclusion AJ Jorgenson said. “They’re also helping to improve lives and communities. More inclusive workplaces strengthen manufacturing.”