Manufacturers Help Hurricane-Hit Communities

Hurricane Ian’s devastating landfall in Florida Wednesday afternoon marked the second significant storm to hit the U.S. and territories in less than two weeks. But as is usually the case when catastrophe strikes, manufacturers are already among those leading the charge to help the communities affected.

Manufacturers mobilize: In Puerto Rico, where approximately one-third of all residents remain without power following Hurricane Fiona Sept. 18, manufacturers including Dow, UPS, Coca-Cola, Ecolab and Toyota are funding product donations across the island through NAM partners Good360 and SBP.

What’s happening: These NAM partner organizations are providing on-the-ground updates and working to get products where they’re needed most. Items of greatest need include:

- Solar-powered power generators;

- Nonperishable foods and ready-to-eat meals;

- Mold remediation products;

- Oxygen tanks;

- Hygiene kits and supplies;

- Drinking water;

- New clothing; and

- School supplies.

Meanwhile, the work is just beginning in Florida to respond to Hurricane Ian, with anticipated items including drinking water, nonperishable foods, hygiene kits, tarps, blankets and mold remediation products.

NAM in action: The NAM’s Emergency Response Committee is an employee-led, volunteer group that works year-round with nonprofit partners, including Good360, SBP and Project HOPE, to provide NAM members with disaster-preparedness resources and training.

- These resources, which include e-learning modules, fact sheets and webinars, enable manufacturers to support their employees ahead of, during and in the aftermath of disasters.

- The NAM’s ERC also helps manufacturers activate to aid their communities when disaster strikes—and it works to identify and highlight members that are leading this critical work.

Be prepared: In a webinar sponsored by the NAM’s ERC, Amanda Gallina, SBP community engagement manager, and Matt Woodruff, vice president of public and government affairs for Texas-based tank barge operator Kirby Corporation, gave their suggestions for hurricane preparation.

For businesses: Woodruff provided some commonsense advice for employers:

- Have a plan: Have a hurricane-preparedness plan and ensure that all employees understand it—before hurricane season starts.

- Make a list: Create a checklist of tasks that must be done during the season, starting with the first day.

- Set up: Create and offer remote work sites for affected communities and employees.

- Support: Provide support to the families of employees who live in disaster-hit areas.

The last word: “The NAM stands ready to provide resources and support for its manufacturing members and the communities in which they operate in all conditions,” said NAM Director of Member and Board Relations Isabelle Powell.

- “We urge members to contact their membership directors with questions on how to better prepare their team or support people in their communities.”

For more information on manufacturer disaster preparedness or to be added to the NAM’s ERC mailing list, please email [email protected].

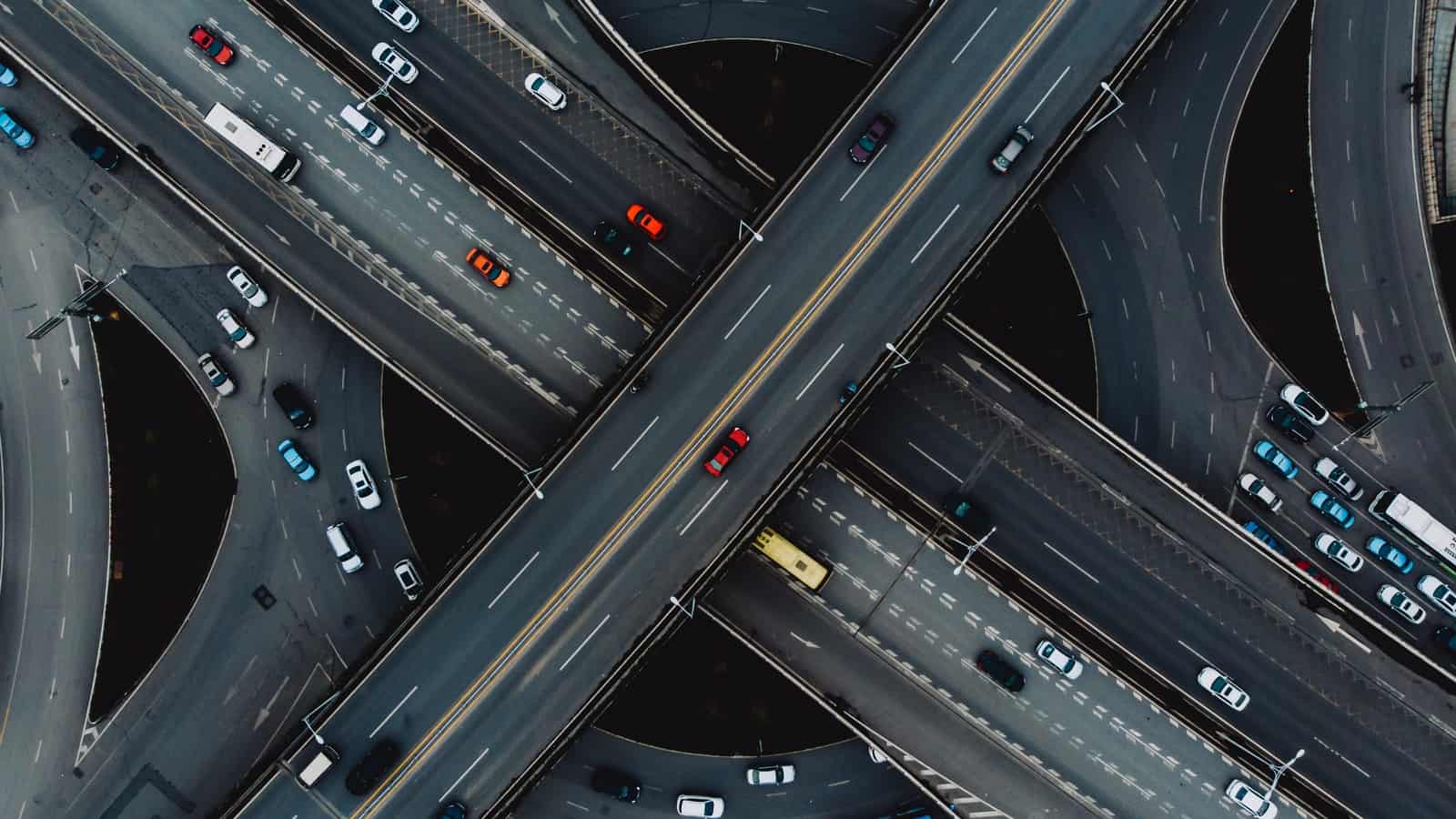

Building Infrastructure That Works

As supply chain disruptions and industrial shipping challenges of the past few years have proven, the U.S. infrastructure network is in dire need of a comprehensive overhaul. That’s why it’s a key focus of the NAM’s “Competing to Win” policy roadmap.

Turnkey fixes: “Competing to Win,” which focuses on immediately implementable solutions for congressional leaders in 12 policy arenas, enumerates a wide range of policies that will bolster manufacturers’ competitiveness.

Historic and bipartisan: With its $1.2 trillion investment, last year’s Infrastructure Investment and Jobs Act provided a solid foundation for upgrading roads, airports, bridges, ports, railroads and more.

- In fact, much of the final legislative text of the IIJA resembled proposals included in “Building to Win,” the NAM’s blueprint for modernizing our transportation, energy, water and digital infrastructure.

- The legislation contains nearly $550 billion in new federal appropriations for projects ranging from bridge and highway updates to significant broadband expansion and community climate resilience efforts.

The NAM’s plan: The NAM’s latest policy prescriptions are commonsense ideas that will help policymakers make the best use of the IIJA and enhance American competitiveness. Here’s a quick tour of the most important aspects it addresses.

Funding: The first order of business is paying for the upgrades. Policymakers should modernize user fees that support road and runway projects with much-needed funding.

Efficiency: Next up is fixing the all-too-sluggish pace of infrastructure projects. Some of the NAM’s recommendations:

- Keep improving the broken permitting process to decrease time-consuming reviews and eliminate burdensome costs.

- Clear the extensive backlog of essential infrastructure projects that are already in the planning process and awaiting final approval.

- And last, streamline regulatory agencies’ processes so that key transportation projects don’t get tripped up by more red tape.

Flexibility: Public–private partnerships and innovative collaboration between industry and government should play a large role in these upgrades, but not every approach is universal. Policymakers should maintain key funding sources and keep the federal government involved but retain a results-oriented focus to improve our nation’s infrastructure.

The last word: “‘Competing to Win’ builds on the historic gains made through last year’s Infrastructure Investment and Jobs Act and presents policymakers with a roadmap for improving American economic prosperity,” said NAM Vice President of Infrastructure, Innovation and Human Resources Policy Robyn Boerstling.

- “Manufacturers are the backbone of our national industrial base and rely on all parts of the transportation supply chain to create, assemble and ship to market essential products and consumer goods. The steps outlined in this plan are commonsense and will generate the economic growth needed to enhance American companies’ competitiveness in a global marketplace.”

Kigali Ratification a Win for Manufacturers

The Senate voted yesterday to ratify the Kigali Amendment—an international greenhouse gas–reduction accord that is more meaningful than any the U.S. had agreed to before. Long advocated by the NAM, this ratification is a major step forward for manufacturers and their ability to compete effectively and sustainably.

A climate-action model: In a strong bipartisan 69–27 vote, the Senate approved the amendment, a change to the 1987 Montreal Protocol that phases down the use of hydrofluorocarbons (commonly used refrigerants) in favor of more efficient next-generation alternatives.

- The measure, which the NAM called for in its climate change roadmap, “The Promise Ahead,” “could help avoid a half-degree Celsius of global temperature increases by the end of this century,” according to POLITICO Pro’s E&E News (subscription).

- The ratification builds on a move for which manufacturers also pushed, the 2020 legislation requiring the Environmental Protection Agency to issue rules to phase down nonessential HFCs by 85% by 2036.

Manufacturers approve: Many manufacturers were delighted by this move. “Trane Technologies applauds senators on both sides of the aisle for voting to ratify the Kigali Amendment,” Trane Technologies Chair and CEO Dave Regnery told Input.

- “In addition to creating 33,000 U.S. jobs, stimulating $12.5 billion in new investment in the U.S. economy and boosting U.S. exports by 25%, ratifying Kigali aligns with our bold commitments to reduce emissions through sustainable innovation.”

Accountability for China, India: Critically, the legislation fortifies “our global leadership and put[s] the U.S. in a position to hold countries like China and India accountable,” NAM Vice President of Energy and Resources Policy Rachel Jones said in a communique to Congress—which was quoted by Environment & Public Works Committee Chairman Sen. Tom Carper (D-DE) on the Senate floor Tuesday.

- The amendment will also “protect American workers, grow the economy and improve our trade balance all while encouraging further innovation to strengthen America’s technology leadership,” Jones wrote.

Inside the NAM’s advocacy: “We were able to leverage our longstanding policy experience, strategic partnerships and our depth of relationships in the Senate to adeptly navigate the ever-changing and challenging politics,” said NAM Senior Vice President of Policy & Government Relations Aric Newhouse.

- “Ultimately, the NAM’s support and long-term engagement was able to shepherd this crucial priority for manufacturers across the finish line in a bipartisan way that doesn’t force a false choice between environmental protection and economic growth.”

The last word: “This action proves that if we work together—if we rise above politics and partisanship and focus on solving problems—we can make our vision of a brighter tomorrow into reality,” Jones said in a statement.

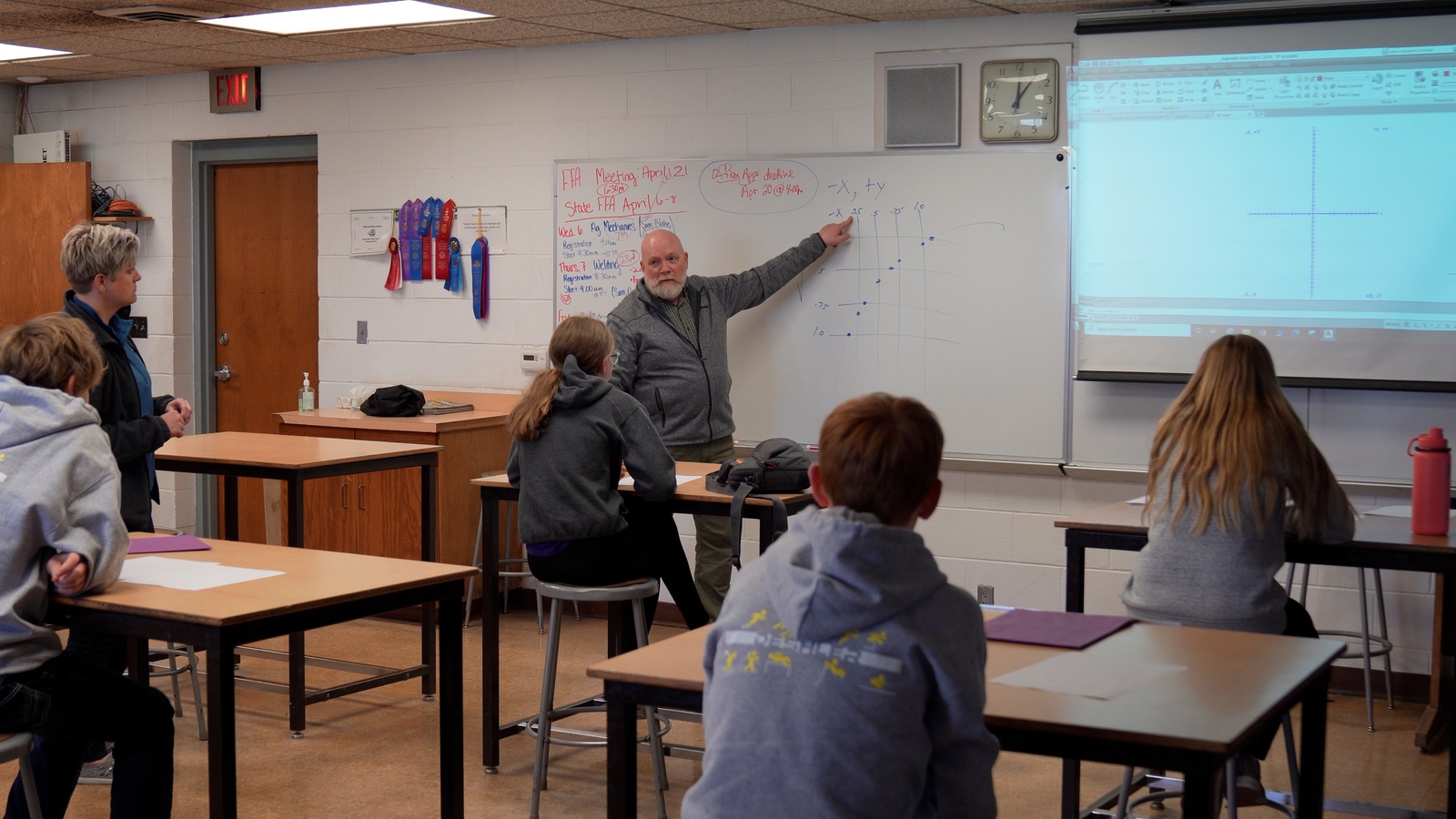

How One Manufacturer Is Reinvigorating a Small Nebraska Town

Deshler, Nebraska, has a population of 747. It has one grocery store and one gas station, and its local high school graduates approximately 18 seniors each spring. It’s also the global headquarters of international irrigation firm Reinke Manufacturing, which employs a large number (about 600) of the town’s residents.

A great job: Working at Reinke has many perks, including generous pay and benefits, but until recently, the company had a hiring challenge to overcome in one specific area: housing.

- “We are so rural that we were having difficulty getting people,” Reinke Manufacturing President Chris Roth said. “We could recruit them easily, but then it was like, ‘Well, where am I going to live?’”

A solution—with an added perk: Around 2012, Roth and other leaders at Reinke came up with a fix: The company would purchase a house for a new employee and rent it to him at a reasonable fee.

- After that, the firm was on a roll. “We started to buy up lots with homes that needed to be torn down, homes that have been vacant for years … and put up something else” in which employees could live, Roth said. The move has “improved the town, too,” he added.

- The first build was a fourplex with efficiency apartments. “There’s a bedroom in the back, a bathroom and a kitchenette. People like those; they’re really nice.”

Expanding a vision: The efficiencies are mostly for single people, however, and Reinke wanted to have options for prospective employees with families, too. So, it began thinking bigger.

- “Our second fourplex was a building with two duplexes,” Roth said. “These are two-bedroom units, and small families live there.”

- Soon the company began purchasing single-family homes, too. It currently rents out seven such houses—all available for sale to the employees.

Even bigger: In early 2021, Reinke made its biggest investment in affordable employee housing yet. It purchased an entire motel in nearby Hebron, Nebraska, and turned it into apartments.

- The building now houses 40 people, some of them families. “It was run down when we bought it, but all brick and had a newish roof, so we were able to save a lot of it,” Roth said.

- In addition, the company recently broke ground in Deshler on a two-story, eight-unit housing complex of two-bedroom apartments that will be ready in spring 2023.

Game changer: Since Reinke got in on the housing game, recruitment and retention of top employees “is easier now,” Roth said. “They’re willing to move because they know we’ll have housing. If you’re going to move several states, you want to know where you are going to live … There really isn’t anything on Apartments.com [in Deshler].”

- Another benefit for Reinke employees has been that their new landlord requires less up-front outlay. “A deposit and first and last months’ rent is a lot, and it can be a problem for a lot of folks,” Roth said. “We don’t necessarily need all that.”

- The program is so popular, Roth said, there’s currently a waiting list for the units.

Other efforts: In addition to employee housing, Reinke is increasing its presence and education efforts at the local schools in a bid to recruit talent sooner.

- The company started an employee-taught welding program at Deshler High School, which allowed the company to develop its own curriculum using American Welding Society Standards.

- “It gives us the opportunity to get in front of kids and teach them skills that we need,” Roth said. Reinke offers a similar program to adults through a cooperative effort at a community college.

- A Reinke-run middle school program helps students learn to use CNC machinery, with which the company manufactures parts. Through another program at the middle school, the company teaches a class on AutoCAD, software that allows users to create detailed two- and three-dimensional drawings, as well as courses on basic electrical and hydraulics skills.

The last word: Worker housing and manufacturing classes for young people will do more than create a top-notch workforce for the company, Roth said.

- “A lot of times kids will graduate and go to Omaha or Lincoln, and they don’t come back,” he said. “This is a way, hopefully, to keep people here in Deshler. They make very good money, have great benefits, so we hope they stay … and keep the town going.”

Manufacturers: Kigali Ratification a Blueprint for Bipartisan Climate Action

Washington, D.C. – Following the Senate’s 69–27 vote to ratify the Kigali Amendment to the Montreal Protocol, National Association of Manufacturers Vice President of Energy and Resources Policy Rachel Jones released the following statement:

“The Senate’s vote to ratify the Kigali Amendment is a blueprint for the type of bipartisan climate action that meets science-based targets while strengthening manufacturing competitiveness. It will reduce emissions by the equivalent of 80 billion metric tons of CO2 by 2050, with the potential to create up to 150,000 more U.S. jobs by 2027. This action proves that if we work together—if we rise above politics and partisanship and focus on solving problems—we can make our vision of a brighter tomorrow into reality.

“Manufacturers have supported the ratification of the Kigali Amendment for years. This treaty will be a boon for manufacturing, for global trade and for products that protect health, safety, comfort and productivity worldwide. Ratification further strengthens our global leadership on the phasedown of hydrofluorocarbons and will help the U.S. hold countries like China and India accountable on emissions. This shows that we can tackle climate change while strengthening our global competitiveness as we deploy next-generation technologies.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers Wake Up to Welcome News of Railway Agreement

Washington, D.C. – Following news of a tentative agreement between U.S. railroad companies and unions to avoid a strike, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“This morning’s announcement of a tentative agreement between the railroads and their workers is a welcome relief. Manufacturers had been putting into place contingency plans as they were facing disruptions with moving their supplies and products. Manufacturers thank President Biden, Secretary Walsh, Secretary Buttigieg and others in the administration who understood the stakes and stepped in to help prevent a very serious nightmare for the supply chain.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers Call for Quick Resolution to Rail Negotiations

Timmons: Delays in concluding the rail negotiations will exacerbate the pain of inflation and supply chain disruptions, and failing to reach an agreem

Washington, D.C. – Following news that White House aides and Cabinet officials spent Tuesday reviewing contingency plans for a work stoppage, including outreach to shippers, truckers and air-freight lines to keep goods moving, National Association of Manufacturers President and CEO Jay Timmons released the following statement on the ongoing negotiations between Class I railroads and labor unions representing the freight rail workforce:

“For years now, America’s manufacturing workers have endured the effects of rapidly rising material costs and severe supply chain disruptions, and our member surveys have shown quarter after quarter that these are among the top challenges affecting manufacturing growth in America. Further delays in concluding the rail negotiations will exacerbate the pain of inflation and supply chain disruptions, and failing to reach an agreement before Friday’s deadline would devastate the movement of manufactured products that families depend on,” said Timmons. “The Presidential Emergency Board has announced reasonable recommendations that nearly all parties have accepted, so now is the time to resolve remaining issues. We appreciate the administration’s proactive approach, and Congress should be ready to act as a last resort. But manufacturers still believe that the parties have it within their power to resolve these talks before they inflict severe economic damage.”

Currently, the American freight rail network accounts for nearly 40% of total freight volume, and a strike or delay in finalizing a long-term contract would have devastating impacts across surface supply chain networks and economic output. The Association of American Railroads recently released a report that found a nationwide freight rail interruption could cost more than $2 billion per day in lost economic activity.

Background: On Monday, Sept. 12, the NAM sent a letter to congressional leaders reiterating support for the work of the Presidential Emergency Board, which has aided in the talks. The NAM also urged Congress to use its statutory authority to institute the PEB’s recommendations should it become necessary to intervene. The NAM supported President Biden’s selection of an independent and objective PEB and believes that the recommendations announced on Aug. 16 have provided an appropriate framework to avoid disruption to freight rail operations.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

From the Air Force to the Railroad: Tara Hogan’s Success Story

When Tara Hogan was growing up in Texas, she wanted to be a basketball coach—a career in freight rail wasn’t on her radar. But after high school and six years of service in the U.S. Air Force, she finished her college degree, took on a few different jobs and went looking for her next gig. She found Union Pacific Railroad on a list of companies looking to employ military veterans and landed a job as an operations management trainee in 2006.

More than 15 years later, after stints in Nebraska, Louisiana and Kansas, Hogan serves as a general manager at Union Pacific in Fort Worth, Texas, leading a team of 1,700 people as she runs the freight rail service in an active—and essential—area of the country.

Starting out: In many ways, Hogan found that her experience in the military gave her the tools to succeed at Union Pacific.

- “Union Pacific is a 24/7 operation that runs 365 days a year, as the military does,” said Hogan. “In the military, there’s a structure and a sense of certainty, and there’s comfort to that; at Union Pacific, there’s the same kind of certainty and structure. There’s a language in the military, and a language at Union Pacific.”

- “For me, it was the place I could go that felt the most familiar…. It’s got the structure of the military but the flexibility of the civilian environment.”

Paying it forward: Today, Hogan isn’t only an outstanding representative of the railroad industry in her own right; she’s also a role model for others who might be interested in a career in the sector—including individuals from communities that are currently underrepresented.

- Through Union Pacific’s UPLift program, which pairs underrepresented employees with executive sponsors, Hogan is sponsoring a woman in Fort Worth, offering career advice and networking support.

- “It’s not a one-and-done mentor situation,” said Hogan. “I’ll be with her throughout her career, and I’ll watch her grow. Hopefully, she’ll be my boss someday.”

A supportive environment: As a woman in freight rail, Hogan is generally in the minority, even as Union Pacific works to double the number of women employed at the railroad. Still, Hogan’s experience has been positive, and she has always felt encouraged to gain skills and rise in the company.

- “Everybody I have come across has wanted to see me succeed,” said Hogan. “If somebody is willing and wanting to learn, there are a ton of people here who want to teach you and see you be successful.”

- “I never thought I’d be in this position. I didn’t aspire to it. But the company saw something and kept challenging me to see what I can do. It’s been a great experience for me.”

The bigger picture: Hogan’s success at Union Pacific is part of the company’s ambitious efforts to advance women throughout its operations.

- Its Careers on Track program—in partnership with The Manufacturing Institute—aims to increase the number of women in the manufacturing and transportation, distribution and logistics industries.

- The program is designed to inspire women and youth to pursue modern industry careers through workforce development and career solutions.

The last word: “You can learn anything you want to learn here, depending on what your job is,” said Hogan. “Manufacturing has changed with the times and become better. All the opportunities to learn and grow have become better. If you’re a hard worker and willing to learn, there’s no glass ceiling anymore.”

Book Tax Would Disproportionately Burden Manufacturers

The proposed “book tax” in the Senate’s reconciliation bill “would overwhelmingly hit U.S. manufacturers,” according to a new analysis by the Joint Committee on Taxation, Congress’s non-partisan tax scorekeeper.

What’s going on: The reconciliation bill, the outline of which was released Wednesday by Senate Majority Leader Chuck Schumer (D-NY) and Sen. Joe Manchin (D-WVA), proposes a 15% minimum corporate levy, or “book tax,” on certain companies.

- The provision is estimated to raise $313 billion, and JCT finds that manufacturers would be responsible for paying nearly half of it.

What it means: The impact would be swift and devastating to manufacturers and the economy as a whole, said NAM Chief Economist Chad Moutray, who conducted his own analysis of the bill’s effects on the manufacturing sector.

Including direct, indirect and induced effects, in 2023 alone the impact would include:

- A real GDP reduction of $68.45 billion

- 218,108 fewer workers in the overall economy

- A labor-income decrease of $17.11 billion

Targeting manufacturers: “‘This is a domestic manufacturing tax, plain and simple,’” said Senate Finance Committee Ranking Member Mike Crapo (R-ID), who asked for the JCT analysis.

- “Despite Democrats’ claims, the book minimum tax does not close tax loopholes. Treatment of capital investments, like those made by American manufacturers, differ for book and tax purposes—for good reason,” according to a press release from Senate Finance Republicans.

- “Congress intentionally designed tax depreciation rules to support domestic investment. Democrats’ tax on U.S. manufacturing would eliminate that benefit.”

Exclusive: Sinema Meets with Manufacturers in Arizona, Talks Policy with the NAM

U.S. Senator Kyrsten Sinema (D-AZ) recently got an in-person look at manufacturing’s success in Arizona on a NAM-arranged tour of Phoenix manufacturer Valley Forge & Bolt. During her visit, which also featured a roundtable with manufacturers from across Arizona, she spoke with the NAM about the successful passage of historic infrastructure legislation without tax increases, the necessity of boosting semiconductor production and more.

- During the roundtable, Valley Forge & Bolt President and CEO Michele Clarke highlighted the direct impact of the 2017 tax reforms on her ability to invest in her facility and workforce. She thanked the senator for standing against future tax increases on manufacturers and for her leadership on infrastructure investment.

The NAM caught up with the senator after the roundtable for an exclusive interview. Here is some of what she said.

Infrastructure in Arizona: “We’ve got over $5.3 billion coming just to improve our roads and bridges in Arizona,” said Sinema. “That’s critical for the work we’re doing to shorten the supply chain. The benefits of this law will be seen for years to come.”

- “It provides a real opportunity for manufacturing businesses in Arizona to be able to utilize this energy and these dollars we’ve created to move forward, attract more companies to Arizona, and become a world leader in manufacturing.”

What’s next? “My number one goal now that this [infrastructure] bill has become law is to make sure that it’s implemented quickly, swiftly, and without bureaucracy,” said Sinema.

- “I want to make sure Arizona is getting its fair share of dollars so that the men and women who are running and working for our manufacturing companies can put these dollars to good use and make sure Arizona retains and grows its status as a domestic manufacturer.”

Creators Wanted: “There’s a need for us to really focus on investment in our education system so that we’re training the highly qualified tradesmen and tradeswomen who can do the work of this domestic manufacturing,” said Sinema. “That’s an area where we have an opportunity to grow, not just here in Arizona but across our nation. To meet this need so we can retain our global independence and competitiveness.”

Chips: “Arizona is already a hub for the microchip and the semiconductor industry; but passing the CHIPS Plus legislation will allow us to triple or even quadruple that investment,” said Sinema. “It’s incredibly important for us—not just for the tax credit and the investment in R&D—but for the tech hubs, for the investment in science, and to help attract more companies to build semiconductors right here in Arizona.”

The last word: “Manufacturing is the bread and butter of our state,” said Sinema. “It ensures that Arizona is a hub to the nation and the entire world in making products that will power our economy for the future.”

Read more: Check out the local coverage of the senator’s visit from the Daily Independent and the Phoenix Business Journal (subscription).