Manufacturers: USTR Report Signals Importance of Concrete Action to Protecting Manufacturing Innovation

Washington, D.C. – Following U.S. Trade Representative Katherine Tai’s release of the agency’s annual Special 301 report on global intellectual property protection, National Association of Manufacturers Vice President of International Economic Affairs Ken Monahan released the following statement:

“Innovation and intellectual property are the lifeblood for manufacturers in the United States, supporting manufacturing businesses and a skilled workforce here at home, creating economic opportunity for Americans of all backgrounds and empowering American leadership around the world. That manufacturing innovation is also a constant target for foreign governments and businesses that want to steal or undermine critical IP protections and rules to boost their own economies at our expense.

“USTR’s latest Special 301 report clearly illustrates many of the biggest IP barriers—and bad actors—that the NAM highlighted in our January 2022 submission to USTR as risks to as risks to our manufacturing businesses and workers. This report is an important step toward concrete action. We urge USTR and other agencies to stand up for innovative manufacturers by knocking down these barriers and by pushing back against those who would weaken critical IP protections around the world.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.71 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers at the Table in U.S.–UK Trade Dialogue

The NAM delivered several key messages to U.S. Trade Representative Katherine Tai this week at the U.S.–UK Dialogue on the Future of Atlantic Trade in Aberdeen, Scotland.

What’s happening: The meetings, convened by Ambassador Tai and UK Secretary of State for International Trade Anne-Marie Trevelyan, were the second in a series begun last month in Baltimore.

- The meetings in Aberdeen featured a series of dialogues on issues including supply chains, digital trade, small- and medium-sized enterprises and green trade.

- They included U.S. and UK government officials as well as U.S. and UK business, labor and civil society leaders.

What the NAM said: NAM Vice President of International Economic Affairs Ken Monahan, who participated in both sets of meetings, told Input that the NAM made two crucial points to Ambassador Tai, Secretary Trevelyan and other leaders this week.

- “Manufacturers in the United States need diverse sources for trade to ensure supply chain resiliency—supported by a robust network of market-opening, comprehensive, enforceable trade agreements and other arrangements with U.S. allies,” Monahan said.

- He added that “as the U.S. and the UK take steps to build a stronger, more open and secure economic relationship, the NAM urged the launch of talks toward a new U.S.–UK market-opening trade agreement that includes strong, clear and enforceable outcomes.”

Monahan also told the leaders that a trade deal with the UK should include several key priorities for manufacturers, including:

- The elimination of tariffs and nontariff barriers;

- Strong digital trade commitments;

- Robust engagement on intellectual property issues;

- Collaboration on standards, technical regulations, testing procedures and conformity assessment;

- The brokering of common approaches to ending forced labor in global supply chains; and

- Ensuring stronger alignment on customs procedures and approaches.

Why it matters: The U.S. and the UK share a strong trade and investment relationship.

- It includes more than $93 billion in two-way trade of manufactured goods and accumulated cross-border investment in manufacturing of more than $273 billion.

- Key U.S.-manufactured goods exports to the UK include metals, chemicals, transportation equipment, computer and electronic products and machinery.

The last word: “Recent events show that we need our friends now more than at any time in recent memory,” Monahan said. “It is vital that we forge deeper trade agreements and other economic partnerships with allies like the UK. It is also essential that we work closely with the UK and others to ensure supply chain resiliency and address shared global economic challenges that our companies face in markets around the world.”

Business Leaders Urge Resolution of U.S.-Canada Border Blockade

The National Association of Manufacturers, U.S. Chamber of Commerce and Business Roundtable today issued the following statement on the disruptions to trade at U.S.-Canada border crossings:

“The disruptions we are seeing at the U.S.-Canada border — at the Detroit-Windsor Ambassador Bridge and at other crossings — are adding to the significant supply chain strains on manufacturers and other businesses in the United States.

“The business community is rolling up its sleeves to find workarounds and keep facilities up and running, but we are already seeing some production cuts, shift reductions, and temporary plant closures. The North American economy relies on our ability to work closely together, including our manufacturing sectors. We need to apply the same spirit of cooperation to tackle this problem.

“We respectfully urge the Canadian government to act swiftly to address the disruption to the flow of trade and its impact on manufacturers and other businesses on both sides of the border. We appreciate that the Biden Administration is engaged with the Canadian government, and we strongly encourage officials to continue efforts to resolve these blockages at the border.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

How Manufacturers Can Navigate Supply Chain Challenges

As the global supply chain, worker shortage and wage inflation challenges many had hoped were transitory dig in their heels, manufacturers everywhere are wondering how best to get around them.

Panelists at “Successfully Navigating Current Supply Chain Disruptions,” a webinar hosted by the NAM’s Manufacturing Institute, Manufacturing Leadership Council and professional services firm PwC, sought to answer that question.

We rounded up the speakers’ top tips for manufacturers seeking to sustainably and profitably maneuver the several sizable hurdles they still face going into 2022.

- Break down siloes. Now that manufacturers are having to replace traditional supply chain models, changing their company operations to have staff work across siloes is more important than ever, said PwC Partner Debjit Banerjee.

- Expect disruption. If it taught us nothing else, COVID-19 conveyed the importance of being prepared for the unexpected. Going forward, manufacturers would do well to not just plan for the possibility of disruption, but to assume it will come. To that end, preplanned “differentiated customer service” and disruption drills should become the norm, Banerjee said.

- Advance your supply chain planning. Increasingly, Nexteer Automotive, a global maker of steering and driveline components, is focusing on advanced supply chain planning, programs that help predict shipments, supply and demand for smoother operations, said Nexteer Automotive Vice President of Global Manufacturing Operations Dennis Hoeg. With it, “decisions can be made smarter, earlier.”

- Automate. Manufacturers should consider automating repetitive “transaction” work and reserving their employees for analytical tasks that only humans can do, according to Hoeg.

- Balance agility and resilience. Before the pandemic, “we were working on a strategy that was based on agility,” said Rockwell Automation Chief Supply Chain Officer Ernest Nicolas Jr. “Through the pandemic … we had to reprioritize. We had to take a step back to balance agility and resilience.” Manufacturers that want a better agility-resilience balance can do so “through data, process and technology” enablement, according to Nicolas.

- “Relentlessly prioritize.” Nicolas so believes in this advice that he ended his presentation with it. “There’s so much going on right now; we want to be certain we manage our priorities,” he said. “So, there’s a lot we’re saying ‘not now’ to …. but it’s not a matter of ‘no.’ It’s a matter of, ‘We’ve got to get these things finished so we can lay the foundation’” in this new normal.

Manufacturers: China Is Not Following Through on Important Commitments Made in the 2020 U.S.–China “Phase One” Agreement

Washington, D.C. – Following remarks today by U.S. Trade Representative Katherine Tai, National Association of Manufacturers President and CEO Jay Timmons released this statement:

“China is not following through on important commitments made in the 2020 U.S.–China ‘Phase One’ agreement, and it also remains a hub of bad behaviors—from intellectual property theft to market-distorting industrial subsidies—that harm manufacturers and their employees here in the United States. Manufacturers agree with Ambassador Tai that we need a new, holistic and pragmatic approach to our relationship with China. We are pleased that the Biden administration’s approach reflects key priorities for manufacturers in the U.S., including holding China accountable on the ‘Phase One’ deal, allowing manufacturers to seek tariff relief, stepping up direct U.S. engagement with Chinese officials and working with our allies to ensure that the U.S. shapes the global rules for trade. We look forward to working with USTR on robust measures to ensure quick action in each of these areas to hold China accountable and to strengthen manufacturers and manufacturing workers in America.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.4 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

“The Culture Is the Company”: An Interview with ALOM’s Hannah Kain

With 19 global locations, ALOM Technologies Corporation specializes in technology-driven supply chains for Fortune 100 companies. ALOM President and CEO Hannah Kain recently sat down with the Manufacturing Leadership Council to share her thoughts on the state of the industry and the keys to successful leadership.

Taking on challenges: Over the long term, Kain sees workforce development—finding and training the next generation of manufacturing leaders—as a significant priority. But in the short term, she cites COVID-19- and trade-related supply chain disruptions as the most pressing issues.

- “Shifts in demand have increased the need for agility in manufacturing, yet U.S. infrastructure, from ports and roads to cybersecurity, is under extreme strain, and geopolitics have made goods movement more complex,” she said.

Meeting the moment: During the COVID-19 pandemic, ALOM manufactured millions of COVID-19 test kits for the medical sector while ensuring its own workers remained safe, Kain said. The company also met the past year’s challenges by investing in digitization to improve its productivity.

Finding opportunities: Kain cites a range of opportunities for manufacturers of the future, from fast-improving technologies to the availability of new manufacturing talent—if manufacturers can find and harness it.

The importance of culture: Kain believes in what she calls “servant leadership”—seeing yourself as a supporter of stakeholders like customers, employees and suppliers and working to put their needs first. She strives to create a culture of collaboration within her own company.

The last word: “In the end, culture is the company, and the company is the culture,” said Kain. “Our culture is inclusive, collaborative, improvement-oriented and quality-focused, with a strong sense of ownership. Supporting that culture may be the most important thing I do.”

Manufacturers: President’s Budget Rightly Prioritizes Bold Infrastructure Investment

Washington, D.C. – Today, following the release of President Joe Biden’s budget for FY 2022, National Association of Manufacturers President and CEO Jay Timmons released this statement:

“A budget is an important statement of a president’s priorities, and manufacturers are pleased to see President Biden prioritizing bold investments in infrastructure. The president’s clear commitment to ‘investing in ourselves’ is encouraging—and infrastructure is the right place to start. Manufacturers will continue working with both parties to secure a strong infrastructure deal.

“We know the president wants America to succeed and lead, and we agree. There are differences of opinion, however, on how to accomplish that laudatory goal. That is why we remain steadfast in our view that the competitive tax structure for businesses in America that was enacted in 2017 must not be disturbed. After the 2017 tax reform law, America saw the best year for manufacturing job creation in more than two decades, and the NAM’s recent tax study showed that tax increases under consideration would eliminate 1 million jobs in just the first two years. We can’t truly move forward as a country if we take a giant step backward with archaic tax laws.

“Manufacturers are confident that by working together in a bipartisan manner, we can find common ground that lifts everyone up and leaves no one behind. We look forward to continuing to work with the administration and members of the House and Senate from both political parties to accomplish exactly that.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.3 million men and women, contributes $2.35 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers: WTO/TRIPS Waiver Will Not Solve Crisis

Washington, D.C. – Following the announcement by the United States Trade Ambassador that the Biden administration will support waiving intellectual property protections for COVID-19 vaccines, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“We are all horrified by the images that we are seeing in India and in other places around the world hard-hit by COVID-19. The proposed WTO/TRIPS waiver would not solve this crisis and would exacerbate the core manufacturing and distribution challenges, as well as introduce serious new safety concerns.

“Rather than rushing to suspend critical protections and standards, investing in even greater production capacity would result in expanded vaccine access. Pharmaceutical manufacturers continue to work around the clock to help the world get armed against COVID-19. We should do everything possible to build on that heroic work, not undermine the protections that make this innovation possible in the first place.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs 12.3 million men and women, contributes $2.33 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

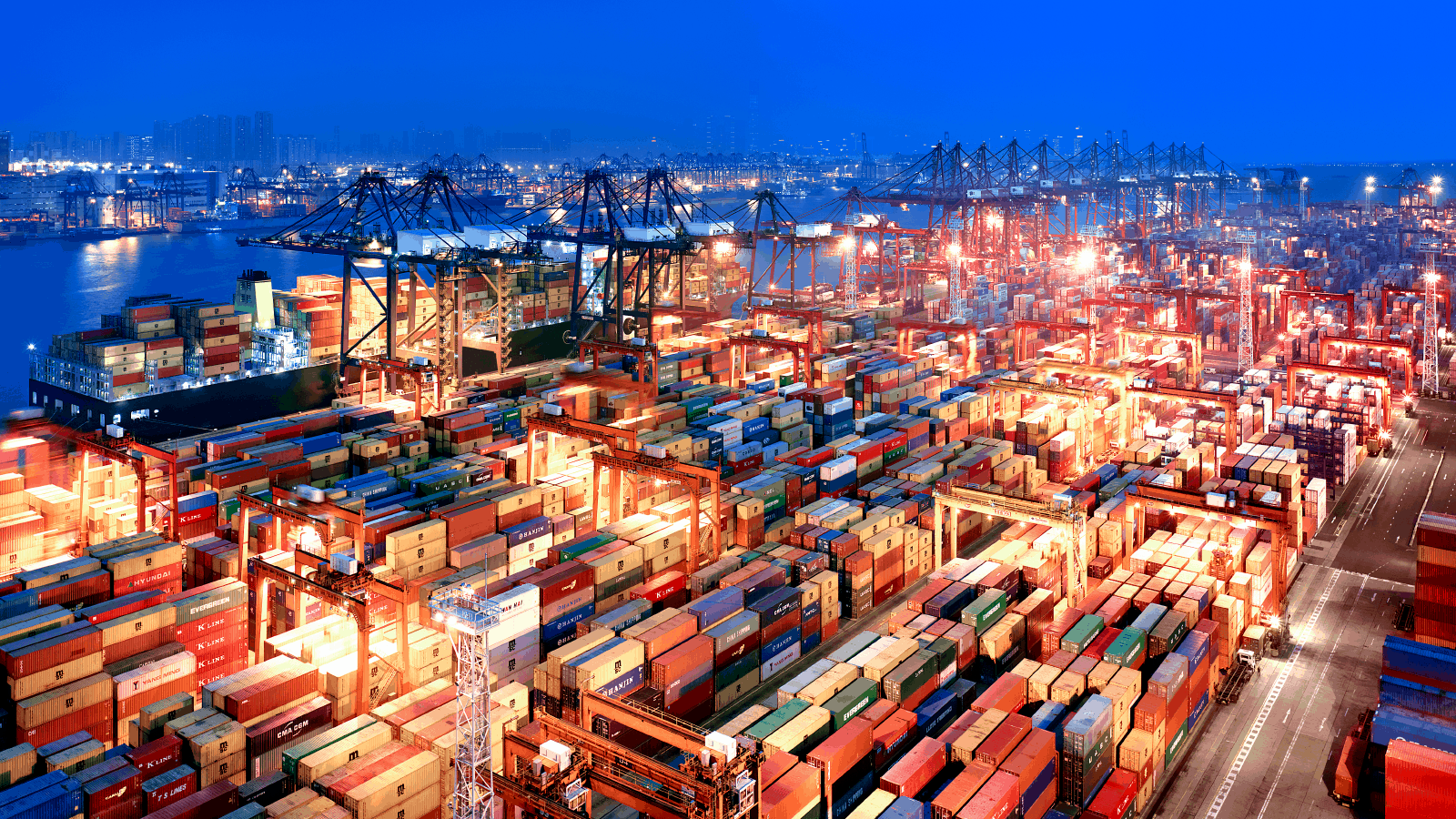

A Bottleneck at California Ports Squeezes Manufacturers

The ship stuck in the Suez Canal may have gotten all the attention, but it wasn’t the biggest shipping problem of the year. That honor goes to the massive traffic jam at the ports of Los Angeles and Long Beach, which has dragged on since late 2020.

As NAM Director of Infrastructure, Innovation and Human Resources Policy Ben Siegrist tells us, this bottleneck is a huge problem for manufacturers in the U.S.—one that is costing our economy many billions of dollars. Dozens of ships are waiting in the harbor for days before they are able to unload, exporters are struggling to get their goods out of the country, and other manufacturers are waiting months for parts or finished goods to arrive.

The problem: The numbers tell the tale: at one point in mid-April, there were 23 ships waiting to dock at the ports, according to The Wall Street Journal (subscription), down from around 40 back in February. For comparison, Siegrist explains, the normal number of ships waiting in harbor is somewhere between 0 and 1.

Why it’s happening: Much of the congestion results from the pandemic—there has been an uptick in e-commerce during the lockdowns, and the economic stimulus has boosted consumption. Meanwhile, the typical increase in shipments during the holiday season just made things worse.

However, other factors are making this congestion particularly hard to fix, says Siegrist. These include:

- A shortage of shipping containers: First of all, shippers don’t have enough containers in the absolute for all of these goods. But in addition, some of them are finding it cheaper to unload in the U.S. and then send the empty containers back to Asia—to the disadvantage of U.S. manufacturers that want to load those containers with exports.

- A shortage of chassis: The trucks that transport containers to warehouses require special chassis to move the containers, but the ports also don’t have enough of these.

- A labor shortage: Like many other Americans, port workers had to deal with COVID-19 infections or exposures as well as cope with family responsibilities during the pandemic.

Logistical complications: Meanwhile, the logistics of international shipping are incredibly complicated, Siegrist explains. There are fewer ocean carriers today—only nine, down from more than 20 a few decades ago—which means manufacturers have fewer competitive shipping options. And the complex relationships between the multiple carriers, port operators and equipment owners are not easy to disentangle or control.

What do we do? Thanks in large part to the complexity of international shipping, there’s no easy answer, says Siegrist. Right now, the NAM is in discussions with the many federal agencies involved in international commerce, including the Department of Transportation, the Department of Commerce, the Office of the U.S. Trade Representative and a lesser known but vital agency called the Federal Maritime Commission. “We’re trying to create opportunities for our members to have a dialogue with policymakers,” says Siegrist.

- The eventual policy options might range from fines or fees for international carriers to legislative updates to the 1984 Shipping Act.

- It will also be important to strengthen the domestic supply chain for equipment like containers—almost none of which are now made in the U.S. The NAM is “talking more holistically about supply chains with the Biden administration,” notes Siegrist.

Stay tuned: The FMC will release its investigation into pandemic-related shipping delays in the coming weeks.

NAM Pursues Free and Fair Policies on China

NAM President and CEO Jay Timmons sent a letter to President Biden on Wednesday urging the president to develop and implement a post-pandemic strategy regarding the U.S. relationship with China.

Why it matters: As the letter notes, China has signed new trade and investment agreements with a variety of nations in Europe and Asia over the past few months, increasing pressure on the United States to engage in a thoughtful and effective way to preserve America’s influence worldwide. But the U.S. relationship with China is also both delicate and complex, requiring the U.S. to challenge China in some areas even as we work to collaborate in others.

A combative adversary: “For manufacturers, China has long been a hub for unfair industrial subsidies and government-fueled overcapacity in areas like steel and aluminum that distort global markets. China continues to promote discriminatory industrial policies, forced technology transfer and intellectual property theft that harm manufacturers and workers in the United States. Increasingly, China is also using global institutions and its economic influence to build alliances that challenge American interests, human rights and democratic values.”

An important partner: “Yet, China will also be a key player in tackling global challenges that matter for manufacturers, from COVID-19 to climate change. And China is a major destination for U.S. exports, with nearly $90 billion in manufactured goods going there in 2020, placing it behind only Canada and Mexico in the ranks of our biggest trade partners and supporting hundreds of thousands of well-paying U.S. manufacturing jobs.”

The big picture: “America’s strategy must reflect the realities of the moment and the future: as we take stock of new post-pandemic realities, China will be a necessary partner, a fierce economic competitor and a major rival challenging American global influence.”

Read the whole thing for a list of the NAM’s policy proposals.