The MI Honors 2024 Women MAKE Award Winners

The Manufacturing Institute—the NAM’s 501(c)(3) workforce development and education affiliate—had ample reason to celebrate last night.

What went on: The MI held the 2024 Women MAKE Awards gala, a night that recognizes outstanding women in manufacturing. Each year, the awards pay special tribute to 100 peer-nominated women leaders (“Honorees”) and 30 rising female stars (“Emerging Leaders,” women under the age of 30) in the industry.

- The event, held this year at The Anthem—a waterfront concert venue in Washington, D.C.—was sponsored by Caterpillar, Toyota, BASF, Trane Technologies, International Paper, Johnson & Johnson, Novelis and others.

- It featured a vocal performance by singer Loren Allred, platinum-selling singer-songwriter of “Never Enough” from “The Greatest Showman” musical, who gained widespread fame after appearing on “Britain’s Got Talent” in 2022.

What was said: Caterpillar Group President of Resource Industries, NAM Executive Committee Member and Women MAKE Awards Chair Denise Johnson told the night’s award winners that she’s been “the only woman in a room, or the only woman on a project” many times in her career.

- But “[l]ooking around this theater and seeing the faces of the Honorees and Emerging Leaders tells me that times are changing.”

- She then addressed the honorees directly, saying, “Your success, your work ethic and your stories will inspire the next generation of manufacturing leaders. … You are moving us along toward a future when women are not underrepresented in our industry.”

From Honoree to Vice Chair: Toyota Motor North America Senior Vice President, Electric Vehicle Supply Susan Elkington—a 2014 Honoree of the awards, formerly called the STEP Ahead Awards—was this year’s awards vice chair. She attested to the power of the awards to help women advance in their careers.

- “[T]he Women MAKE network … helped me realize the many qualities and experiences uniting all the women who have been inducted into this amazing network.”

- She noted the cruciality of the MI’s Women MAKE initiative, which “provides a platform for role models and mentors to encourage women to enter the field and succeed in it.”

No limits: NAM President and CEO and MI Chairman of the Board Jay Timmons also discussed the importance of role models, a label aptly applied to all the award nominees.

- Timmons, a parent of three, told the audience that he and his children recently learned the story of 30-year-old Cole Brauer, who last month made history as the first American woman to sail solo nonstop around the world.

- Brauer’s story “sends a message to those—frankly, women or men—who might have been led to believe there were limits to what they could achieve or that their careers might be confined within guardrails,” he said. “Your examples are inspiring people in a similar way. You are powerhouses—your dynamism, your drive, your enthusiasm—all these qualities supercharge modern manufacturing, making our industry an even more powerful force for good.”

“Amazing things”: MI President and Executive Director Carolyn Lee called the nominated women “powerhouses who have accomplished amazing things.”

- “You deserve this recognition for your excellence and for everything you do to uplift others,” Lee told the award nominees. “But we’re not just celebrating. Being here to recognize these winners is shining a light and fueling the work to close the gender and talent gap in manufacturing.”

- Women account for less than one-third of the American manufacturing workforce, she went on, but endeavors such as the MI’s Women MAKE America initiative—the nation’s premier program dedicated to closing the gender gap in the sector—“and companies like yours are committed to closing that gap.”

Learn more: For a full list of this year’s award winners, click here.

From Mentee to Mentor: Rockwell Automation’s Aaliyah Brown

To hear Aaliyah Brown tell it, the start of her career in manufacturing was the result of a happy accident.

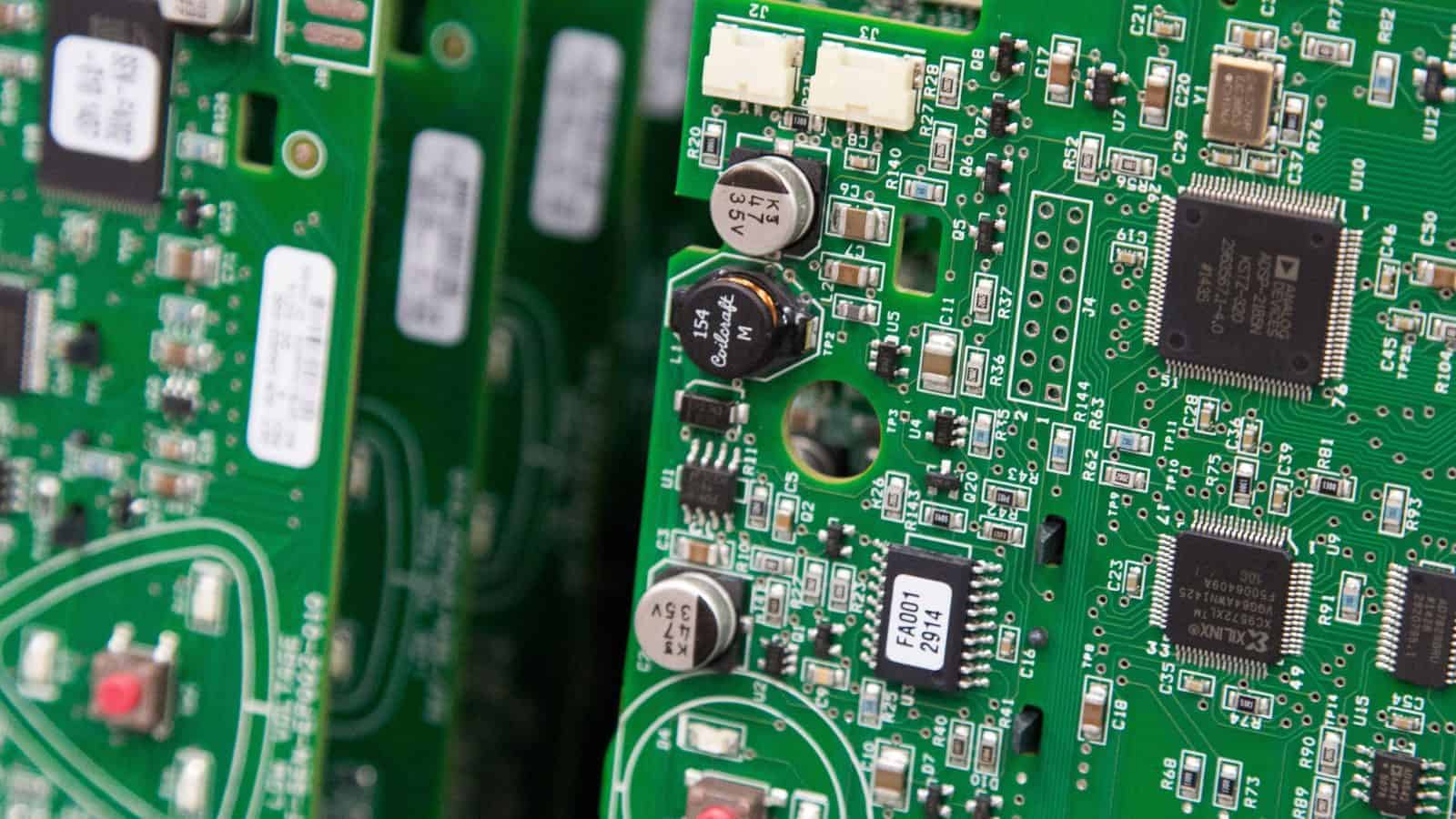

“My interest in manufacturing actually started accidentally,” the Rockwell Automation quality engineering team lead said with a laugh. “I was hired as a high school intern [at age 16]. I had a lot of different positions within my role, from [learning] how our different products are utilized in the field, to project management, to printed circuit board design. That’s when I really started to dip my toe into manufacturing.”

A quick ascent: After obtaining her bachelor’s degree in electronic engineering technology from Cleveland State University in 2019, Brown—who works at Rockwell Automation’s Twinsburg, Ohio, location—was hired full time by the automation and digital transformation technologies company as a process engineer.

- Three years later, she was made a quality engineer. Just a year after that, she was promoted to quality team lead.

- Her meteoric rise is one of the reasons her colleagues nominated her for this year’s Women MAKE Awards, honors given annually by the Manufacturing Institute, the NAM’s 501(c)(3) workforce development and education affiliate, to women in manufacturing who have accomplished remarkable successes at their companies.

The elevator speech: Her day-to-day job may be complex, but for the layperson, Brown can break down her duties in just a few sentences.

- “Manufacturing quality can be explained as anything that goes wrong within a manufacturing facility,” she said. “My team has to figure out why it happened and how to fix it to make sure it does not happen again.”

Paying it forward: Brown credits a great deal of her early professional success to mentor and colleague Marzell Brown (“no relation whatsoever”), a talent management lead at Rockwell Automation.

- Like Brown, Marzell Brown is a graduate of the Cleveland Metropolitan School District. Years ago, seeing a lack of programs in the greater Cleveland area designed to expose youth from traditionally underrepresented communities to science, technology, engineering and math careers, he helped found Brown’s alma mater, Cleveland’s MC2 STEM High School. Later, he spearheaded the internship program at Rockwell Automation’s business engineering unit that Brown completed.

- “Before I started going to summer camp at a private school, I had no idea what an engineer was,” Brown continued. “No engineers were in my family at the time. I was in the second graduating class of MC2 and about, I think, the seventh cohort of students Marzell brought in.”

- Inspired by her own experiences, in 2017—while still in college—Brown founded the nonprofit Build Sessions CLE, a mentorship initiative for college-bound STEM students from underrepresented communities.

- “All of the wonderful things that Marzell did for me and others like me, all of those best practices, those are what I brought over” to my job and to Build Sessions CLE, she said.

Changing perceptions: Brown—who helps lead Rockwell Automation’s annual Manufacturing Day events—believes that if more young people knew what modern manufacturing was really like, they would be much more inclined to enter the field.

- “I want to reach back … into these high schools, to provide these students with the great opportunities [I had] and show them that, yes, you can be successful here, and manufacturing facilities aren’t dirty and dingy,” she said.

Calling all women: She knows, too, the importance of shoring up the percentage of women in manufacturing in the U.S., which is around 30%.

- And there’s encouraging news on that front from the Rockwell Automation internship program that launched Brown’s career: If current trends continue, the number of women coming into the company from that program is going to rise, she told us.

- “[To all the] young ladies who don’t know exactly what they want to do, but have interests—say, sewing or project management or just wanting to help people— there are ways to be able to use all of those” talents in manufacturing, Brown said. “And you can have a very lucrative career here.”

U.S. and European Union Strengthen Transatlantic Trade Ties

The sixth ministerial of the United States–European Union Trade and Technology Council, held in Leuven, Belgium, emphasized the deepening cooperation between the U.S. and the EU in navigating global economic pressures and technological advancements.

What’s going on: Secretary of State Antony Blinken, joined by Secretary of Commerce Gina Raimondo and U.S. Trade Representative Katherine Tai, joined European Commission leaders in a discussion that centered on fostering economic security, the importance of AI governance, cooperation on secure supply chains and a transatlantic commitment to reducing reliance on high-risk suppliers.

- This collaboration, Secretary Blinken said in remarks to the press at the council’s outset, proved that there has been “increasing alignment” between the United States and the European Union on these and other issues in recent years.

- “Together, we represent almost half of world GDP, and that means that there’s a certain weight that comes with having a shared position on something,” Secretary Blinken said. “And whether that’s dealing with China or any other challenge, it makes a big difference.”

Growing collaboration in AI: The meeting additionally underscored unwavering support for Ukraine from the U.S. and the EU amid geopolitical challenges, as well as a commitment to driving innovation and security in technology and trade.

- One tangible outcome of the TTC was an update of the “Terminology and Taxonomy for Artificial Intelligence” (i.e., of the definitions of key terms used by the EU and U.S. when discussing AI). This underpins the workstream of the TTC to “ensure the safe, secure and trustworthy development and use of AI,” according to the U.S.–EU joint statement.

Shared concerns about Chinese semiconductors: Competition from heavily subsidized chips produced in China was a key focus at the ministerial, particularly in light of the anticipated ramping up of “legacy chips” manufactured in China over the next few years. The Chinese government’s significant financial subsidization of the chip-producing sector, Secretary Raimondo warned, could lead to considerable market imbalances between China and the U.S. and EU.

- Both the U.S. and EU pledged to continue working together to address destabilizing Chinese exports of semiconductors in the coming years, including to collect and share nonconfidential information and market intelligence about nonmarket policies and practices, to consult each other on planned actions and to potentially develop joint or cooperative measures to address distortionary effects on the global supply chain for legacy semiconductors.

TSMC to Receive Up to $6.6 Billion in CHIPS Funding

The Biden administration on Monday announced that TSMC’s Arizona subsidiary will receive up to $6.6 billion in grants from the 2022 CHIPS and Science Act, The New York Times reports. The announcement is the latest move by the Biden administration to make the United States a leading producer of cutting-edge semiconductor technology.

What’s going on: The funding “will help support the construction of TSMC’s first major U.S. hub, in Phoenix. The company has already committed to building two plants at the site and will use some of the grant money to build a third factory in Phoenix, U.S. officials said on Sunday.”

- The company will “increase its total investments in the United States to more than $65 billion, up from $40 billion.”

- “TSMC’s investment is expected to create about 6,000 direct manufacturing jobs and more than 20,000 construction jobs, federal officials said.”

- In addition to the grants, the federal government is also offering TSMC up to $5 billion in loans.

Impact on U.S. chip production: “With projects such as TSMC’s, the U.S. is on track to make about 20% of the world’s cutting-edge chips by 2030, the Commerce Department said. It called the project the largest foreign direct investment in a new project in U.S. history,” reports The Wall Street Journal (subscription).

- Earlier this year, the Biden administration announced major chips funding awards for Intel and GlobalFoundries.

The NAM’s reaction: “Today’s announcement from TSMC and @CommerceGov makes America stronger,” the NAM wrote in a social post Monday. “The NAM-championed CHIPS and Science Act continues to spur new investments in cutting-edge semiconductor technology that is essential to advancing U.S. economic competitiveness.”

Honda Winds Up a One-of-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”

Honda Winds Up a One-of-a-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind-tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”

U.S. Awards Intel Largest Chips Grant

The U.S. will award Intel up to $8.5 billion in grants and as much as $11 billion in loans to expand chipmaking capacity and capabilities in four states, The Wall Street Journal (subscription) reports.

What’s going on: The funds, set aside under the NAM-backed 2022 CHIPS and Science Act to bolster domestic semiconductor production, “will go toward new factories and expansion projects in Arizona, New Mexico, Ohio and Oregon, the Commerce Department said.”

- Spurred by the federal funding, “Intel’s total investment in U.S. projects in the next five years is expected to exceed $100 billion,” according to the Journal, and to create more than 10,000 manufacturing jobs and about 20,000 construction jobs, according to the Commerce Department.

Largest award: The grant to Intel, the largest American chipmaker by revenue, is also the largest CHIPS Act award. It follows a February announcement of a $1.5 billion award to GlobalFoundries Inc.

- The award will support the reshoring of production of leading-edge logic chips, which are “essential to the world’s most advanced technologies like artificial intelligence,” the Commerce Department said.

- President Biden was in Chandler, Arizona, Wednesday to visit Intel’s Ocotillo chip-manufacturing campus.

Why it’s important: “We can’t just design chips; we have to make them in America,” Commerce Secretary Gina Raimondo told reporters on Tuesday, the Journal reports. “It’s an economic security problem. It’s a national security problem. And we’re going to change that.”

How it will work: The funding will be doled out in stages, “according to construction and manufacturing milestones,” the Journal said.

- “In Chandler, Arizona, the money will help to build two new chip plants and modernize an existing one,” CBS News reports. “The funding will establish two advanced plants in New Albany, Ohio, [and] … [t]he company will also turn two of its plants in Rio Rancho, New Mexico, into advanced packaging facilities. And Intel will also modernize facilities in Hillsboro, Oregon.”

The NAM weighs in: Wednesday’s “record, multibillion-dollar award is great news for [Intel] and U.S. manufacturing competitiveness,” the NAM wrote in a social post. “The NAM was a vocal supporter of the CHIPS and Science Act, and we will continue to champion policies that support the expansion of chip production in America.”

Trend of the Week: Smart Factories

In 2024, factories will just keep getting smarter. From product design to supply chain management, the sophistication of Manufacturing 4.0 (the current wave of technological evolution) will keep on growing. Here’s what manufacturers should know about these advances and how the NAM can help.

What manufacturers should do: Manufacturers looking to make their factories smarter are focusing on four key strategies:

- Creating efficiencies to improve the bottom line with automation and other M4.0 technologies

- Leveraging smart factories to overcome challenges, such as the workforce crisis and supply disruptions

- Ensuring connectivity on the factory floor to allow for use of plant data to create new business models and revenue streams

- Using M4.0 technologies to improve quality control, speed time to market, enhance safety, boost profits, contribute to sustainability goals and engage employees

Expert opinion: Companies are increasingly investing in industrial connectivity, according to PTC Vice President of Market Development of IoT James Zhang.

- “Rather than approaching industrial connectivity with point-to-point integrations, companies are developing holistic, enterprise-wide strategies,” he explained.

- “This approach streamlines and standardizes data from heterogenous manufacturing environments to a single industrial connectivity platform to provide secure, reliable data for OT systems, including MES and SCADA, and IT systems, including data analytics and industrial IoT.”

Resources for you: Check out these NAM resources that will help guide you through these technological changes:

- The Manufacturing Leadership Council, the NAM’s digital transformation division, offers extensive advice and expertise on Manufacturing 4.0 technologies and how to use them.

- NAM Cyber Cover can help you protect your smart factories, as the increase in digitization also opens new avenues for cyber criminals.

- Check out this podcast from the Innovation Research Interchange (the NAM’s innovation division), which covers current research into the adoption of cutting-edge technologies.

Read the full 2024 trends report here.

Trend of the Week: Building Resilience

Some disruptions—like global pandemics—are just too unexpected to anticipate. As manufacturers consider the unknowns they may face in the years ahead, they are prioritizing general resilience instead of attempting to plan for everything. Here’s what you should know about this major trend in 2024.

What manufacturers should do: Manufacturers should focus on these four areas to increase their resilience, according to the NAM’s experts:

- Enhance cybersecurity to guard against new and emerging cyberthreats.

- View resilience as a necessary tool to protect business amid economic uncertainty.

- Shift leadership strategies to build a strong plan for future success, including establishing a path for development and cultivation of future leaders.

- Plan for more and as-yet-unknown disruptions in the future.

Expert opinion: Mike Lipinski, cybersecurity partner at Plante Moran, advises manufacturers concerned about the rising threat of ransomware. He points out how the dangers have evolved in recent years:

- “Manufacturing businesses that fall prey to ransomware can be attacked multiple times. Adversaries who breach your system sell other cybercriminals information about how they got in. The risk isn’t only data theft and access to information but also the criminals’ ability to create backdoors into your environment.”

Resources for you: Check out these NAM resources that can help companies bolster their resilience:

- Here is a useful guide that can guide you through dealing with disasters.

- Check out the NAM Shipping & Logistics program, which can help you cope with delays in shipments and funds in case the unexpected happens.

- If you’re facing legal issues, the NAM’s Legal Referral Service, powered by Meritas, can connect you to world-class legal talent in every sector of law.

Read the full 2024 trends report here.

Arizona: Manufacturing’s Crossroads

In the heat of Arizona’s “Silicon Desert” and surrounding communities, the future of America’s global competitiveness and climate goals aren’t just being forged—they also hang in the balance.

Last week for the first time in 2024, the NAM brought its Competing to Win Tour to Arizona, and that stark contrast between the status quo and the probable future was on display in Phoenix at global semiconductor equipment manufacturer Benchmark and small manufacturer Valley Forge & Bolt and at Resolution Copper in Superior.

- NAM President and CEO Jay Timmons, Manufacturing Institute President and Executive Director Carolyn Lee—who leads the NAM’s 501(c)3 workforce development and education affiliate—and Arizona Chamber of Commerce & Industry President and CEO Danny Seiden met with local manufacturers to gain their perspective and insights.

Why it matters: The Biden administration and Congress have secured key measures to bolster manufacturing in the U.S., including the NAM-championed CHIPS and Science Act and tax credits in the Inflation Reduction Act to manufacturers investing in advanced production and energy projects. But raw material, workforce and tax and regulatory policy challenges threaten to undermine policy aspirations.

Silicon Desert expansion: With the CHIPS and Science Act poised to transform the sector, Benchmark President and CEO Jeff Benck and Executive Vice President and Chief Operating Officer Dave Valkanoff led the tour of their state-of-the-art Phoenix facility.

- In a good spot: Benchmark is well-positioned for the coming growth in semiconductor equipment demand. It is focused on securing its workforce and navigating a complex regulatory landscape to maximize the opportunity.

- Workforce woes: Even with the NAM and the MI’s Benchmark-supported Creators Wanted campaign boosting the industry’s image and the MI’s FAME initiative training thousands of technicians, finding skilled labor remains the top challenge. Benchmark advances earn-and-learn programs and partnerships with Arizona State University and community colleges to help fill the pipeline, actions that, according to Lee, “can help change the game.”

- Red tape delays: Regulatory hurdles pose obstacles. Benchmark seeks streamlined permitting and sensible rules to maintain their global edge.

- Bullish outlook: Benck is optimistic about the future of U.S. manufacturing and semiconductor demand. Investments in people and technology position the company well to deliver the next generation of innovation.

Taxes and immigration: The NAM’s return visit to Valley Forge & Bolt, after a stop last year with Sen. Kyrsten Sinema (I-AZ), shone a spotlight on the real-world impact of stalled tax policy and the urgent need for reform.

- Valley Forge & Bolt saw record sales in 2023 thanks to 2017 tax reforms boosting its equipment upgrades. Now, with provisions like full capital investment expensing stalled in Congress, orders have slowed.

- CEO Michele Clarke and COO Bret Halley made the case for R&D expensing, interest deductibility and a return to full capital investment expensing. Without these, they said, job growth and America’s manufacturing competitive edge are at risk.

- Skilled workers needed: Despite its success, Valley Forge says finding skilled workers is a constant struggle. Immigration reform is a must to secure the right talent pipeline, said Clarke. “Did you notice our engineers? Most of them are under 30 because we’re snatching them right out of college,” added Clarke. “The engineering talent in this country is dwindling, and we’re not authorizing enough green cards. I, myself, was a green card holder before I became a citizen.”

Policy roadblocks: The NAM’s visit to Rio Tinto’s Resolution Copper site highlighted the urgency of permitting reform in the face of critical mineral needs.

- Copper’s critical role: Copper is essential for clean energy. Electric vehicles, solar power grids and wind turbines all demand huge quantities. Yet, the U.S. remains heavily reliant on imported copper, jeopardizing progress.

- Massive potential: The domestic solution lies within the stalled Resolution Copper mine. With its potential to supply 25% of U.S. copper demand, it’s poised to be a key piece of the puzzle.

- Project in limbo: Despite a 350-strong workforce modernizing and maintaining the mine, permitting delays stifle the project’s full impact.

- Sustainable practices: “Resolution Copper is the future of eco-conscious mining,” said NAM Managing Vice President of Brand Strategy Chrys Kefalas, who toured the site. “Their team innovates sustainable practices, leads in water conservation and even supplies 7 billion gallons of water to Arizona farms. And what is more, it isn’t just the facts of the matter or what you saw that drives this point home, but the people who have worked on the site for years make all that clear with the pride they have about the project and their determination to see Resolution Copper through to making lives better for everyone.”

- Jobs and growth: Led by President and General Manager Vicky Peacey, the project promises to contribute $1 billion annually to the economy and more than 1,500 Arizona jobs. “This is about people, jobs and supply chains; and it’s also about realizing clean energy ambitions at the speed and scale that climate goals demand,” said Kefalas.

The bottom line: “The future of U.S. manufacturing might hinge on these contrasting stories. Are we a nation that champions innovation, attracts and keeps the brightest here, supports our manufacturers and tackles climate goals with homegrown solutions, or one that stalls progress in its own backyard,” said Timmons.

- “Arizona is at the epicenter of American manufacturing’s next chapter, and with smart policies and fewer unforced errors at the federal level, we can clear the runway for growth,” added Seiden.