Timmons Delivers 2020 NAM State of Manufacturing Address in Iowa

Speech Marked 125th Anniversary of NAM’s Founding and Highlighted ‘Creators Wanted’ Campaign to Address Growing Workforce Shortage

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons delivered the eighth-annual NAM State of Manufacturing Address today at equipment manufacturer Vermeer Corporation in Pella, Iowa. Speaking to Vermeer Corporation employees, business and community leaders and local manufacturers, Timmons highlighted the NAM’s ambitious plan to address the industry’s growing workforce crisis with the groundbreaking, multimillion-dollar “Creators Wanted” campaign.

In his remarks, Timmons said:

“For 125 years, your NAM has led the business community and fought for all who make things in America. And all of you in this room, and the 13 million men and women in our industry, some of whom are watching today, are part of the storied history of building an exceptional nation. And Vermeer, this very company, embodies the story of manufacturers’ progress.”

. . . .

“In this pivotal year, the NAM and The Manufacturing Institute, our workforce and education partner, are setting out on an unprecedented campaign to inspire a new generation—and tell the real story of our industry. . . . Our historic effort, called “Creators Wanted,” is a capital campaign that will support the programs of the Manufacturing Institute—including the STEP Women’s Initiative, youth engagement and Heroes MAKE America, which trains our returning servicemembers for high-paying manufacturing jobs.”

. . . .

“Just yesterday, in his remarks at the World Economic Forum, President Trump touted manufacturing’s growth and success during his presidency. As I’ve said before, from tax reform to regulatory certainty to leveling the playing field, promises made to manufacturers have been promises kept—and the employment and output numbers show it.”

. . . .

“Here’s what I will say about this election . . . It’s not the label next to a candidate’s name—whether an “R,” a “D” or an “I”—that determines whether he or she will be a good president or even a good member of Congress. The test is whether he or she will work to uphold the values that make America exceptional. These are the same four values, the same four pillars, that make our industry’s success possible.”

Timmons also noted the generous contributions made by Vermeer and Pella Corporation to the NAM’s Creators Wanted campaign.

“And I am proud to announce today that Vermeer Corporation, along with your foundation and Mary and Dr. Dale Andringa, have contributed $100,000 to this cause. And another local manufacturer, Pella Corporation, is also leading by example with a $100,000 contribution of their own,” said Timmons.

Vermeer Corporation President and CEO Jason Andringa thanked Timmons for his visit and the NAM’s commitment to ensuring the long-term success of manufacturing in the United States.

“Thank you to Jay Timmons and the National Association of Manufacturers for visiting Vermeer Corporation and recognizing the incredible work of our team members and manufacturers across the country,” said Andringa. “These men and women truly demonstrate the impact our industry makes every day and represent the success of American manufacturing.”

To read the full address, click here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.37 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the Manufacturers or to follow us on Twitter and Facebook, please visit www.nam.org.

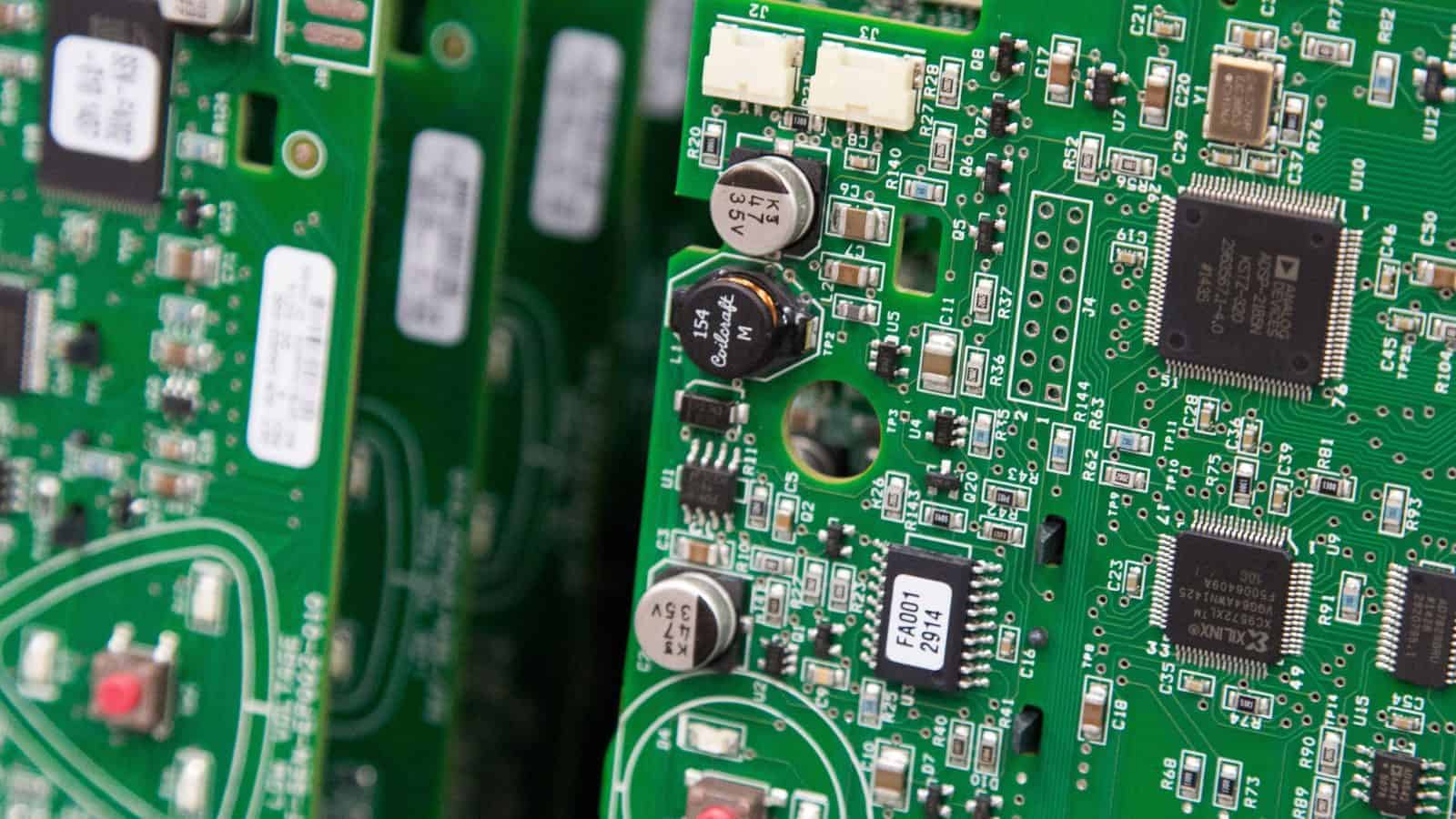

Manufacturers Make Cybersecurity Central to Industry Culture

As rapid technological innovation sweeps across the manufacturing industry, cybersecurity has become a top priority. David Brousell, Vice President and Executive Director of the Manufacturing Leadership Council—the world’s first member-driven, global business leadership network dedicated to senior executives in the manufacturing industry—explains the importance of cybersecurity and what manufacturers are doing to combat global threats in the digital age.

Why is cybersecurity important for modern manufacturing?

Manufacturers are using cutting-edge digital technology to a greater degree than ever before. We’re putting sensors in equipment, digitizing supply chains and gathering data from customers to better the customer experience, to name just a few examples. The number of electronic connections we’re making is enormous—and the more you electronically link products and processes, the more vulnerable they become to cyberattacks.

What are the impacts of cyberattacks?

When we talk about cybersecurity, we’re not just talking about people trying to steal intellectual property. We’re also talking about attacks that target business operations, which can actually bring business to a halt. Manufacturers need to be able to guard against these attacks across the board in order to do their own innovative, cutting-edge work and to deliver for customers in the United States and around the world. That’s why manufacturers must invest in developing solutions that can stand strong against even the most sophisticated assault.

What are some of the challenges manufacturers face in cybersecurity?

The number one challenge is the increase in attacks. We do a lot of survey work among manufacturers of the Manufacturing Leadership Council, and the overwhelming majority of survey participants say they’re expecting more attacks in the year ahead. Just keeping up with the sheer volume of attacks is a big issue for manufacturing companies—large and small alike. This isn’t just an issue for multibillion-dollar enterprises. Cybersecurity is everyone’s concern.

What are manufacturers doing in the cybersecurity space to keep their work secure?

We’re taking a variety of actions. We’re continuing to invest in technology. We’re training people to understand best behaviors and best practices. And we’re trying to protect more and more on a systems level. For example, some companies are housing their information in the cloud because they feel that there are greater protections in a cloud environment than in a system on their own premises.

Most importantly, though, companies are adopting cybersecurity as a cultural discipline and making cybersecurity part of their business’ DNA and culture. Over many decades, manufacturers have made physical safety a well-honed science. Now we have to raise cybersecurity up to that level of safety if we’re going to bring it under control. We talk about how safety is everybody’s business—and now cybersecurity has to become everybody’s business, too.

MLC Releases Blueprint for Next Phase of Manufacturing Digitization

Washington, D.C. – The Manufacturing Leadership Council has released a new blueprint to guide manufacturers as they transition to the digital model of doing business. The blueprint, called the 2019/2020 Critical Issues Agenda, is the latest strategic guidance on digital transformation released by the MLC, a division of the National Association of Manufacturers.

The MLC’s mission is to help senior manufacturing executives and emerging leaders define and shape a better future for themselves, their organizations and the industry by focusing on the intersecting business and technology issues driving manufacturing growth. The Critical Issues Agenda encompasses the technology, organizational and leadership requirements of implementing the digital model of modern manufacturing, also known as Manufacturing 4.0.

The agenda covers five categories:

- Factories of the Future

- Establishing M4.0 Cultures: Collaborative, Innovative, Integrated and Connected

- Transformative Technologies in Manufacturing

- Next-Generation Manufacturing Leadership and the Changing Workforce

- Manufacturing 4.0 Sustainability

The 2019/2020 Critical Issues Agenda identifies opportunities for manufacturers to become more efficient, more productive and even to develop new business models and services by successfully implementing new digital technologies and practices. These include data entrepreneurship, deploying artificial intelligence, the use of digital twins and providing digital skills training.

For nearly 10 years, our Critical Issues Agenda has proven to be a comprehensive and reliable model for embracing Manufacturing 4.0, said David R. Brousell, Co-Founder of the MLC. But what’s new and important this year is the need for leaders to develop greater digital acumen and for manufacturing organizations to deal with even greater volumes of data from increasingly connected factories and plants. If manufacturers can rise to these challenges, they will go a long way to unleashing the potential of M4.0.

The agenda is the result of a unique member-driven process designed to capture and reflect the views and insights of the MLC’s 1,500-strong executive membership. The resulting agenda is then finalized and approved by the MLC’s Board of Governors.

I am delighted that the MLC’s member-driven process continues to enable us to identify the critical issues that MLC members themselves have defined as most important in their drive to transform their businesses to world-class levels of efficiency and competitiveness, said John Fleming, chairman of the MLC’s Board of Governors and former executive vice president of global manufacturing and labor affairs at Ford Motor Company. The MLC will work tirelessly to deliver thought-leading knowledge and insights around these key transformational issues in the year ahead.

Full descriptions of the 2019/2020 Critical Issues Agenda are available on the MLC’s website and in the August 2019 issue of the Manufacturing Leadership Journal.

-MLC/NAM-

Founded in 2008, and now a division of the National Association of Manufacturers, the Manufacturing Leadership Council’s mission is to inspire and support manufacturing executives to achieve transformational growth for themselves, their companies and the industry at large through enlightened leadership. With more than 1,500 senior-level members from many of the world’s leading manufacturing companies, the MLC focuses on the intersection of advanced digital technologies and the business, identifying growth and improvement opportunities in the operation, organization and leadership of manufacturing enterprises as they pursue their journeys to Manufacturing 4.0.

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.38 trillion to the U.S. economy annually, has the largest economic multiplier of any major sector and accounts for more than three-quarters of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the Manufacturers or to follow us on Shopfloor, Twitter and Facebook, please visit www.nam.org.

Manufacturers Adapt to Lead in an Increasingly Digital Age

"You can’t make this transition to the digital era by yourself. You need to be with other companies, to learn from them."

In September 2018, the National Association of Manufacturers acquired the Manufacturing Leadership Council, an association for manufacturing executives that is dedicated to helping the industry transition to the digital era. Nearly one year later, the MLC wraps up its 15th Anniversary Manufacturing Leadership Summit and continues to provide its members with programs and services around digitization.

MLC’s Co-Founder, Vice President and Executive Director David R. Brousell shares the groundbreaking work of the organization and why it matters to manufacturers today.

What is the Manufacturing Leadership Council?

The MLC is designed to help senior manufacturing executives and emerging leaders define and shape a better future for themselves, their organizations and the industry at large by focusing on the intersection of critical business and technology issues that will drive growth today and in the future. We do live events like conferences; we do plant tours that enable members to see firsthand how different companies are implementing the latest digital technologies; and we publish in-depth articles that focus on best practices and cutting-edge ideas on the use of technologies and the leadership requirements of the digital age.

How is leadership changing in the digital age?

It’s changing in some very important ways. There’s a whole new layer of competency that has to be added to the traditional functions of leadership. We call this “digital acumen,” which has to do with understanding the potential of advanced technologies like analytics, artificial intelligence, collaborative robotics, 3D printing and other technologies. It’s not just improving efficiencies, but also offering new business models, ways of doing things and services.

This new era in manufacturing requires leaders to manage organizations that are flatter and more collaborative, with more and more employees having the benefit of information at their fingertips. Managing in prior years was around a top-down structure. That doesn’t cut it in the digital age.

What benefit do companies get from being a part of this group?

The MLC presents the opportunity to be part of a community that is collectively sharing ideas, insights and best practices to as the industry continues its radical transition. The truth is, you can’t do this alone as a company. You can’t make this transition to the digital era by yourself. You need to be with other companies, to learn from them, to learn what’s possible, to see what works and what may not work well in your company and to form that bond. It’s a tremendous learning experience.

What does the future look like for manufacturing—and how does the Manufacturing Leadership Council fit in?

The future looks very, very bright for manufacturing. We’re going to increase efficiency and produce products that satisfy personalized needs—everything from cars to medicine. We’re going to be able to have better quality and create jobs that are fulfilling, exciting and intellectually stimulating. The extent of innovation happening right now in manufacturing is mind-blowing.

But this is not an easy transition. The future offers tremendous opportunities, but only if we make the transition industry-wide. If we’re able to do that, not only will individual companies be more successful globally, but the U.S. manufacturing industry as a whole will continue to lead the world. There’s a lot at stake for manufacturers. That’s why the partnership between the Manufacturing Leadership Council and the NAM is so important.

Cooley Group’s Dan Dwight Joins the Manufacturing Leadership Council’s Board of Governors

Washington, D.C. – The Manufacturing Leadership Council, a division of the National Association of Manufacturers, has announced the election of Dan Dwight, president, CEO and director of Cooley Group, to the MLC’s Board of Governors. The MLC’s mission is to help senior manufacturing executives and emerging leaders define and shape a better future for themselves, their organizations and the industry at large by focusing on the intersection of critical business and technology issues that will drive growth today and in the future.

The MLC Board approved Dwight’s nomination in a unanimous vote. With his appointment, the MLC Board of Governors consists of 21 industry thought leaders who represent the full ecosystem of the manufacturing industry. As an advisory body, the MLC Board of Governors provides guidance to the MLC on its “Critical Issues” agenda, research studies and programs and services for the MLC membership.

“I am delighted to welcome Dan to the Board,” said John Fleming, chairman of the MLC Board of Governors. “He has truly established himself as a thought leader who is implementing Manufacturing 4.0. into his business. His hands-on experience will add to the value of the MLC for all of our members.”

“For the past four years, I experienced the value the Council brings to its constituent members by connecting global manufacturers with industry experts who share global best practices and the latest in academic research,” said Dwight. “Joining the Council as a board member is an exciting opportunity to collaborate with other executives and academic leaders in setting the Council’s strategic and operational objectives around Manufacturing 4.0 and beyond.”

Since his appointment as president, CEO and director of Cooley Group in 2011, Dwight successfully repositioned the 90-year-old company around three pillars of sustainable growth (economic prosperity, environmental stewardship and social responsibility) while improving the health, well-being, engagement and ultimately the capacity for innovation of the entire Cooley team. Under his leadership, Cooley has sustained revenue and profitability growth for seven consecutive years. During this time, Cooley generated more than 40 percent of its revenue from new products, won PBN Awards, including “Healthiest Employer of Rhode Island” and “Product Innovation & Design,” and cultivated collaborative partnerships such that more than 70 percent of Cooley’s revenue is managed under long-term customer supply agreements.

The Manufacturing Leadership Board of Governors comprises senior executives and industry experts at leading manufacturing, academic and research organizations around the world, including Lockheed Martin, Procter & Gamble, Ford Motor Company, Dow Chemical, Merck, Cisco Systems, IBM, Germany’s SmartFactory Technology Initiative, Lexmark International, Protolabs, Premio Foods, Virtex Enterprises, S&S Hinge, Graphicast, MIT, UCLA, the University of Cincinnati, the University of Cambridge’s Institute for Manufacturing in the UK, the U.S. National Center for Defense Manufacturing and Machining and consultants Frost & Sullivan. For more information and MLC membership details, visit www.manufacturingleadershipcouncil.com.

-MLC/NAM-

Founded in 2008, and now a division of the National Association of Manufacturers, the Manufacturing Leadership Council’s mission is to inspire and support manufacturing executives to achieve transformational growth for themselves, their companies and the industry at large through enlightened leadership. With more than 1,500 senior-level members from many of the world’s leading manufacturing companies, the MLC focuses on the intersection of advanced digital technologies and the business, identifying growth and improvement opportunities in the operation, organization and leadership of manufacturing enterprises as they pursue their journeys to Manufacturing 4.0.

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.35 trillion to the U.S. economy annually, has the largest economic impact of any major sector and accounts for more than two-thirds of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the Manufacturers or to follow us on Shopfloor, Twitter and Facebook, please visit www.nam.org.

733 10th St. NW, Suite 700 • Washington, DC 20001 • (202) 637-3000

Manufacturers Take Action on Climate

With a recent three-year United Nations environmental report spearheaded by the Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Services (IPBES) highlighting dire warnings about human impact on the planet, leaders in the United States are under renewed pressure to find solutions that work. In communities across the country, manufacturers are taking a stand for sustainability – and demanding action against climate change.

While manufacturers have created their own policies to reduce pollution and increase sustainability, manufacturing leaders are increasingly pushing for action. Although policymakers in Washington have yet to settle on a unified approach, the manufacturing industry is making clear that the existing state of affairs is unsustainable.

“Manufacturers hope we can all agree that the current policy – a disjointed system of federal and state regulations that take decades to install and often fail – is not the answer,” said Ross Eisenberg, Vice President of Energy and Resources Policy at the National Association of Manufacturers. “A piecemeal regulatory approach just isn’t going to cut it.”

While proposals like the Green New Deal have garnered significant press coverage without gaining a single vote in Congress, manufacturing leaders are seeking opportunities for consensus on climate legislation by focusing on actionable solutions. These proposals include scaling up the adoption of energy- and water-efficient products and technologies, prioritizing innovation and creating pathways for the deployment of new technologies like carbon capture, utilization and storage. It also involves working collaboratively by creating public-private partnerships between government and manufacturers to help them further decarbonize. Finally, manufacturers are encouraging the United States to reengage with the international community in order to reduce greenhouse gas emissions together, rather than in isolation.

Manufacturers have unique qualifications to speak about this issue, as most have implemented meaningful programs to reduce greenhouse gas emissions, pioneer new strategies and technologies to reduce greenhouse gas emissions and set aggressive emissions reduction targets.

These actions have had a significant effect. Over the past decade, the manufacturing industry has reduced its greenhouse gas emissions by 10 percent while the sector’s value to the economy has increased 19 percent. It’s outpacing competitors and demonstrating that it is possible to reduce emissions without falling behind in a global market.

“Our barometer is that manufacturers in America must stay competitive in the global economy, and that requires realistic, practical policies that we can implement while we continue to do the things that make the manufacturing sector strong,” said Eisenberg. “Speaking for the 12.8 million men and women who make things in America, we’re ready.”