Semiconductor Makers Look to “Chiplets”

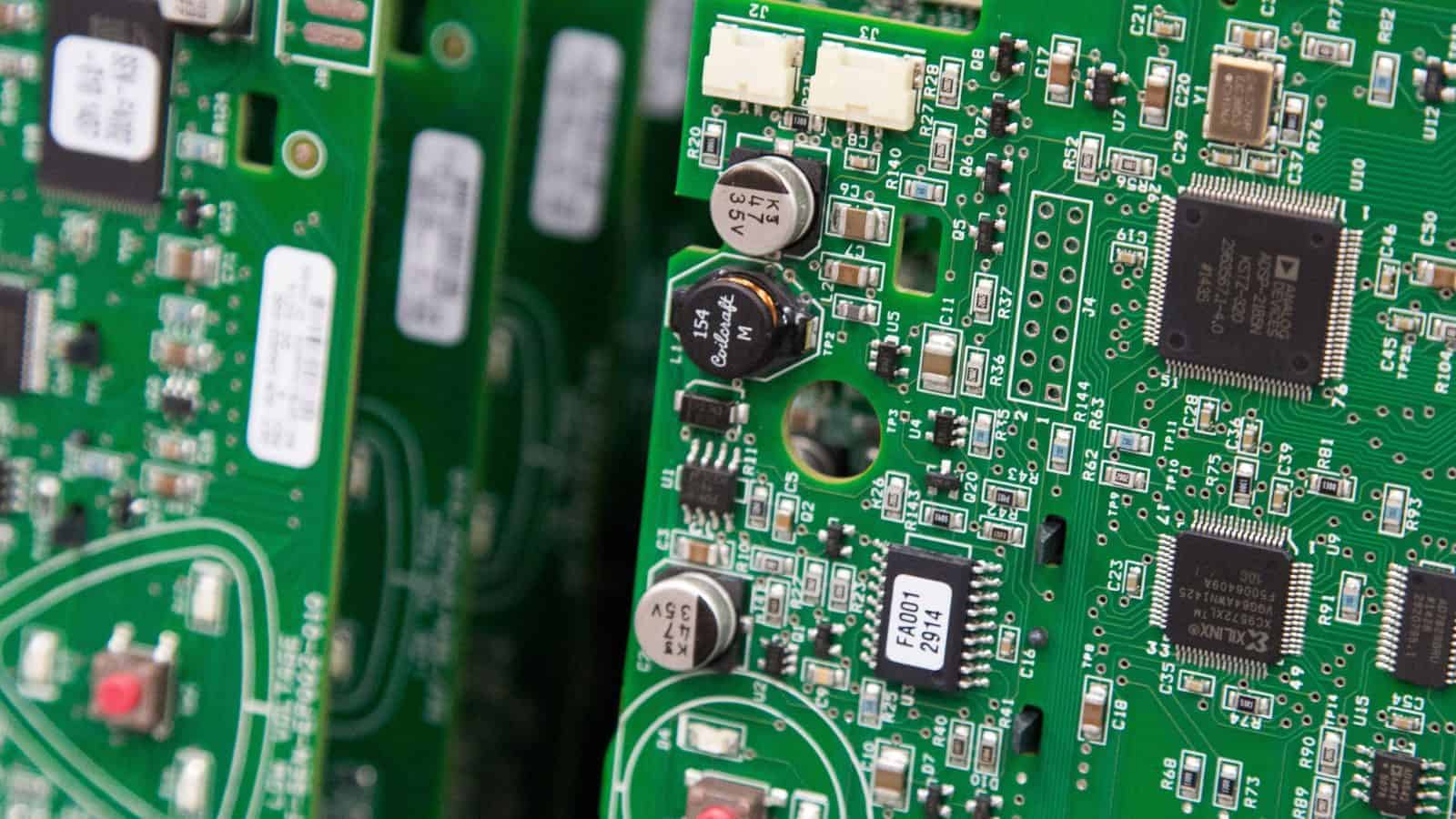

The explosive growth of artificial intelligence is leading semiconductor makers to move quickly to create “designs that stack chips together like high-tech Lego pieces,” according to The Wall Street Journal (subscription).

What’s going on: “‘Chiplets’ can be an easier way to design more-powerful chips, according to industry executives who call the technology one of the most significant advances since the dawn of the integrated circuit more than 60 years ago.”

- The technology has the potential to deliver more powerful, cost-effective semiconductors, sources told the Journal.

- Last year, some of the world’s largest technology companies, including Qualcomm and Intel—which recently announced products containing chiplets—formed a coalition to craft chiplet-designing standards.

How it works: “A typical consumer device such as a smartphone contains many types of chip[s] for functions including data processing, graphics processing, memory, telecommunications and power control.”

- “The chips are delicately tethered to minuscule wires and ensconced in a protective plastic casing, forming a package that can be fixed to a circuit board.”

- “With the new chiplet packaging, engineers have found ways to bolt together pre-existing chips, the equivalent of using a few Lego pieces to build a toy car.”

The caveats: Chiplet manufacturing is not cheap, however, and the technology requires its own performance-verification process.

- What’s more, chiplets “aren’t suited to every function,” and lend themselves better to high-end desktop computers than mass-marketed cell phones.

China’s role: It is estimated that China controls 38% of the semiconductor assembly, testing and packaging market, a fact that “poses two potential risks for the U.S. While many American companies have been working with factories in China to handle these specialist chip-making roles, the supply chains could be tangled by a geopolitical crisis or another pandemic.”

- “In addition, the U.S. has imposed export controls on advanced semiconductor technology and could seek to expand controls in the future.”

How Are Companies Using AI?

To learn how sectors and businesses are using artificial intelligence, The Economist (subscription) created an index of firms in the S&P 500—and the results show that “even beyond tech firms the interest in AI is growing fast.”

What’s going on: “We looked at five measures: the share of issued patents that mention AI; venture-capital (VA) activity targeting AI firms; acquisitions of AI firms; job listings citing AI; and mentions of the technology on earnings calls. … [C]lear leaders and laggards are already emerging.”

The findings: In the past three years, approximately two-thirds of the companies examined by The Economist have placed a job ad that refers to AI. One of the sharpest increases in such mentions has been among chipmakers.

- The number of registered AI-related patents rose between 2020 and 2022.

- This year, about 25% of venture deals by S&P 500 companies involved AI start-ups, an increase from 19% just two years ago.

Outside Silicon Valley: While the index found that the most “enthusiastic” users of AI are technology companies, “[b]eyond tech, two types of firms seem to be adopting AI the quickest.”

- Data-heavy sectors, including insurance, pharmaceutical and financial-services companies “account for about a quarter of our top 100.” In this category, Abbott is building AI-powered medical tools.

- The other category of company quickly adopting AI includes “industries that are already being disrupted by technology,” such as automakers, telecom, retail and media. Among these are Ford and General Motors, which are using AI in electric-vehicle manufacturing.

The last word: AI use may have some drawbacks, including cybersecurity risks, potential legal liability and possible inaccuracy of results. However, these “must be weighed against the potential benefits, which could be vast.”

Start-ups Seek Improved AC

With the backing of major HVAC manufacturers, start-ups are working to make air conditioners that are capable of easing the strain on the power grid, according to The Wall Street Journal (subscription).

What’s going on: “Companies such as Blue Frontier, Transaera and Montana Technologies are raising money from investors including industry giant Carrier Global … to develop more efficient technologies. Many of those efforts focus on the humidity rather than the heat, using new materials like liquid salt to dry out the air.”

Why it’s important: The number of air conditioners in use worldwide is expected to more than double by the middle of the century, to 5.5 billion, with many units likely to be inefficient.

- “Stalwarts such as Carrier and Trane Technologies say they are spending billions of dollars to offer more efficient versions of conventional ACs while evaluating the new approaches.”

A different AC unit: Traditional air-conditioning units work by converting refrigerants from gas to liquid and then back again, while circulating air with fans. They are unable to remove humidity without cooling the air, which is what makes them inefficient, according to the article.

- “Blue Frontier aims to separate humidity and temperature control using a liquid salt solution that was developed with the National Renewable Energy Laboratory. The solution also stores energy, reducing consumption at peak times, when electricity grids are strained on hot days.

- Innovation is also required to make air conditioning affordable for people in developing nations, according to the Journal.

More investment: “The need for new approaches is pushing Carrier to make venture investments to complement its other growth strategies, said Jennifer Anderson, Carrier’s chief sustainability officer. Trane is investing in startups like data-center-cooling company LiquidStack while looking at new technology approaches, CEO Dave Regnery said.”

Second Phase of CHIPS Act Funding Begins

Businesses “that provide tools, chemicals and other supplies for the semiconductor industry” may now apply for a piece of the funds set aside in last year’s CHIPS and Science Act, according to The Wall Street Journal (subscription).

What’s going on: Late last week, the Biden administration announced broadened eligibility for companies capable of using federal subsidies to increase chip production in the U.S.

- Last year’s legislation, which the NAM championed, earmarked $39 billion for the purpose.

- In February, the Commerce Department’s CHIPS Program Office began “accept[ing] applications for the construction, expansion, or modernization of semiconductor materials and manufacturing equipment facilities for which the total capital investment equals or exceeds $300 million,” according to the National Institute of Standards and Technology, which is part of Commerce.

Why it’s important: “‘We can have as many fabs [chip plants] as we want, but the reality is, we also need the supply chain—the chemicals, the material, the tools that go into those fabs,’ Commerce Secretary Gina Raimondo said at a briefing,” according to the Journal.

Lots of interest: Nearly 400 businesses across 37 states have signaled their interest in receiving funds under this latest phase.

- “The department is already accepting full applications for the C[HIPS] Act funding from companies with plans to build facilities for leading-edge semiconductors, and will soon accept submissions from companies that plan to build chips that are currently state-of-the-art or older.”

- Suppliers may begin submitting applications this fall, but the administration has not yet said when the funds will be disbursed.

NAM Honors Vermeer’s Mary Andringa

When Mary Andringa arrived at NAM headquarters on Wednesday, she expected a tour of the renovated office. Instead, the former NAM Board chair was surprised by an applauding crowd who gathered for the ribbon-cutting for one of the NAM’s meeting rooms, now named the Mary Andringa Room in commemoration of her decades-long service to manufacturers in the U.S. The NAM’s conference rooms are named for many luminaries of manufacturing, including Andrew Carnegie, Thomas Edison, the Wright Brothers, Jonas Salk and Marie Curie.

“I was absolutely overwhelmed, humbled and honored,” Andringa said.

A longtime supporter: Now chair emeritus of Vermeer Corporation—a family-owned, midsized manufacturer of industrial and agricultural machines in Pella, Iowa—Andringa served as NAM Board chair from 2011 to 2013 and has been an active participant on the NAM Board since the early 2000s.

- Andringa found her experience as NAM Board chair deeply meaningful, remarking on the close relationship she developed with NAM President and CEO Jay Timmons, who was also newly appointed in 2011.

- “It was a really great experience because I had a few years under my belt as CEO [of Vermeer],” Andringa said, “and I could share best practices with Jay. It was great to see how he took initiative and dug into some areas that needed more cooperation, like the NAM’s partnerships with state associations.”

Visiting the Hill: Andringa said she “enjoyed being a voice for manufacturing” in meetings on the Hill and with several administrations.

- Whether advocating against compliance regulations that created needless hardship for manufacturers, or for removing trade barriers impeding U.S. exports, Andringa stressed that she always made her case to policymakers on both sides of the aisle.

- “The NAM tries to be the voice of reason. … It has done a good job connecting with both parties and whoever is in the White House,” she said.

Read the full story here.

Manufacturers Seek Smart AI Policy

Artificial intelligence is transforming manufacturing, and federal policies shouldn’t get in the way, NAM Director of Human Resources and Innovation Policy Julia Bogue told the Department of Commerce last week.

Four key areas: Manufacturers are chiefly concerned about AI in four areas.

- Safety: “AI is broadly used in the factory setting to prevent injury by making tasks safer,” Bogue pointed out. “AI is also used to prevent future injury by studying repetitive movement that could lead to torn rotator cuffs, wear on knee cartilage and other injuries caused over time.”

- Training: AI is also revolutionizing training for workers, teaching them how to complete tasks and learn new procedures while on the job.

- Efficiency: AI aids efficiency in a number of ways, including through predictive maintenance for manufacturing equipment. It can predict when a part will need to be replaced, so that maintenance can be scheduled at the least disruptive time. “An example of this is utilizing AI to monitor fan vibration to calculate when the fan will need to be replaced,” Bogue noted.

- Product design and development: “AI can be used to make products safer, improve quality and improve efficiency,” Bogue said.

Regulations: “Regulation should not restrict innovation or competitiveness, as the NAM believes the growth of AI represents an opportunity for manufacturers,” said Bogue. Manufacturers understand the need for careful, smart regulation, she added.

- In a recent survey by the Manufacturing Leadership Council (the NAM’s digital transformation arm), 75.9% of survey respondents said that “manufacturers should adopt a code of ethics or conduct” for the use of AI.

How to do it: The federal government should tailor its regulations to different sectors, evaluating the risks of particular use cases instead of applying a single standard, said Bogue.

- As the agency conducts its analysis, it should also consider that “our present understanding of risks, costs and benefits may be limited because technology lends itself to future unanticipated breakthroughs and applications.”

Further reading: Interested in learning how manufacturers can apply AI technologies to their operations? Connect with the MLC to learn more—and consider signing up for its annual conference, Rethink, coming up soon on June 26–28 in Marco Island, Florida. Virtual attendance is also an option!

Manufacturers Seek Smart AI Policy

Artificial intelligence is transforming manufacturing, and federal policies shouldn’t get in the way, NAM Director of Human Resources and Innovation Policy Julia Bogue told the Department of Commerce last week.

Four key areas: Manufacturers are chiefly concerned about AI in four areas.

- Safety: “AI is broadly used in the factory setting to prevent injury by making tasks safer,” Bogue pointed out. “AI is also used to prevent future injury by studying repetitive movement that could lead to torn rotator cuffs, wear on knee cartilage and other injuries caused over time.”

- Training: AI is also revolutionizing training for workers, teaching them how to complete tasks and learn new procedures while on the job

- Efficiency: AI aids efficiency in a number of ways, including through predictive maintenance for manufacturing equipment. It can predict when a part will need to be replaced, so that maintenance can be scheduled at the least disruptive time. “An example of this is utilizing AI to monitor fan vibration to calculate when the fan will need to be replaced,” Bogue noted.

- Product design and development: “AI can be used to make products safer, improve quality and improve efficiency,” Bogue said.

Regulations: “Regulation should not restrict innovation or competitiveness, as the NAM believes the growth of AI represents an opportunity for manufacturers,” said Bogue. Manufacturers understand the need for careful, smart regulation, she added.

- In a recent survey by the Manufacturing Leadership Council (the NAM’s digital transformation arm), 75.9% of survey respondents said that “manufacturers should adopt a code of ethics or conduct” for the use of AI.

How to do it: The federal government should tailor its regulations to different sectors, evaluating the risks of particular use cases instead of applying a single standard, said Bogue.

- As the agency conducts its analysis, it should also consider that “our present understanding of risks, costs and benefits may be limited because technology lends itself to future unanticipated breakthroughs and applications.”

Further reading: Interested in learning how manufacturers can apply AI technologies to their operations? Connect with the MLC to learn more—and consider signing up for its annual conference, Rethink, coming up soon on June 26–28 in Marco Island, Florida. Virtual attendance is also an option!

From JFK to Mother Teresa: The Career of Snap-on CEO Nick Pinchuk

In an interview with Nick Pinchuk, you will start with JFK, meander through Ralph Waldo Emerson and the New Testament, meet Mother Teresa along the way and find out only at the end that he helped send the Viking probe to Mars. And let’s not forget another achievement: he delivered his own child in the backseat of the family car.

The Snap-on chairman and CEO, an executive committee member and stalwart supporter of the NAM, sat down for a very wide-ranging interview with NAM President and CEO Jay Timmons at the NAM’s recent board meeting, at which he received the Manufacturing Icon Award. Here are some of the highlights.

Starting with Kennedy: When asked how he got into manufacturing, Pinchuk cites Kennedy’s 1961 speech promising that the U.S. would put a man on the moon by the end of the decade. Pinchuk was one of the “millions of young people” who pursued STEM careers because Kennedy inspired them, he said.

- He then found himself shipped to Vietnam after a stint in the Reserve Officers’ Training Corps. His experience in the army later helped launch him into management at Ford, when the company was looking for someone who could “run something 24 hours a day”—just as he had in Vietnam.

- He “parlayed” that experience into a business degree, then rose fast in two other organizations—United Technologies and Carrier. His experience in Vietnam helped a second time, leading Carrier to choose him to run its Asia operations.

- Finally, Snap-on came calling, looking for someone with international experience. “On a day in which the board of directors likely had too much wine,” Pinchuk joked, “they decided to give me the CEO job.”

The life lesson? “I probably am sitting here because I went to Vietnam. It could never have been planned.” Pinchuk said. “I’ve made friends in many countries. I’ve opened factories. I’ve met two canonized saints of the Catholic Church and actually a lot of presidents. They weren’t part of a life plan. They were opportunities that arose in which I was prepared and privileged to participate.”

- And here’s another thing he didn’t exactly plan: while driving his wife to the hospital at 4:30 a.m. after she went into labor, he found himself forced to “pull into an empty parking lot and run around, open the door and play catch.”

Purpose: Timmons and Pinchuk discussed the necessity of upskilling the workforce, and in the course of explaining why a sense of purpose is so important to workers, Pinchuk mentioned the time he met Mother Teresa.

- “I talked to her, and she said a bunch of things to me that changed my life. She said, here’s an example that might be useful to you. I was walking down a street with some of my sisters and a beggar got up from the curb.”

- “This was someone I would usually consider to be the subject or focus of my mission to help. The beggar walked over and gave me a coin of little value. And she said, you know why? It’s because he could find respect in the fact that he helped Mother Teresa. Purpose. Purpose is everything.”

On strategy: When asked about his successful 20 years at Snap-on, Pinchuk said, “I believe that an organization’s strategy best emanates from what actually works for it. And so if you understand what works for you, what’s inherent in the DNA and the capabilities of the people, then you say to yourself, ‘Well, that should be my strategy.’”

- “We have people who send me pictures of small Snap-on toolboxes with ashes of their loved ones in them because the loved ones believed that among the most important things in their lives were Snap-on tools,” he continued. “We cannot break that faith.”

- “Therefore, we have to know who we are. And, that is, we are those who give working men and women the means, through the use of Snap-on tools, to declare they’re doing something special and to signify the pride they have in their profession. Making Snap-on worthy of that belief is the core of our strategy.”

The last word: Timmons concluded the conversation by thanking Pinchuk for his support of the NAM and the Manufacturing Institute, saying, “We’re so grateful for your unwavering service to the NAM and your industry. You’re a true model for business leaders in America.”

NAM Announces New Leadership

Yesterday, NAM President and CEO Jay Timmons announced recent changes to the organization’s leadership team.

Newhouse to senior advisor: Last month, NAM Senior Vice President Aric Newhouse announced he would step back from his day-to-day management responsibilities of the policy and government relations teams on July 1. Newhouse will now serve the NAM as a senior advisor.

Aligning advocacy: Managing Vice Presidents Chris Netram and Jordan Stoick, respectively, will lead the NAM’s best-in-class policy team and government relations team. To further combine the strengths of the NAM’s government relations, public affairs and communications operations, Stoick and Netram will report to NAM Executive Vice President Erin Streeter.

- Over the past few years, Streeter has led engagement with all of the NAM’s external stakeholders, overseeing advocacy campaigns and key relationships with the White House and members of Congress, while continuing her leadership of communications, marketing and brand reputation.

- “I’m excited about what this means to further integrating our advocacy efforts,” said Timmons following the announcement. “These changes will elevate the leadership and expertise of our best-in-class policy professionals.”

Membership: NAM Chief of Staff Alyssa Shooshan will take on the role of senior vice president of membership in addition to her current roles of overseeing the executive office and the board initiatives teams. Jeff Pierce will increase his focus on sponsorships, issue advocacy development and new member growth as the senior vice president of strategic development. Pierce’s leadership has been instrumental in the rapid growth of sponsorships and other new revenue streams, and he will continue to lead their expansion.

- These changes bring the membership and board initiatives teams into closer alignment. They also recognize the demand from NAM members to grow operational and thought leadership programming.

The last word: “As Aric steps back after 16 years, he leaves a record of accomplishment widely recognized by his peers in the association community,” said Timmons. “From being named CEO Update’s Association Lobbyist of the Year in 2016, to The Hill naming him a ‘top lobbyist’ for many years, to his most recent inclusion in Washingtonian Magazine’s Top 500 Influential list, his wisdom, influence and bipartisan approach are legendary.”

- “There are two things any high-performing organization looks to achieve in these moments of change: continuity and improvement. And that’s what this leadership will deliver—to continue advancing the competitiveness of manufacturers in the United States.”

NAM Announces New Leadership

Yesterday, NAM President and CEO Jay Timmons announced recent changes to the organization’s leadership team.

Newhouse to senior advisor: Last month, NAM Senior Vice President Aric Newhouse announced he would step back from his day-to-day management responsibilities of the policy and government relations teams on July 1. Newhouse will now serve the NAM as a senior advisor.

Aligning advocacy: Managing Vice Presidents Chris Netram and Jordan Stoick, respectively, will lead the NAM’s best-in-class policy team and government relations team. To further combine the strengths of the NAM’s government relations, public affairs and communications operations, Stoick and Netram will report to NAM Executive Vice President Erin Streeter.

- Over the past few years, Streeter has led engagement with all of the NAM’s external stakeholders, overseeing advocacy campaigns and key relationships with the White House and members of Congress, while continuing her leadership of communications, marketing and brand reputation.

- “I’m excited about what this means to further integrating our advocacy efforts,” said Timmons following the announcement. “These changes will elevate the leadership and expertise of our best-in-class policy professionals.”

Membership: NAM Chief of Staff Alyssa Shooshan will take on the role of senior vice president of membership in addition to her current roles of overseeing the executive office and the board initiatives teams. Jeff Pierce will increase his focus on sponsorships, issue advocacy development and new member growth as the senior vice president of strategic development. Pierce’s leadership has been instrumental in the rapid growth of sponsorships and other new revenue streams, and he will continue to lead their expansion.

- These changes bring the membership and board initiatives teams into closer alignment. They also recognize the demand from NAM members to grow operational and thought leadership programming.

The last word: “As Aric steps back after 16 years, he leaves a record of accomplishment widely recognized by his peers in the association community,” said Timmons. “From being named CEO Update’s Association Lobbyist of the Year in 2016, to The Hill naming him a ‘top lobbyist’ for many years, to his most recent inclusion in Washingtonian Magazine’s Top 500 Influential list, his wisdom, influence and bipartisan approach are legendary.”

- “There are two things any high-performing organization looks to achieve in these moments of change: continuity and improvement. And that’s what this leadership will deliver—to continue advancing the competitiveness of manufacturers in the United States.”