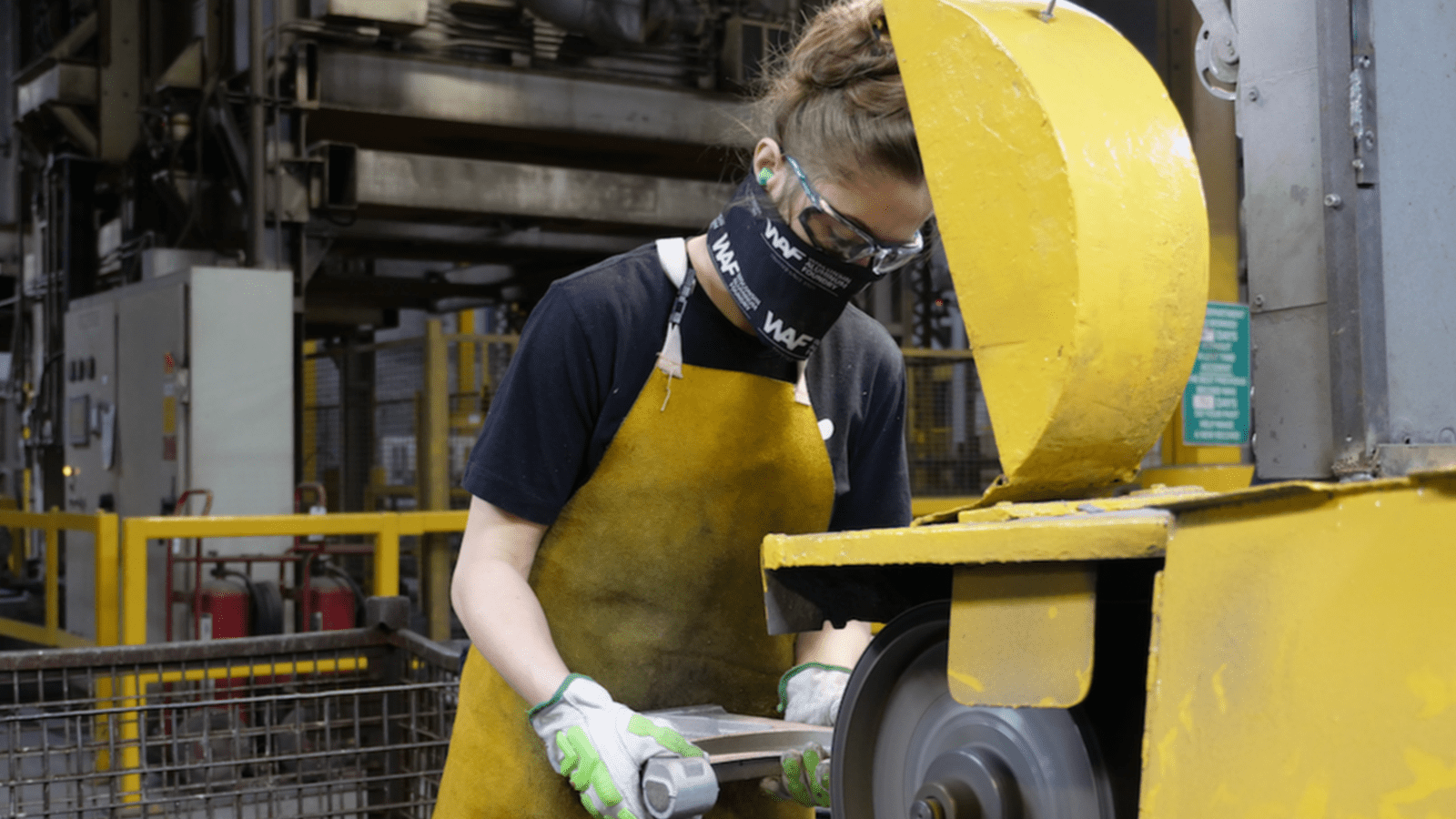

WAFCO Seeks a Child Care Solution to the Labor Shortage

It all started with a conversation in a parking lot.

Wisconsin Aluminum Foundry CEO Sachin Shivaram was chatting with a second-shift employee outside the WAFCO building one evening last summer when he happened to glance into the man’s car.

- “[I notice] he’s got a car seat in there, so I ask him, ‘What do you do for child care?’” Shivaram recalled. “He said he’s a single dad of a 4-year-old daughter, and he takes her to a different [caretaker’s] house every night. I thought, ‘That can’t be a good environment for her.’ It got me thinking, ‘How can we help this man get better care?’”

Oasis needed: Shivaram aims to find out. While the top executive of a century-old aluminum casting and molding manufacturer may seem an unlikely advocate for affordable child care, helping employees care for their kids has practically become a business imperative for WAFCO.

- “When the frenzy of the labor shortage got going, we connected” child care and the inability to fill jobs, Shivaram said, adding that the Manitowoc area is a “child care desert” with few available spots in centers. “One day we had no women on second shift, [yet] women are 50% of the population. [That’s because,] unfortunately, the burden of caring for children falls primarily on women. We realized, ‘If we’re going to make a dent in the labor shortage, we have to fix this.’”

Lending a hand: So, the company started trying to do just that. On Shivaram’s watch, it began giving employees $400 a month in child care reimbursement, on top of its $27-an-hour median wage, health care benefits and double pay for overtime.

- WAFCO has also purchased spots, when available, at a high-quality local day care center owned by the wife of a company associate and subsidized the cost of those spots for employee children.

Doing even more: Then Shivaram learned about the state’s Workforce Innovation Grant Program, the aim of which is “to help the regions of Wisconsin solve their most pressing workforce challenges by financially supporting collaborative, sustainable and innovative pandemic-recovery plans developed by regional organizations.”

- In addition to setting aside $1 million of its own capital for the creation of a child care center, WAFCO applied for $5 million of grant money last year in the program’s first round. While the company didn’t get the funds then, Shivaram plans to redouble the firm’s efforts and apply for round two this year.

The response: “Employees love it,” Shivaram said of the child care subsidy. Of WAFCO’s approximately 580 employees, about 80 make use of the funds. “Even those employees who don’t have children of child care age say this is really helpful.”

What’s next: WAFCO has identified a site for the planned center, a former adult day care facility. It is also working with KinderCare Learning Centers, the Oregon-based childhood-education company, to decide on an operating model.

- “There will be a strong emphasis on early learning for 0-to-5-year-olds,” Shivaram said. “We’re not just going to have check-the-box child care. And we are committed to paying [child care workers] more than a living wage.”

Advice for other manufacturers: Manufacturers looking to offer child care help to their employees should chiefly remember one thing as they start to plan: You can’t go it alone.

- “This does take a coalition,” Shivaram said. “This is really businesses coming together to help a need in society that, if we don’t resolve it, is only going to make us less successful. This is not going to happen with one business [working] alone.”

Industry-wide efforts: WAFCO’s initiative is part of a larger wave of manufacturers offering increasingly competitive benefits—including child care—for their teams.

- The Iowa-based Vermeer Corp. has full onsite child care facilities for the children of its employees.

- Rockwell Automation, headquartered in Wisconsin, has a generous “caregiver leave” policy to allow workers to take paid time off to look after dependents.

- When schools were closed at the beginning of the pandemic, the Pennsylvania-based i2M employed teachers to host onsite learning “pods” for the children of employees. The company is now working on a similar setup for after-school care.

The NAM says: “As we look to close the skills gap and resolve ongoing talent shortages, manufacturers continue to outperform other industries when it comes to pay and benefits packages they offer,” said Manufacturing Institute President Carolyn Lee. The MI is the NAM’s workforce development and education partner.

- “Manufacturers are constantly finding innovative ways to provide quality-of-life-improving services, such as child care, health care options, leave and retirement savings, that will motivate and empower millions of manufacturing team members nationwide and make our industry more equitable and inclusive.”

How Manufacturers Can Navigate Supply Chain Challenges

As the global supply chain, worker shortage and wage inflation challenges many had hoped were transitory dig in their heels, manufacturers everywhere are wondering how best to get around them.

Panelists at “Successfully Navigating Current Supply Chain Disruptions,” a webinar hosted by the NAM’s Manufacturing Institute, Manufacturing Leadership Council and professional services firm PwC, sought to answer that question.

We rounded up the speakers’ top tips for manufacturers seeking to sustainably and profitably maneuver the several sizable hurdles they still face going into 2022.

- Break down siloes. Now that manufacturers are having to replace traditional supply chain models, changing their company operations to have staff work across siloes is more important than ever, said PwC Partner Debjit Banerjee.

- Expect disruption. If it taught us nothing else, COVID-19 conveyed the importance of being prepared for the unexpected. Going forward, manufacturers would do well to not just plan for the possibility of disruption, but to assume it will come. To that end, preplanned “differentiated customer service” and disruption drills should become the norm, Banerjee said.

- Advance your supply chain planning. Increasingly, Nexteer Automotive, a global maker of steering and driveline components, is focusing on advanced supply chain planning, programs that help predict shipments, supply and demand for smoother operations, said Nexteer Automotive Vice President of Global Manufacturing Operations Dennis Hoeg. With it, “decisions can be made smarter, earlier.”

- Automate. Manufacturers should consider automating repetitive “transaction” work and reserving their employees for analytical tasks that only humans can do, according to Hoeg.

- Balance agility and resilience. Before the pandemic, “we were working on a strategy that was based on agility,” said Rockwell Automation Chief Supply Chain Officer Ernest Nicolas Jr. “Through the pandemic … we had to reprioritize. We had to take a step back to balance agility and resilience.” Manufacturers that want a better agility-resilience balance can do so “through data, process and technology” enablement, according to Nicolas.

- “Relentlessly prioritize.” Nicolas so believes in this advice that he ended his presentation with it. “There’s so much going on right now; we want to be certain we manage our priorities,” he said. “So, there’s a lot we’re saying ‘not now’ to …. but it’s not a matter of ‘no.’ It’s a matter of, ‘We’ve got to get these things finished so we can lay the foundation’” in this new normal.

Sharpening America’s Competitive Edge

The Biden administration is making new commitments to semiconductor production and planning new policies designed to bring STEM talent to the United States—and manufacturing leaders are weighing in.

The background: Last week, the White House announced a series of actions to attract STEM talent, to strengthen the U.S. economy and to improve American competitiveness around the world.

What we’re saying: NAM President and CEO Jay Timmons joined Manufacturing Institute President Carolyn Lee in praising the actions, while also pushing for continued work on these critical issues.

- “The supply chain and economic disruptions facing American families and the manufacturing industry are driven in part by the severe worker shortage and by the serious chip shortage,” said Timmons. “Today, the White House has announced promising developments on both fronts, and we will work with the administration and Congress to build on this progress even further.”

- “Manufacturers are leading America’s recovery, but we still need to hire more than 800,000 workers right now,” said Lee. “And according to the MI’s research with Deloitte, we will have 4 million jobs to fill by the end of the decade, 2.1 million of which could go unfilled if current trends continue. That sustained need is why the NAM and the MI launched our nationwide Creators Wanted workforce campaign. It’s why we have long focused on programs and policies of all types that will grow the pool of STEM talent in America. We have to come at this crisis from every angle, and the MI and the entire industry will continue using every tool at our disposal to inspire, educate and empower the next generation of creators.”

The road ahead: Timmons highlighted the path forward and noted additional important actions to meet current and future needs.

- On semiconductor production: “To ramp up domestic semiconductor production, we can’t stop at today’s action, though,” said Timmons. “Too many manufacturing sectors have been unable to deliver the products American families need because they lack key components. Manufacturers are working overtime to overcome this challenge, but Congress has to do its part, which means passing USICA. Doing so will not only shore up our recovery and ease supply chain strains but also strengthen our economy and national security.”

On attracting STEM talent: “These immigration policies will also undoubtedly sharpen America’s competitive edge and help us outpace and out-innovate the rest of the world,” said Timmons. “In far too many cases, we’ve seen brilliant minds educated at American universities leave because our outdated immigration system doesn’t let them put their talents to work for America’s future. Now we can start to reverse that trend, among other key policy changes. As part of ‘A Way Forward,’ our plan for comprehensive immigration reform, we have long called for immigration policies that are responsive to clear economic needs. These policies meet that test, meaning that they will benefit our workers, our communities and our industry, empowering us to create even more opportunities for the American people.”

Labor Shortage Will Continue, But Manufacturing Is a Bright Spot

The future workforce will continue to ‘favor’ workers over employers, with the labor pool set to grow just 0.2% a year from 2024 to 2031, according to the Congressional Budget Office and Axios.

What’s happening: “In the 2010s, the massive millennial generation was entering the workforce, the massive baby boom generation was still hard at work, and there was a multi-year hangover from the deep recession caused by the global financial crisis. But now, boomers are retiring, millennials are approaching middle age, and the Gen Z that follows them is comparatively small.”

- Unlike in the recent past, organizations now and in the future won’t be able to count on “a flood” of job applicants for all advertised positions.

What it means for manufacturers: “On the one hand, manufacturers added 349,000 manufacturing workers in 2021, the most since 1994, and on the other, the sector has 219,000 fewer workers today than it did before the pandemic began,” said NAM Chief Economist Chad Moutray.

- “In addition, job openings remain near record highs, and firms continue to note difficulties in finding and retaining workers. In 2022, we would expect to add around 150,000 to 180,000 employees, building on last year’s strong gains.”

What it also means: “The reality of the labor shortage makes clear that we need an all-of-the-above solution to our workforce crisis,” said Manufacturing Institute President Carolyn Lee. “We need to attract new workers and provide them with the needed skills. That’s why the NAM and the MI’s Creators Wanted campaign is so critical and so timely. Research shows the next generation is looking for careers that matter. They want to have an impact, and they want the potential for family-supporting jobs with upward mobility, all of which are characteristics of modern manufacturing.”

“This data also underscores why we also need comprehensive immigration reform to ensure that we are bringing the best and brightest to the U.S. to help strengthen manufacturing in America.”

“What’s Ahead for 2022?” Predicts Growth, Continued Challenges

Remote work, digital twins, an increased focus on sustainability and continued talent shortages: these are just some of the trends affecting manufacturers that we’re likely to see in 2022 and beyond, according to a group of expert panelists on the recent Manufacturing Leadership Council’s “What’s Ahead in 2022?” Critical Issues Panel. The NAM’s MLC is a global business leadership network dedicated helping to senior executives leverage digital transformation in the manufacturing industry.

We rounded up some of the top predictions as they pertain to manufacturers.

Economy

- Manufacturing production will continue to be strong, said panelist and NAM Chief Economist Chad Moutray. Toward the end of 2021, it was 2% above February 2020, “a sign that we’re continuing to move in the right direction despite … continuing supply chain challenges.”

- S. labor-force participation is not likely to return “where it was pre-pandemic,” Moutray said. “A fair share of that is coming from retirement … [and] some people who are continuing to worry about child care and schooling.”

- The economy will grow about 4% in 2022, Moutray predicted.

Policy

- Washington will make moves to ease supply chain problems. “Congress knows they must do something to unleash the bottlenecks,” said panelist and NAM Senior Vice President of Policy and Government Relations Aric Newhouse. Legislation could involve workforce-participation incentivization in the form of training programs, as well as giving additional resources to ports.

- The vaccination and testing Emergency Temporary Standard will be “an area for continued movement” in 2022, Newhouse said.

Technology

- Technology will find ways to cope with what are likely to be ongoing workforce shortages, IDC Energy and Manufacturing Insights Group Vice President Kevin Prouty said. These will include automation and technologies to enable virtual and remote work.

- More manufacturers will begin using vision analytics, Prouty said, owing to the increased affordability of cameras and the ease with which footage can be analyzed, shared and moved in the cloud.

- Use of artificial intelligence will start to become the norm among manufacturers rather than the exception, panelist and MLC Content Director Penelope Brown said. “We’re seeing manufacturers move away from that research phase and much more toward a roadmap” for how they’re going to use AI in their plants.

Environment

- There will be greater, more widespread movement toward sustainability. In a recent MLC survey of manufacturers, 87% said they believed manufacturing had a responsibility to society to be more sustainable, Brown said.

Dive in deeper with the MLC’s recently redesigned website, and ensure your team has access to the MLC’s full network and suite of intel, events and other resources.

NAM Announces New Board Leadership

Fitterling and Wengel Take Helm at a Pivotal Time for the Manufacturing Industry

Washington, D.C. – The National Association of Manufacturers announced the Executive Committee of its Board of Directors has elected Dow Inc. Chairman and CEO Jim Fitterling as board chair and appointed Johnson & Johnson Executive Vice President and Chief Global Supply Chain Officer Kathy Wengel as vice chair.

With the industry on the front lines of an ongoing pandemic, supply chain disruptions, a persistent worker shortage and critical policy debates, these manufacturing leaders will take charge at a particularly consequential time.

“Jim and Kathy have well-earned reputations as respected and visionary leaders of renowned global brands. We have many challenges to confront, and they will ensure our industry continues to lead our recovery and leverage new innovations to raise standards of living in America and around the world,” said NAM President and CEO Jay Timmons. “And no matter what comes our way, our association and industry remain steadfastly committed to policies that uphold the values that make America exceptional: free enterprise, competitiveness, individual liberty and equal opportunity.”

“Manufacturing is vital to the long-term sustainability and prosperity of our citizens and our economy and continues to play an increasing role in solving some of the greatest challenges facing society,” said Fitterling. “It is a privilege to represent such a critical sector as board chair of the NAM, which is committed to continually advancing our collaboration across business, government, academia and all stakeholders for the betterment of all people and our planet.”

“The NAM is widely respected for its unique ability to convene key stakeholders and address important challenges across the manufacturing industry,” said Wengel. “Now more than ever, market dynamics and the acceleration of the Fourth Industrial Revolution are providing important opportunities to advance policies that foster growth, promote sustainable manufacturing and ensure readiness and diversity of the workforce of the future. I look forward to continuing to work with fellow members and the incredible staff that make up this organization to confront the challenges of today, while addressing our industry’s needs for tomorrow.”

The NAM Board of Directors guides the association’s leadership in policy advocacy, workforce solutions, legal action, operational excellence and news and insights. More than 200 manufacturing leaders serve on the NAM Board, helping the industry advance an agenda that promotes growth and prosperity for all Americans.

The new board chair was elected at the December meeting of the Executive Committee of the NAM Board. Additionally, the NAM announced significant promotions for key staff members effective Jan. 1, 2022.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers: Today’s Ruling Does Not Change the Fact That Getting Vaccinated Is the Best Defense Against COVID-19

Washington, D.C. – Following the Supreme Court’s decision to block the federal government’s COVID-19 vaccine-or-test requirement for large workplaces, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“Manufacturers have a profound commitment to protecting employees and communities. It’s why we have been at the forefront of innovating and sustaining safe workplace practices from the very beginning of the pandemic and promoting the benefits of getting vaccinated. That’s how we have been able to continue delivering for the American people—even when the challenges seem insurmountable.

“Today’s ruling does not change the fact that getting vaccinated is the best defense against COVID-19 and central to our ability to keep businesses and schools open and prevent our hospitals from being overwhelmed. Manufacturers believe strongly in getting our teams armed against COVID-19, and we appreciate the administration’s sustained focus on making vaccines accessible to every American.

“We call on all Americans to make the choice to get vaccinated, get boosted when eligible and wear the appropriate mask in public places—so that we can save lives, protect our economy and get through this latest wave of infection. We must all do our part, so join us in rolling up your sleeves and moving forward together toward brighter, healthier, more prosperous days.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

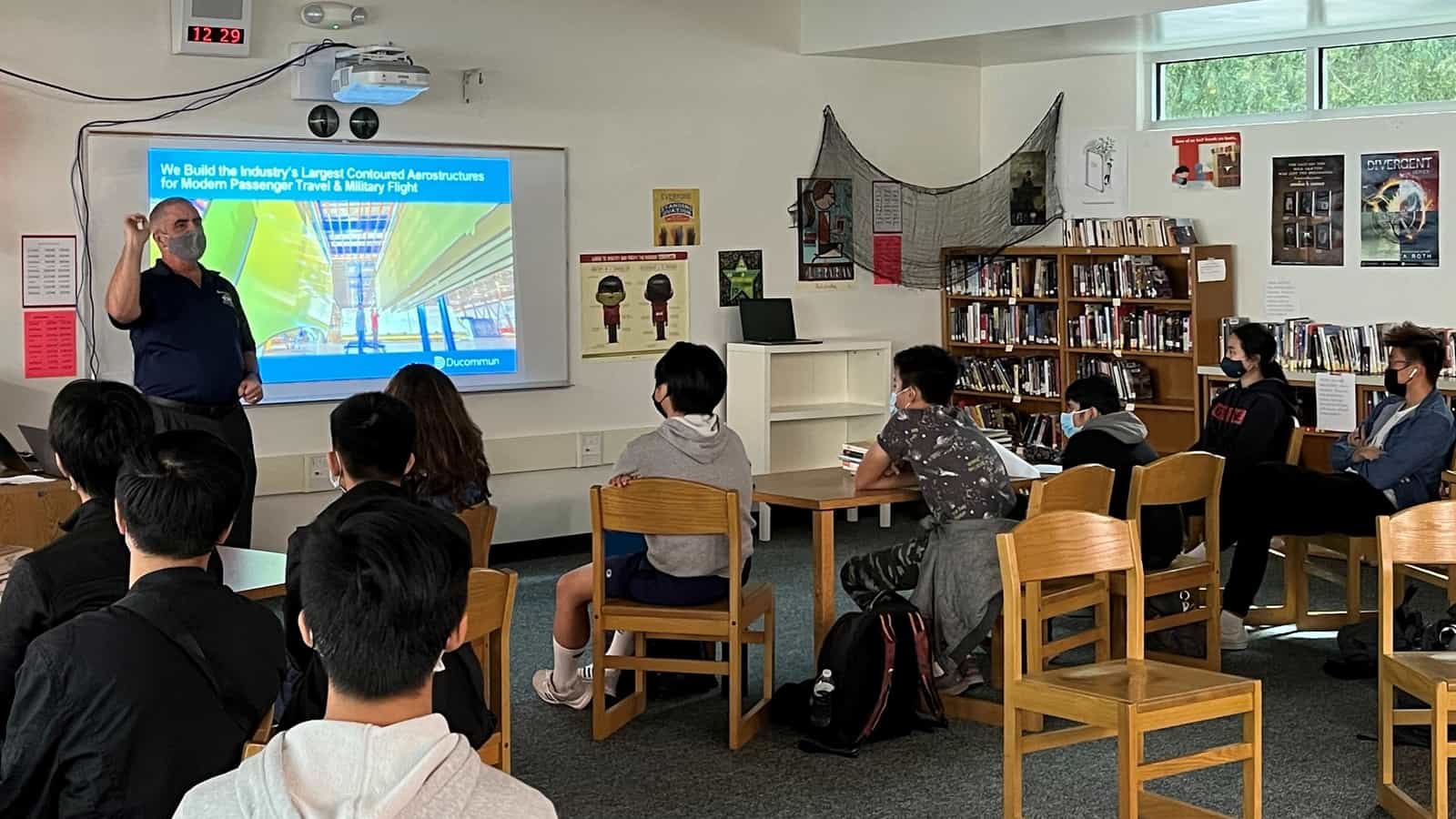

Ducommun’s #MFGDay21 Was a Roaring Success

It would have been an impressive feat no matter what, but Ducommun’s achievement of a robust and highly attended MFG Day 2021 was made all the more remarkable by the fact the company had been an NAM member for just nine months.

MFG Day, an annual program of the NAM’s nonprofit workforce development and education partner, The Manufacturing Institute, highlights the opportunities and potential of modern manufacturing careers by encouraging thousands of companies and educational institutions around the nation to open their doors to students, parents, teachers and community leaders.

“As a leader in innovative manufacturing, Ducommun supports National Manufacturing Day, as well as other education and community-based STEM programs and initiatives, that nurture and develop the next generation of creators, builders, technicians and innovators,” said Chonta Salts, Ducommun corporate HR business partner. “Our goal for MFG Day was to engage with students, parents and educators to broaden their understanding of modern manufacturing and to highlight the range of full-time opportunities, internships and part-time summer jobs available to them.”

Their MFG Day: Ducommun, a 172-year-old Santa Ana, California-based provider of technology-driven structural and electronic solutions for the aerospace, defense and industrial markets, coordinated employee and representative visits with 11 high schools and colleges nationwide. Each school is local to one of Ducommun’s U.S. manufacturing performance centers.

- Events were held in person at Ducommun, in classrooms at local schools and online through livestream. Ducommun leadership teams, engineers, technicians and production team members engaged with students about what a career in modern manufacturing is really like—and how much room it offers for professional growth and advancement.

- “Employees shared their own success stories: starting out in entry-level production positions, completing training programs to advance to technical, engineering or other professional positions and what they do in their current role,” said Ducommun Vice President and Chief Human Resources Officer Rose Rogers. “I think that’s a key component of rolling it out. You have to engage with students at their level. By having our employees connect with the students, they were able to ask questions directly to our employees.”

What they did: Ducommun’s MFG Day success was bolstered by the fact that the company has long been involved in sponsoring local-school science, technology, engineering and math (STEM) activities. So come October, it already had many connections at nearby schools.

- Ducommun team members attended the virtual training sessions offered on the MFG Day section of creatorswanted.org,Salts said.

- Using the site’s resources page, Salts worked with the company’s communications team to transform their standardized presentation into one for high school audiences that could be easily customized by HR leaders responsible for local events.

- Rogers and Salts “got buy-in and feedback from senior leadership” early in the planning process.

- They ensured their events were dynamic, interactive and interesting to the students because “we didn’t want to sit them in a conference room, watch a presentation and wish they were back at school!” Rogers said, with a laugh.

Facts and figures: Ducommun started its MFG Day planning “months” in advance, Salts said, and the work paid off. Here are some of the specific results:

- More than 500 students attended and participated in Ducommun’s MFG Day events.

- There were five in-school presentations by Ducommun team members.

- The day included 17 student presentations.

- There were six onsite visits by students to Ducommun performance centers.

- The day had one virtual presentation.

The payoff: Ducommun’s participation in MFG Day is part of its commitment to build the next generation of creators and innovators, Salts said. Though it’s still too early for the company to have reaped the workforce rewards of its autumn outreach, Rogers said it has received a great deal of interest from students about full- and part-time jobs after graduation. Ducommun expects to fill many open positions in late spring and summer 2022.

- “We invested in MFG Day because one of our core beliefs and commitments is to support the communities where we live and work,” Rogers said. “We emphasized that working at Ducommun wasn’t going to be just a job—this could be a long-term play for students because they can build a career with us. Being able to engage with them was invaluable.”

For more information on MFG Day and how to host a successful one next year, visit www.creatorswanted.org/resources/.

The “Megatrends” Are Coming: Global Predictions Manufacturers Should Know

Several “megatrends” affecting manufacturers and the world at large will begin unfolding in coming years. University of Cambridge Judge Business School Dean Dr. Mauro F. Guillen made this prediction during a presentation at the recent Manufacturing Leadership Council’s “Manufacturing in 2030: The Shape of Things to Come” event.

Three trends: “Three kinds of trends … are coming together to produce a very different situation by the year 2030,” said Guillen, the author of “2030: How Today’s Biggest Trends Will Collide and Reshape the Future of Everything.” He categorized them as “population trends, trends about emerging markets and technological trends.”

Here, we break down some of the highlights from these three umbrella trends.

Durable-goods demands will start earlier—and extend later: Owing largely to immigration patterns, large durable-goods purchases will, on average, start to come earlier in life, Guillen said.

- Thus, in coming years, durable-goods manufacturers can probably expect their customer demographic to broaden to include younger people.

- At the same time, Guillen said, given that people are living longer and better, consumers will wield purchasing power for longer than they did in decades past. “There is a massive concentration of wealth in the upper age groups,” Guillen said. This will mean greater demand for certain goods, such as robotics capable of caretaking, later into people’s lives.

Purchasing-power centers will shift: Currently, the U.S. and Europe are the world’s largest consumer economies, but by 2030, those distinctions will belong to China and India, Guillen said. And by 2040, India will have eclipsed China in this regard, due to population growth.

- While older people will hold onto their purchasing power, younger consumers will hold sway for larger buys as they spend their money on homes, cars and other major purchases.

- Meanwhile, wealth accumulation will continue to grow everywhere in the world, he said, fueling the appetite for manufacturers’ goods.

Emerging markets will overtake developed ones: Manufacturers can soon expect to see emerging markets become larger than developed ones, Guillen said.

- That trend will mean a shift in manufacturer focus away from the U.S. and Europe and toward Africa and India. Said Guillen, “Sooner or later consumer markets will gravitate toward where the population is.”

The last word: Guillen’s main point of advice for manufacturers? To “identify the wave that you want to surf and take that opportunity, go with that wave. It’s so much better than going against the prevailing winds. You’ll be aligning yourself with the global economy.”

Parts Life, Inc. Family of Companies Builds Employee Homeownership

At the Parts Life, Inc. family of companies (Parts Life, Inc.; DeVal Life Cycle Support, LLC; and LC Engineers), they’re not just working to solve product obsolescence, they’re also making it possible for employees to put down roots in their community.

The company, based in Moorestown, New Jersey, works with all military branches, original equipment manufacturers and prime contractors in aerospace and defense to manufacture critical components that extend the life of mission-critical assets. Through a novel initiative, Parts Life also offers loans to employees to help them buy homes.

How it started: The Help U Buy program, or HUB, was the brainchild of founder and CEO Sam Thevanayagam, who knows just how important a home can be.

- “The primary way that you create capital for yourself is to buy your first home,” said Thevanayagam. “I downsized my first home and bootstrapped Parts Life. I used my home as collateral to fund the acquisition of another company. Most things are funded by using your home as collateral.”

Thevanayagam thought up the program three years ago. After a few conversations with his Human Resources Department, he formalized the initiative and set it in motion.

How it works: The company offers interested employees a forgivable loan, and the employees work it off through service over the course of five years, with no additional responsibilities. According to Thevanayagam, more than 25 people have taken advantage of the program since he created it—including 17 employees in the last year alone.

- “We want every single person who works for us to be part of the American Dream,” said Thevanayagam. “When you own your first home, that sets you up for everything else. It gives you stability.”

The impact: Thevanayagam believes that the culture of a company is critical and that the HUB program speaks to Parts Life’s commitment to its employees. Parts Life also focuses on training designed to strengthen employees’ skill sets. The company frequently fills new positions by promoting from within as a demonstration of its investment in its workers.

- “It’s mutually beneficial, because it’s helping people become more valuable to the organization and themselves,”said Thevanayagam.

The last word: “My purpose is to create an environment where others can meet their God-given potential,” said Thevanayagam. “It’s a CEO’s responsibility to have the right culture. At the end of the day, I’m the bearer of that culture. I help create it, defend it. I take that job very seriously. It’s like gardening; you have to create the environment and make sure you’re working on it carefully so people have chance to grow and bloom.”