Manufacturers Bracing for FCC Vote on Broadband Regulation Rule

The Federal Communications Commission is set for an April 25 vote to bring back “net neutrality,” aiming to reinstate a national regulatory framework for broadband internet services, Fox Business reports. The NAM is speaking out against it.

What is it: “The Biden administration’s rule would regulate broadband services as an essential resource under Title II of the Communications Act.’’

How did we get here: “In 2015, the FCC adopted the Obama administration’s [net] neutrality rules, known as the Open Internet Order. The rules survived a legal challenge with a favorable ruling by a federal appeals court in 2016.”

- In 2017, the Trump administration rolled back broadband regulation with a regulation known as the Restoring Internet Freedom rule, citing it as an impediment to innovation and investment by internet service providers. This decision held up against a legal challenge.

- By 2021, President Biden’s executive order suggested reviving Obama-era broadband rules. With Democrats leading the FCC by October 2023, a formal process began, setting the stage for a conclusive vote.

What would happen next: The NAM sent detailed feedback to the FCC last December, warning that reinstating broadband regulation “will lead to a slowdown in innovation and investment.”

- The NAM’s feedback pointed to the negative impact of the Obama administration’s previous attempt to implement the policy: “In 2015, the last time the FCC sought to regulate broadband under Title II, annual industry capex fell by half a billion dollars.”

- The FCC’s decision exceeds its authority and could also be subject to litigation: “Congress has not explicitly given the commission the authority to regulate broadband and reclassify it in this way; therefore, the FCC lacks authority to do so.”

Our take: “As with the other elements of the regulatory onslaught out of Washington these past few years, this is yet another solution in search of a problem, because we already have an open and fair internet,” said NAM Senior Director of Technology Policy Franck Journoud. “As we’ve warned, this will regulate broadband as if it were the same as rotary telephone service, which would slow innovation. The commission really is doing nothing to answer the question of ‘why’ this policy should be brought back.”

- The NAM has long opposed broadband regulation and went to court to support the FCC’s 2017 decision to repeal the rule. As NAM Chief Legal Officer Linda Kelly said, “Internet-driven technology is at the heart of modern manufacturing, and the FCC’s decision to repeal the onerous 2015 net neutrality rule was a victory for the competitiveness of manufacturers in America.”

The NAM will closely follow the FCC’s latest vote on net neutrality and is prepared to oppose any decision to restore this outdated policy.

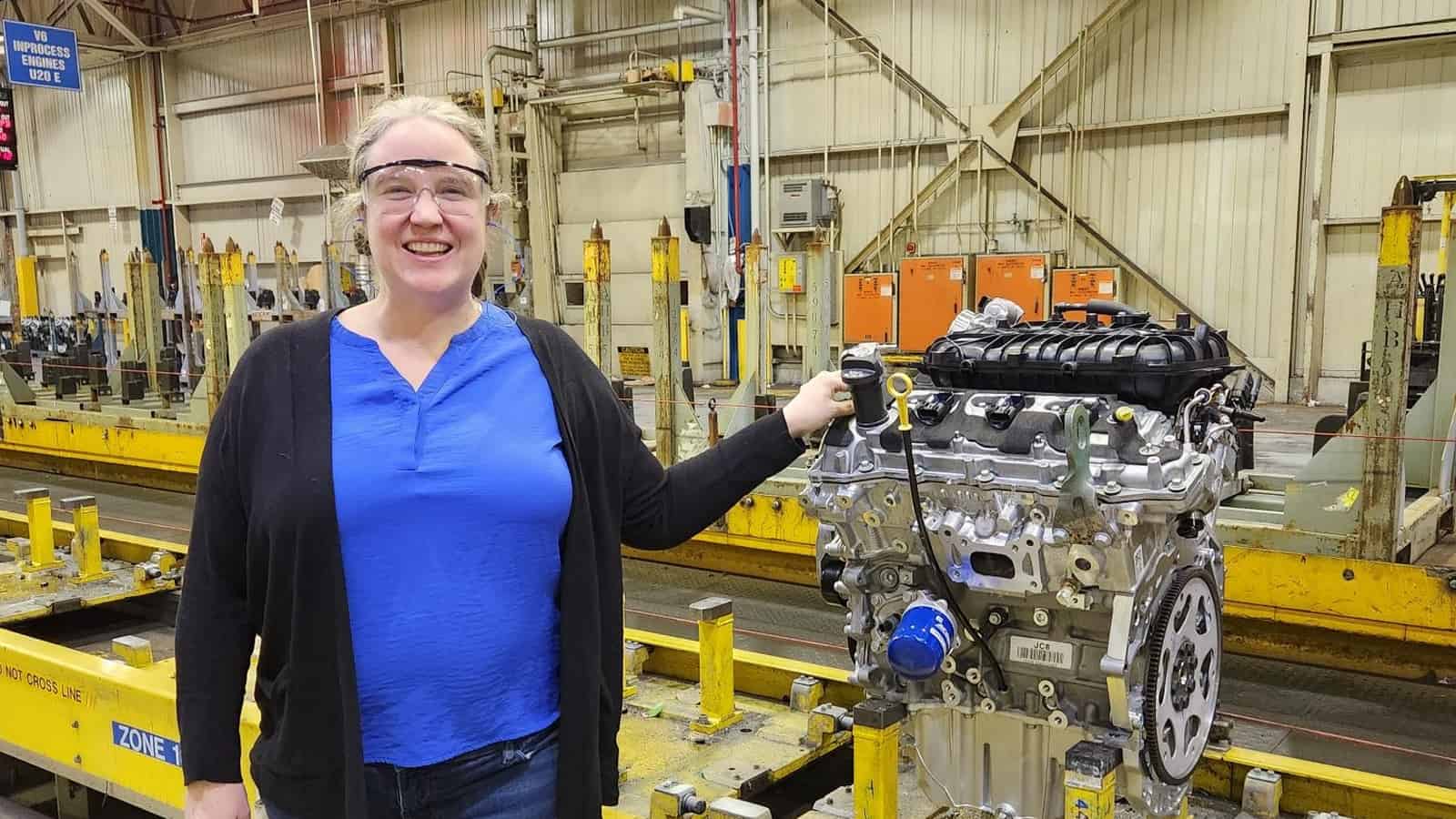

“Why Inclusion Matters”: GM’s Stephanie Thompson on STEM, Women in Manufacturing

Stephanie Thompson may not have always intended to go into manufacturing, but she’s very glad she did.

The path taken: “You don’t necessarily plan your journey, but sometimes you can look back and see how those paths presented themselves,” and you’re thankful they did, said the engineering manager at General Motors’ facility just outside St. Catharines, Ontario, Canada.

- “My career in manufacturing started in internships in university. I worked for a food manufacturer, for a company that made above-ground swimming pools … It was a great chance to try out different businesses, and I [realized that I] love the buzz and excitement that manufacturing has.”

Award nominee: Thompson is a 2024 Honoree of the Women MAKE Awards, honors given annually to 130 women making a difference in manufacturing by the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate.

- Thompson—who started working for GM full time right after university and has held multiple positions in her 23 years there—was the first woman to become an engineering manager in her time at her site.

- Women MAKE Award winners will be celebrated April 18 at the 2024 Women MAKE Awards Gala in Washington, D.C.

Always improving: An Ottawa native and graduate of the University of Waterloo, Thompson sums up her very complex job as “a manufacturing assembly specialist [who] makes sure people can do their jobs safely—and do it over and over again.”

- She oversees the assembly of whole powertrain lines. For one particular engine, “I was there for the first one made, and I was here for the last—we made over 5 million,” she said of a recently retired line.

- “We are always looking to make improvements, to make things more cost effective, to make things simpler,” she said. “The problem-solver part of me really enjoys making those incremental differences every day. [In manufacturing,] you get that sense of satisfaction from making stuff and ultimately giving a customer what they want.”

Women in STEM: Thompson, who has been recognized several times in her native Can

ada for her commitment to women’s education in science, technology, engineering and math, somehow found the time a few years ago to launch STEMbySteph.com, a STEM-focused website that includes a workshop series for women in the fields.

- She is also a mentor for FIRST Canada, which aims to interest kids in science and technology, and a regular speaker on related topics.

- “There are so many great women coming up through the ranks” in manufacturing today, she told us. “I want them to know there isn’t a limit to what they can do. I want to put myself out there as a technical role model, so women who apply [for manufacturing and STEM jobs] see themselves on the interview panel. They should know there’s a space for them in manufacturing.”

Work in progress: And while she’s had “nothing but great experiences with the men in manufacturing,” Thompson said the industry as a whole could benefit from “having some conversations” to make sure women feel welcome.

- “I don’t think it’s malicious,” she said, of the relatively low number of women in manufacturing (they make up about 30% of the

manufacturing workforce). “But one of the things you have to do as a leader is create intentionality and create environments where conflict is positive, where you can all create ideas to [fix] the problem and where individuals feel safe being themselves.”

Honda Winds Up a One-of-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”

Honda Winds Up a One-of-a-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind-tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”

Trend of the Week: Smart Factories

In 2024, factories will just keep getting smarter. From product design to supply chain management, the sophistication of Manufacturing 4.0 (the current wave of technological evolution) will keep on growing. Here’s what manufacturers should know about these advances and how the NAM can help.

What manufacturers should do: Manufacturers looking to make their factories smarter are focusing on four key strategies:

- Creating efficiencies to improve the bottom line with automation and other M4.0 technologies

- Leveraging smart factories to overcome challenges, such as the workforce crisis and supply disruptions

- Ensuring connectivity on the factory floor to allow for use of plant data to create new business models and revenue streams

- Using M4.0 technologies to improve quality control, speed time to market, enhance safety, boost profits, contribute to sustainability goals and engage employees

Expert opinion: Companies are increasingly investing in industrial connectivity, according to PTC Vice President of Market Development of IoT James Zhang.

- “Rather than approaching industrial connectivity with point-to-point integrations, companies are developing holistic, enterprise-wide strategies,” he explained.

- “This approach streamlines and standardizes data from heterogenous manufacturing environments to a single industrial connectivity platform to provide secure, reliable data for OT systems, including MES and SCADA, and IT systems, including data analytics and industrial IoT.”

Resources for you: Check out these NAM resources that will help guide you through these technological changes:

- The Manufacturing Leadership Council, the NAM’s digital transformation division, offers extensive advice and expertise on Manufacturing 4.0 technologies and how to use them.

- NAM Cyber Cover can help you protect your smart factories, as the increase in digitization also opens new avenues for cyber criminals.

- Check out this podcast from the Innovation Research Interchange (the NAM’s innovation division), which covers current research into the adoption of cutting-edge technologies.

Read the full 2024 trends report here.

Biden Touts Accomplishments, but Misses the Mark Elsewhere

In his State of the Union address Thursday, President Biden rightly celebrated manufacturing’s accomplishments—but he “missed the mark in several key areas,” according to NAM President and CEO Jay Timmons.

What happened: President Biden has reason to be proud when it comes to certain manufacturing-critical pieces of legislation, Timmons said, and the president touched on these in his speech.

- “On my watch, federal projects like helping to build American roads, bridges and highways will be made … creating good-paying American jobs,” President Biden told the audience, referring to the NAM-supported Bipartisan Infrastructure Law. And “[t]hanks to my CHIPS and Science Act, the United States is investing more in research and development than ever before.”

- The NAM has been a vocal supporter of CHIPS, which has supported large and small businesses all along the supply chain through an infusion of funds to boost much-needed domestic semiconductor production.

- And the president stood strong with the people of Ukraine and in defense of democracy, two areas in which the NAM has been consistent and unwavering in its own support. “Overseas, Putin of Russia is on the march, invading Ukraine and sowing chaos throughout Europe and beyond. … But Ukraine can stop Putin if we stand with Ukraine and provide the weapons it needs to defend itself. That is all Ukraine is asking.”

No new taxes: But the president also laid out some wrongheaded plans for America, manufacturers and the economy, the NAM said, such as his push to raise taxes on manufacturers.

- “If the cost of manufacturing in America is driven up by his agencies’ continued regulatory onslaught and a successful push to raise taxes, investment will be driven overseas and Americans will be driven out of work,” said Timmons, who appeared on Bloomberg’s “Balance of Power” ahead of the speech to discuss manufacturing priorities.

Protect U.S. innovation, competitiveness: In addition, the Biden administration’s push to invoke so-called “march-in” rights—which would allow it to seize the patents of any innovations it deems too highly priced in the event those patents had been developed in any part with federal money—would “rob Americans and the world of future cures and chill research into new breakthroughs across the manufacturing industry,” Timmons continued.

- “And if President Biden continues to heap blame on pharmaceutical manufacturers, rather than reining in pharmacy benefit managers with cost-saving reforms, Americans and their employers will continue to endure rising health care costs.”

What should happen: The president and manufacturers in America “share a profound commitment to democracy and to the values that have made America exceptional,” Timmons went on.

- A surefire way to restore faith in the democratic system is for Democrats and Republicans to prove it still works—“by delivering smart policies for the American people and by bolstering the industry that is the backbone of our economy and improves lives for all.”

NAM, Allies File Suit Against EPA Over Air Standard

The NAM and seven association partners have filed suit against the Environmental Protection Agency to challenge the office’s overly stringent, recently finalized rule on particulate matter, or PM2.5, the NAM said Wednesday.

What’s going on: The eight groups filed suit in the D.C. Circuit to push back on the EPA’s National Ambient Air Quality Standards rule, which last month it lowered from 12 micrograms per cubic meter of air to 9, a 25% reduction and a stifling burden on manufacturers, the NAM said.

- “In pursuing this discretionary reconsideration rule, the EPA should have considered the tremendous costs and burdens of a lower PM2.5 standard,” said NAM Chief Legal Officer Linda Kelly. “Instead, by plowing ahead with a new standard, the agency not only departs significantly from the traditional NAAQS process, but also gravely undermines the Biden administration’s manufacturing agenda—stifling manufacturing investment, infrastructure development and job creation in communities across the country.”

- Participating in the suit with the NAM—which has repeatedly urged the EPA against overtightening the standard—are the American Chemistry Council, the American Forest & Paper Association, the American Petroleum Institute, the American Wood Council, the U.S. Chamber of Commerce, the National Mining Association and the Portland Cement Association.

Why it’s important: If it’s enacted, the stricter PM2.5 standard would cost businesses and the U.S. economy huge sums, hampering company operations and job growth and forcing tough choices on states and towns nationwide.

- The total cost of complying with the new acceptable concentration level could be as much as $1.8 billion, according to the EPA’s own estimates—and that number could go up.

- What’s more, it would make the U.S. less competitive globally. “Europe’s current PM standard is 25; China’s is 35,” NAM Managing Vice President of Policy Chris Netram told the House Energy and Commerce Subcommittee on Environment, Manufacturing and Critical Materials last month. “If we want the next manufacturing dollar to be spent in America rather than abroad, a standard of 9 is simply not feasible.”

NAM in the news: The New York Times (subscription) covered the lawsuit.

Previewing the SEC’s Climate Rule

For the past two years, the U.S. Securities and Exchange Commission has been considering a rule that would require businesses to report huge amounts of information about companies’ climate-related risks, strategies and impacts. As the SEC prepares to release its final version of the rule this Wednesday, we spoke with NAM Vice President of Domestic Policy Charles Crain about what manufacturers should expect.

The background: In March 2022, the SEC proposed what the NAM has called an overreaching, unworkable and burdensome climate disclosure rule. According to Crain, the initial proposal would have required extensive disclosures as well as invasive tracking procedures to gauge climate impact and emissions throughout companies’ supply chains—significantly increasing costs and liability for manufacturers.

- “The proposal would have had major implications for the entire manufacturing sector, including both large and small public companies—and even privately held businesses throughout manufacturing supply chains,” said Crain. “As proposed, the rule represents a significant threat to manufacturing competitiveness.”

The pushback: In the two years since the rule was first proposed, the NAM has pressed for significant changes—in detailed letters to the SEC, in congressional testimony and in meetings with SEC commissioners and staff.

- “Manufacturers have made it a top priority over the past two years to convince the SEC that they need to change their approach,” said Crain. “The NAM has spent significant time and effort explaining to the SEC why its proposal was unworkable and likely unlawful and illustrating the impact of the rule’s overwhelming cost burden on manufacturers.”

- “But we also offered specific and actionable suggestions to help the agency tailor the rule, make it more workable to manufacturers and bring it back within the SEC’s statutory authority.”

The preview: With the SEC set to publish its final rule tomorrow, Crain says the NAM is keeping an eye on key inflection points, including the following:

- Scope 3 emissions reporting: The proposal’s Scope 3 mandate would require public companies to disclose the emissions of their supply chain partners—including small and family-owned businesses. If Scope 3 is curtailed or absent, that would represent significant progress for manufacturers.

- Financial statement reporting requirements: The NAM will be tracking the degree to which companies are required to incorporate climate information into their financial statements. The NAM called the proposal’s approach to financial statement reporting “unworkable [and] highly burdensome.”

- Materiality: The SEC is only allowed by law to require “material” disclosures—i.e., financial information that allows investors to make informed decisions. Mandates in the final rule that require immaterial disclosures or seek to redefine materiality could exceed the SEC’s legal authority.

- Implementation: The NAM will consider when and how the rule takes effect, and whether the SEC has provided scaled requirements for smaller companies or tailored implementation plans for certain provisions within the rule.

- Small-business impact: The proposal would have harmed small and privately held businesses disproportionately. The SEC must do a better job at protecting these companies in the final rule.

The expectation: Crain says the NAM’s advocacy appears to have made a difference.

- “Recent news reports suggested that some provisions in the rule may have been modified in alignment with the NAM’s suggested changes,” said Crain. “But it remains to be seen whether the final rule, taken as a whole, is actually workable for manufacturers.”

The next step: The NAM’s next moves will depend on the specifics of the final rule—but the conversation is unlikely to end there.

- “The NAM has been clear that a failure to bring the rule back within the agency’s statutory authority could invite legal action. On the other hand, a balanced, workable rule could obviate the need for litigation,” said Crain.

- “Regardless of the exact content of the rule, the NAM is committed to providing resources to our members to help companies understand and comply with any new requirements. We will also continue to engage with the SEC and Congress to address any implementation issues, seek guidance on any unclear provisions and, if necessary, push for changes to the final rule.”

- “As we have for the past two years, the NAM will continue to advocate on manufacturers’ behalf.”

Trend of the Week: Process Innovation

Amid an uncertain economy, manufacturers will have to reinvent and upgrade their processes, from training employees to organizing supply chains and more. For today’s manufacturing trend of 2024, we’re looking at manufacturers’ efforts to improve their processes across their operations.

What manufacturers should do: Manufacturers looking to guard against economic upheaval should consider these steps, according to NAM experts:

- Consider improvements to techniques, tools, software, technologies and behaviors.

- Streamline customer service and the way products are sold to customers.

- Optimize the supply chain with help from partners, automation and design improvements.

- Reinvent processes to realize benefits (e.g., speed time to market, cut costs, work around supply challenges).

Expert opinion: Manufacturers are investing heavily in innovation, even as budgets have become tighter, according to EY Americas Industrial Products Sector Leader Brian M. Legan.

- As he points out, “Nearly half (49%) of manufacturing CEOs who participated in the EY CEO Outlook Survey plan on accelerating or maintaining current levels of innovation investment and portfolio transformation.”

- Meanwhile, “more than half of these CEOs (56%) also indicated that the main source of financing for these investments will be from savings generated from business performance improvements.”

Resources for you: Check out these NAM resources to learn more about manufacturers’ process improvements:

- The Innovation Research Interchange is an NAM division devoted to studying the next wave of manufacturing innovation and providing manufacturers with the resources they need to benefit from it.

- You can also get an inside look at process innovation by attending the Manufacturing Leadership Council’s plant tours. (The MLC is the NAM’s digital transformation division.)

Read the full 2024 trends report here.

NAM: Withdraw Administration March-in Framework Now

The Biden administration’s proposed “march-in” framework would be devastating for American innovation and competitiveness and must be withdrawn immediately, according to the NAM.

What’s going on: In December, the administration issued proposed guidelines to enable the government to “march in” and seize manufacturers’ patents if their products were developed in any part with federal dollars.

- But the move—which a bipartisan group of 28 legislators opposed in a letter to the White House last week—would be fundamentally ruinous to manufacturing in the U.S., according to the NAM.

- “Undermining America’s world-leading patent system is a recipe for reduced innovation and significant economic damage, with a disproportionate impact on small manufacturers,” said NAM Vice President of Domestic Policy Charles Crain.

Price controls: The proposal is tantamount to government price controls, the NAM said.

- “If finalized, this threat to innovation would for the first time enable the government to set price controls on products that incorporate [intellectual property] from early-stage federally funded research.”

- “Manufacturers that do not comply with the proposal’s arbitrary and uncertain pricing criteria could see the government march in, seize their IP and license it to a competitor.”

Undoing advancements: Prior to the 1980 enactment of the Bayh-Dole Act, which allowed for the commercialization of federally funded research, groundbreaking discoveries “often remained stuck in the lab, as private-sector entrepreneurs and investors were unwilling to license innovative technologies given the uncertain path to commercialization,” the NAM said.

- “Limiting manufacturers’ ability to commercialize groundbreaking innovation means that early-stage research will remain on the shelf in university labs.”