First-of-Its-Kind-in-U.S. Facility Breaks Ground

Construction of a manufacturing plant that promises to be vital to the world’s move toward electrification is now underway, according to Chemical Industry Digest.

What’s going on: “Orion S.A., a specialty chemicals company, broke ground on a plant in Texas that will be the only facility in the U.S. producing acetylene-based conductive additives for lithium-ion batteries and other applications vital for the global shift to electrification.”

- Batteries require conductive additives, and those produced at the Texas facility southeast of Houston will be made using acetylene, a colorless gas.

- Equistar Chemicals LP, a subsidiary of polymer and polyolefin technologies manufacturer LyondellBasell, will manufacture acetylene at a nearby location.

- The new plant will be similar to an Orion facility already in operation in southern France that also uses acetylene from LyondellBasell.

“A crucial part”: “[W]e see electrification as a crucial part of our plan to reduce carbon emissions across our industries,” said LyondellBasell Executive Vice President of Global Olefins and Polyolefins, Refining and Supply Chain Kim Foley. “By supporting the production of key battery components, we’re contributing to solutions for a better tomorrow.” The company recently released its annual sustainability report.

- The battery additives produced at the Texas facility will have “one-tenth of the carbon footprint of other commonly used materials,” according to the article.

- And the plant “will bring new technology and high-skilled jobs including laborers, millwrights, welders, equipment operators, among others jobs in Texas, and [will] positively impact long-term job creation for the local community,” Energy Job Shop reports.

IRI Announces Winner of Prestigious Holland Award

Should manufacturers strive to be “cutting edge”?

That’s the question explored in “Is ‘Cutting-Edge’ Good? Assessing Product Newness Factors in Technologically Turbulent Environments,” the paper that won the Innovation Research Interchange’s 2023 Maurice Holland Award.

- The honor, named for the IRI’s founder, has been bestowed annually since 1982 by the IRI, the NAM’s innovation division. It goes to the best article published in the IRI’s flagship publication, Research-Technology Management.

- Winning papers exemplify a commitment to significant work in research and development and innovation management, originality of new management concepts and excellence in presentation.

- The 2023 award-winning paper, by Michael Obal, Todd Morgan and Wesley Friske, does all three, according to the IRI.

Providing value: “In innovation, novelty generates the most attention but does not always translate into better value for the company and customers,” said Research-Technology Management Editor-in-Chief Yat Ming Ooi.

- “This article tells readers when and to whom novel new products matter and why companies need to strike the right balance to ensure better new product performance.”

Authors respond: Research-Technology Management “is a leading academic journal for innovation-related research, and thus having an opportunity to publish an article in RTM is a significant accomplishment in its own right,” said co-author Friske, an associate professor at Missouri State University’s marketing department. “I am also grateful for the opportunity to share this award with my friends and co-authors, and it is particularly important to me now that Todd is no longer with us.”

- Co-author Morgan, an assistant professor at Cleveland State University’s Monte Ahuja College of Business, passed away in 2023.

- “I’m honored to receive the Holland Award from Research-Technology Management alongside Todd and Wes,” said co-author Obal, an associate professor at the University of Massachusetts Lowell’s Manning School of Business.

About the IRI: The IRI offers insights, case studies, research, benchmarks and strategic connections—all built around a set of innovation growth drivers as determined by members annually. Click here to learn more about the IRI.

Read the full story here.

Manufacturers: EPA Chemical Decision Will Directly Threaten Our Ability to Innovate, Create Jobs and Defend Our Nation

Washington, D.C. – Following the release of the Environmental Protection Agency’s rulemaking surrounding the monitoring for per- and poly-fluoroalkyl substances (PFAS) in municipal water systems, National Association of Manufacturers Managing Vice President of Policy Chris Netram released the following statement:

“Manufacturers support efforts to remove potentially harmful chemicals from our water systems, but again the EPA has set standards that are not feasible and will directly threaten manufacturers’ ability to invest, innovate and create jobs in America. In many instances, there is no viable alternative for these chemicals, and companies may be forced to change plans dramatically to grow facilities and hire new workers.

“The severity of the proposed regulations will mean higher prices for everything—community water and waste systems, medical treatments and electronics. More alarming, the regulations will make it more difficult to produce the equipment our military needs to defend our nation. The final rule requires water systems to monitor, sample and treat at near zero levels, which will increase costs throughout the supply chain. We are looking at all options to reverse this harmful decision and to slow the regulatory onslaught that directly undermines the president’s efforts to grow manufacturing in the United States.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.89 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Small Manufacturer: Industry Needs Tax Consistency

Small manufacturers need one thing from Congress, BTE Technologies President Chuck Wetherington told lawmakers on Wednesday: a consistent, pro-growth tax code.

What’s going on: Speaking at a hearing of the House Committee on Small Business, Wetherington told lawmakers how increased taxes and frequent changes to the tax code have harmed his company, a 40-employee medical device manufacturer in Hanover, Maryland.

- By passing the 2017 Tax Cuts and Jobs Act, “Congress was able to take a stale, outdated tax code and update key provisions to reduce taxes on small manufacturers,” Wetherington said. That legislation “drove a new wave of economic activity and industrial expansion. BTE, and many of our peers in the industry, experienced historic growth in the years between tax reform and the pandemic.”

- But the expiration in 2022 and 2023 of three crucial tax provisions—immediate expensing for domestic R&D, enhanced interest deductibility and full expensing, each of which the NAM is leading the charge to reinstate—is now hurting BTE and other businesses in its supply chain.

- And more tax hikes are on the horizon, with tax reform’s small business incentives—including the 20% pass-through deduction—set to expire at the end of 2025.

Less capital, fewer projects: “Bringing a medical device to market is extremely risky and takes years and millions of dollars of investment,” Wetherington continued. “But now, BTE cannot immediately expense those costs—reducing the working capital I have available to invest in my business and my employees … [and] delay[ing] projects to redesign and improve BTE’s flagship products.”

- As a direct result of the changes, BTE has had to put off expansions that would have allowed it to expand its workforce by 50%.

- And because most of BTE’s suppliers are pass-through businesses (entities in which profits pass through to the owner and are taxed at the individual rate), BTE will see even higher operating costs at the end of 2025, when tax rates are scheduled to increase and the pass-through deduction is set to expire.

What must be done—now: The Senate must pass the House-passed Tax Relief for American Families and Workers Act, which would reinstate the three expired provisions that are so critical to manufacturers. And Congress must commit to preventing the economic damage from the scheduled tax increases.

- “We deserve a tax code that promotes innovation and demonstrates to the rest of the world what our values will be for the next decade and beyond,” Wetherington said.

NAM: Ethylene Oxide Rule Needs Revision

A newly finalized rule from the EPA will require chemical and plastics plants to slash emissions of two widely used compounds, according to The Wall Street Journal (subscription).

What’s going on: The EPA’s final rule, released Tuesday, requires manufacturing facilities to curb emissions of chemicals including ethylene oxide and chloroprene. These two chemicals have broad applications, from sterilizing medical equipment to producing synthetic rubber.

- The rule would affect about 200 plants across the U.S. and include a requirement for “fenceline monitoring,” the use of technology to measure the ambient air concentration for certain chemicals.

- Once in effect, the regulation could reduce emissions of both compounds by almost 80% annually, the EPA said.

The background: The news comes less than a month after the EPA finalized a rule to regulate the use of ethylene oxide as a sterilizing agent, a decision that will affect the way most medical devices—including complex, lifesaving ones, such as artificial heart valves—are sterilized.

Regulatory onslaught continues: “While the EPA listened to some of manufacturers’ concerns, such as allowing more time for companies throughout the supply chain to assess the impact on their operations, the rulemaking adds to the ongoing regulatory onslaught our industry has been facing,” said NAM Managing Vice President of Policy Chris Netram.

Effect on supply chains: The fenceline monitoring schedule will be a “significant burden” to manufacturers, as will the EPA’s requirement that operations be fully shut down for small plant repairs, Netram continued.

- “The potential disruption to supply chains could make it more difficult to create jobs in communities across the country.”

Manufacturers Bracing for FCC Vote on Broadband Regulation Rule

The Federal Communications Commission is set for an April 25 vote to bring back “net neutrality,” aiming to reinstate a national regulatory framework for broadband internet services, Fox Business reports. The NAM is speaking out against it.

What is it: “The Biden administration’s rule would regulate broadband services as an essential resource under Title II of the Communications Act.’’

How did we get here: “In 2015, the FCC adopted the Obama administration’s [net] neutrality rules, known as the Open Internet Order. The rules survived a legal challenge with a favorable ruling by a federal appeals court in 2016.”

- In 2017, the Trump administration rolled back broadband regulation with a regulation known as the Restoring Internet Freedom rule, citing it as an impediment to innovation and investment by internet service providers. This decision held up against a legal challenge.

- By 2021, President Biden’s executive order suggested reviving Obama-era broadband rules. With Democrats leading the FCC by October 2023, a formal process began, setting the stage for a conclusive vote.

What would happen next: The NAM sent detailed feedback to the FCC last December, warning that reinstating broadband regulation “will lead to a slowdown in innovation and investment.”

- The NAM’s feedback pointed to the negative impact of the Obama administration’s previous attempt to implement the policy: “In 2015, the last time the FCC sought to regulate broadband under Title II, annual industry capex fell by half a billion dollars.”

- The FCC’s decision exceeds its authority and could also be subject to litigation: “Congress has not explicitly given the commission the authority to regulate broadband and reclassify it in this way; therefore, the FCC lacks authority to do so.”

Our take: “As with the other elements of the regulatory onslaught out of Washington these past few years, this is yet another solution in search of a problem, because we already have an open and fair internet,” said NAM Senior Director of Technology Policy Franck Journoud. “As we’ve warned, this will regulate broadband as if it were the same as rotary telephone service, which would slow innovation. The commission really is doing nothing to answer the question of ‘why’ this policy should be brought back.”

- The NAM has long opposed broadband regulation and went to court to support the FCC’s 2017 decision to repeal the rule. As NAM Chief Legal Officer Linda Kelly said, “Internet-driven technology is at the heart of modern manufacturing, and the FCC’s decision to repeal the onerous 2015 net neutrality rule was a victory for the competitiveness of manufacturers in America.”

The NAM will closely follow the FCC’s latest vote on net neutrality and is prepared to oppose any decision to restore this outdated policy.

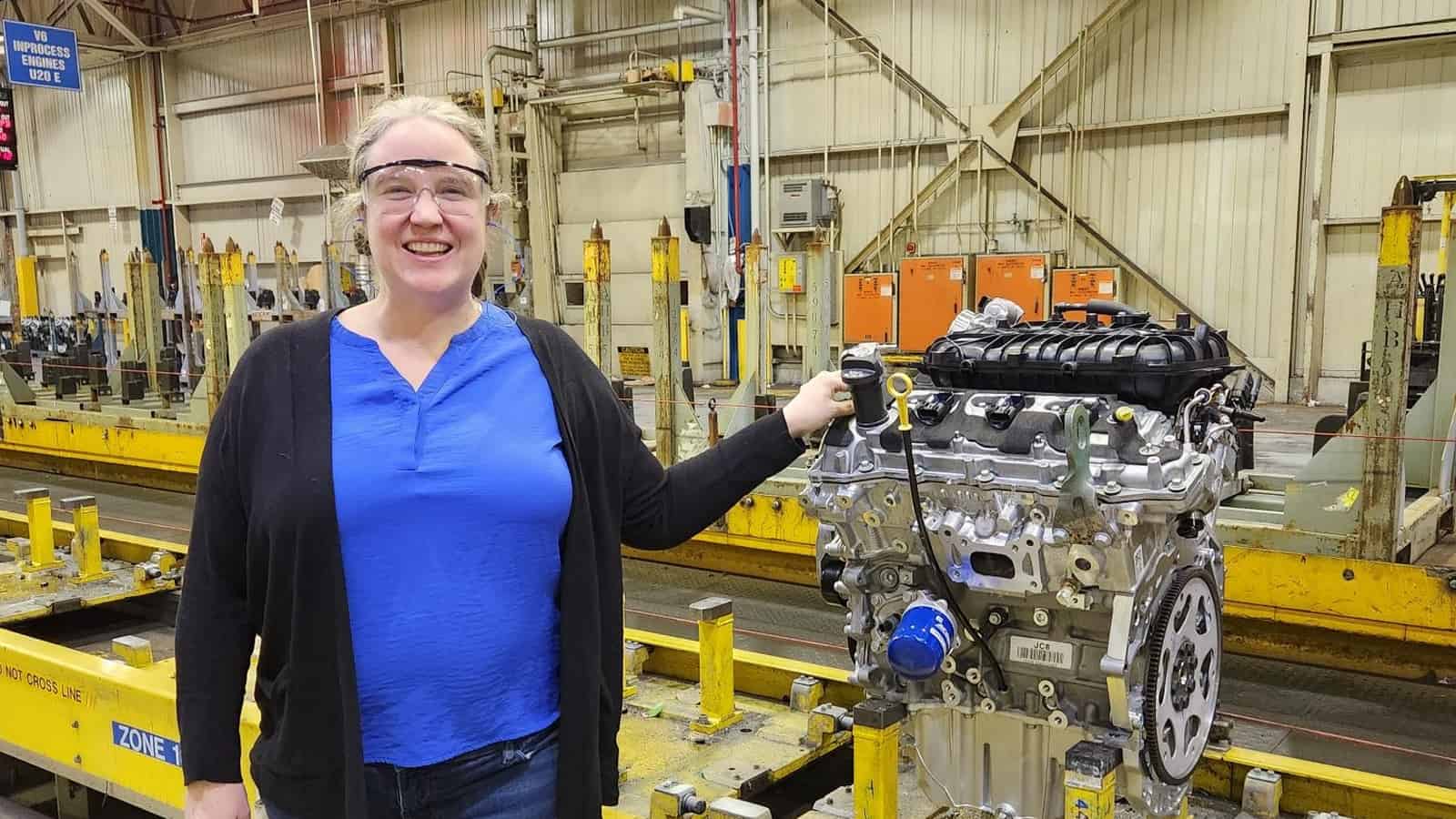

“Why Inclusion Matters”: GM’s Stephanie Thompson on STEM, Women in Manufacturing

Stephanie Thompson may not have always intended to go into manufacturing, but she’s very glad she did.

The path taken: “You don’t necessarily plan your journey, but sometimes you can look back and see how those paths presented themselves,” and you’re thankful they did, said the engineering manager at General Motors’ facility just outside St. Catharines, Ontario, Canada.

- “My career in manufacturing started in internships in university. I worked for a food manufacturer, for a company that made above-ground swimming pools … It was a great chance to try out different businesses, and I [realized that I] love the buzz and excitement that manufacturing has.”

Award nominee: Thompson is a 2024 Honoree of the Women MAKE Awards, honors given annually to 130 women making a difference in manufacturing by the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate.

- Thompson—who started working for GM full time right after university and has held multiple positions in her 23 years there—was the first woman to become an engineering manager in her time at her site.

- Women MAKE Award winners will be celebrated April 18 at the 2024 Women MAKE Awards Gala in Washington, D.C.

Always improving: An Ottawa native and graduate of the University of Waterloo, Thompson sums up her very complex job as “a manufacturing assembly specialist [who] makes sure people can do their jobs safely—and do it over and over again.”

- She oversees the assembly of whole powertrain lines. For one particular engine, “I was there for the first one made, and I was here for the last—we made over 5 million,” she said of a recently retired line.

- “We are always looking to make improvements, to make things more cost effective, to make things simpler,” she said. “The problem-solver part of me really enjoys making those incremental differences every day. [In manufacturing,] you get that sense of satisfaction from making stuff and ultimately giving a customer what they want.”

Women in STEM: Thompson, who has been recognized several times in her native Can

ada for her commitment to women’s education in science, technology, engineering and math, somehow found the time a few years ago to launch STEMbySteph.com, a STEM-focused website that includes a workshop series for women in the fields.

- She is also a mentor for FIRST Canada, which aims to interest kids in science and technology, and a regular speaker on related topics.

- “There are so many great women coming up through the ranks” in manufacturing today, she told us. “I want them to know there isn’t a limit to what they can do. I want to put myself out there as a technical role model, so women who apply [for manufacturing and STEM jobs] see themselves on the interview panel. They should know there’s a space for them in manufacturing.”

Work in progress: And while she’s had “nothing but great experiences with the men in manufacturing,” Thompson said the industry as a whole could benefit from “having some conversations” to make sure women feel welcome.

- “I don’t think it’s malicious,” she said, of the relatively low number of women in manufacturing (they make up about 30% of the

manufacturing workforce). “But one of the things you have to do as a leader is create intentionality and create environments where conflict is positive, where you can all create ideas to [fix] the problem and where individuals feel safe being themselves.”

MLC Announces Manufacturing Leadership Award Finalists

The Manufacturing Leadership Council, the NAM’s digital transformation division, has announced the 2024 Manufacturing Leadership Awards finalists.

About the awards: Now in their 20th season, the Manufacturing Leadership Awards

honor the most outstanding manufacturing companies and their leaders for groundbreaking use of advanced manufacturing technology.

- This year’s program features nine project categories, including Artificial Intelligence and Machine Learning, Digital Supply Chains and Sustainability and the Circular Economy.

- It also includes two categories for individuals: Digital Transformation Leadership for executive-level manufacturing leaders and Next-Generation Leadership for up-and-coming leaders age 30 and under.

How we decide: Nominations are judged by an outside panel of digital manufacturing experts with deep industry knowledge and experience.

- For project entries, judges assess an initiative’s effect on improving manufacturing processes, furthering business goals and advancing company strategy, as well as how much digital technology the project used.

- For individual nominations, judges look at each person’s impact both inside and outside their organization, and whether they meet the criteria as a role model for other manufacturing leaders.

Celebration and ceremony: Winners for both of these categories will be announced at the Manufacturing Leadership Awards Gala on June 5 at the JW Marriott Marco Island Beach Resort.

- Award finalists will also be recognized, as will winners of the Manufacturing in 2030 Award, the Manufacturing Leader of the Year, the Small/Medium Enterprise Manufacturer of the Year and the Large Enterprise Manufacturer of the Year.

- The gala caps off Rethink, the industry’s leading event for accelerating digital transformation. (Rethink also takes place in Marco Island, June 2–5.)

The last word: “More than ever, manufacturers are finding that digital technology investment is good for business as they achieve new levels of performance in efficiency, productivity and innovation,” said MLC Founder, Vice President and Executive Director David R. Brousell.

- “The finalists we are recognizing for this year’s awards have demonstrated not just the business benefit of Manufacturing 4.0 technology, but also a fresh and imaginative approach to applying it in a transformative way.”

Honda Winds Up a One-of-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”

Honda Winds Up a One-of-a-Kind Wind Tunnel

If the Honda Automotive Labs of Ohio facility is a marvel of technology and design, it is also a $124 million testament to the role of cutting-edge engineering in automobile manufacturing.

- “When I started 30 years ago, few really cared about aerodynamics,” said Honda Development & Manufacturing of America Full-Scale Wind Tunnel Lead Mike Unger with a wink. “Now everybody wants to talk to me.”

New interest: Though wind tunnel testing dates back many years, the increasing emphasis in recent years on greater fuel efficiency has brought a new wave of interest in the field.

- Honda owns three full-sized wind tunnels near its global headquarters, as well as several smaller test facilities around the world for examining scale models.

- But in 2015, Honda—which for decades had been sending its U.S.-based people, cars and tools all over the world for wind-tunnel testing or else booking time at third party-owned facilities in America—began mulling constructing a North American wind tunnel, too.

Behold, HALO: The result was HALO, unveiled in 2022 in a 110,000-square-foot facility in East Liberty, Ohio.

- To make it, the company had gathered its “wind tunnel road warriors”—Honda team members who boasted decades of combined experience in the world’s most advanced research facilities—and asked them how they’d do it better.

- Among their top requests was the need for better, faster communications with the designers and builders of the cars they were testing. To facilitate this, HALO was strategically located just across from a Honda development center and a mere 10-minute drive from two manufacturing plants (including the Marysville, Ohio, facility where Honda has been building automobiles since 1982).

Wind-tested, Honda approved: Every new Honda passenger vehicle model undergoes extensive aerodynamic and acoustic testing during its design phase, and further changes are often made during the manufacturing process. Race cars, meanwhile, are tested primarily with an eye to managing the downforce caused by passing air.

The new digs: Now, instead of hashing out design challenges across oceans, everyone sits side-by-side in the same control room.

The state-of-the-art site also boasts a fully outfitted machine shop, custom loading bays and a car wash (the last a recommendation of Honda engineers who had more than once found themselves outside a wind tunnel with a dusty test car and a bucket of soapy water).

- “Absolutely everything was designed with intention,” said HALO Business Strategy Lead Chris Combs.

The details: The tunnel itself is an elaborately engineered circuit. It comprises a settling chamber, a heat exchanger the size of a movie screen and a safety grill to catch any debris that might come loose and threaten HALO’s pulmonary system: a colossal, 6,700-horsepower fan with 12 hollow carbon fiber blades that are 26 feet long each.

- Turning at 250 rotations per minute, the fan drives air through the tunnel and into an anechoic chamber.

- On a recent day, that chamber held both a race car (for downforce testing) and an SUV from the plant across the field (for acoustic work).

Saving time: At most wind tunnels, switching from aerodynamic work to acoustic testing takes nearly two hours. At the HALO wind tunnel, however, technicians swapped the Indy car for the SUV and reconfigured the test chamber in about 20 minutes.

- When it designed the facility, Honda focused on “simple things like that—things that really promote efficiency,” said HALO Operations Manager Jimmy Przeklasa.

Quiet and furry: HALO’s test chamber is lined with acoustic tiles and “teddy bear fur,” a soft, sound-absorbing material.

- Even with the wind blowing, the room is so quiet that technicians working inside must don harnesses to prevent them from stepping into a gale they can neither see nor hear.

- A software system translates the wind noises into visuals, similar to the way a weather radar displays a moving storm.

Complex but simple: Technologically and visually dazzling, the HALO wind tunnel can seem like a futuristic fever dream: color-coded maps of the whistling wind, a two-story fan more finely tuned than a jet engine and a scale capable of sensing a breeze.

- In fact, from its inception, the goal of creating the HALO wind tunnel was simple: make cutting-edge aerodynamic and acoustic research as easy, intuitive and cost-effective as possible. And Honda’s done it.

The last word: “This is the latest and the greatest,” Unger said. “This place is unmatched.”