Sharpening America’s Competitive Edge

The Biden administration is making new commitments to semiconductor production and planning new policies designed to bring STEM talent to the United States—and manufacturing leaders are weighing in.

The background: Last week, the White House announced a series of actions to attract STEM talent, to strengthen the U.S. economy and to improve American competitiveness around the world.

What we’re saying: NAM President and CEO Jay Timmons joined Manufacturing Institute President Carolyn Lee in praising the actions, while also pushing for continued work on these critical issues.

- “The supply chain and economic disruptions facing American families and the manufacturing industry are driven in part by the severe worker shortage and by the serious chip shortage,” said Timmons. “Today, the White House has announced promising developments on both fronts, and we will work with the administration and Congress to build on this progress even further.”

- “Manufacturers are leading America’s recovery, but we still need to hire more than 800,000 workers right now,” said Lee. “And according to the MI’s research with Deloitte, we will have 4 million jobs to fill by the end of the decade, 2.1 million of which could go unfilled if current trends continue. That sustained need is why the NAM and the MI launched our nationwide Creators Wanted workforce campaign. It’s why we have long focused on programs and policies of all types that will grow the pool of STEM talent in America. We have to come at this crisis from every angle, and the MI and the entire industry will continue using every tool at our disposal to inspire, educate and empower the next generation of creators.”

The road ahead: Timmons highlighted the path forward and noted additional important actions to meet current and future needs.

- On semiconductor production: “To ramp up domestic semiconductor production, we can’t stop at today’s action, though,” said Timmons. “Too many manufacturing sectors have been unable to deliver the products American families need because they lack key components. Manufacturers are working overtime to overcome this challenge, but Congress has to do its part, which means passing USICA. Doing so will not only shore up our recovery and ease supply chain strains but also strengthen our economy and national security.”

On attracting STEM talent: “These immigration policies will also undoubtedly sharpen America’s competitive edge and help us outpace and out-innovate the rest of the world,” said Timmons. “In far too many cases, we’ve seen brilliant minds educated at American universities leave because our outdated immigration system doesn’t let them put their talents to work for America’s future. Now we can start to reverse that trend, among other key policy changes. As part of ‘A Way Forward,’ our plan for comprehensive immigration reform, we have long called for immigration policies that are responsive to clear economic needs. These policies meet that test, meaning that they will benefit our workers, our communities and our industry, empowering us to create even more opportunities for the American people.”

NAM Announces New Board Leadership

Fitterling and Wengel Take Helm at a Pivotal Time for the Manufacturing Industry

Washington, D.C. – The National Association of Manufacturers announced the Executive Committee of its Board of Directors has elected Dow Inc. Chairman and CEO Jim Fitterling as board chair and appointed Johnson & Johnson Executive Vice President and Chief Global Supply Chain Officer Kathy Wengel as vice chair.

With the industry on the front lines of an ongoing pandemic, supply chain disruptions, a persistent worker shortage and critical policy debates, these manufacturing leaders will take charge at a particularly consequential time.

“Jim and Kathy have well-earned reputations as respected and visionary leaders of renowned global brands. We have many challenges to confront, and they will ensure our industry continues to lead our recovery and leverage new innovations to raise standards of living in America and around the world,” said NAM President and CEO Jay Timmons. “And no matter what comes our way, our association and industry remain steadfastly committed to policies that uphold the values that make America exceptional: free enterprise, competitiveness, individual liberty and equal opportunity.”

“Manufacturing is vital to the long-term sustainability and prosperity of our citizens and our economy and continues to play an increasing role in solving some of the greatest challenges facing society,” said Fitterling. “It is a privilege to represent such a critical sector as board chair of the NAM, which is committed to continually advancing our collaboration across business, government, academia and all stakeholders for the betterment of all people and our planet.”

“The NAM is widely respected for its unique ability to convene key stakeholders and address important challenges across the manufacturing industry,” said Wengel. “Now more than ever, market dynamics and the acceleration of the Fourth Industrial Revolution are providing important opportunities to advance policies that foster growth, promote sustainable manufacturing and ensure readiness and diversity of the workforce of the future. I look forward to continuing to work with fellow members and the incredible staff that make up this organization to confront the challenges of today, while addressing our industry’s needs for tomorrow.”

The NAM Board of Directors guides the association’s leadership in policy advocacy, workforce solutions, legal action, operational excellence and news and insights. More than 200 manufacturing leaders serve on the NAM Board, helping the industry advance an agenda that promotes growth and prosperity for all Americans.

The new board chair was elected at the December meeting of the Executive Committee of the NAM Board. Additionally, the NAM announced significant promotions for key staff members effective Jan. 1, 2022.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers Announce Addition of Innovation Research Interchange

Key Milestone in Vision to Be One-Stop Shop for Manufacturing

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons today announced plans to continue the NAM’s ambitious organizational growth by combining with the Innovation Research Interchange.

The IRI is a leader in helping companies drive innovation and develop the cutting-edge technologies that keep manufacturing strong. The NAM’s growing array of services and thought leadership represents another key milestone in the vision adopted by the NAM Board of Directors to become the one-stop shop for manufacturers.

“The modern association must constantly innovate and evolve to best serve its industry, and with the addition of the Innovation Research Interchange, NAM members will have access to the widest array of expertise and services in the history of the association. With this transformational development, the NAM and our industry will benefit from world-class R&D thought leadership and the proven strategies that the IRI has perfected. The IRI will continue to support organizations in their mission to drive innovation, and it will enjoy access to the largest network of manufacturing companies and leaders,” said Timmons. “This development enhances the value proposition for NAM members and is part of our ongoing commitment to provide programming that exceeds our members’ expectations.”

IRI President Ed Bernstein will continue to lead the IRI’s day-to-day operations as vice president and executive director, reporting to NAM Chief Operating Officer Todd Boppell.

“The NAM is the perfect partner for the IRI,” said Bernstein. “Together, we will be the preeminent thought leadership organization for innovation management. We have a proud history of helping manufacturers and others lead R&D that produces lifechanging products and technologies. As part of the NAM, we will be able to equip even more industry leaders with the tools to ensure that innovation is impactful throughout the entire enterprise.”

The combination with the IRI follows the NAM’s acquisition of the Manufacturing Leadership Council in 2018. “As a member of the Manufacturing Leadership Council, I’ve seen firsthand how the MLC has been strengthened since becoming part of the NAM,” said Entegris Director of Digital Transformation and IRI Board Chairman Steven Moskowitz. “The access to even more resources and an incredible network has been invaluable—especially through the ongoing pandemic and supply chain disruptions. That’s why I believe that bringing the IRI, MLC and NAM together is the right move for everyone—IRI members, NAM members and the entire industry. The combination of the IRI, MLC and NAM will not only provide continued leadership from each individual organization for their members, but also create opportunities for new value across the entire product lifecycle, thus demonstrating the old adage that the total is greater than the sum of the parts. This positions all of us for even greater success and creates the future-facing organization we need.”

As part of the transition, IRI staff will join the NAM team. More information on the IRI can be found here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

-Innovation Research Interchange-

Innovation Research Interchange (formerly the Industrial Research Institute) is an inclusive membership organization with hundreds of global members in private-sector companies, federally funded laboratories, universities and others. Founded in 1938, we lead and advance the field of innovation management by creating contemporary practices. Some of the world’s most widely adopted models—such as “open innovation,” “front end of innovation” and “stage-gate”—were born from the work of our members. We value strength in cooperation and partner with other organizations at the forefront of developments in innovation management, creating a hub for all to convene and contribute in an experimental, noncompetitive and noncommercial environment. For more information, visit www.iriweb.org.

Philip Bell to Chair NAM’s Council of Manufacturing Associations

Washington, D.C. – The National Association of Manufacturers announced new 2022 leadership for its Council of Manufacturing Associations at the CMA 2022 Winter Leadership Conference. Philip Bell, president of the Steel Manufacturers Association, will serve as chair, and Melissa Hockstad, president and CEO of the American Cleaning Institute, will serve as vice chair. Made up of 220 industry-specific manufacturing associations representing 130,000 companies worldwide, the CMA creates powerful partnerships across the industry and ensures manufacturers have the strongest possible voice.

“Steelmakers and manufacturers are a force for good in the world. We support innovation, efficiency and sustainability. We help our employees build their lives, our customers build their businesses and the communities where we operate build their futures,” said Bell. “During this very dynamic time in our country, I am honored to articulate the important role manufacturing plays in America’s economic success and national security.

“Americans are counting on manufacturers to lead our economic recovery, deliver promising career opportunities and solve our global health crises, and the collaboration made possible through the CMA empowers our entire industry to rise to the challenge,” said NAM President and CEO Jay Timmons. “Philip and Melissa are trusted and tested leaders who will continue to cultivate the collaborative, cooperative spirit that has made the CMA such a consequential organization for our industry and country. I look forward to working with them to advance policies and plans that uphold the values that have made America exceptional and keep manufacturing strong: free enterprise, competitiveness, individual liberty and equal opportunity.”

The CMA’s mission is focused on bolstering the industry’s nationwide grassroots mobilization efforts and improving the competitiveness of manufacturers in the United States. CMA members work with the NAM to unite the manufacturing association community, and ultimately the broader business community, around strategies for increased manufacturing job creation, investment and innovation in America.

Bell is a 25-year industry veteran. Prior to leading the SMA, Bell served as director of external communications and public affairs for Gerdau Long Steel North America based in Tampa, Florida. Bell previously served as CMA vice chair.

Newly appointed 2022 CMA board members include the following:

- Alison Bodor, president and CEO, American Frozen Food Institute

- Nicole Harris, president and CEO, National Glass Association

- David Loftus, president and CEO, Electronic Components Industry Association

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

NAM Announces Promotions

Timmons: “We are ready to create the future for our industry and our country, with a focus on 2030 and beyond.”

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons today announced an evolution of the NAM management team that will expand capabilities, leadership opportunities and innovations and strengthen manufacturing in the United States for 2030 and beyond. Amid an unprecedented pandemic, historic workforce shortages, supply chain and opportunity gap challenges, new and emerging threats to U.S. manufacturing and the country, the digital transformation and once-in-a-generation policy and legal achievements, manufacturers in the U.S. and the NAM continue to play an outsized role in creating the future for people, communities and the country.

These leadership promotions will bolster the NAM’s impact as the industry’s unified voice. They will promote, perpetuate and preserve the values that guide manufacturers’ unrivaled contributions to society and make America exceptional: free enterprise, competitiveness, individual liberty and equal opportunity.

“More than six years ago, the NAM Board of Directors put its support behind a vision to strengthen our association and make the NAM a ‘one-stop shop’ for manufacturers by expanding and diversifying the NAM’s portfolio of offerings in advocacy, operational excellence, legal action, workforce development and news and insights,” said Timmons. “The NAM’s record-breaking results in 2020 and 2021—in the face of crises many of us have never seen in our lifetimes—were a direct result of turning that vision into reality with an entire team resolutely focused on supporting manufacturers and America’s business sector every day. So, now we are putting more responsibility in the hands of this immensely talented team that has proven in the best and worst circumstances to be the strongest, most effective voice and resource for manufacturers in the United States. We are ready to create the future for our industry and our country, with a focus on 2030 and beyond.”

The NAM ends 2021 with a net membership retention rate on track to be in the top historical tier in the 126-year history of the association. Initiatives realized during the pandemic spurred tremendous growth for the association in 2020 and 2021. Those initiatives included efforts to mobilize and support manufacturers’ pandemic response and personal protective equipment production; advance vaccinations; provide greater operational insights to the industry; run momentous campaigns for policy and legal wins, notably infrastructure investment and pandemic relief; and deliver comprehensive solutions to the industry’s most pressing issues, including workforce development.

“Our capability to drive solutions for manufacturers is central to everything we do, and we are aligning this team to provide even more solutions moving forward,” said Timmons.

The following leadership promotions become effective Jan. 1:

- Erin Streeter will be named Executive Vice President of the NAM. Currently serving as Senior Vice President of Communications and Brand Strategy, Erin will work alongside the President and CEO to set the strategic direction of the association and align and integrate teams, strengthen internal and external communications and grow audiences toward that direction. She will continue to oversee all brand, communications and marketing activities but will also add public affairs and mobilization as well as advocacy campaigns to her portfolio. The integration of these critical portfolios will ensure the NAM is positioned to advance the needs and priorities of manufacturers by providing first-in-class advocacy.

- Carolyn Lee has been named President of The Manufacturing Institute by its board of directors. The workforce crisis of more than 1 million open jobs today isn’t just an existential threat to manufacturing in America; it also threatens the security of our country. To meet this moment, the MI continues to break new ground in supporting manufacturers’ efforts to recruit and retain a skilled, diverse workforce. Carolyn’s focus for 2022 will be on developing a strategic growth plan and expanding partnerships and thought leadership to carry the MI and the industry into the future.

- Carolyn has asked Keith Smith to serve as Chief Administrative Officer of the MI. In this new role, Keith will work with Carolyn and the MI team to develop and implement a new organizational growth plan and help achieve the strategic vision of the organization. As a member of the NAM Senior Staff, Keith will also continue his leadership of the Association Partnerships Division as an NAM Senior Vice President, overseeing the NAM’s membership programs with association partners at the national, state and local levels.

- In addition to her current responsibilities as NAM Chief of Staff, Alyssa Shooshan will assume leadership of NAM Board strategy. Alyssa will advance board engagement, initiatives, mobilization, partnerships and programming.

Six current NAM vice presidents will be promoted to the newly created role of managing vice president. This group will be charged with leading the NAM’s Leadership Team in creating new opportunities in advocacy, membership value/thought leadership and culture/operations. In addition to serving as counselors to the NAM President and CEO, they will work with senior staff on all issues impacting the association.

- Adria Brockman, Managing Vice President of Membership

- Jamie Hennigan, Managing Vice President of Communications and Public Affairs

- Chrys Kefalas, Managing Vice President of Brand Strategy

- Daryl Muller, Managing Vice President of Membership

- Chris Netram, Managing Vice President of Tax and Domestic Economic Policy

- Shonzia Thompson, Managing Vice President of Association Partnerships

Based on considerable input from across the association, the following team members will be promoted to vice president and named to the NAM Leadership Team, which meets quarterly to help enhance and strengthen the organization’s service to manufacturers and the country. The Leadership Team will be charged to work with the managing vice presidents in a select area of the team’s portfolio.

- Rob Damschen, Vice President of Strategic Communications

- Mark Isaacson, Vice President of Executive Communications and Chief Speechwriter

- Brian James, Vice President of Conference and Office Operations

- Mike O’Brien, Vice President of Public Affairs and Advocacy

- Chris Schmitt, Vice President of Strategic Partnerships

- Patrick Smith, Vice President of Member and Board Relations

- Megan Stewart, Vice President of National Department

In recognition of the expansive growth of the MI, the following MI vice presidents will be named to the NAM’s Leadership Team:

- Gardner Carrick, MI Vice President of Workforce Solutions

- Herb Grant, MI Vice President of Program Execution

- AJ Jorgenson, MI Vice President of Strategic Engagement and Inclusion

- David McKnight, MI Vice President of Strategic Partnerships

A new group of leadership influencers, recognized by their peers as agents of organization-wide progress, was also appointed for one-year terms to work directly with the NAM Leadership Team to provide insight and counsel on key issues that affect the strategic direction of the NAM.

- Cameron Alvarez, Art Director

- Kristie Arslan, Senior Director, Member and Board Relations

- Penny Brown, Content Director, Manufacturing Leadership Council

- Julie Chase, Senior Compliance Counsel

- Charles Crain, Senior Director, Tax and Domestic Economic Policy

- Kirk Fordham, Senior Director, Member and Board Relations

- Jeni Littlepage, Senior Manager, Benefits Administration

- Ryan Ong, Director, International Business Policy

- Cassi Zumbiel, Director, Workforce Programs and Policy, MI

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

When Something Smells Phishy: A Cybersecurity Lesson for Manufacturers

When an email account with a nonsensical address pretends to be your CEO asking you to buy gift cards, you might deduce that it’s a phishing scam, right? That attempt probably won’t get far, but cyberattacks are a more sophisticated threat and potentially much more damaging to manufacturers of all sizes than they might imagine, warns eSentire Vice President of Industry Security Strategies Mark Sangster.

In a recent webinar produced by the NAM’s Leading Edge program, titled “Go Phish: Building Cyber-Resilience with Managed Phishing and Security Awareness Training,” Sangster laid out some useful advice for businesses. Here’s some of what he had to say.

The threat: Cyberattacks pose a threat to manufacturers of all sizes. While there is a widespread assumption that attackers are only interested in larger corporations, the truth is that small and medium-sized businesses make up a significant number of targeted organizations. Lest manufacturers imagine that they don’t have anything a hacker or attacker would want, Sangster made clear that a great deal of information held by manufacturers is extremely valuable to attackers.

- “If you look at the insurance data on claims, it’s small and medium-sized businesses, and in particular manufacturers, that are targeted,” said Sangster. “In fact, about a third of those attacks generally focused on manufacturers.”

- “You have data and assets worth stealing,” said Sangster. “You have secret recipes and manufacturing automation controls, and data that’s involved in that. And personally identifiable records and intellectual property. And depending on the type of business you’re in, it might be health care records and so on.”

The approach: While stereotypes often suggest that most phishing emails and other scams are obviously fake, many cyberattacks are extremely sophisticated, using specifically targeted methods to gain access to vulnerable networks, Sangster noted.

The good news: Even nation states and powerful ransomware gangs tend to leave a trail before an attack that can help manufacturers identify looming problems and thwart a breach.

- “There are signs and symptoms that something’s going on,” said Sangster. “There are steps you can take to prevent this from happening. And if you get into a hand-to-hand battle with these guys, there is an opportunity to identify it before it metastasizes throughout your organization and becomes those massive business-disrupting ransomware outages that we sadly read about.”

Some low-hanging fruit: Sangster highlighted a few protocols that manufacturers use to prevent most cyber attackers from gaining access, including multifactor authentication or a secure remote connection, like a VPN, or a software-defined perimeter that verifies the identity of a device before it is granted access to application infrastructure.

- “Following these recommendations knocks away 90% of the risks that you face,” said Sangster.

Roll tape: For more information about the stakes of this moment, the importance of cybersecurity and the steps that you can take to protect yourself and your business, check out the full webinar here and learn more about eSentire here.

The next step: Solid cybersecurity is a must for any organization. To help manufacturers protect themselves, the NAM created NAM Cyber Cover, a risk-mitigation and cyber-insurance program that helps manufacturers detect and cover any vulnerabilities. Check it out here.

How Manufacturers Can Stay Cyber-Safe

What is the biggest cybersecurity threat to manufacturers today? It’s ransomware, according to the experts who spoke at a recent NAM webinar.

What they’re saying: “Ransomware … has really become the biggest threat to a lot of organizations,” said ABB Global Cyber Security Manager of Power Generation Jim Lemanowicz during the “The State of Cybersecurity,” a webinar hosted by the NAM’s Leading Edge program. Ransomware is malicious software that encrypts a victim’s data until a ransom is paid to the attacker.

- “It’s not intended to necessarily attack the industry” it’s victimizing, he continued. “It’s purely a financial incentive, and it’s indiscriminate.”

No more small-time hits: Up until recently, one-time hacks into computer systems were more the norm among hackers seeking an illegal payday. “One thing that’s drastically changed is, now [cybercriminals] recognize that massive operational outages are the way to go,” said eSentire Vice President and Industry Security Strategist Mark Sangster. “And they can elicit seven-figure payments. It’s been professionalized. You can hire a freelancer.”

Assess your risks: What does all this mean for manufacturers? Assessment is key, said Lemanowicz.

- “Address the risk based on the criticality of the system—you know, what’s going to really cause you to have something that you can’t recover from, something that’s going to be a lasting problem,” he said. “Some systems you may be able to take offline” or use once a week or once a month.

- In cases where the isolation of a device would wreak operational havoc on your business, consider building redundancies into the system to isolate the devices effectively in the event of a breach. “Controlled access points between systems [mean] a ‘cascading effect’ is less likely,” Lemanowicz continued.

The way in: As the saying goes, an ounce of prevention is worth a pound of cure. Beware of often legitimate-looking spear-phishing attacks, which will appear to come from someone you or your employees know.

- Today’s cybercriminals “have lists,” Lemanowicz said. “They map out the different industries. They have an understanding of who’s involved in what levels in that organization.”

What else can you do? The panel experts had some additional tips for manufacturers looking to keep their systems free of cybercriminals.

- Use multifactor authentication.

- Use a virtual private network (VPN).

- Train all team members—including the C-suite—on good “digital hygiene” practices.

- Regularly update all systems.

The last look: One of the best ways to view cyberattacks is by “using a cooking analogy,” Sangster said. “People think of state-sponsored actors and criminal gangs as being highly sophisticated, [but] what they don’t necessarily understand is that the ingredients they might use aren’t sophisticated. It’s salt, and it’s pepper, and it’s chicken. But it’s how they combine those” that can make a situation dangerous to companies.

- The top way to avoid falling victim to these “recipes”? Said Sangster: “Having the basic [digital] hygiene in place.”

The Company That Puts UV Light to Work

Did you know that several of the components in your car may have passed under high-intensity UV light prior to your purchase? You may have heard that manufacturers coat headlights with a UV protective film to keep them from getting scratched by road debris, but several other components are also manufactured using UV—including windshield borders and the protective coating on interior trim. The process is called UV “curing,” which dries coatings consistently, efficiently, durably—and without releasing harmful chemicals into the atmosphere, as other drying processes do.

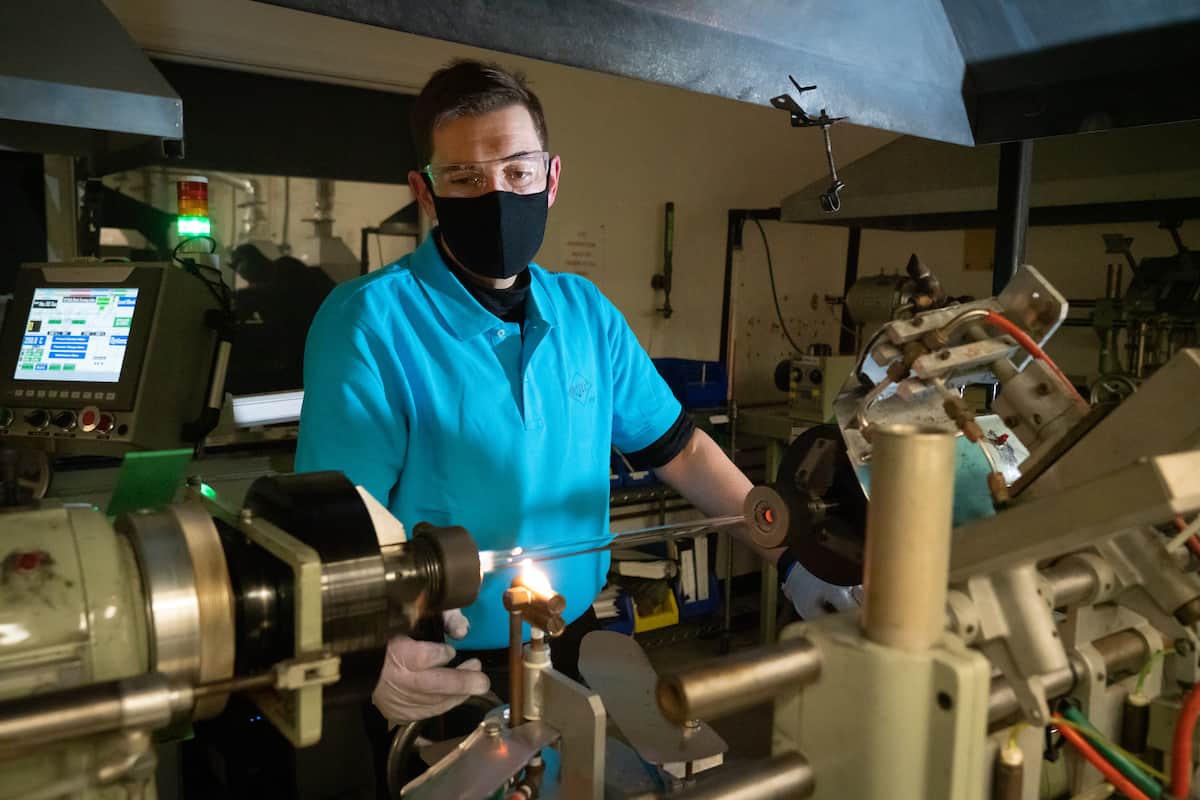

The NAM got a firsthand look at this technology recently, thanks to manufacturer Miltec UV of Stevensville, Maryland. The company manufactures UV systems that cure products like optical fiber, semiconductors, prefinished hardwood floors and cars, supplying this technology across the country and around the world. NAM Director of Photography David Bohrer visited Miltec’s facility to check it out.

Here, an employee at the Bulb division is making a UV bulb. Miltec manufactures thousands of bulbs each year for export around the globe:

When dealing with UV technology, safety comes first. Here, an employee working in the Li-ion Battery Research and Development lab is assembling coin cell batteries in a glove box. The batteries will be used as test samples.

The set of a sci-fi movie? Nope. It’s just the testing of a 16-lamp UV curing system that produces more than 530 KW of UV power. Ultimately, the customer will use this system to cure inks and coatings on a high-speed printing press that manufactures outdoor packaging bags, such as for Miracle-Gro.

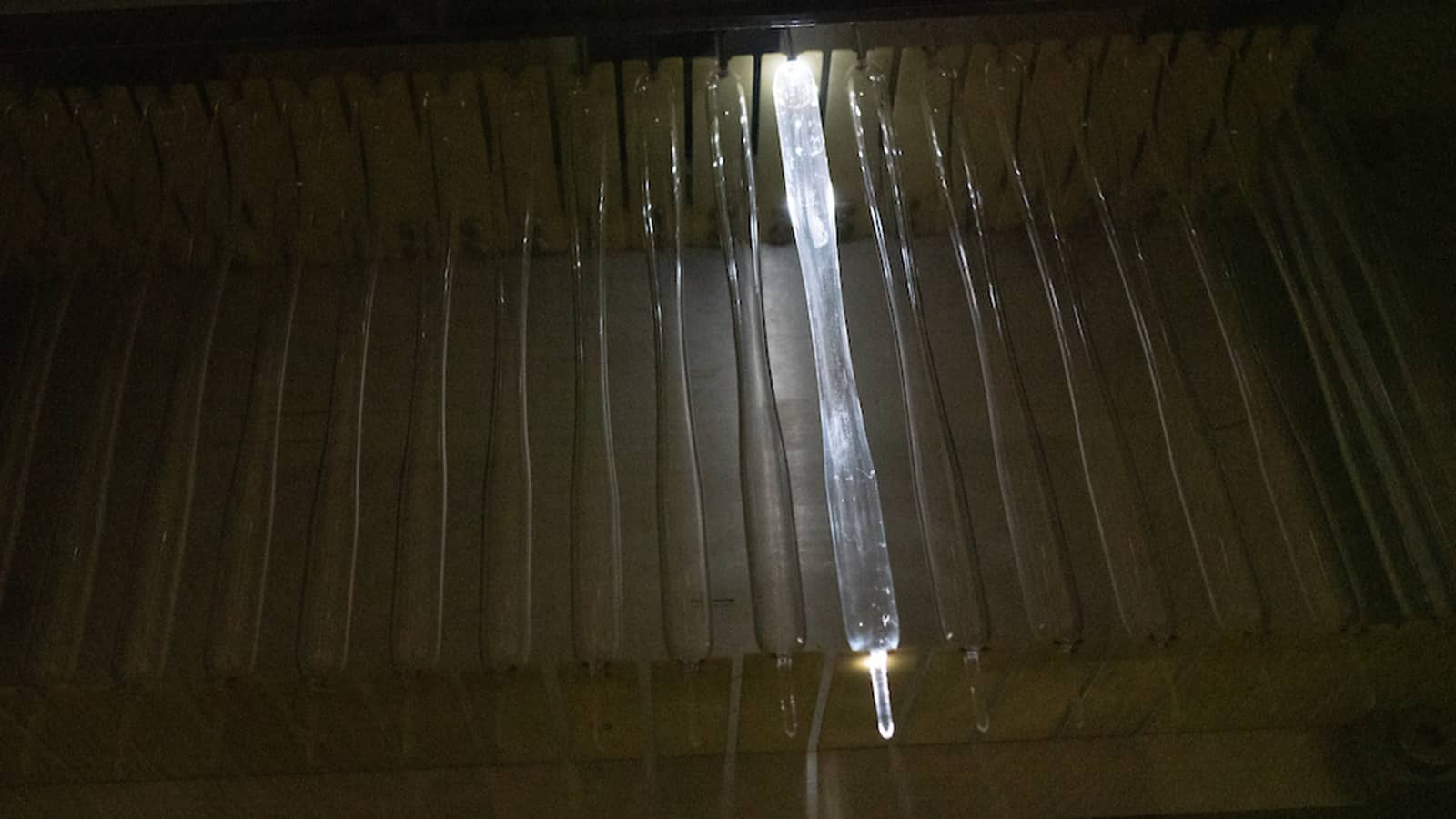

Of course, you can’t go through an entire story about UV light without a cool picture of UV light—so here it is. This is a UV bulb after it’s been filled with an inert gas, which helps it illuminate its powerful UV light.

Miltec says: “Miltec UV is proud to be a member of the NAM and extremely grateful for all of the work that the NAM does to protect the jobs of our team members that do so much to help our company grow and succeed in the international market,” said Miltec President Bob Blandford. “We are also honored and blessed to have such a dedicated manufacturing team that truly understands the importance of making products in the USA and satisfying customers with reliable and high-performance products. With the help of tax cuts, Miltec UV is doing its part by creating more jobs, increasing salaries and offering end-of-year bonuses for its employees.”

How Eastman Strives for a Circular Plastics Economy

Eastman may be a specialty materials company, but its focus these days is expansive: the well-being of the planet and the sustainability of manufacturing practices.

“We have three main pillars,” Eastman Executive Vice President and Chief Technology & Sustainability Officer Steve Crawford told us. “How do you improve the climate? How do you care for society? And how do you eliminate waste?”

Eastman means to do all three.

Circular economy: Among Eastman’s goals for the foreseeable future is making major strides toward the creation of a circular plastics economy, a model of production and usage that emphasizes the reuse and refurbishment of plastic products over new creation.

- Eastman encourages traditional, also known as mechanical, recycling when it can be used. However, “300 million metric tons of plastic get produced in the world every year, with less than 20% collected for mechanical recycling. In the U.S., less than 10% actually gets recycled,” said Crawford, who has been with Eastman for 35 years. “Most of it ends up in landfills, incinerated or worse.”

Under construction: Eastman, which plans to make its operations carbon-neutral by 2050, is constructing what will be one of the world’s largest plastic to plastic molecular recycling facilities in Kingsport, Tennessee. It is slated for completion by the end of 2022.

- Eastman estimates that by 2025, the facility will be diverting 250 million pounds of plastic waste every year. By 2030, the company plans to make that figure 500 million.

Why it’s important: “Mechanical recycling—where you go out and take items like single-use bottles, chop, wash and re-meld them and put them back into textiles or bottles—can only really address a small portion of the plastics that are out there,” Crawford said. After a few cycles, the polymers in the products degrade and the process is no longer possible.

- Instead, Eastman uses advanced, also known as molecular or chemical, recycling. “We unzip the plastic back to its basic building blocks, then purify those building blocks to create new materials,” Crawford said. This “creates an infinite loop because that polymer can go through that process time and time again.”

Additional measures: Eastman also makes use of carbon renewal technology, in which hard-to-recycle mixed plastics are brought into the recycling stream, broken down to the molecular level and reformed into textiles and other materials. Fully 40% of the material in Eastman’s Naia Renew cellulosic fiber, in fact, comes from the plastic reclaimed through this process, Crawford said.

- The company is involved in polyester renewal technology as well. Using colored soda bottles, old carpet and a variety of other mixed plastic waste streams, Eastman creates new materials that can be used to make everything from reusable containers to electronics to eyeglass frames.

First do no harm: Before implementing any new technology, Eastman makes sure of one thing: that it has a lower greenhouse-gas footprint than the process it will replace. Said Crawford: “We fundamentally believe that solving the waste issue should not hurt the climate.”

- The company also has a long-term goal regarding emissions: it plans to reduce its greenhouse-gas output by one-third by 2030.

The policy angle: To make a real difference where plastic waste is concerned, the U.S. needs “smart” policies in place, Crawford said. Eastman’s recommendations include:

- Incentives, mandates and infrastructure investment that will increase all recycling;

- Cooperation between companies, nonprofits and local and state governments that have effective models for aggregating and collecting plastic waste; and

- Legislation to ensure the definition of recycling includes advanced-recycling techniques.

The last word: “There is no one company that’s going to be able to create the circular economy by themselves,” Crawford said. “It’s going to take partnerships across the value chain and really smart public policy. We can’t solve this issue alone.”

How PTC Onshape Helps Formlabs Print the Future

The NAM’s Makers Series is an exclusive interview series featuring creators, innovators and trailblazers in the industry sharing their insights and advice. In this episode, you’ll meet Matt Lipsitz and Adam Lebovitz of Formlabs, who discuss how PTC Onshape helps Formlabs improve their 3D-printer design. Learn how PTC has helped Formlabs “try out new ideas that weren’t possible in the past.”