NAM Board Leaders Headline Creators Wanted Kickoff in Decatur

Two of manufacturing’s top executives took centerstage yesterday as a part of the industry’s largest perception campaign to build the workforce of the future—by helping educators, parents and other career mentors coach students on their career journeys.

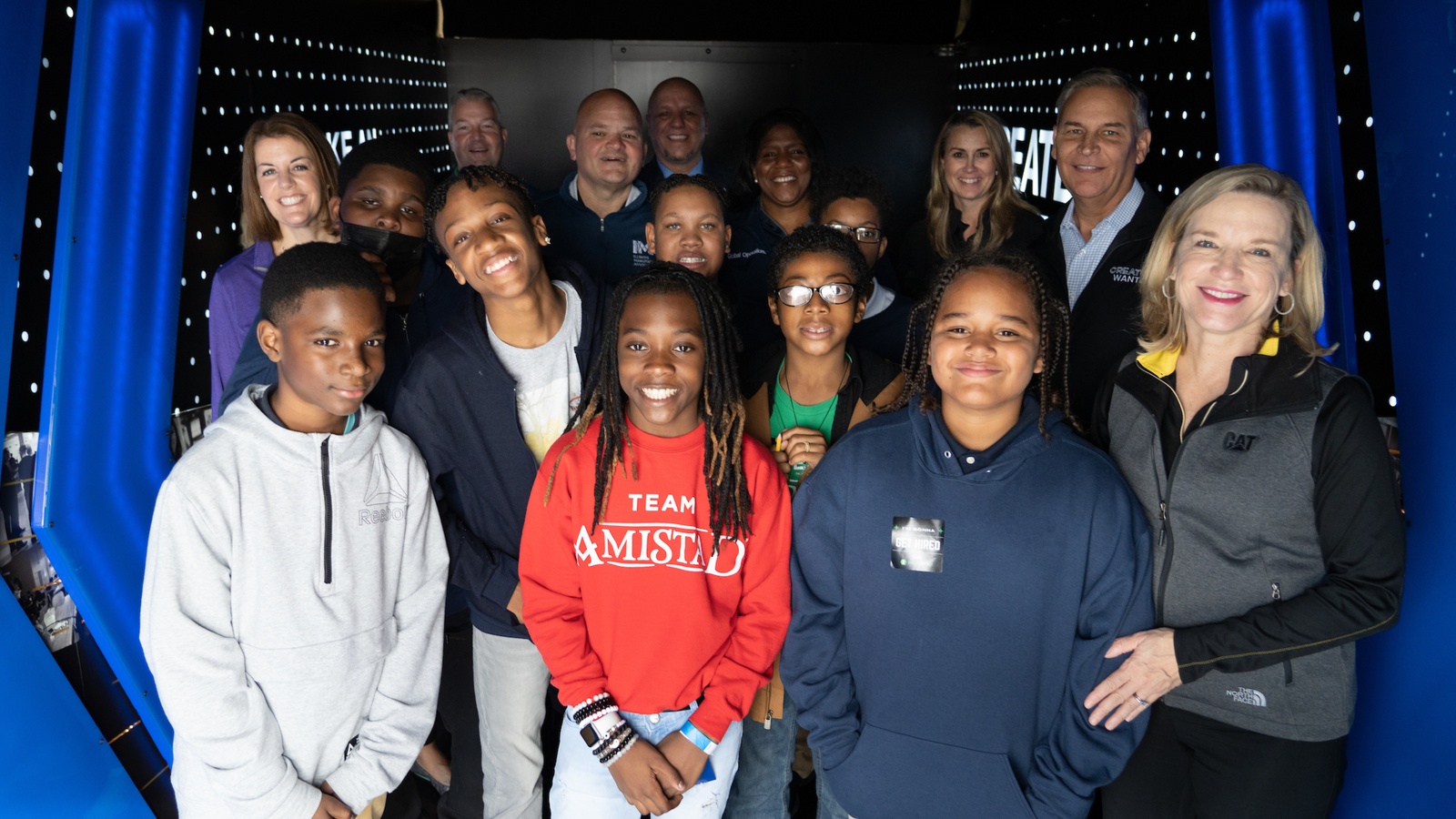

- Caterpillar Group President of Resource Industries (and NAM Executive Committee member) Denise Johnson and ADM Senior Vice President of Global Operations (and NAM board member) Veronica Braker joined NAM President and CEO Jay Timmons, Manufacturing Institute President Carolyn Lee, Illinois Manufacturers’ Association President and CEO Mark Denzler and other notable state, community and education leaders to kick off the Decatur, Illinois, stop of the Creators Wanted Tour at Richland Community College.

- More than 120 students from American Dreamer STEM Academy attended the kickoff event. (More than 800 students are expected over the tour stop’s three days.) There they heard manufacturing leaders’ perspectives before exploring the various exhibits and activations showcasing the many opportunities in modern manufacturing.

Power of visibility: “Not everyone has a perspective or has heard from someone who looks like me or is from the same place,” said Braker, who is also on the global nutrition company’s Executive Council. “But together, we can change one event at a time.”

- “While pursuing my degree in chemical engineering, I interned with several manufacturing companies. … For me, manufacturing was always an attractive choice due to the fast pace, the energy, as well as the opportunity to solve problems while working as a part of a team, making a real impact on people’s lives,” emphasized Braker.

- On the rewards of her own manufacturing career, spanning more than a quarter of a century in operations leadership, Braker pointed out, “I’ve made lifelong friends. I’ve been exposed to innovative technologies that will change the way that people and generations live forever.”

Teamwork and growth drove Johnson’s path into manufacturing—and an ascent to the upper echelons of the world’s leading manufacturer of construction and mining equipment.

- “I was working in the design and engineering arena, and I was really wanting to move into manufacturing because I thought it would give me an opportunity to learn some new skills and be able to … work with teams and people to a larger degree.”

- In a panel conversation, Johnson, along with Tara Tolly, operations director of ADM’s Decatur manufacturing complex, highlighted more of the advantages of manufacturing careers, including great pay, diverse career paths and roles, upward mobility, variability of days, earn-and-learn options and chances to lead and develop transferable skills.

Answering the call: “It’s events like Creators Wanted where we need to be present and active for our students and encouraging them to start early and get engaged with opportunities that offer rich and fulfilling experiences for them,” said Braker.

- Braker and Johnson were instrumental in arranging the Creators Wanted Tour appearance in Decatur, in partnership with the Illinois Manufacturers’ Association, mobilizing not just financial backing but also team and community support to help excite the next generation of creators.

Why it matters: “Fifty percent of Macon County’s economy [where Decatur is located] comes from manufacturing … the single highest share of any county in Illinois,” said Denzler. “Programs like Creators Wanted are crucial for making significant progress in narrowing the workforce shortage … in manufacturing,” added Braker.

Beyond the campus: WAND-TV, the local NBC affiliate, covered the kickoff, and Timmons and Denzler joined Decatur’s top morning radio talk show, “Byers & Co.,” to amplify the Creators Wanted message. More than 500,000 students and career mentors have signed up to date through the Creators Wanted Tour to learn more about modern manufacturing careers.

How Do You Change a Tire on the Moon?

When the new lunar mobility vehicle takes its first spin around the moon, it will be sporting a familiar logo on its wheels: Goodyear’s. But unlike the tires on your car, the lunar vehicle’s will be airless, made entirely of metal and clad in mesh.

Yet, the lunar tire isn’t entirely a separate beast, according to Goodyear Senior Program Manager for Non-Pneumatic Tires Michael Rachita. The tires might be rolling around the moon, but they are closely related to some Earth-bound technology—and will help that technology evolve even further.

- Rachita chatted with us recently about Goodyear’s contributions to the lunar mobility vehicle, which is being designed and built by Lockheed Martin and GM for deployment later this decade (read our interview with Lockheed Martin Vice President for the Lunar Exploration Campaign Kirk Shireman).

- It is intended to stay on the moon for years, both supporting NASA missions and functioning autonomously when the astronauts are not around. Here’s what Rachita told us about the tires that will make it all possible.

The design: A traditional rubber tire simply wouldn’t work on the moon, Rachita explains. It wouldn’t hold its air pressure in the vacuum of space, and without an atmosphere to filter out the sun’s radiation, the rubber would quickly degrade.

- Instead, Goodyear will be using metal alloys, such as aluminum and special steels. As Rachita puts it, “You can tap into the standard materials that are used in satellites as a starting point”—materials that are already tried and tested for space.

The environment: These are some of the environmental factors that engineers must consider, says Rachita.

- Temperatures: The moon undergoes extreme transitions in temperature, ranging from -280 degrees Fahrenheit at night to 260 degrees Fahrenheit during the day.

- Gravity: At only 1/6th that of Earth’s, the moon’s gravity changes the calculation of flexibility. The metal tires act something like a spring, but since objects bear down with much less weight on the moon, the tires must be correspondingly more flexible than they would have to be on Earth, Rachita says.

- Moon dust: The lunar regolith is sharp, abrasive and electrostatic, says Rachita, and acts something like very soft sand. In designing these tires, Goodyear has taken inspiration from off-roading techniques used for sandy or rocky areas, such as deflating tires to create a soft, broad surface that almost floats over the landscape.

The tests: Some of the testing is familiar, including sessions on a traditional flat track at Goodyear’s headquarters in Akron, Ohio. The track has a rotating band like a treadmill, which the testers must slow down, as the rover will top out at 12 mph (for safety reasons). The engineers can still learn a lot from the tires’ behavior even in Earth’s gravity, Rachita says.

- For other tests, however, the company has had to “create an event,” he says. That includes finding facilities with cryogenic chambers to test the tires’ durability in extreme temperatures.

- To mimic the lunar surface, the company will use soil rigs filled with simulated lunar soil developed by NASA.

The big question: Rachita responds to our inevitable question—“How do you change a tire on the moon?”—with a simple answer: you don’t.

- In fact, he adds, the technology that gives these tires a high degree of redundancy—allowing them to sustain damage and still keep going—has important applications here on Earth.

- “This is where it all connects for Goodyear and its strategy,” he says.

A tire revolution: Goodyear is working to make products that are “maintenance free,” Rachita explains, which is essential to new developments in mobility. Airless tires have an enormous advantage for both electric and autonomous vehicles, he says.

- First, electric vehicles have far fewer parts to maintain (like spark plugs and oil systems), so it makes sense to eliminate another source of frequent maintenance—air-filled tires.

- Meanwhile, if an autonomous vehicle gets a flat, who’s going to fix it? As Rachita says, often no one will be around; AVs will spend a lot of time traveling without passengers to their next pickup points.

- Air-filled tires don’t have redundancy, as Rachita points out—you get a flat tire and it’s an immediate problem. But on an airless tire with a “tension bridge” that supports its structure, up to 20% of the spokes can break without requiring a change. And if the mesh covering the tire tears, you don’t immediately start losing all of the air inside it.

Just in case . . . The lunar mobile’s tires will be attached rather traditionally, with either multiple lugs or one lug (as found on racecars)—so they could technically be changed on the moon. But the plan is to ensure this never becomes necessary, says Rachita.

The last word: Creating tires for a long-lasting lunar vehicle is a “challenge to engineering thinking,” as Rachita puts it. It’s the sort of challenge that will pay off for the rest of us, too.

“Manufacturing on the Moon”: The Next Lunar Vehicle

When astronauts return to the surface of the moon in 2025, they will find a car waiting to pick them up. The new lunar mobility vehicle, designed and built by Lockheed Martin and GM with tires by Goodyear, will be sent up prior to the humans—but more excitingly, it will stay there long after they leave. In fact, the vehicle will remain on the moon for many years, performing experiments and fulfilling commercial contracts autonomously in between NASA missions.

We were delighted to learn all this and more in a recent interview with Kirk Shireman, Lockheed Martin’s vice president for the Lunar Exploration Campaign, who told us all about the astonishing technology involved. Here’s what we learned about the vehicle, which will be the first on the moon since 1972. Though those rovers were the “finest technology” of their day, as Shireman says, the new lunar vehicle is certainly the finest of ours.

The new design: To withstand the moon’s environment for years on end, the vehicle will require state-of-the-art components and materials. The companies are still in the “materials selection phase,” says Shireman, but he did share several of the broad requirements.

- The vehicle will use the latest in battery technology, allowing it to power down almost completely during the long, frigid lunar night (which, like a lunar day, lasts for 14 Earth days). Temperatures will range from -280 degrees Fahrenheit at night to 260 degrees Fahrenheit during the day.

- Not only must the materials hold up under the temperature shifts, which occur very rapidly, they must also withstand the sharp, abrasive electrostatic dust that “clings to everything,” says Shireman.

- In addition, the vehicle must be light—it’s tough to transport things to the lunar surface, and every ounce counts.

- And last, safety is of course paramount; the vehicle must be easy to enter and exit for the astronauts. The vehicle’s speed will top out at about 12 mph, also for safety reasons.

Testing: The moon has only one-sixth of the Earth’s gravity, and it’s pretty much impossible to simulate driving in such conditions while here on Earth. The engineers must rely on virtual reality as well as some physical tests, Shireman explains.

- GM’s “driver in the loop” simulator fulfills this function, allowing engineers to “drive” in the environment and gravity of the moon. (Shireman, who recently tried out the simulator, tells us that it is extremely challenging.)

- However, physical testing does have some important uses. Just like any other autonomous vehicle, the lunar vehicle must be tested to ensure it “can’t get into a place it can’t get out of,” as Shireman puts it—and that can be done in Earth’s gravity.

- Engineers will also perform other physical tests on the materials, including lighting tests to ensure the vehicle’s sensors can cope with the blinding light on the moon, where everything looks either white or black.

Advanced manufacturing . . . for the moon: Once the vehicle is on the moon, Lockheed Martin and GM will face a challenge very familiar to other manufacturers: deciding how to collect, organize and transmit data from their equipment.

- The vehicle will monitor its own performance and the lunar environment via a host of sensors. It can also physically carry other instruments for experimentation, says Shireman.

- However, the lunar program will “have more data than pipe” (i.e., the means of returning data to Earth) and will need to prioritize how much and how frequently it transmits information.

- And unlike manufacturers communicating with their equipment on Earth, the engineers will have to cope with delays in response time, which could take several seconds or longer, says Shireman. If the rover is located on the back side of the moon, the signal must go through a relay satellite before reaching Earth.

No garage: Out of curiosity, we asked Shireman an earthling’s question: will the lunar vehicle have some sort of garage where it can seek protection from the cold or sun?

- The answer to that is no—it will simply park itself wherever it happens to be to wait out the night. It’s “much more useful if you can avoid going back anywhere,” says Shireman, because that means the vehicle is not tied down to one spot.

- Even though it would be nice to be able to park it in a garage, which would keep the vehicle warm, the tradeoff is not worth it, he explains.

Moon activities: The lunar missions will have tremendous scientific value, not least because these vehicles can roam widely and produce granular maps of the moon’s landscape. However, they are designed for commercial applications as well.

- The companies are still exploring their options, Shireman says, but these may include transporting commercial lunar payloads and helping other companies (and countries) explore the moon’s resources.

- Then there is the “coolness” factor—people might pay just to interact with this technology, for example by driving the rover telerobotically from Earth. (Sounds like fun!)

The last word: As Shireman says, the rover itself is the foundation of a new venture, not an end point. “The rover isn’t just a thing to be manufactured; it will help us manufacture things on the moon”—and advance lunar exploration and commercialization where it hasn’t gone before.

Take a look: Check out the lunar mobile design in action here, in an animated video made by GM and Lockheed Martin.

Manufacturers Unite to Protect Intellectual Property

Manufacturing associations across almost 40 states joined with the NAM in calling on the White House to safeguard intellectual property at the World Trade Organization.

What’s happening: The WTO is considering waiving IP rights for COVID-19-related vaccines and treatments—an action that would harm American manufacturers that have led the fight against COVID-19.

What we’re doing: The NAM has previously pushed back aggressively on the proposal, and alongside manufacturers nationwide, we are stepping up our work. In a letter addressed to Secretary of State Antony Blinken, United States Trade Representative Katherine Tai and other senior Biden administration officials, the NAM joined nearly 40 state manufacturing organizations in arguing that waiving these IP rights will negatively affect American manufacturing—as well as the overall fight against COVID-19.

- “This proposal would weaken critical global rules for IP protections that support innovation in a range of manufacturing sectors by including not only broad new categories of COVID-19 products, but also their upstream supply chains. Furthermore, an expanded waiver allows commercial rivals like China to unfairly seize American innovation to benefit their domestic economies.”

The importance of IP: Those manufacturing associations argue that IP gives an incentive for manufacturers to broaden research and development and a reason to invest in expanding industries. American manufacturers are concerned that the IP waivers would expose them to unfair competition from foreign rivals and would take away employment opportunities from Americans.

The last word: “Our organizations strongly urge the Biden administration and Congress to stand with manufacturers and workers to firmly oppose an expanded IP waiver at the WTO. We stand ready to work with you and your agencies in support of real solutions to the pandemic and future health crises—and to advance U.S. leadership in manufacturing and innovation.”

A Winning Formula at AB InBev

Anheuser-Busch InBev recently got to raise a toast to its team members—not just once, but four times.

After being named a 2022 Manufacturing Leadership Awards Gala winner in three categories—AI and Machine Learning, Digital Network Connectivity and Operational Excellence—the company took home the ultimate prize: the MLC’s Large Enterprise Manufacturer of the Year. (The MLC is the NAM’s digital transformation partner.)

Recipe for success: What’s brewing in AB InBev’s recipe for success? According to Global Vice President of Engineering and Operations Marcelo Ribeiro, a focus on world-class performance in all of the company’s operations.

- This means leveraging disruptive technologies and empowering frontline teams to drive sustainable and reliable performance, all with the dream of “to create a future with more cheers.”

Utilizing AI: One of AB InBev’s award-winning projects was its innovative use of AI to improve utilities performance. The company implemented a set of smart algorithms to optimize the performance of its air compressors and boilers, giving managers and operators a real-time, utilities-performance dashboard that alerted them when a target was not being hit.

- Started as a pilot in just five breweries, the project was so successful, the company rolled it out to more than 30 other breweries worldwide.

- AB InBev plans to expand the algorithm beyond boilers and compressors to provide utilities usage forecasts and prediction models.

Preventing downtime: Another AB InBev winner was the firm’s approach to attaining 100% reliability and optimization of all equipment and processes. This led to the development of a tool that monitors equipment performance and prescribes maintenance actions, both of which minimize downtime.

- The company’s ambitious reliability goal also creates safer working conditions in breweries and maximizes sustainability by reducing consumption of raw materials, packaging and spare parts.

Lessons on digital transformation: While technology can provide solutions to problems, resist the urge to simply “do” technology for technology’s sake, Ribeiro cautioned. First identify a problem, then determine how technology can help fix it. Don’t work the other way around.

- “One thing we have learned in recent years is that future is becoming less predictable,” Ribeiro said. “Manufacturing needs to create an ecosystem in the future where we can learn from each other. And we have to actually enable that to happen as becoming more resilient will require building a collaborative ecosystem.”

Nominations are being accepted now for the 2023 Manufacturing Leadership Awards. Find complete details here.

Creators Wanted “Lends a Helping Hand” in S.C.

Last week was a milestone for the Creators Wanted Tour—it marked the first time the nationwide initiative returned to a community and got to see how perceptions of manufacturing had changed since its first visit.

Welcome back: The Creators Wanted Tour, a joint venture of the NAM and its workforce development and education partner, The Manufacturing Institute, returned to host and champion sponsor Nephron Pharmaceuticals Corporation in West Columbia, South Carolina, in the 11th stop of the roadshow, which took place Oct. 4–7.

Happy MFG Day! On MFG Day, Oct. 7, Creators Wanted campaign co-chair Lou Kennedy, president, CEO and owner of Nephron Pharmaceuticals Corporation, and her team hosted the tour stop’s premier event at its new Nephron Nitrile Glove Factory. The 426,000-square-foot facility is scheduled to open next month and will produce nitrile gloves used in hospitals and sterile rooms globally.

- The protective-glove shortage in the U.S. during the pandemic inspired Kennedy to build the factory, which is set to produce 2 million gloves a year at full capacity.

- South Carolina legislators from both sides of the political aisle were on hand for a tour of the site. House Democratic Majority Whip James Clyburn and Republican Reps. Joe Wilson and Jeff Duncan joined hundreds of local students, educators, community leaders and manufacturers to view and learn more about the campaign and its resources.

Ready for the “boom”: “There is a manufacturing boom taking place all over the country,” Majority Whip Clyburn said. “We’ve got to focus on getting these young people prepared” for manufacturing careers.

- As Rep. Wilson said, “The opportunities for manufacturing just can’t be better.”

- “401(k), great salary—average wage of 75 to 80K—clean and beautiful working conditions and hard work with a lot of fun,” Kennedy said of jobs at Nephron, while extolling opportunities at modern manufacturers across the state and in nearby communities.

- Major Creators Wanted supporters Honda and Trane Technologies also have operations in the Palmetto State, and several other campaign sponsors, including Chroma Color Corporation, are within a short distance of West Columbia.

More career guidance: Students seeking tailored advice about their professional futures got it from representatives of FactoryFix, official recruiting partner of Creators Wanted, who were on hand to meet and coach job seekers.

- South Carolina Chamber of Commerce President and CEO Bob Morgan, whose organization is a tour partner, was on site with his team to give students information on manufacturing opportunities in South Carolina.

- On Friday, Creators Wanted sponsor Autos Drive America had an exhibit showing attendees the types of vehicles being manufactured in South Carolina.

Women in manufacturing: During a “fireside chat” panel on the tour stop, Kennedy was joined by Autos Drive America President and CEO Jennifer Safavian and MI President Carolyn Lee to discuss the importance of advancing more women in manufacturing.

- “Growing up here in the deep south 20, 30 years ago, we were supposed to be teachers or … nurses; we weren’t supposed to be pharma CEOs,” Kennedy said. “And so, my goal is to help every young lady be what she wants to be, even if it’s the nontraditional career path. … If you want to be a super-genius chemist, you can do that. If you want to be a super-genius engineer, you can do that.”

- Echoed Safavian, “I think the message [of Creators Wanted] is, ‘Don’t be afraid to ask questions. Don’t be afraid to try something. For women especially, this is a terrific opportunity. … A lot of people think manufacturing is dark, dirty, dangerous. It is not. … it is the complete opposite.”

Calling all veterans: Modern manufacturing is also a natural fit for those who have been in the military, speakers told the audience during another panel discussion.

- “I started at Nephron as a senior system analyst, and throughout my career everything that I was faced with at Nephron I’d already seen in the military,” said Air Force veteran Eric Jackson, now a senior IT security analyst at Nephron. “So, I think the [military] training … is what prepared me for this job.”

The reach: The South Columbia 2022 tour stop, made possible by additional support from Dow, Honda and Nephron Pharmaceuticals, was a record breaker.

- More than 700 students from 13 schools—most located in traditionally underrepresented communities—participated in the tour stop’s events. Last year, those numbers were 500 and seven, respectively.

- This year’s West Columbia email signups—people wishing to learn more about manufacturing careers—brought Creators Wanted’s total signups to more than 520,000.

The last word: The tour stop may have been best summarized by one young student who attended the events. “Creators Wanted,” she said, “is a helping hand.”

MFG Day 2022 Kicks Off in North Carolina

The Manufacturing Institute, the NAM and SAS kicked off MFG Day 2022 at SAS world headquarters in Cary, North Carolina, where manufacturing, technology and political leaders highlighted the transformation in the industry and the promise of manufacturing careers.

The CEO: The session began with a welcome from SAS CEO Jim Goodnight, who spoke about manufacturing innovation and the way that cutting-edge technology is creating a more resilient industry and a more productive future.

- “We are committed to help teach and reskill the workforce for the demands of modern manufacturing, from data scientists and process engineers to robotic technicians,” said Goodnight. “There is great potential for growth in progress, especially when you bring analytics knowledge and tech experience to this critical sector.”

The governor: North Carolina Gov. Roy Cooper addressed the group and spoke about the value of workforce development.

- “When I talk with CEOs about coming to North Carolina or expanding in North Carolina, their top three issues right now are workforce, workforce and workforce,” said Gov. Cooper. “They know that they need this skilled, diverse help in their businesses.”

The NAM: NAM President and CEO Jay Timmons spoke about the skills gap in manufacturing and urged attendees—including students and young people—to see the opportunities for a rewarding career in the manufacturing industry.

- “If we don’t find the talent that we need to keep shop floors running and research and development moving, we’re going to lose out on productivity, on innovation, on growth,” said Timmons. “And this could cost America’s edge in global economic leadership. We cannot let that happen. We have to redouble our commitment to ensure that that does not happen.”

Transforming the workforce: The first panel of the day included a conversation with manufacturing leaders—moderated by Timmons and including experts from Deere & Company, Mack Trucks, SAS and Johnson Controls—discussing how technology and analytics continue to transform the industry and workforce. The conversation touched on:

- The way that companies are using advanced analytics to improve their products and processes in the modern age;

- The need for engagement programs and partnerships with professional organizations and school systems to help change perceptions of manufacturing; and

- The opportunity that manufacturing provides to solve big problems and make the world a better place.

Recruiting manufacturers: The day continued with a “creators” conversation moderated by MI President and Executive Director Carolyn Lee, which included panelists from SAS, ABB Inc. and Mack Trucks. The discussion covered:

- The dynamic nature of the industry—and how the sector innovated and adapted to new realities during the COVID-19 pandemic;

- The importance of networking, education and inclusive programming to attracting a diverse workforce; and

- The extraordinary range of careers in manufacturing—from sales, to operations, to HR and beyond—and the diverse set of skills and backgrounds needed to fill them.

The last word: “Manufacturing careers have a higher impact on local communities than any other sector in the economy,” said Lee. “So, manufacturing’s reach goes far and wide. But it’s not just the people on the plant floor; it’s all of the systems and all of the supports and all of the pieces that come together to support manufacturing.”

Learn more: For more information, and to check out video of the full event, click here.

“FAME Set the Path for My Entire Career”: a Manufacturing Success Story

Ellery Kring didn’t set out to begin a career in manufacturing. In fact, she wasn’t initially focused on a long-term career at all.

“I was pretty typical out of high school,” said Kring. “I needed some money and a job.”

The Kentucky native heard of a job opening at appliance manufacturer Bosch through someone she knew and secured an entry-level role that helped pay the bills. But when she learned about an apprenticeship opportunity through the Federation for Advanced Manufacturing Education (FAME) program, she saw a chance to build something more substantial.

someone she knew and secured an entry-level role that helped pay the bills. But when she learned about an apprenticeship opportunity through the Federation for Advanced Manufacturing Education (FAME) program, she saw a chance to build something more substantial.

The program: Founded in 2010 by Toyota and operated today by The Manufacturing Institute, FAME aims to help students become highly skilled, sought-after makers capable of meeting the unique needs and challenges of the modern manufacturing sector.

- It serves as a career pathway program for current and aspiring manufacturing workers, providing them with on-the-job training and classroom education, leading to an associate degree and the FAME Advanced Manufacturing Technician (AMT) certificate.

A “no-brainer”: “Bosch is a pretty big sponsor of FAME in northern Kentucky, and I heard about it through word of mouth on the plant floor,” said Kring. “I had a strong feeling that I liked being in industry, and when I heard that Bosch had a program that would train you in maintenance and pay for your school, it was a no-brainer.”

- “They allowed us to shadow other departments—quality, manufacturing, logistics,” Kring said. “And in addition to a technical degree, they also gave you the soft skills to help you make your own career.”

The path: After her FAME graduation four years ago, Kring served as a Manufacturing Engineering Systems (MES) application engineer, helping to digitize the shop floor and integrate solutions to improve efficiency in production lines. Kring describes the role as “production IT”—maintaining, troubleshooting and implementing new solutions.

- She has recently moved onward and upward—on Aug. 1, she began a new project role that will allow her to focus on building server infrastructure and communications.

The support: Kring credits the FAME program with her success and especially appreciates that it allowed her to keep working while furthering her education.

- “I definitely have that program to credit for where I am now,” said Kring. “They got me the associate degree, which was such a big deal—having an actual degree. Other employers had certification programs, but this got me a degree.”

- “Because it’s hands on, I got to shadow an engineer, and since I was an apprentice, I got my foot in the door in this department,” said Kring. “If it wasn’t for the FAME program, I wouldn’t have seen this department, or known that I would have been interested in such a job.”

The industry: Kring notes that the reality of advanced manufacturing is far different from the stereotypes she had in mind when she first began considering a career in the industry. She encourages other job seekers to give it a second look:

- “Manufacturing is versatile,” said Kring. “I would highly advise people to be aware of

- how diverse and advanced it is. You could be in logistics and planning, or IT, or purchasing, or marketing.”

- “It’s important to keep in mind that there’s no one thing in manufacturing. It’s constantly growing and expanding. . . . Once you get your foot in the door, you have limitless possibilities for the rest of your life.”

Kring also encourages other women to join the field and says that, while manufacturing may currently be a male-dominated industry, there are plenty of opportunities for women who are interested in making their mark.

- “Women are perfectly capable of doing anything that a man” can do, said Kring. “There are women in this field, and we need more. I would tell women not to have preconceived notions about the industry. Don’t be intimidated, and don’t let any preconceived ideas or stereotypes stop you from going after it.”

The last word: “FAME set the path for my entire career,” said Kring. “I can’t speak highly enough about it. You can’t go wrong—it’s only a year and a half long program. It pays for your school, you get hands-on work experience, and you come out of it debt-free. It’s a quick program that has a lifetime effect in a positive way.”

MFG Day 2022 Is Almost Here!

This Friday, Oct. 7, manufacturers across the country will open their doors in an epic celebration of manufacturing in America. Students, parents, teachers, local leaders and many others will be welcomed into factories, technical schools and similar venues to see what modern manufacturing is really about.

What it is: Led by The Manufacturing Institute—the NAM’s workforce development and education partner—MFG Day kicks off a monthlong series of events that provide an inside view of the industry and the exciting careers it offers.

This year’s events: MFG Day events include open houses, expos, job fairs, roundtable discussions and more across the United States, featuring many different types of manufacturing.

- This year, more than 500 companies and organizations are already on the national map of registered events, beating last year’s total.

- One of the flagship events will be hosted by SAS at its world headquarters in Cary, North Carolina, and include remarks from SAS CEO Jim Goodnight and Gov. Roy Cooper, as well as discussions with manufacturing leaders from Deere & Company, Mack Trucks, Johnson Controls and ABB. Experts from SAS and the MI will speak about technology, analytics and career paths in manufacturing, while manufacturing and technology exhibits will be open to visitors.

- In addition, the NAM and MI’s Creators Wanted mobile experience will stop at Nephron Nitrile’s new glove factory in West Columbia, South Carolina, giving visitors the chance to complete challenges that resemble real, creative manufacturing work.

Why it matters: The manufacturing industry will need to fill about 4 million jobs by 2030, and a lack of high-skilled workers threatens to leave more than half of those positions empty, according to a study by the MI and Deloitte. MFG Day is designed to increase awareness among the young people who could become the stars of tomorrow’s industry, showing them how much they stand to gain from choosing manufacturing as their career.

- Changing misconceptions: MFG Day helps the industry push back against misguided stereotypes, demonstrating that today’s industry is high skilled, high tech, clean, creative and welcoming to people of all backgrounds and talents.

- Opening doors: MFG Day events are also excellent opportunities to demystify the industry and show young people (along with their parents and teachers) a vision of an exciting future. The coolness factor matters—taking students through a dynamic, high-tech factory floor can fire their imaginations and change the course of their lives.

Don’t forget: If your company or organization is already on board and planning an MFG Day event, register it so that the MI can keep track of the industry’s outreach and highlight the impact of MFG Day nationwide.

- Find more resources to help you with MFG Day planning here. And check out these useful tips for promoting and sharing MFG Day content on social media.

What we’re saying: “This is manufacturing’s biggest annual stage to inspire the next generation,” said MI Director of Student Engagement Jen White. “We hope anyone who cares about the industry’s future will use their social media platforms and amplify #MFGDay22, to showcase why manufacturers are saying ‘Creators Wanted.’”

Creators Wanted Inspires Students in Tennessee

If you’re a student or job seeker looking for tailored career guidance combined with some hands-on, immersive fun, White House, Tennessee, was the place for you to be last week.

National impact: The Creators Wanted Tour, a joint project by the NAM and MI, made its 10th national tour stop at White House Heritage High School on Sept. 27–29.

- There, more than 700 students from four schools in Tennessee’s Robertson County went through the Creators Wanted mobile immersive experience, the award-winning, manufacturing-themed escape room–like activity in which participants work together to solve challenges in a “race to the future.”

- They also got the opportunity to chat with on-site sponsor representatives from Electrolux, Schneider Electric and FactoryFix about the many rewarding, well-paying career paths available in the industry.

- Local partners, including the Robertson County Economic Development Board, the Tennessee Chamber of Commerce & Industry and the Tennessee Manufacturers Association, were also on hand to answer jobs- and manufacturing-related questions.

Calling all creators: During the Tennessee stop’s premier event, speakers underscored the need for more skilled workers to fill the millions of open manufacturing jobs in the U.S.

- “Here in Tennessee, our industry has more jobs to fill than there are people looking for them,” Tennessee Chamber of Commerce & Industry and Tennessee Manufacturers Association President and CEO Bradley Jackson said.

- Speaking from firsthand experience about the many benefits of choosing one of those jobs was Tony Fraley, a plant manager for Electrolux. “I’m living proof of the great career opportunities in the field of advanced manufacturing,” said Fraley, who started at the company “running a process that coats dishwasher racks.”

- “I grew up about two hours from here in a small town very similar to White House,” he continued. “I always liked math and science. … I hope that stories like [mine] inspire the next generation of workers to consider a career that’s not only been good to me, but also offers a strong opportunity to earn a family-sustaining wage in a high-demand field.”

The numbers: The Tennessee stop resulted in more than 52,000 email signups from people interested in learning more about manufacturing careers.

An eye-opener: Students had a great time at last week’s events—and were pleasantly surprised to learn just how many interesting options manufacturing could offer them.

- “Creators Wanted made me excited about my future,” said one student.

- Added another, “Creators Wanted made me think more about my future in manufacturing.”

The last word: It’s past time for manufacturing careers to get their due as the gratifying professions they are, according to the Creators Wanted Spotlight panelists (and manufacturing company employees).

- Manufacturing “is definitely very rewarding [from a salary standpoint] but also the lifestyle that you get to have,” said Schneider Electric Manufacturing Engineer Zoie McFarland. “I get to go boating every weekend. I get to go hiking. I travel a lot. … Also, I was able to buy a house at 25. So, I think that is one major benefit—the lifestyle [manufacturing] gives you and the benefits that come from it.”