Manufacturers Grateful for Administration’s Emphasis on Strengthening Critical Supply Chains

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons released the following statement after the Biden administration’s completion of their 100-day review assessing vulnerabilities in, and strengthening the resilience of, critical supply chains.

“Our industry is grateful for the administration’s continued focus on investments in manufacturing in America. Ramping up production in the United States is one of the key ways we alleviate the supply chain challenges that have been affecting our industry and all American families.

“Succeeding in a global economy also requires the ability to manufacture where customers are; after all, 95% of customers live outside of the United States. The NAM has been leading on supply chain issues, providing initial recommendations for policymakers back in spring 2020. We look forward to working with the administration and learning more about these specific proposals while also continuing our work to ensure we maintain a business climate in the United States that attracts investment and promotes growth and job creation.”

Background:

In May 2020, the NAM released a detailed agenda of policy recommendations to strengthen the manufacturing supply chain in America.

In February 2021, President Biden signed E.O. 14017 directing his administration to conduct a 100-day review of, and address vulnerabilities in, America’s critical supply chains.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.3 million men and women, contributes $2.35 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers React to President Biden’s First Speech to Congress

Timmons: “Manufacturers are focused on building the next, post-pandemic world.”

Washington, D.C. – Following President Joe Biden’s first presidential address to Congress, National Association of Manufacturers President and CEO Jay Timmons released this statement:

“Thanks to the leadership of vaccine manufacturers and the Biden administration’s successful vaccine distribution efforts, Americans are getting back to the activities and the people they love. Though the capacity limits in the House chamber tonight remind us that we still have a long way to go, our future is looking brighter.

“We look forward to working with President Biden to achieve historic infrastructure investment, including the many priorities offered in our ‘Building to Win’ plan, which, in addition to identifying areas of investment, also provides multiple funding solutions.

“Manufacturers have also provided roadmaps on critical issues ranging from immigration to climate change. We’re ready to work with President Biden and members of any party to deliver bipartisan progress on these issues and more, all while ensuring we’re strengthening the manufacturing workforce, not jeopardizing manufacturing growth in the United States.

“To that point, raising taxes on manufacturers—including many small businesses that pay at the individual rate—would stop our recovery in its tracks; we would lose 1 million jobs in just the first two years alone. Small manufacturers would be especially hard hit at this critical juncture, restricting their ability to raise wages and benefits, hire more workers and invest in their communities. Similarly, changes to the longstanding tax rules on the transfer of family businesses to the next generation of manufacturers would cost American jobs.

“Returning to archaic tax policies and one of the highest business tax rates in the developed world is not the way to build our future, nor are federal policies to force workers to join a union. Anti-worker policies like the PRO Act would inject uncertainty by driving a wedge in established employee–employer relationships and curtail future manufacturing investments that support our communities and families.

“As we continue to get armed against COVID-19, manufacturers are focused on building the next, post-pandemic world—one that affords even greater opportunity for all Americans.”

Background:

The NAM continues to put forward commonsense proposals to educate and inform policymakers on ways to strengthen manufacturing in America while achieving our shared objectives.

- Tax Policy Protecting Manufacturing Jobs

- “Building to Win” Infrastructure Plan

- “The Promise Ahead,” Taking Action on Climate

- “A Way Forward” on Immigration

- “Strengthening the Manufacturing Supply Chain”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs 12.3 million men and women, contributes $2.35 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

How PTC Onshape Powers the FireFly ESV’s Engineering Teams

The NAM’s Makers Series is an exclusive interview series featuring creators, innovators and trailblazers in the industry sharing their insights and advice. Meet David Solomont and Greg Horne from ev Transportation Services, Inc., which makes the FireFly ESV vehicle. In this edition of the NAM’s Makers Series, Solomont and Horne explain how ev Transportation Services uses PTC’s Onshape cloud-based CAD system to power its distributed manufacturing and engineering teams working on the FireFly ESV.

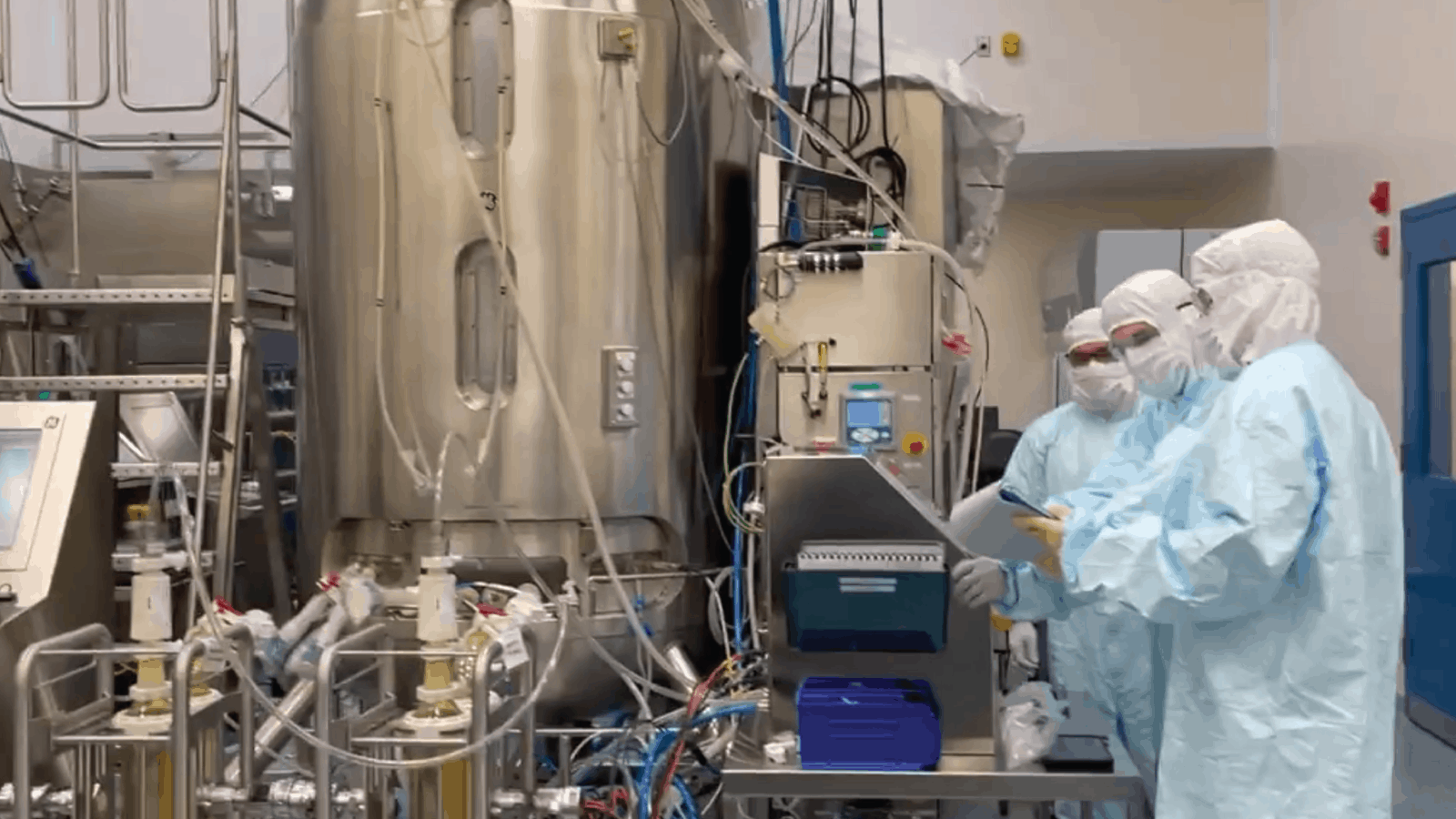

What It Takes to Manufacture a Vaccine

You may not know it, but one company has the capacity to manufacture bulk drug substance for more than a billion doses of COVID-19 vaccines annually: Emergent BioSolutions, a global supplier for the Johnson & Johnson vaccine and U.S. supplier for the AstraZeneca vaccine. Emergent Executive Vice President of Manufacturing and Technical Operations Sean Kirk spoke with us recently to explain what goes into the heroic production of all these doses—in other words, what it takes to help defeat COVID-19.

How the vaccine works: The complexity begins with the vaccines themselves, which are amazing feats of bioengineering. The two vaccines have broadly similar structures, though they are made by separate, quarantined production lines in the Emergent facility. (As Kirk says, you can’t even take a wrench from one production suite to the other.)

You can think of this type of vaccine as a sort of beneficial Trojan Horse:

- Particles of a virus called an adenovirus, which usually causes cold and flu-like symptoms, are engineered to hold the DNA of SARS-CoV-2 (the official name of the coronavirus)—and to not be infectious themselves.

- Those adenovirus particles enter your cells and program them to produce a component of SARS-CoV-2 called a spike protein.

- That process provokes an immune response, teaching your system how to defeat the real COVID-19.

So how do you make it? As you might guess, making such a precise vaccine is itself a complicated and delicate process.

- You need to make a lot of modified adenovirus particles very fast, while ensuring they aren’t infectious and can deliver their payload of SARS-CoV-2 DNA.

- To cut a long story very short, the production process involves “infecting living cells [with the modified adenovirus] and turning them into virus factories,” as science writer Derek Lowe says.

Where Emergent comes in: Emergent handles the manufacturing process, which results in something called “bulk drug substance,” Kirk explains.

- “Our facility produces the high concentration active pharmaceutical ingredients, the viral vectors themselves,” he says. “Then we freeze them down and ship them out to what’s called a fill/finish facility, which dilutes the concentrate and fills vials or syringes with it.”

The numbers: That concentrate will eventually become part of the 100 million Johnson & Johnson doses and 300 million AstraZeneca doses purchased by the U.S. government.

What it takes: Kirk gave us a glimpse of just how much effort went into getting ready for a new vaccine.

- 6 or 7 months: That’s all Emergent had, for a process that normally takes years. Consider how much goes into it, Kirk says: ordering equipment, getting that equipment to work correctly and comply with regulations, “working out the kinks from the complex biological manufacturing process”—and then scaling it up and optimizing it to make large quantities of vaccines as quickly and safely as possible.

- 800 new jobs: Emergent had to increase hiring, adding approximately 800 new jobs in 2020, many of which were dedicated to COVID-19 response across three Maryland sites.

- Group effort: Emergent works incredibly closely with Johnson & Johnson and AstraZeneca, along with the U.S. government and the company’s own suppliers. “We have leveraged U.S. government rated orders to get access to critical raw materials and equipment. We’ve depended upon certain suppliers, who were likewise rallying to the cause, to really step up and ramp up their overall capability and capacity,” says Kirk.

Why can’t you go faster? Kirk says he gets this question all the time and wants to impress upon readers that these are very complex biologic manufacturing processes.

- “They are highly regulated, highly technical and have to be highly reproducible,” he continued. “We are growing living cells and then we are infecting them with these viral vectors.”

- Furthermore, everything that Emergent produces must have the same characteristics of the product used in the clinical trials—“that’s the essence of biologic vaccine development,” Kirk says. “That’s the only way you can ensure safety and efficacy.”

The last word: Kirk tells us what he tells his employees: “It’s unbelievably difficult, more difficult than anything I’ve done in my entire career. But I can’t think of a more awesome opportunity to leave an indelible mark on the course of human history. We are going to help return a degree of normalcy to society. We’re going to help reunite families, open up economies and put a smile on children’s faces when they go back to school. And that’s an honorable and amazing thing.”

This article is the first in an exclusive four-part series on Emergent’s accelerated production efforts.

Timmons Opening Statement to U.S. Senate Committee on Finance Hearing on Made in America: Effect of the U.S. Tax Code on Domestic Manufacturing

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons delivered the following opening statement at a U.S. Senate Committee on Finance hearing entitled Made in America: Effect of the U.S. Tax Code on Domestic Manufacturing.

Click here to watch the hearing.

Remarks as prepared for delivery:

Good morning. Thank you, Mr. Chairman.

I’m joining you virtually because of the pandemic that this country has endured for more than a year now. But this pandemic is far more than a story of economic hardship and painful loss. It’s also a story of communities and companies rising to the challenge.

America’s manufacturing workers mobilized in ways reminiscent of their resolve during World War II, when manufacturers became the arsenal of democracy. The companies joining me today are part of this effort. Ford remade shop floors to make ventilators and face shields. Intel accelerated access to technology to combat the pandemic. From iconic global brands to family-owned shops, manufacturers answered the call.

Today, one year after health restrictions began, the light at the end of the tunnel is growing brighter by the second—thanks to the innovation of pharmaceutical manufacturers. Their heroic work, combined with the previous administration’s Operation Warp Speed and this Congress and this administration’s focus on and investment in vaccine distribution, is now saving about 2 million American lives every single day.

Manufacturing workers’ achievements are all the more impressive when you consider the disruptions they had to overcome. This pandemic exposed and exacerbated serious supply chain issues that we now must address as we work to build the next post-pandemic world.

In spring 2020, the National Association of Manufacturers released our plan for strengthening manufacturing supply chains. I’ve discussed it directly with some of you.

Our goal is your goal: Ensuring that the next dollar invested in manufacturing is invested in America.

The plan is comprehensive, from taxes to workforce. The central premise is that incentives—not punitive measures—will allow us to achieve our shared goal.

Let me call out three key recommendations.

Number one: We must recognize the importance of predictability and stability in the tax code. Tax reform made manufacturers more competitive, driving historic job creation, wage growth and productivity in its immediate aftermath. Let’s not undo that progress.

Number two: Manufacturers in America can only remain at the cutting edge if our tax code supports innovation. Unfortunately, it will do just the opposite starting next year.

A looming change to the tax treatment of research costs will make it more expensive to perform R&D—potentially costing America its innovation edge.

Number three: Let’s recognize a simple truth—policies that are successful in growing manufacturing will require significant capital expenditures by the small and medium-sized firms that are the backbone of our domestic supply chain.

But two other looming changes to the tax code will make those expenditures difficult. More stringent limitations on interest deductions and the phase out of immediate expensing will take effect in the years ahead. If not reversed, these changes will make it hard to grow manufacturing.

Ultimately, ensuring that next manufacturing dollar is invested right here in America requires looking at the entire business climate.

And that means that this Congress will have to address other pressing questions.

Will tax rates for businesses of all sizes remain competitive—or better yet, become more competitive—so that we can keep attracting investment?

Will the regulatory system provide certainty and clarity?

Will health care become more affordable—without compromising free market principles?

Will this nation finally make the bold investments in infrastructure that are long overdue?

Will energy be abundant, affordable and reliable?

Will export opportunities increase while we enforce our existing trade agreements to protect American workers?

And will we achieve comprehensive immigration reform to ensure that those hidden in the shadows or brought here as children can become permanent, productive members of society?

If the answer to those questions is “yes,” if we tackle these fundamental issues, then I’m certain that this Next World that we are building in the aftermath of the pandemic will be built by American workers in American factories, restoring American leadership in the world.

Thank you, and I look forward to your questions.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.3 million men and women, contributes $2.32 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Tax Policy Makes Innovation Possible for Big Ass Fans

For Big Ass Fans, a Kentucky-based company that manufactures fans, evaporative coolers and controls for industrial, agricultural, commercial and residential use, the eye-catching name isn’t the only thing that makes them distinctive. The company is also a leader in research and development, crediting U.S. tax policy with supporting its innovations and the jobs they create.

Investing in innovation: BAF has spent millions of dollars in R&D, even building an R&D lab on its global headquarters campus in 2008. Most recently, it pioneered new ways of disinfecting air to keep manufacturing employees healthy during the COVID-19 pandemic. And when Congress approved tax reform in 2017—including a lower corporate tax rate—the company got additional fuel for its efforts.

- “The more incentives that are there for us to create and for our customers to purchase, the more we can deliver for everyone,” said BAF Government and Public Relations Director Alex Risen.

Risen cautions, however, that a higher corporate tax rate could impact the company’s ability to grow. Meanwhile, a prospective tax change on R&D spending could stymie innovation by requiring the amortization of expenses (as opposed to current tax policy, which allows expenses to be fully deducted in the same year).

- “We’re always going to innovate. That’s in our DNA. But if our customers have higher corporate tax rates, that can take money out of our pockets and theirs,” said Risen. “If this new R&D tax policy detracts from a company’s ability to push and pioneer…then we’re all at risk of losing out on expedited innovation.”

Creating American jobs: BAF isn’t just using its revenues to invest in innovation; it’s also working to bring jobs and supply chains into the United States. In addition to its headquarters in Lexington, Kentucky, the company has offices in Canada, Australia and Singapore. Up until recently, it also had a manufacturing facility in Malaysia in addition to a sales office there—but BAF is in the process of moving those production jobs to the United States.

- “It doesn’t just mean new jobs at BAF; it brings more business to American vendors and suppliers,” said Risen. “It allows them to continue trying to grow even during a downturn and uncertain times.”

Bolstering supply chains: In addition to job creation, strengthening the supply chain was another top priority for BAF.

- “We were already working on moving those operations before the pandemic hit, but the pandemic is a reminder that you want to have that supply chain close,” said Risen. “We’ve been fortunate that we haven’t had to slow production down, because the majority of our product is here in our backyard. That speaks to where we want to be as a company that is internationally headquartered in the U.S. but serves 175 countries. We want to do our part in order to make high-end machinery a U.S. export.”

NAM support: To support companies like BAF and its customers, the NAM is leading the effort to ensure that the tax code keeps encouraging innovation. Recently, a bipartisan group of U.S. policymakers introduced legislation that would allow manufacturers to continue to deduct their R&D expenses immediately—a move that the NAM advocated for. The NAM is also working to strengthen U.S. supply chains, releasing an agenda for such actions last year.

The bottom line: “A high tide floats all boats,” said Risen. “We need to continue to innovate and deliver for companies in America—and we need to help Americans push the envelope, innovate and deliver for all of us.”

Hirebotics’ Co-Founders on Powering a Remote Team with PTC Onshape

The NAM’s Makers Series is an exclusive interview series featuring creators, innovators and trailblazers in the industry sharing their insights and advice. Meet Rob Goldiez and Matthew Bush, co-founders of Hirebotics. In this edition of the NAM’s Makers Series, Goldiez and Bush explain how Hirebotics uses PTC’s Onshape cloud-based CAD system to power its design teams.

How an Analytics Company Keeps Hospitals Running

Behind every hospital bed, doctor, ventilator, mask and the millions of other components that make up a hospital is the same thing: a prediction. How much will we need, and where, and when? Analytics make those predictions as precise as possible—and that’s never been more essential than during COVID-19.

Analytics software company SAS understood the problem better than almost anyone. And not long after the pandemic started, it partnered with the Cleveland Clinic to create an innovative dashboard that would help hospitals optimize their resources and keep saving lives.

How it started: On March 17, the Cleveland Clinic asked SAS to create models that could predict the spread of COVID-19. They wanted to understand the strain that COVID-19 might put on the hospital, and by extension, its resources—from ventilators to PPE to dialysis machines to their doctors’ time.

Why it’s different: While plenty of organizations around the world were building epidemiology curves to track the course of the virus, SAS and the Cleveland Clinic built a framework that offers more. The collaborative team came up with a range of scenarios based on varying inputs like virus transmissibility and social distancing. With SAS vetting the math behind the models, the Cleveland Clinic identified which curve it was on at a given time and developed action plans in advance.

How it worked: The models helped the Cleveland Clinic identify markers for potential surge scenarios and recognize when the actual severity of the outbreak would fall short of some projections. That means it did not have to cancel planned events like routine surgeries and treatments and was able to continue treating non-COVID-19 patients.

- “One of the challenges of this pandemic is the public health cost of dislodging patients with cancer or chronic disease to make room for COVID-19 patients,” said Dr. Steve Bennett, director of the global government practice at SAS. “These models can tell you that you may not need the surge capacity; you can keep doing the sorts of standard work that you’re doing. That has a valuable public health benefit.”

Sharing the wealth: SAS didn’t want to keep such a potentially valuable tool to themselves—so the team made their code publicly available on software development site GitHub. Other hospitals and public health agencies have adapted it, given feedback and made it their own, thus contributing to innovation and effective response.

- “Cleveland Clinic is very advanced in analytics—but at the same time, they really wanted to help smaller organizations and smaller clinic hospitals that may not have big data science teams,” said Natalia Summerville, senior manager at SAS. “That’s why they allowed us to make everything publicly available, which was amazing.”

What’s next: The technology has applications even beyond the current crisis. “SAS aspires to be the platform of the future,” said Dan Abramson, executive director of U.S. manufacturing at SAS (and an NAM board member). “It’s got capabilities in modeling and AI and data management and visualization. So, the knowledge we gain from projects like these can be a launching point for pretty much any business problem or challenge.”

The last word: “The collaboration worked,” said Andrew Williams, principal analytical solutions architect at SAS. “The analyst community has always spoken very highly of our technology and analytic capabilities in AI, machine learning and optimization—and I think what we’ve shown here is that we can apply them to critical use cases across the board and across industries.”

Manufacturers Outline Executive Action Policy Priorities for Incoming Administration

Washington, D.C. – The National Association of Manufacturers called on President-elect Joe Biden to help ensure the future strength of manufacturing in America by extending key executive orders into the new administration and rescinding those that have harmed manufacturing.

“For decades, we have worked with policymakers from across the ideological spectrum to craft policies that encourage the growth of manufacturing in the United States,” said NAM President and CEO Jay Timmons in a letter to the incoming administration. “Now more than ever, America needs leaders in Washington who are focused on increasing American jobs, wages and investment.”

The letter outlines executive orders that have had a significant impact, positive or negative, on manufacturers over the past four years, and it urges the president-elect “to reverse the most harmful of these orders and keep or expand those that create an environment that is conducive to growing America’s manufacturing sector.”

The NAM’s recommendations will help manufacturers continue to respond to the devastating pandemic and will also power the United States’ economic recovery by setting the stage for manufacturing growth.

To read the full letter, click here.

Background:

The NAM has requested President-elect Biden repeal the following executive orders and consider executive orders for extension.

Executive Orders

Rescind:

- “Rescission of the Deferred Action for Childhood Arrivals Program”

- E.O. 13950 – “Combating Race and Sex Stereotyping”

- E.O. 13672 – “Revocation of Federal Contracting”

- E.O. 13769 – “Protecting the Nation from Foreign Terrorist Entry into the United States”

- “President’s Report to Congress on the Proposed Refugee Admissions for FY 21”

- Presidential Proclamation 10052 – “Suspending Entry of Aliens Who Present a Risk to the U.S. Labor Market Following the Coronavirus Outbreak”

- E.O. 13944 – “Ensuring Essential Medicines, Medical Countermeasures and Critical Inputs Are Made in the United States”

- E.O. 13948 – “Lowering Drug Prices by Putting America First”

- E.O. 13957 – “Creating Schedule F in the Excepted Service”

Extend:

- E.O. 13771 – “Reducing Regulation and Controlling Regulatory Costs”

- E.O. 13805 – “Establishing a Presidential Advisory Council on Infrastructure”

- E.O. 13766 – “Expediting Environmental Reviews and Approvals for High-Priority Infrastructure Projects”

- E.O. 13845 – “Continuing the President’s National Council for the American Worker and the American Workforce Policy Advisory Board”

- E.O. 13932 – “Modernizing and Reforming the Assessment and Hiring of Federal Job Candidates”

- E.O. 13777 – “Enforcing the Regulatory Reform Agenda”

- E.O. 13806 – “Assessing and Strengthening the Manufacturing and Defense Industrial Base and Supply Chain Resiliency of the United States”

- E.O.s – “Strengthening the Federal Government’s Anti-Counterfeiting Efforts”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.3 million men and women, contributes $2.32 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 62% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

How NAM Cyber Cover Helps Manufacturers

Cyberspace seems to get more dangerous every day. The latest scare comes from the likely Russian hack of tech company SolarWinds’ software, which affected several U.S. government agencies along with major corporations. But manufacturers can give themselves some peace of mind by investing proactively in security measures—such as cyber insurance.

One industry executive is very happy with his decision to buy cyber coverage from the NAM to protect his company. After its sister company was attacked in a cyber incident, Manitoba Corporation’s Partner and Vice President of Marketing Adam Shine shopped around for plans that would safeguard the family-run metal recycling business based in New York. After considering his options, Shine signed up with NAM Cyber Cover because it offered proactive protection in addition to coverage, tailored to manufacturers at a competitive price.

“I think the NAM has done a good job of providing value for money, so it’s not like you’re just writing a check for cyber insurance on an if-come basis,” said Shine. “You’re actually signing up for some user training and some tools that will help you mitigate that risk.”

What it is: NAM Cyber Cover is a cybersecurity and risk-mitigation program developed exclusively for the NAM’s member companies and organizations in partnership with AHT Insurance and Coalition, which specializes in underwriting cyber and technology insurance.

What it offers: Cyber Cover presents a range of benefits for manufacturers seeking to secure themselves against cyber intrusions, allowing them to:

- Manage risks through a free Cyber Risk Assessment, as well as gain access to threat monitoring and vulnerability alerts;

- Mitigate the severity of intrusions with training platforms and programs that help employees recognize issues, while also working with ethical hackers to identify vulnerabilities;

- Receive 24-hour-a-day coverage from Cyber Cover support; and

- Recover from an attack with instant support that helps manufacturers survive and rebuild after a breach.

The word from Manitoba: “Speaking from experience, don’t think it can’t happen to you,” said Shine. “[Cyber attackers are] targeting every company from every walk of life…. To know that you have coverage and a safety net is critical. I would highly advise everybody now to have cyber coverage.”

The word from the NAM: “Modern manufacturers are deploying advanced technologies that are transforming what we make and how we make it. This rapid digitization and the workplace disruptions created by the COVID-19 pandemic have created new and unprecedented risks for our members,” said NAM President and CEO Jay Timmons. “Our partnership with AHT and Coalition will help protect our industry from cyberattacks and ensure we can continue to lead our economic recovery and renewal.”

Watch this interview with Shine about his experience, and take a look at what Cyber Cover offers here.