Manufacturers: Climate Disclosures Must Be Tailored and Targeted

Washington, D.C. – Following the release of a proposed rule by the U.S. Securities and Exchange Commission on climate disclosures, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“Manufacturers support key disclosures related to publicly traded companies’ climate strategies, as this information can help shareholders make informed decisions. However, broad, sweeping disclosures could be counterproductive—requiring manufacturers to waste time and resources reporting irrelevant information that will not be decision-useful for shareholders. The SEC should focus on requiring disclosure of material information, and the NAM looks forward to working with the SEC to ensure that its proposed climate reporting rule enables smart, company-specific disclosures that are tailored and targeted.

“Manufacturers are proudly leading on climate solutions. After all, it is manufacturers that make the products and technologies needed to face this generational challenge—clean energy, carbon capture, batteries, microgrids, advanced vehicles and more. And through our policy proposal, “The Promise Ahead,” the NAM has offered lawmakers a guide for achieving climate solutions alongside economic growth. Especially at this time of global turbulence and supply chain disruptions, our actions must allow for an all-of-the-above approach to safeguarding America’s energy security.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.57 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Manufacturers Announce Addition of Innovation Research Interchange

Key Milestone in Vision to Be One-Stop Shop for Manufacturing

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons today announced plans to continue the NAM’s ambitious organizational growth by combining with the Innovation Research Interchange.

The IRI is a leader in helping companies drive innovation and develop the cutting-edge technologies that keep manufacturing strong. The NAM’s growing array of services and thought leadership represents another key milestone in the vision adopted by the NAM Board of Directors to become the one-stop shop for manufacturers.

“The modern association must constantly innovate and evolve to best serve its industry, and with the addition of the Innovation Research Interchange, NAM members will have access to the widest array of expertise and services in the history of the association. With this transformational development, the NAM and our industry will benefit from world-class R&D thought leadership and the proven strategies that the IRI has perfected. The IRI will continue to support organizations in their mission to drive innovation, and it will enjoy access to the largest network of manufacturing companies and leaders,” said Timmons. “This development enhances the value proposition for NAM members and is part of our ongoing commitment to provide programming that exceeds our members’ expectations.”

IRI President Ed Bernstein will continue to lead the IRI’s day-to-day operations as vice president and executive director, reporting to NAM Chief Operating Officer Todd Boppell.

“The NAM is the perfect partner for the IRI,” said Bernstein. “Together, we will be the preeminent thought leadership organization for innovation management. We have a proud history of helping manufacturers and others lead R&D that produces lifechanging products and technologies. As part of the NAM, we will be able to equip even more industry leaders with the tools to ensure that innovation is impactful throughout the entire enterprise.”

The combination with the IRI follows the NAM’s acquisition of the Manufacturing Leadership Council in 2018. “As a member of the Manufacturing Leadership Council, I’ve seen firsthand how the MLC has been strengthened since becoming part of the NAM,” said Entegris Director of Digital Transformation and IRI Board Chairman Steven Moskowitz. “The access to even more resources and an incredible network has been invaluable—especially through the ongoing pandemic and supply chain disruptions. That’s why I believe that bringing the IRI, MLC and NAM together is the right move for everyone—IRI members, NAM members and the entire industry. The combination of the IRI, MLC and NAM will not only provide continued leadership from each individual organization for their members, but also create opportunities for new value across the entire product lifecycle, thus demonstrating the old adage that the total is greater than the sum of the parts. This positions all of us for even greater success and creates the future-facing organization we need.”

As part of the transition, IRI staff will join the NAM team. More information on the IRI can be found here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

-Innovation Research Interchange-

Innovation Research Interchange (formerly the Industrial Research Institute) is an inclusive membership organization with hundreds of global members in private-sector companies, federally funded laboratories, universities and others. Founded in 1938, we lead and advance the field of innovation management by creating contemporary practices. Some of the world’s most widely adopted models—such as “open innovation,” “front end of innovation” and “stage-gate”—were born from the work of our members. We value strength in cooperation and partner with other organizations at the forefront of developments in innovation management, creating a hub for all to convene and contribute in an experimental, noncompetitive and noncommercial environment. For more information, visit www.iriweb.org.

Philip Bell to Chair NAM’s Council of Manufacturing Associations

Washington, D.C. – The National Association of Manufacturers announced new 2022 leadership for its Council of Manufacturing Associations at the CMA 2022 Winter Leadership Conference. Philip Bell, president of the Steel Manufacturers Association, will serve as chair, and Melissa Hockstad, president and CEO of the American Cleaning Institute, will serve as vice chair. Made up of 220 industry-specific manufacturing associations representing 130,000 companies worldwide, the CMA creates powerful partnerships across the industry and ensures manufacturers have the strongest possible voice.

“Steelmakers and manufacturers are a force for good in the world. We support innovation, efficiency and sustainability. We help our employees build their lives, our customers build their businesses and the communities where we operate build their futures,” said Bell. “During this very dynamic time in our country, I am honored to articulate the important role manufacturing plays in America’s economic success and national security.

“Americans are counting on manufacturers to lead our economic recovery, deliver promising career opportunities and solve our global health crises, and the collaboration made possible through the CMA empowers our entire industry to rise to the challenge,” said NAM President and CEO Jay Timmons. “Philip and Melissa are trusted and tested leaders who will continue to cultivate the collaborative, cooperative spirit that has made the CMA such a consequential organization for our industry and country. I look forward to working with them to advance policies and plans that uphold the values that have made America exceptional and keep manufacturing strong: free enterprise, competitiveness, individual liberty and equal opportunity.”

The CMA’s mission is focused on bolstering the industry’s nationwide grassroots mobilization efforts and improving the competitiveness of manufacturers in the United States. CMA members work with the NAM to unite the manufacturing association community, and ultimately the broader business community, around strategies for increased manufacturing job creation, investment and innovation in America.

Bell is a 25-year industry veteran. Prior to leading the SMA, Bell served as director of external communications and public affairs for Gerdau Long Steel North America based in Tampa, Florida. Bell previously served as CMA vice chair.

Newly appointed 2022 CMA board members include the following:

- Alison Bodor, president and CEO, American Frozen Food Institute

- Nicole Harris, president and CEO, National Glass Association

- David Loftus, president and CEO, Electronic Components Industry Association

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

NAM Announces Promotions

Timmons: “We are ready to create the future for our industry and our country, with a focus on 2030 and beyond.”

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons today announced an evolution of the NAM management team that will expand capabilities, leadership opportunities and innovations and strengthen manufacturing in the United States for 2030 and beyond. Amid an unprecedented pandemic, historic workforce shortages, supply chain and opportunity gap challenges, new and emerging threats to U.S. manufacturing and the country, the digital transformation and once-in-a-generation policy and legal achievements, manufacturers in the U.S. and the NAM continue to play an outsized role in creating the future for people, communities and the country.

These leadership promotions will bolster the NAM’s impact as the industry’s unified voice. They will promote, perpetuate and preserve the values that guide manufacturers’ unrivaled contributions to society and make America exceptional: free enterprise, competitiveness, individual liberty and equal opportunity.

“More than six years ago, the NAM Board of Directors put its support behind a vision to strengthen our association and make the NAM a ‘one-stop shop’ for manufacturers by expanding and diversifying the NAM’s portfolio of offerings in advocacy, operational excellence, legal action, workforce development and news and insights,” said Timmons. “The NAM’s record-breaking results in 2020 and 2021—in the face of crises many of us have never seen in our lifetimes—were a direct result of turning that vision into reality with an entire team resolutely focused on supporting manufacturers and America’s business sector every day. So, now we are putting more responsibility in the hands of this immensely talented team that has proven in the best and worst circumstances to be the strongest, most effective voice and resource for manufacturers in the United States. We are ready to create the future for our industry and our country, with a focus on 2030 and beyond.”

The NAM ends 2021 with a net membership retention rate on track to be in the top historical tier in the 126-year history of the association. Initiatives realized during the pandemic spurred tremendous growth for the association in 2020 and 2021. Those initiatives included efforts to mobilize and support manufacturers’ pandemic response and personal protective equipment production; advance vaccinations; provide greater operational insights to the industry; run momentous campaigns for policy and legal wins, notably infrastructure investment and pandemic relief; and deliver comprehensive solutions to the industry’s most pressing issues, including workforce development.

“Our capability to drive solutions for manufacturers is central to everything we do, and we are aligning this team to provide even more solutions moving forward,” said Timmons.

The following leadership promotions become effective Jan. 1:

- Erin Streeter will be named Executive Vice President of the NAM. Currently serving as Senior Vice President of Communications and Brand Strategy, Erin will work alongside the President and CEO to set the strategic direction of the association and align and integrate teams, strengthen internal and external communications and grow audiences toward that direction. She will continue to oversee all brand, communications and marketing activities but will also add public affairs and mobilization as well as advocacy campaigns to her portfolio. The integration of these critical portfolios will ensure the NAM is positioned to advance the needs and priorities of manufacturers by providing first-in-class advocacy.

- Carolyn Lee has been named President of The Manufacturing Institute by its board of directors. The workforce crisis of more than 1 million open jobs today isn’t just an existential threat to manufacturing in America; it also threatens the security of our country. To meet this moment, the MI continues to break new ground in supporting manufacturers’ efforts to recruit and retain a skilled, diverse workforce. Carolyn’s focus for 2022 will be on developing a strategic growth plan and expanding partnerships and thought leadership to carry the MI and the industry into the future.

- Carolyn has asked Keith Smith to serve as Chief Administrative Officer of the MI. In this new role, Keith will work with Carolyn and the MI team to develop and implement a new organizational growth plan and help achieve the strategic vision of the organization. As a member of the NAM Senior Staff, Keith will also continue his leadership of the Association Partnerships Division as an NAM Senior Vice President, overseeing the NAM’s membership programs with association partners at the national, state and local levels.

- In addition to her current responsibilities as NAM Chief of Staff, Alyssa Shooshan will assume leadership of NAM Board strategy. Alyssa will advance board engagement, initiatives, mobilization, partnerships and programming.

Six current NAM vice presidents will be promoted to the newly created role of managing vice president. This group will be charged with leading the NAM’s Leadership Team in creating new opportunities in advocacy, membership value/thought leadership and culture/operations. In addition to serving as counselors to the NAM President and CEO, they will work with senior staff on all issues impacting the association.

- Adria Brockman, Managing Vice President of Membership

- Jamie Hennigan, Managing Vice President of Communications and Public Affairs

- Chrys Kefalas, Managing Vice President of Brand Strategy

- Daryl Muller, Managing Vice President of Membership

- Chris Netram, Managing Vice President of Tax and Domestic Economic Policy

- Shonzia Thompson, Managing Vice President of Association Partnerships

Based on considerable input from across the association, the following team members will be promoted to vice president and named to the NAM Leadership Team, which meets quarterly to help enhance and strengthen the organization’s service to manufacturers and the country. The Leadership Team will be charged to work with the managing vice presidents in a select area of the team’s portfolio.

- Rob Damschen, Vice President of Strategic Communications

- Mark Isaacson, Vice President of Executive Communications and Chief Speechwriter

- Brian James, Vice President of Conference and Office Operations

- Mike O’Brien, Vice President of Public Affairs and Advocacy

- Chris Schmitt, Vice President of Strategic Partnerships

- Patrick Smith, Vice President of Member and Board Relations

- Megan Stewart, Vice President of National Department

In recognition of the expansive growth of the MI, the following MI vice presidents will be named to the NAM’s Leadership Team:

- Gardner Carrick, MI Vice President of Workforce Solutions

- Herb Grant, MI Vice President of Program Execution

- AJ Jorgenson, MI Vice President of Strategic Engagement and Inclusion

- David McKnight, MI Vice President of Strategic Partnerships

A new group of leadership influencers, recognized by their peers as agents of organization-wide progress, was also appointed for one-year terms to work directly with the NAM Leadership Team to provide insight and counsel on key issues that affect the strategic direction of the NAM.

- Cameron Alvarez, Art Director

- Kristie Arslan, Senior Director, Member and Board Relations

- Penny Brown, Content Director, Manufacturing Leadership Council

- Julie Chase, Senior Compliance Counsel

- Charles Crain, Senior Director, Tax and Domestic Economic Policy

- Kirk Fordham, Senior Director, Member and Board Relations

- Jeni Littlepage, Senior Manager, Benefits Administration

- Ryan Ong, Director, International Business Policy

- Cassi Zumbiel, Director, Workforce Programs and Policy, MI

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.52 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

The Company That Puts UV Light to Work

Did you know that several of the components in your car may have passed under high-intensity UV light prior to your purchase? You may have heard that manufacturers coat headlights with a UV protective film to keep them from getting scratched by road debris, but several other components are also manufactured using UV—including windshield borders and the protective coating on interior trim. The process is called UV “curing,” which dries coatings consistently, efficiently, durably—and without releasing harmful chemicals into the atmosphere, as other drying processes do.

The NAM got a firsthand look at this technology recently, thanks to manufacturer Miltec UV of Stevensville, Maryland. The company manufactures UV systems that cure products like optical fiber, semiconductors, prefinished hardwood floors and cars, supplying this technology across the country and around the world. NAM Director of Photography David Bohrer visited Miltec’s facility to check it out.

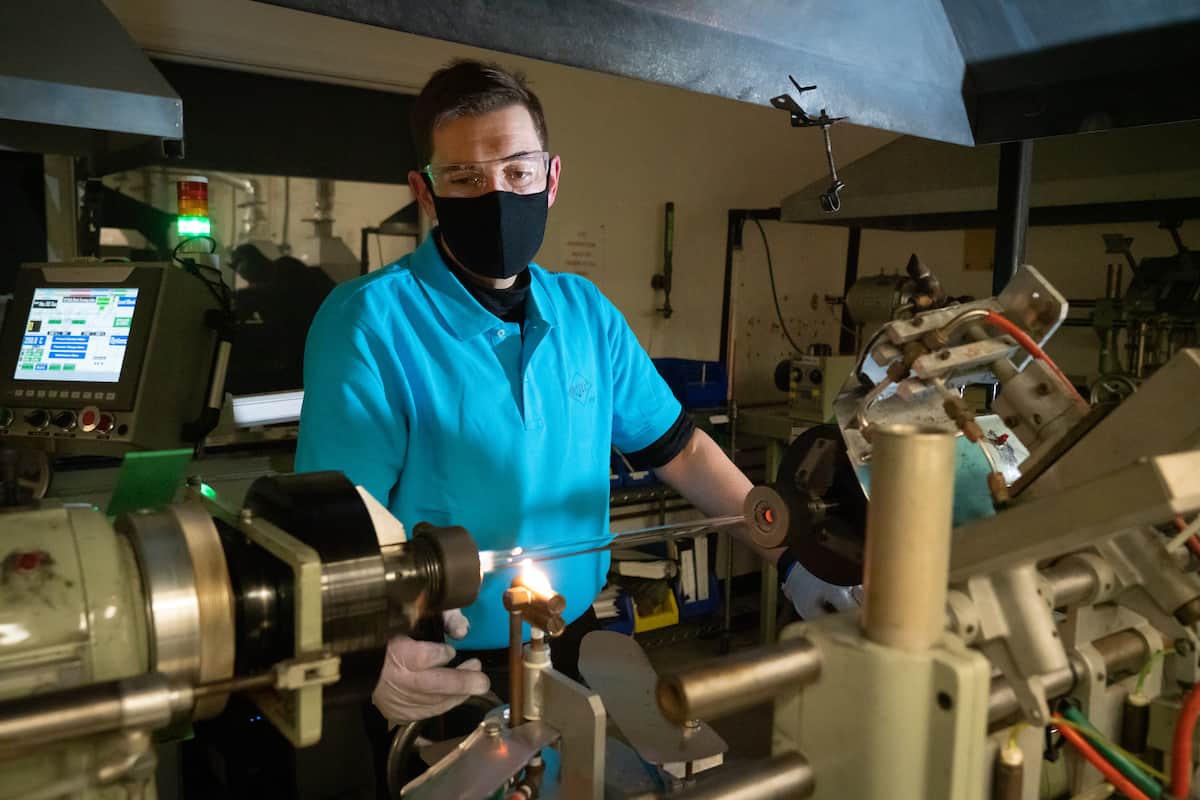

Here, an employee at the Bulb division is making a UV bulb. Miltec manufactures thousands of bulbs each year for export around the globe:

When dealing with UV technology, safety comes first. Here, an employee working in the Li-ion Battery Research and Development lab is assembling coin cell batteries in a glove box. The batteries will be used as test samples.

The set of a sci-fi movie? Nope. It’s just the testing of a 16-lamp UV curing system that produces more than 530 KW of UV power. Ultimately, the customer will use this system to cure inks and coatings on a high-speed printing press that manufactures outdoor packaging bags, such as for Miracle-Gro.

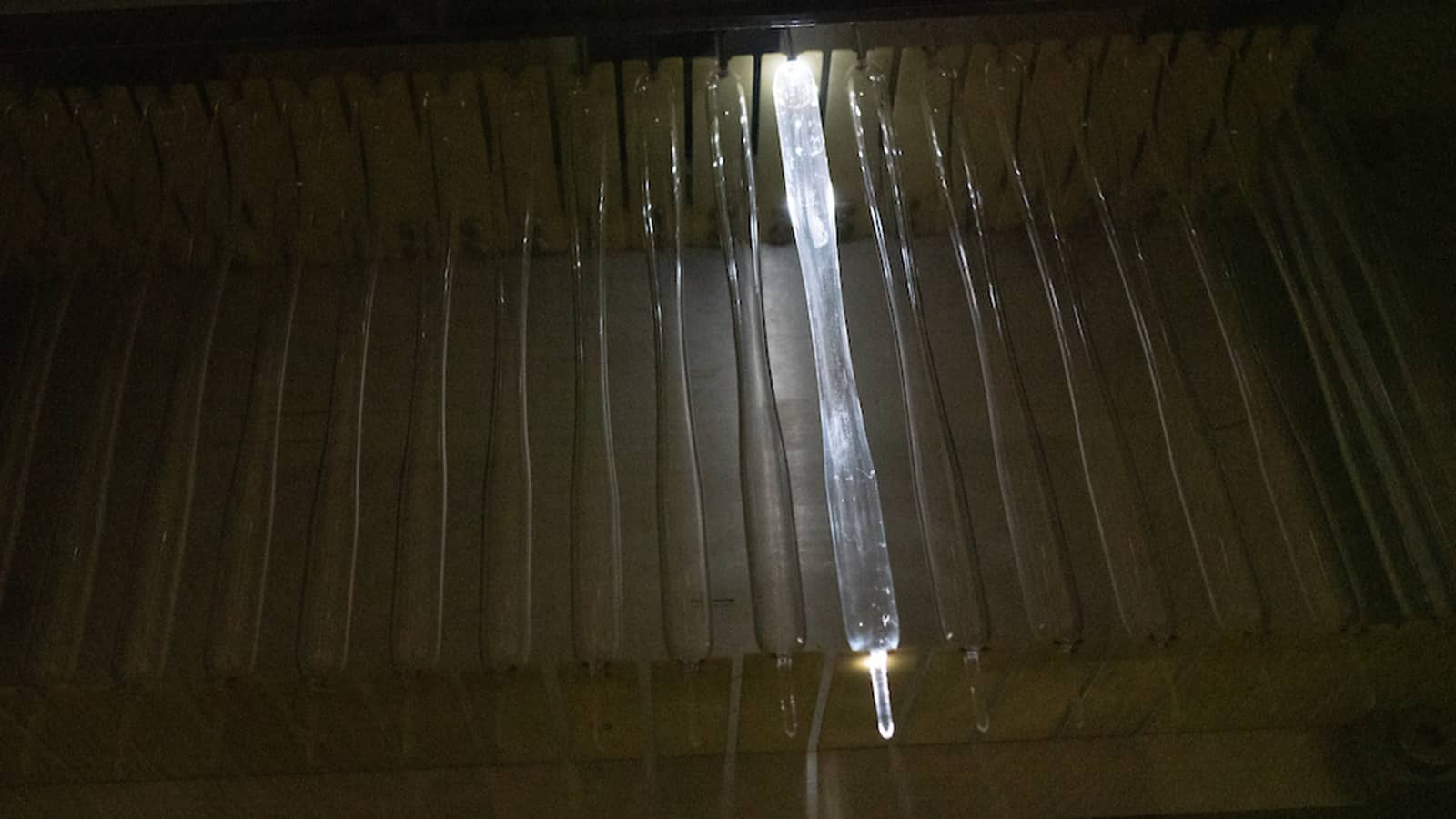

Of course, you can’t go through an entire story about UV light without a cool picture of UV light—so here it is. This is a UV bulb after it’s been filled with an inert gas, which helps it illuminate its powerful UV light.

Miltec says: “Miltec UV is proud to be a member of the NAM and extremely grateful for all of the work that the NAM does to protect the jobs of our team members that do so much to help our company grow and succeed in the international market,” said Miltec President Bob Blandford. “We are also honored and blessed to have such a dedicated manufacturing team that truly understands the importance of making products in the USA and satisfying customers with reliable and high-performance products. With the help of tax cuts, Miltec UV is doing its part by creating more jobs, increasing salaries and offering end-of-year bonuses for its employees.”

How PTC Onshape Helps Formlabs Print the Future

The NAM’s Makers Series is an exclusive interview series featuring creators, innovators and trailblazers in the industry sharing their insights and advice. In this episode, you’ll meet Matt Lipsitz and Adam Lebovitz of Formlabs, who discuss how PTC Onshape helps Formlabs improve their 3D-printer design. Learn how PTC has helped Formlabs “try out new ideas that weren’t possible in the past.”

Fortune Brands Puts Sustainability Front and Center

When it comes to making strides in sustainability, Fortune Brands Home & Security knows the power of small, steady steps. The company works to improve sustainability in a wide variety of ways, from water conservation to the recycling of ocean plastics and wood. We talked to two of its leaders recently to get the inside scoop.

Mission Moen: In 2020, the company launched Mission Moen, its commitment to conserving 1 trillion gallons of water by 2030. To meet that goal, Moen has employed cutting-edge innovation, explained Fortune Brands Global Plumbing Group Chief Marketing and Innovation Officer Mark-Hans Richer.

- Its Flo by Moen, for example, is a “smart water security system” that, through a mobile app, standalone sensors, detectors and other tech, allows consumers to monitor their water usage—and detect leaks they may not even know about.

- “There is an immense amount of water that’s wasted every year in the United States … due to lack of knowledge,” said Richer. “Flo by Moen allows users to see where water use is any minute of any day.”

“The key to saving water is in small fixes,” Richer emphasized. For example, “a faucet that has a little bit more managed gallon-per-minute flow can add up over the course of its use … to some pretty substantial savings.”

Cleaning up the oceans: The second pillar of Mission Moen is the company’s commitment to cleaning up the world’s oceans—specifically, 2,000 tons of plastic that’s currently floating in them.

- “We’ve found a lot of very useful, interesting things” that can be made with ocean-recycled plastic, Richer said. These include product packaging and components in showerheads.

- “When you commit yourself to a large goal, then you start to look for ways” to meet that goal, he continued.

Recycled wood and plastic: FBHS’s dedication to conservation extends throughout the company. Recycled wood and plastic are used to create its Fiberon Balance composite decking, Fiberon President Fenton Challgren told us. It’s a complex process:

- First, there is an “intensive search … for the right plastic, which comes in bales by the truckload,” said Challgren.

- The company then must “sort the contaminants, contain them, grind them, get them into different extruders … and create a stable pellet” that can be used for the decking, he continued.

What should manufacturers learn from FBHS? Manufacturers seeking to reduce the size of their company’s environmental footprint should think of these efforts as a long-term investment, according to Challgren.

- “On the water recycling side, have a really robust filtration system,” Challgren urged. “Spend the money, get the technology. It’s a big investment, but if you’re doing any type of high-volume water usage,” it will be less expensive in the long run.

The last word: As Challgren summed it up, “The impact your company could have by going down this path … will be worth it both financially and for the greater good.”

New NAM Report Highlights the Impact and Importance of Pharmaceutical Manufacturing

Timmons: Pharmaceutical manufacturers are essential to America’s health and well-being and to the success of our economy.

Washington, D.C. – After the publication today of the National Association of Manufacturers’ latest report, “Ensuring a Healthy Future: The Impact and Importance of Pharmaceutical Manufacturing,” NAM President and CEO Jay Timmons released the following statement:

“Pharmaceutical manufacturers are essential to America’s health and well-being and to the success of our economy. They have helped lead our country through crisis, fight the pandemic and drive our recovery. The sector creates hundreds of thousands of jobs, and the work its quarter of a million employees perform is literally lifesaving, improving society in ways that are almost impossible to overstate.”

The report finds that not only have pharmaceutical manufacturers been pioneers in improving the human condition, but the industry also fuels other sectors of the economy.

According to the report:

- Pharmaceutical and medicine manufacturing directly employs an estimated 267,000 workers in the United States and supports nearly 1.9 million more jobs across the country.

- One job in the industry helps support six other jobs in the overall workforce.

- Pharmaceutical and medicine manufacturing generates nearly $339 billion in output. Further, $1.00 in pharmaceutical and medicine manufacturing output generates $1.09 in output elsewhere in the economy.

- For every $1.00 earned by an employee within the industry, $2.42 is earned by others elsewhere in the economy.

“The American public and policymakers too often overlook these accomplishments,” Timmons added. “Traditional economic analysis ignores the way this industry extends and enriches lives, and the public is not fully aware of pharmaceutical manufacturers’ constant focus on innovation and improving the quality of life for everyone. Pharmaceutical manufacturers are always researching, discovering and developing new medicines and treatments, operating at the core of our modern health care system. Their products make it possible for medical professionals to introduce and manage innovative new therapies, and of course, these manufacturers helped create lifesaving COVID-19 vaccines. Moreover, the industry has high economic multipliers that drive production and job creation in other industries.”

Additional Key Findings:

- A successful pharmaceutical ecosystem requires strong private-sector investment.

- In 2019, American pharmaceutical companies invested more than $83 billion in research and development, topping off nearly $1 trillion in R&D investment over the past 20 years. A recent study from the National Science Foundation’s National Center for Science and Engineering Statistics estimates that the pharmaceutical and medicine manufacturing sector alone accounts for roughly 17% of total R&D investment in the United States.

- The pharmaceutical industry invests nearly 11.4% of its sales back into R&D. Indeed, the U.S. pharmaceutical industry invests on average roughly three times more in R&D as a percentage of sales than all other manufacturing industries.

- The industry creates valuable STEM jobs.

- While roughly 6.7% of the U.S. workforce has a STEM occupation, 29.9% of all jobs in pharmaceutical and medicine manufacturing are STEM related. The pharmaceutical manufacturing sector employs more than four times the percentage of STEM workers employed in the overall workforce.

- Industry employees are highly productive.

- Industry employees produce $1.3 million in output per employee. This is nearly seven times greater than the U.S. economy’s average output per employee ($188,000).

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.4 million men and women, contributes $2.44 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

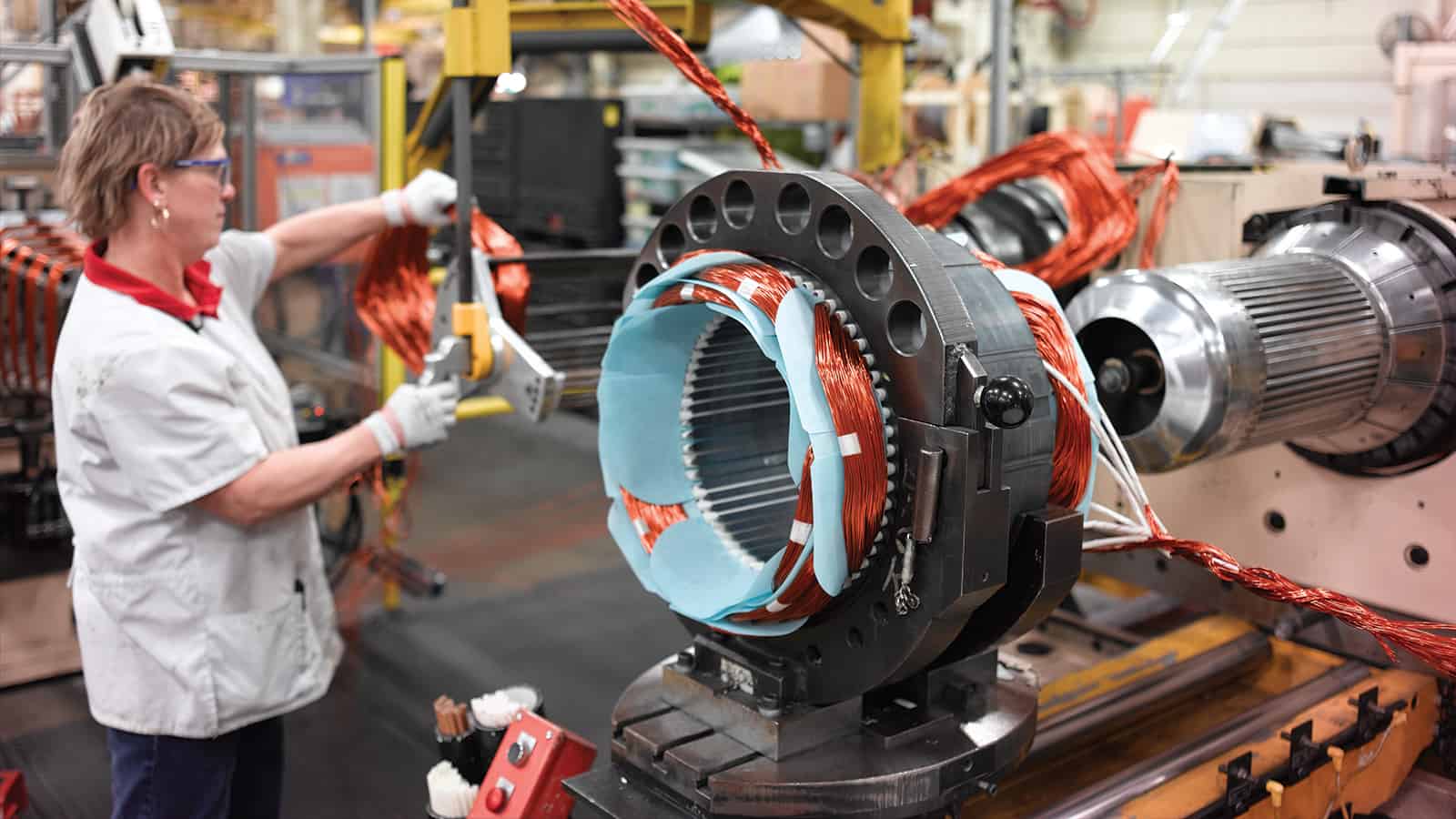

ABB: Motoring Toward Greater Energy Efficiency

Jesse Henson wants you to think of motors the way you think of lightbulbs.

Most people recognize the energy and cost savings to be had by switching from incandescent bulbs to LED light sources. In the same way, they should see the advantages of swapping out anachronistic, clunky motors for newer alternatives, said Henson, president of ABB’s NEMA Motors Division.

“You’ve [still] got the old incandescent lightbulbs out there—which are your motors—that need to be replaced with newer technology,” Henson told the NAM.

Not too different from 1921: The humble motor, which Henson says has “really not changed much in over 100 years,” is ubiquitous in manufacturing. Motors are found in factories in fans, pumps, compressors and more, powering everything from systemwide HVAC systems to individual power tools. But new technology could make them much more efficient and environmentally friendly—and save manufacturers a lot of money in the process.

Motor movement: ABB is working to change the way motors are used across the manufacturing sector, where they account for the lion’s share of expended electricity—approximately 70%, according to the U.S. Department of Energy.

- A sizable portion of that electricity is wasted because the motors using it are running constantly, consuming energy even when no task is being performed, Henson noted. That’s a costly reality for manufacturers.

Use only what is needed: ABB’s variable speed drives address this problem, allowing manufacturers to tailor a motor’s speed to the job it is doing. “That’s how you save energy,” Henson said.

- Adding a drive to a motor-driven system typically reduces power consumption by 25%, according to ABB.

- However, most companies aren’t getting that level of efficiency—just a quarter of motors in use today have such energy-saving drives, Henson noted.

No rare-earths needed: Of particular importance at a time of global supply-chain disruption is the fact that ABB motors achieve higher levels of efficiency without using rare-earth magnets.

- ABB’s EC Titanium motor, for example, does not use rare earths. Instead, it employs synchronous reluctance (the conversion of electrical energy to mechanical) technology and ferrite magnets for an even higher level of efficiency.

Easy savings: In fact, just by adding the EC Titanium motor drive to a fan array with 50 motors, one ABB manufacturing customer that already used drives cut its electricity consumption in half.

- The company slashed its annual energy bill from $20,000 to $10,000, according to Henson.

The last word: “We want to continue embracing sustainability . . . today and into the future,” said Henson. “These motors and drives are truly a game-changer in our marketplace today.”

Rethink Presents Lessons for Manufacturing Leaders

Are you grappling with the fast pace of competition in manufacturing? Are you working to keep up with the massive amount of disruption brought on by artificial intelligence, advanced robotics and digital breakthroughs? Are you racing to create new competitive advantages by using the power of Manufacturing 4.0—the next wave of industrial progress based on digitization?

The NAM has you covered with Rethink: The Manufacturing Leadership Council Summit, on June 22–24.

What it is: Rethink is the premier conference on Manufacturing 4.0 for industry leaders as they continue to navigate disruption. Hosted by the Manufacturing Leadership Council—a member-driven, global business leadership network dedicated to senior executives in the manufacturing industry—the summit offers participants strategies and solutions that are designed to advance their operations and improve their competitiveness.

Why it matters: The COVID-19 pandemic supercharged some of the changes that were already occurring in the manufacturing industry. Across the past year, businesses have seen an even greater need for flexibility, agility and speed in operations, and many manufacturers have accelerated their adoption of digital technologies to achieve these goals.

What it includes: The summit will offer a wide range of informative conversations with next-generation leaders and experts. A few elements include the following:

- Case study sessions showcasing real-world examples of advanced manufacturing technologies in action—from efforts to transform legacy facilities into smart factories, to the role of analytics in digital transformation, to the growth of robotics in manufacturing and logistics. By hearing from manufacturing leaders who have taken on these challenges, executives can learn best practices and gain new ideas for their own companies.

- “Think tank” sessions that will allow participants to ask questions and share ideas about advanced manufacturing technology. These conversations will include discussions of topics like quantum computing, manufacturing execution systems, augmented and virtual reality, blockchain, edge computing and sustainability.

The big difference: Most importantly, Rethink gives participants the chance to learn from other manufacturing executives and experts. Many of the industry’s most forward-thinking leaders will collaborate at this summit to make manufacturing better and stronger.

Check it out: Click here for more information and to register for the summit.