Illinois Manufacturers’ Association Wins Inaugural COSMA Leadership Award

San Diego, California – For their work to attract and maintain the manufacturing workforce, the Illinois Manufacturers’ Association won the 2022 Leadership Award from the Conference of State Manufacturers Associations. COSMA members also serve as the NAM’s official state partners and drive manufacturers’ priorities on state issues, mobilize local communities and help move federal policy from the ground up in all 50 states and Puerto Rico.

“I am so pleased to present the inaugural COSMA Leadership Award to the Illinois Manufacturers’ Association,” said Kris Johnson, president of the Association of Washington Business and chair of COSMA. “These are challenging times, but manufacturers in America have demonstrated once again, as they have throughout our nation’s history, that they are equal to the challenge. All manufacturers should be proud of the role they have played in navigating the pandemic, and the Illinois Manufacturers’ Association should be especially proud of the innovative ways it has helped its members address the workforce challenges we have all faced. Congratulations to my friend Mark Denzler and his talented team.”

The association’s recent achievements included its $7 million Manufacturing Jobs Campaign aimed at attracting students, veterans, communities of color, women, ex-offenders and other individuals to the manufacturing sector. They were also asked by Governor JB Pritzker to co-chair the state’s Equipment Task Force during the pandemic and appointed by Chicago Mayor Lori Lightfoot to lead the B2B Recovery Group that included manufacturing, transportation and warehousing, construction and utilities companies in the state.

“Mark is more than an inspirational colleague and true friend. He is an amazing representative for Illinois’ manufacturing workers on the national stage,” said NAM President and CEO Jay Timmons. “At a time when there are more than 800,000 open jobs in our industry, we need the efforts of groups like the IMA to help us find that next generation of talent and strengthen manufacturing competitiveness so that we can continue to lead our economy and our country toward a better future.”

In this inaugural year, the COSMA Leadership Award drew many extraordinary applications, each demonstrating how manufacturing associations across the country are rising to meet workforce and supply chain challenges in new and innovative ways.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

What Manufacturing Leaders Learned at Rethink 2022

Manufacturers flocked to Florida this summer to discuss the cultures, skills and technologies necessary for digital transformation at the 2022 Rethink Summit, the signature event of the NAM’s Manufacturing Leadership Council. The MLC is the world’s first member-driven, global business leadership network dedicated to senior executives in the manufacturing industry.

The big event: The first in-person Rethink since 2019, this year’s summit drew the largest crowd since the annual event began 18 years ago.

- The conference in Marco Island, Florida, hosted some of the most innovative leaders and teams in the industry, from companies such as Pfizer, Intel, Dow, Saint-Gobain and many more.

- Participants learned about real-world advances and shared best practices in supply chain resilience, effective business cultures, machine learning, business ecosystems and more—as explained by industry experts who put these innovations into practice themselves.

The panels: Here is a quick sample from the array of manufacturing expertise on offer.

- A Pfizer case study: Pfizer Vice President of Digital Manufacturing Mike Tomasco explained how Pfizer Global Supply transformed itself from a digitally siloed operation to a world-class digital powerhouse.

- Bridging the digital divide: A panel of leaders—including Graphicast President Val Zanchuk, BTE Technologies President and NAM SMM Board Chair Chuck Wetherington and Intel Senior Director of Industrial Innovation Irene Petrick—discussed how small and medium-sized manufacturers can keep up with the digital transformation occurring throughout the industry.

- Reaching the next generation: A panel of young manufacturing leaders from Dow, Cooley Group and Saint-Gobain North America discussed what young people are looking for in manufacturing jobs, including interdisciplinary teams and lots of communications up and down the organization levels.

A week of manufacturing: The Rethink Summit was only one highlight of a week of manufacturing events put on by the MLC. The roster of events also included the MLC’s Council Day and the ML Awards Gala.

- Council Day offers MLC members the opportunity to chart the agenda for the MLC’s next year, thus influencing how the whole industry thinks about and plans for digital innovation.

- The Awards Gala spotlights companies and individuals doing incredible work to advance M4.0. The black-tie event honored leaders and companies in 11 project categories, plus the Manufacturers of the Year and Manufacturing Leader of the Year.

- This year, the MLC named Pfizer CEO Dr. Albert Bourla the Manufacturing Leader of the Year, for Pfizer’s extraordinary and ongoing contributions in fighting the COVID-19 pandemic.

The last word: “[T]he fundamental shift in our economy to doing business digitally in all industries, including manufacturing, not only continues but is gaining greater speed and urgency,” said MLC Co-Founder David R. Brousell during an address at Rethink.

Join us next year: Keep up to date with the MLC by visiting the website and stay tuned for Rethink 2023!

Why Nuclear is Key to Climate & Energy Security

As energy prices remain at their highest levels in more than a decade, there’s little sign that the U.S. is on a steady course toward energy security. That’s why the NAM is urging the federal government to pursue all available options—including nuclear.

The lowdown: Nuclear energy is a safe, reliable and the largest zero-emission source of energy in the U.S.

- At a time of pronounced supply chain challenges, oil-and-gas lease cancellations and costly shortages of critical minerals, nuclear energy could go a long way toward fortifying the grid.

- In addition, the technology has advanced enormously in recent years. Microreactors, small enough to be moved by truck, are poised to help solve the challenge of powering remote areas.

- The Department of Energy also recognizes the importance of nuclear energy, recently noting its relevance to energy security in the department’s Supply Chain Assessments.

What we’re saying: “The reality is that to meet our growing electricity needs and climate goals, nuclear-generated power must be part of the solution,” said NAM Director of Energy and Resources Policy Chris Morris. Here are his key policy recommendations:

- Encourage capital formation: The NAM secured a significant $6 billion investment in the Civilian Nuclear Credit Program through the recent infrastructure bill, but more robust investments will be needed to ensure operations continue at current nuclear projects, Morris said.

- Relicensing: Licensing and permitting processes should meet the highest standards, but the Nuclear Regulatory Commission often takes years to complete them. The NRC should use its position on the Federal Permitting Improvement Steering Council to make efficiency improvements in its licensing processes under the recently announced Permitting Action Plan.

- Fuel supply chain security: The U.S. imports uranium for civilian nuclear use from Russia, Kazakhstan, Uzbekistan, Canada and Australia, among others. Meanwhile, new advanced reactor concepts will utilize high-assay low-enriched uranium (HALEU) which is now solely produced by Russia and China. The NAM has been calling on policymakers to prioritize increasing domestic production.

- SMRs and microreactors: Small modular reactors use factory-built components to streamline construction, while microreactors are portable and self-sufficient. Both will be crucial for next-generation nuclear power—but the U.S. government must invest in their manufacturing and modernize regulations accordingly.

- Spent fuels: The NAM has long supported ongoing R&D into the storage and transportation of spent fuels—and progress is being made. Just yesterday, NRC staff recommended licensing a new storage project in New Mexico, “determining there would be largely minor environmental impacts from the project,” according to POLITICO (subscription).

- Public perception: Commercial nuclear power is sometimes viewed as dangerous or unstable based on historic misconceptions. In truth, the U.S. nuclear industry is leading the world in best practices, safety and accountability. Policymakers must engage with local communities to provide the facts and emphasize the importance of nuclear power for combating climate change.

The last word: “Our current fleet and the next generation of nuclear power must be a substantial part of a clear-eyed strategy to address climate and energy security,” Morris said.

Dow Doubles Commitment to $2 Million for Manufacturing’s Largest Workforce Campaign

Investment Will Enable Creators Wanted to Build on Its Historic Impact in More Communities Across the Country

MIDLAND, Mich. – Dow, the National Association of Manufacturers and The Manufacturing Institute announced today that Dow has committed an additional $1 million to the Creators Wanted campaign. This new pledge is on top of the $1 million Dow has already contributed to the NAM and the MI’s campaign designed to educate, inspire and empower the next generation of manufacturers.

Dow’s latest financial contribution ensures Creators Wanted can continue to recruit new manufacturers online and in person throughout 2022, bringing the experience to thousands of additional students, parents, career mentors and community leaders nationwide. Creators Wanted will make its next public stop at the Ladies Professional Golf Association’s Dow Great Lakes Bay Invitational July 13–16, bringing the experience to thousands of tournament goers and students.

“It is now more important than ever to invest in America’s future manufacturing workforce,” said Dow Chairman and CEO and NAM Board Chair Jim Fitterling. “Not only does the fate of U.S. manufacturing competitiveness rest in significant part on our ability to build the future workforce, but we also have an opportunity to lift up more people with the promise and possibility of manufacturing careers. Dow is proud to invest an additional $1 million in the NAM and MI’s Creators Wanted campaign. We’ve already been able to inspire thousands of students through Creators Wanted and look forward to bringing this experience to Midland and other communities moving forward.”

In addition to the upcoming Creators Wanted activation at GLBI, Dow’s new round of support will bring the mobile experience to several more cities, including Chicago, Columbia, South Carolina, and Baton Rouge, Louisiana, among others, throughout fall 2022 and into spring 2023. This capitalizes on the momentum from Dow’s previous contribution that helped bring Creators Wanted to six U.S. cities—Columbus, Ohio; Columbia, South Carolina; Pella, Iowa; Charlotte, North Carolina; Fort Worth, Texas; and Freeport, Texas—for its inaugural fall 2021 tour.

Manufacturing in the United States today has more than 900,000 open jobs. By 2025, Creators Wanted aims to recruit 600,000 new manufacturers; increase the number of students enrolling in technical and vocational schools or reskilling programs by 25%; and increase the positive perception of the industry among parents and career mentors. The campaign features a first-of-its-kind student- and teacher-endorsed traveling immersive experience and jobs tour, which has brought together more than 5,000 students in person and recruited more than 200,000 students and career mentors to learn more about modern manufacturing careers after only seven brief stops.

“Dow’s unwavering commitment to manufacturing and Creators Wanted will allow us to do more to tackle the critical need for workers now and reach into more local communities to educate teachers, parents and other career mentors and students about rewarding careers in modern manufacturing,” said NAM President and CEO and MI Board Chair Jay Timmons. “The NAM is proud to announce our continued and strong partnership with Dow to strengthen U.S. manufacturing competitiveness and build the American manufacturing workforce of tomorrow.”

The campaign is also underpinned by sustained workforce development and education initiatives at the MI, targeting youth, veterans, women and other underrepresented communities throughout the country.

“The MI is grateful to Dow whose support bolsters our ability to achieve a critical component of our mission—to attract and develop world-class manufacturing talent,” said MI President Carolyn Lee. “With Dow’s support, the MI can expand our reach, furthering our opportunities to educate the next generation of manufacturers on the lucrative and fulfilling careers that exist in modern manufacturing for people of all backgrounds and interests.”

Through the campaign, the NAM seeks to continue its mission to remediate common misperceptions about careers in manufacturing and provide resources and opportunities that will help reduce the skills gap and improve lives.

For more information on the campaign, visit CreatorsWanted.org and view results from previous tour stops here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.7 million men and women, contributes $2.71 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

-The Manufacturing Institute-

The MI grows and supports the manufacturing industry’s skilled workers for the advancement of modern manufacturing. The MI’s diverse initiatives support all workers in America, including women, veterans and students, through skills training programs, community building and the advancement of their career in manufacturing. As the workforce development and education partner of the NAM, the MI is a trusted adviser to manufacturers, equipping them with resources necessary to solve the industry’s toughest challenges. For more information on the MI, please visit www.themanufacturinginstitute.org.

-Dow-

Dow (NYSE: DOW) combines global breadth; asset integration and scale; focused innovation and materials science expertise; leading business positions; and environmental, social and governance (ESG) leadership to achieve profitable growth and deliver a sustainable future. The Company’s ambition is to become the most innovative, customer centric, inclusive and sustainable materials science company in the world. Dow’s portfolio of plastics, industrial intermediates, coatings and silicones businesses delivers a broad range of differentiated, science-based products and solutions for its customers in high-growth market segments, such as packaging, infrastructure, mobility and consumer applications. Dow operates 104 manufacturing sites in 31 countries and employs approximately 35,700 people. Dow delivered sales of approximately $55 billion in 2021. References to Dow or the Company mean Dow Inc. and its subsidiaries. For more information, please visit www.dow.com or follow @DowNewsroom on Twitter.

Manufacturing Leadership Council Recognizes Pfizer CEO

The Manufacturing Leadership Council—a division of the NAM that helps manufacturers leverage digital transformation—named Pfizer CEO Dr. Albert Bourla the 2022 Manufacturing Leader of the Year at the 18th annual Manufacturing Leadership Awards Gala.

The details: The ML Awards are the U.S. manufacturing industry’s biggest stage for recognizing excellence in digital manufacturing. Since the program’s founding in 2005, more than 1,000 high-performing projects and individual leaders have been honored with an award. Winners represent companies of varying sizes in a wide array of industries.

The big award: The Manufacturing Leader of the Year award was presented to Bourla for Pfizer’s extraordinary and ongoing contributions in fighting the COVID-19 pandemic.

- “Manufacturing in America today is stronger thanks to the leadership of Dr. Bourla and his team at Pfizer, including our Executive Committee member Mike McDermott,” said NAM President and CEO Jay Timmons. “Albert and Mike’s passion and dedication to defeating COVID-19 set an example for thousands of companies as our industry navigated and responded to the evolving pandemic, and their leadership and innovation will make us better prepared to respond to the next crisis.”

Other honorees: Awards were given to companies that excelled in various categories of manufacturing, including Protolabs for collaborative ecosystems, AB InBev for digital network connectivity and operational excellence, Dow for digital supply chains, General Motors for engineering and production technology, Flex and Johnson & Johnson for enterprise integration technology, AUO Corporation for sustainability and ALOM Technologies for transformative cultures.

Manufacturers of the Year: Protolabs was named the Small/Medium Enterprise Manufacturer of the Year, and AB InBev was named the Large Enterprise Manufacturer of the Year.

The last word: “Manufacturers continue to be the driving force for global economic recovery and pandemic response as they establish innovative ways to problem-solve in an increasingly complex environment,” said MLC Co-Founder, Vice President and Executive Director David R. Brousell. “Those recognized tonight have helped establish a roadmap for the future of the sector and highlight the importance of Manufacturing 4.0.”

Calling All Creators: Creators Wanted Live Arrives at Open Call 2022

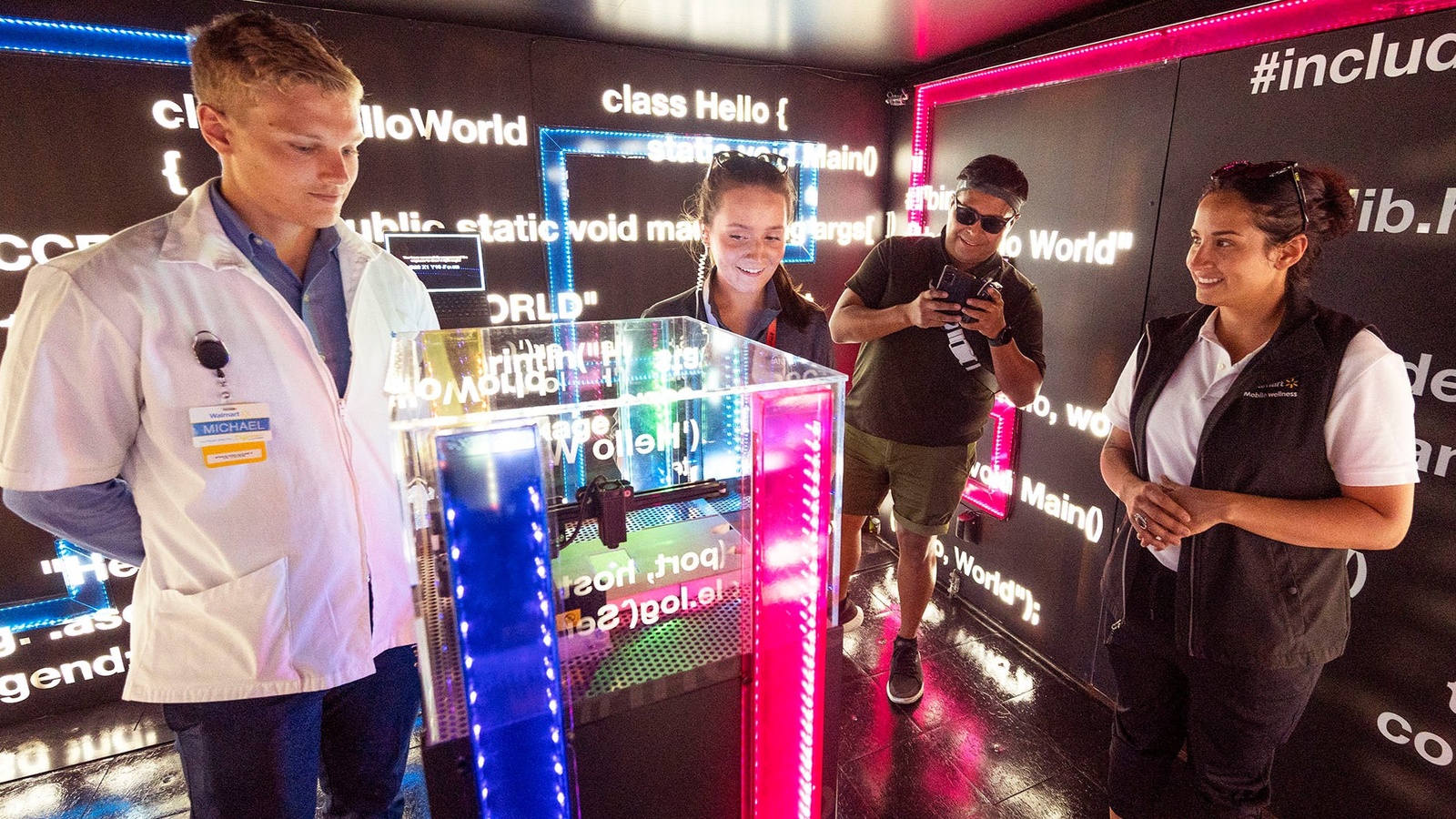

This week, the Creators Wanted Tour Live made its eighth national tour stop—at Walmart’s 9th annual open call for entrepreneurs and manufacturers.

Drawing a crowd: On Tuesday and Wednesday, the Creators Wanted mobile experience was onsite in Bentonville, Arkansas, as 1,100 small and medium-sized business owners pitched their products to Walmart and Sam’s Club for Walmart’s Open Call 2022. The ultimate prize for the business owners? A “gold ticket” to get their products into the stores.

- The two-day Creators Wanted stop drew more than 2,000 people, many of whom jumped at the opportunity to solve puzzles and “race to the future” in the award-winning, immersive escape room.

- In addition to Walmart, Chart Industries, a leading global manufacturer of highly engineered equipment servicing multiple applications in clean energy and industrial gas markets, helped bring the experience to Open Call attendees and the Bentonville community.

- The tour, which aims to generate interest in and excitement about manufacturing careers, is a joint project of the NAM and its workforce development and education partner The Manufacturing Institute.

Committed to manufacturing: The aim of bringing Creators Wanted to this year’s Open Call was to bolster the positive perception of modern manufacturing careers, recruit new manufacturers and connect entrepreneurs and manufacturers with the MI’s workforce-shortage solutions.

- Walmart has committed to spending $350 billion on products made, grown or assembled in the U.S., in addition to the $250 billion the company pledged in 2013 to spend on similar products.

- Total estimated job growth from these investments: 750,000 new American positions by 2031.

Who was there: MI President Carolyn Lee and Vice President of Program Execution Herb Grant were on hand to give manufacturers greater insight into the MI’s growing set of solutions to the dearth of skilled manufacturing labor.

- Also onsite was new Creators Wanted partner FactoryFix, whose team members helped attendee manufacturers source new talent for their businesses and taught job seekers how to build rewarding careers in the industry.

The reaction: “Wherever we go with our Creators Wanted Tour—including here in Bentonville, Arkansas—students, parents, career mentors and even professionals in other industries see what manufacturing can mean and create for futures,” said NAM Managing Vice President of Brand Strategy Chrys Kefalas. “It’s showing there’s dignity, a “cool” factor and massive reward in making things in the United States. Eyes light up.”

The reach: On the second day of the event, more than 3,000 students had already signed up online to learn more about modern manufacturing careers.

Up next: Coinciding with the Dow Great Lakes Bay Invitational on the LPGA tour, the Creators Wanted Tour Live will make its ninth stop in Midland, Michigan, July 13–16.

NAM Drives Conversation on Innovation and Competition

The NAM is urging Congress to bolster American innovation and make the U.S. more competitive with China.

The big picture: NAM Senior Vice President of Policy and Government Relations Aric Newhouse wrote to Congress, “we urge the completion of a strong, bipartisan agreement that strengthens domestic manufacturing, increases our global competitiveness and provides opportunities for the more than 12.7 million people who make things in America.” The NAM’s recommendations include the following:

- Semiconductor manufacturing: Newhouse emphasized the NAM’s support for the $52 billion provided to bolster domestic semiconductor manufacturing in both the Senate’s United States Innovation and Competition Act (USICA) and the House’s America COMPETES Act.

- Supply chain resilience: 88.1% of manufacturers report supply chain issues as their primary business challenge, which is why the NAM supports the creation of the Manufacturing Security and Resilience Program and the $45 billion investment to support supply chain resilience included in the America COMPETES Act.

- Shipping: The Ocean Shipping Reform Act, which has passed both chambers of Congress in some form, is aimed at increasing port efficiency, reducing shipping delays and decreasing transportation costs through the improvement of ocean shipping standards and implementation of better oversight mechanisms.

- R&D: The NAM recommends reversing a new provision in the tax code that requires companies to deduct research and development expenses over a period of years rather than the year the costs are incurred—a provision that effectively makes R&D and innovation more expensive and more difficult for American companies.

- Eliminating card check: “Manufacturers are strongly opposed to the labor and card check provisions included in the America COMPETES Act,” wrote Newhouse. “Implementing ill-considered labor and card check provisions would upend decades of labor precedent with an anti-competitive, anti-democratic process that abolishes the secret ballot and eliminates appropriate oversight.”

Other recommendations: Newhouse also expressed the NAM’s support for policies that reduce emissions and promote sustainability to make the U.S. a global leader in energy efficiency. The letter recommends the reauthorization of the Miscellaneous Tariff Bill, the implementation of strong anti-counterfeiting legislation to protect consumers and small businesses and federal investment to improve the domestic critical mineral supply chain.

Take action on these issues and more at Manufacturers United.

Manufacturers: Lawmakers Must Prioritize Provisions That Will Streamline Essential Domestic Supply Chains and the Production of Key Inputs

Washington, D.C. – Following today’s Senate–House conference committee meeting on the China competition legislation, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“Manufacturers are encouraged by efforts in Congress to reach a strong, bipartisan agreement that strengthens domestic manufacturing, increases our global competitiveness and provides new opportunities for the more than 12 million people who make things in America. The first meeting of the conference committee to finalize legislation reconciling the United States Innovation and Competition Act and the America COMPETES Act is an important step toward overcoming ongoing supply chain disruptions, countering inflation and supporting U.S. manufacturing in the face of major global competitors, namely China.

“Lawmakers must prioritize provisions that will streamline essential domestic supply chains and the production of key inputs, such as an investment of $52 billion to bolster domestic semiconductor manufacturing, the creation of a fund to strengthen supply chain resiliency and inclusion of the Ocean Shipping Reform Act. Manufacturers also support policies to advance and grow U.S. international trade and provisions that strengthen U.S. energy innovation leadership. The conference committee should also avoid labor provisions that would harm American manufacturers and workers alike as we look to fill more than 800,000 jobs in the sector.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.7 million men and women, contributes $2.71 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Case Studies for Success in the Factory

There’s nothing quite like a real-world test run to determine whether a new technology is right for your business. That’s where Rethink, the annual summit of the NAM’s Manufacturing Leadership Council, comes in.

The world’s leading event on Manufacturing 4.0, Rethink boasts an agenda packed with case studies to help manufacturing leaders see exactly how various digital technologies might help them improve their operational quality and efficiency.

The featured case studies coming to Rethink include the following:

- The Expanding Reach of Collaborative Robots: Examine practical applications for collaborative robots in manufacturing. Discover the benefits already being realized from the use of robots and identify ways to maximize the benefits.

- Extracting Insights from Plant Floor Data: See firsthand how to use data to monitor equipment performance, predict conditions and take preemptive action to avoid downtime. Gain practical takeaways on how to leverage data for bottom-line benefits.

- How AR/VR Can Empower Frontline Workers: Take a deep dive into one company’s advanced deployment of augmented and virtual reality technologies. Explore how these technologies helped transform operational activities and empower frontline workers.

- Fostering Data Literacy: The What, Why and How: Learn how to manage and analyze data from all aspects of your operations and use it effectively to improve decision making. Gain an understanding of the emerging discipline of data literacy as a way to overcome business culture hurdles.

How to participate: The Rethink summit takes place June 27–29 in Marco Island, Florida.

- In addition to case studies, the agenda will include inspirational keynote speeches, thought-provoking panel discussions and hands-on think tanks.

- More than 300 top-level executives and their teams attend each year.

- Participants include professionals in operations, IT, supply chain, engineering, C-level management, HR and more.

Click here to browse the agenda and to register.

An ExxonMobil Engineer Makes a Difference

Erika Anderson didn’t always know she wanted to be an engineer. In fact, for most of her childhood, it wasn’t a career path she had even heard about.

- “I didn’t know what engineering was until my senior year in high school,” said Anderson. “I thought an engineer was a train driver, and nobody told me differently.”

A moment of truth: During her senior year, Anderson was told to research the major she wanted to explore after high school. She searched online, looking for careers for people who liked math and science—and the first thing that came up was engineering.

wanted to explore after high school. She searched online, looking for careers for people who liked math and science—and the first thing that came up was engineering.

- “It was all about people who like a challenge; people who are lifelong learners,” said Anderson. “And as I kept reading, I kept hearing myself in this description. People had always said, you’re smart, you should be a doctor or a lawyer. But nobody ever said engineer.”

Her journey: At Spelman College and the Georgia Institute of Technology, Anderson studied mathematics and mechanical engineering, respectively, while working for GE Aviation and NASA. But it was during a semester spent working at ExxonMobil that she found her passion.

- “ExxonMobil was challenging, and I absolutely loved it,” said Anderson. “I loved the boots, the hard hats, getting my hands dirty. I was able to go out into the field, see all the equipment. I was in awe. I fell in love with it.”

Her job: On her last day in the office during her program at ExxonMobil, the company offered Anderson a full-time job. Today, she’s in her eighth year, working as both the reliability engineer and the reliability coordinator in Baytown, Texas. For ExxonMobil, those are critical roles, tasked with ensuring that the company’s equipment keeps functioning as designed. The way Anderson explains it:

- “Your car comes with a manual and it tells you when you’re supposed to change your oil or rotate your tires. And someone has to figure out how long that oil or those tires can run. I’m not dealing with cars, but I’m dealing with heat exchangers, compressors and pumps. I ensure that this equipment works, that it works reliably, and that we’re making repairs at an interval that keeps your equipment working as it should.”

Making a difference: As a Black woman in manufacturing, Anderson is used to being different from the people around her. She has found herself confronting stereotypes and preconceived notions about who she is. It hasn’t always been easy, but she’s doing vital work—and ensuring that other young women have the opportunity to follow their passions.

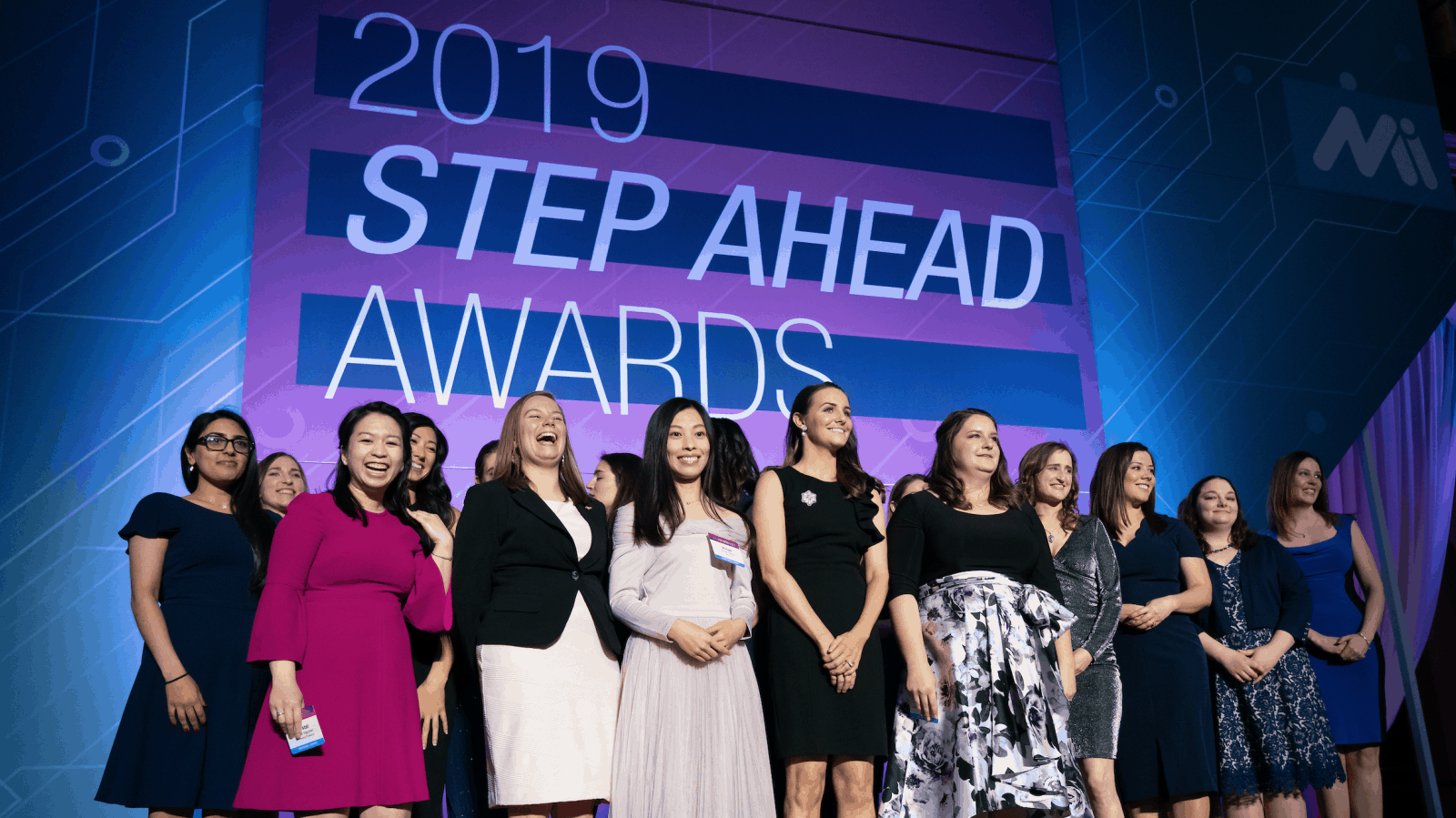

An example to others: Anderson was recently recognized by The Manufacturing Institute, the workforce development and education partner of the NAM, as a 2021 STEP Award Emerging Leader. The award is presented to women leaders in science, technology, engineering and production careers who exemplify leadership within their companies and in manufacturing in general.

- She’s also been featured in a book called Everyday Superheroes: Women in Energy about women in different fields in the energy industry; a TV show on CBS highlighting women in STEM; and a project by The Smithsonian and IF/THEN to put up 120 3D-printed statues of women trailblazers in Washington, D.C.

Advice for others: Anderson is an advocate for other women who are considering a career in manufacturing. She encourages women to find mentors, build a network and, above all, be confident.

- “Self-doubt is real, and sometimes, we can be our own biggest critics,” said Anderson. “We have to understand that we are excellent. We are great. And at the end of the day, for any woman coming to this industry—if you’re even thinking about it—there’s something in you. If it were easy, everyone would be doing it.”

The last word: “My grandmother always told me: you’ve got to get comfortable with being uncomfortable. The only way things will change is by having more people like me in the room. We are just as capable as anyone else, and whatever preconceived notions that may exist, I am here to kick those doors down.”