The Manufacturing Experience: Closing the Gender Gap

The Manufacturing Institute with support from Colonial Life released a new paper that explores what manufacturers are doing to help close the gender gap, incorporating survey responses and interviews with various company executives that identify key insights and practical advice for other manufacturers. To address the workforce shortage, manufacturers need to expand their talent pools, bringing in more diverse and underrepresented candidates.

Women represent a sizable talent pool that manufacturers cannot ignore, especially as the sector becomes more advanced. Earlier this year, the MI launched our 35×30 campaign, which aims to do just that—increase the percentage of women among manufacturers from 29%, where we hover now, to 35% by 2030 by changing perceptions among women and girls about manufacturing as a career, attracting and retaining more female employees.

Read the full report here.

Building the Future Workforce at Rockwell’s Automation Fair

Automation isn’t just changing the manufacturing industry; it’s enabling human-centric progress in tackling the industry’s workforce crisis.

In action: As part of the Automation Fair in Chicago last week, more than 15,000 attendees got to see how manufacturers—and companies like Rockwell Automation—are providing solutions to the shortage, which could reach 2.1 million unfilled jobs by 2030, according to research from the Manufacturing Institute (the workforce development and education partner of the NAM) and Deloitte.

- Rockwell Automation brought the Creators Wanted Tour, a project of the NAM and the MI, to its Automation Fair, giving students, parents, educators and manufacturers the chance to see firsthand how digital transformation and new technologies are supporting careers and opportunities in modern manufacturing.

- The tour’s much-heralded immersive experience, along with displays and programs featuring experts from the MI and the Manufacturing Leadership Council (the digital transformation division of the NAM), gave attendees insight into the pathways and support available in the industry.

- FactoryFix, the official recruiting partner of Creators Wanted, was also on hand to showcase its manufacturing talent platform for job seekers—and manufacturers searching for a one-stop recruiting solution.

Changing perceptions: Creators Wanted aims to shrink the workforce gap by dispelling myths about automation and attracting the next generation to manufacturing jobs. It’s seeing impressive success, MI President Carolyn Lee said during a session at the event.

- “Today 40% of parents have a positive perception of manufacturing,” Lee said, citing a recent joint Deloitte–MI study. “And what we’re finding is that parents see these are durable careers with great possibility and opportunity, and they’re encouraging their children to consider them.”

Digital help: “Digital is going to help manufacturers deal with their workforce issues because it’s going to not only help change the perception of the industry, but create new jobs going forward, particularly in math-intensive areas like data analytics and artificial intelligence,” said MLC Vice President and Executive Director David Brousell.

- Brousell cited the MLC’s “Manufacturing in 2030 Project,” saying, “We have to think about digital transformation as human-centric digital transformation—because we’ve got to bring the technology and the people together simultaneously to have an effective transformation.”

Impressive results: Since it began just more than a year ago, the Creators Wanted Tour has seen more than 8,000 students pass through its immersive mobile experience, where more than 75% of attendees leave with a significantly improved view of manufacturing.

- More than 510,000 students and career mentors have also signed up to learn more about modern manufacturing careers.

- Creators Wanted has recruited successfully both mentors and mentees for the mentorship program of Women MAKE America, an MI initiative that aims to close the gender gap in manufacturing.

- The Automation Fair offered more than 150 interactive sessions on the newest industrial solutions and best practices, and more than 200 companies exhibited across 200,000 square feet at Chicago’s McCormick Place.

Media mentions: The fair and Creators Wanted’s presence drew a slew of media coverage, including from “Morning in America” with Adrienne Bankert, “The John Howell Show” on WLS-AM, Univision Chicago and suburban Chicago’s Daily Herald.

- In addition, the Daily Line published an op-ed on the future of manufacturing by NAM President and CEO Jay Timmons and Rockwell Automation Chairman and CEO and NAM Executive Committee member Blake Moret.

The last word: “As the world’s largest company dedicated to industrial automation and digital transformation, Rockwell is always looking toward the future of manufacturing,” Moret said. “Campaigns like Creators Wanted are critical to recruiting the best future talent to create a thriving workforce.”

“Cybersecurity Finds You”: An Interview with Rockwell Automation’s CISO

When asked how she got into cybersecurity, Nicole Darden Ford replies “cybersecurity kind of finds you.” The new chief information security officer at Rockwell Automation began her career in the military, where she first got into cybersecurity, then created a cybersecurity program for the U.S. Department of Agriculture before taking several leadership roles in the private sector.

Today, her advice for companies is surprisingly similar: cyberattacks will find you. As she puts it, “It’s not if, it’s when. And it’s not one time, it’s several.”

So how should manufacturers prepare for these threats? We spoke to Darden Ford recently about her recommendations, as well as Rockwell’s efforts to safeguard its own supply chain and provide services to other companies.

The current situation: “Manufacturers account for 65% of industrial ransomware last year. We’ve seen an unprecedented number of attacks, and we’ve seen attackers focus on OT,” Darden Ford says. She predicts the attacks on OT will only escalate.

- Meanwhile, many manufacturers have a clear strategy for IT, but they have not given as much thought to protecting their operational technology. Yet, as machines get more connected, their operations may become more vulnerable—especially as companies try to integrate legacy systems that weren’t “meant to be connected or patched.”

- In addition, “because we are so connected, there are third-party risks,” Darden Ford says. Small manufacturers may be more inviting targets for hackers than they realize, since their systems could provide a back door into the networks of their larger clients.

- On the plus side, manufacturers are getting smarter in building their defenses, she says. And that’s where Rockwell comes in.

Rockwell’s role: Rockwell aspires to become a “trusted advisor” to companies seeking cyber defenses, says Darden Ford. It already manufactured OT, so moving into cybersecurity for such equipment was a natural next step.

- Its partnerships with other firms, including Dragos, CrowdStrike, Cisco and others, allows

Rockwell to offer bespoke cyber monitoring and other services to its clients.

Rockwell to offer bespoke cyber monitoring and other services to its clients. - These services include penetration testing, threat detection and response and an OT “SOC”—i.e., a security operations center, which monitors threats to clients’ operations remotely.

How it works: “We have an OT cybersecurity roadmap—it starts with an assessment in your specific OT space, then walks through potential risks,” Darden Ford says. (See the end of this article for her detailed description of this roadmap.)

- The process includes building an “asset inventory, as you can’t protect what you don’t know.”

- “Then we talk about ways you can reduce your attack surface,” Darden Ford continues. “This is about segmentation. We help organizations divide their network into different domains. If you have ransomware or malware that propagates very quickly, then you have the opportunity to quarantine it.”

- In addition, the roadmap helps companies decide which tools and resources to use. For OT, you need to use very passive systems that don’t interfere with “getting the product out the door,” Darden Ford says.

After this process is complete, Rockwell’s SOC helps clients stay safe and hone their responses to real attacks.

- The SOC keeps eyes on a company’s operations remotely, notifies it of breaches within the plant network and helps it decide which threats to tackle. As Darden Ford says, the SOC stands in for the teams that companies would otherwise have to hire themselves.

On-site resources: Manufacturers can tap their existing staff to work on cyber defenses, including with offsite monitors. Darden Ford recommends drafting “the plant engineering team, along with the IT team,” who would have the knowledge and resources required.

A community effort: Large manufacturers should help educate small manufacturers on cyber issues, says Darden Ford.

- “We have a lot of suppliers, so to mitigate third-party risk, we provide more awareness about OT and advice about upping their cyber hygiene. We work closely with suppliers and do a lot of knowledge sharing,” she says.

Collaboration at the top: In addition, it’s also beneficial for CISOs and manufacturing leaders to consult their peers in what Darden Ford calls “mastermind sessions.”

- These conversations have provided her with “a lot of insights and data,” she says. She gets indispensable input on “strategies, frameworks, journeys and roadmaps,” as companies try to find their way through this cyber landscape together.

The bottom line: When asked what she says to companies that doubt the need for cyber protections, Darden Ford has a simple answer: “You wouldn’t drive your car without insurance—that’s what this is.”

- “What used to be optional is becoming mandatory,” she adds. “For small or midsize companies, you are still going to have to report” back to your large customers, many of whom require stringent protections of their suppliers. Those requirements will only get “more and more rigorous over time,” she warns.

- In other words, however you choose to do it, “you need a plan.”

The Roadmap

Darden Ford supplied us with her account of Rockwell’s cyber roadmap for its own suppliers, below. “The playbook aligns with the NIST framework, showing you step-by-step how to audit your current security state, identify gaps and take a proactive approach to mitigate risk,” she says. Here is her account of the key steps.

Step #1: Discover

- Know where you stand. Conduct a security and risk assessment—log all issues and review progress against findings.

- You can’t protect what you can’t see. You must gain a full understanding of what network assets you have on your plant floor and their current state. Start by conducting extensive network discovery and asset inventory.

Step #2: Remediate

- Work with stakeholders to prioritize assets and organizational risk levels. Take the necessary steps to eliminate, upgrade or replace unneeded, unused or unsupported OT applications and infrastructure. This will look different for every organization based on what you discover in Step #1.

Step #3: Isolate

- Establish a perimeter by physically and logically segmenting your networks. Put up a firewall and establish internal and external cybersecurity policies to protect your OT assets. Set up an on-premises industrial data center to encapsulate critical applications inside the protected OT network.

- Secure endpoints with security software on plant floor assets.

- Enable third-party remote access. Third parties need access, but you must control the access and maintain visibility into what they’re doing in your network by enabling OT access controls.

Step #4: Monitor and Respond

- Now that you have a solid foundation in place, the next step is to implement OT network monitoring to provide real-time OT cybersecurity, including malicious event/asset risk alerting, network diagnostics, AI learning and KPI dashboarding. The data only works for you if you are continuously viewing and reacting to it.

- Establish an OT SOC for 24/7 real-time alert monitoring, acknowledgement and triage. Cyberattacks aren’t limited to 9–5.

- Create an integrated IT/OT cyber event response team. Define event response and isolation protocols. IT/OT must have equal involvement and buy-in for these protocols to be successful. Execute tabletop exercises to simulate attacks and outcomes.

How Managers Can Produce Top-Notch R&D

As innovation in manufacturing continues at breakneck speed, research and development is more important than ever—but it requires outstanding managers to make it all happen.

So how do these managers get the education and insights they need? The Innovation Research Interchange, a network of cross-industry innovators that the NAM combined with earlier this year, has an answer: an executive management course called Shaping Innovation Leaders.

The gist: Co-hosted by the Kellogg School of Management at Northwestern University, the course provides a forum for strategic thinking, education and networking for technology leaders from around the world.

- In 2023, it will take place on May 13–19 on the Northwestern campus in Evanston, Illinois.

The details: The goal of this seven-day program is to develop midlevel managers into leaders for their companies, by covering topics including:

- Evaluating financial results;

- Segmentation, targeting and positioning;

- Growing and defending your brand;

- Legal and strategic investments;

- Building a better network; and

- Negotiating skills and strategic alliances;

Who’s involved: To get a sense of this event’s caliber, look no further than the attendees from the 2022 course.

- They hailed from a wide range of companies, including manufacturers such as Mars, Procter & Gamble, John Deere, Hershey, NatureWorks, Air Liquide, Kimberly-Clark Corporation, Sherwin-Williams and many, many more.

The reviews are in: Participants in the 2022 course were enthusiastic about what they learned and experienced.

- “[I’m] really super impressed with the program, soup to nuts,” said John Deere Manager for Global Strategic Communications & Culture Jacqueline Kiple. “One of my favorite aspects of the program was really getting a chance to think about our business a little bit differently … to take a step back and think about the higher-level impacts that affect decision-making in our respective organizations.”

- “What I really enjoyed about this course was first and foremost the esteemed professors. … [The course] gives you a really big view of all the information you need to really understand business and understand the decisions that are getting made,” said Sherwin-Williams Associate R&D Director Tony Rook. “It gives you that top-level view of how you add value to [your] organization.”

Get involved: Registration is now open for the 2023 course. You can find additional information and register here.

How Adaptive Skills Can Play a Pivotal Role in Building the Manufacturing Sector of the Future

This new research from MI and EY on adaptive skills in the manufacturing workplace. What are adaptive skills? Simply put, they are skills or traits that enable individuals to transform their abilities as their demands and environment change. There is a need for broader and evolving skillsets in the manufacturing sector and for building a workforce motivated by opportunities for growth. Doing this will help manufacturers transition to workplaces to a point where forward-thinking, engaging, and digitally enabled work is the norm.

Future Skills Needs in Manufacturing: A Deep Dive

The Manufacturing Institute, in partnership with Rockwell Automation and PTC, released a forward-looking study on where the manufacturing sector will be headed over the next 5 to 10 years and how those changes will impact the necessary skills that will be required of employees. More advanced processes and innovations will necessitate enhanced data and technological skills. As a result, manufacturers will need to support or provide new elements of continuous learning for existing employees, and the skill sets of new employees will need to become increasingly more sophisticated. At the same time, soft skills will always be important. This need for advanced skills sets for modern manufacturers comes against a backdrop of a tight labor market, complicating the search and heightening the already fierce competition for talent.

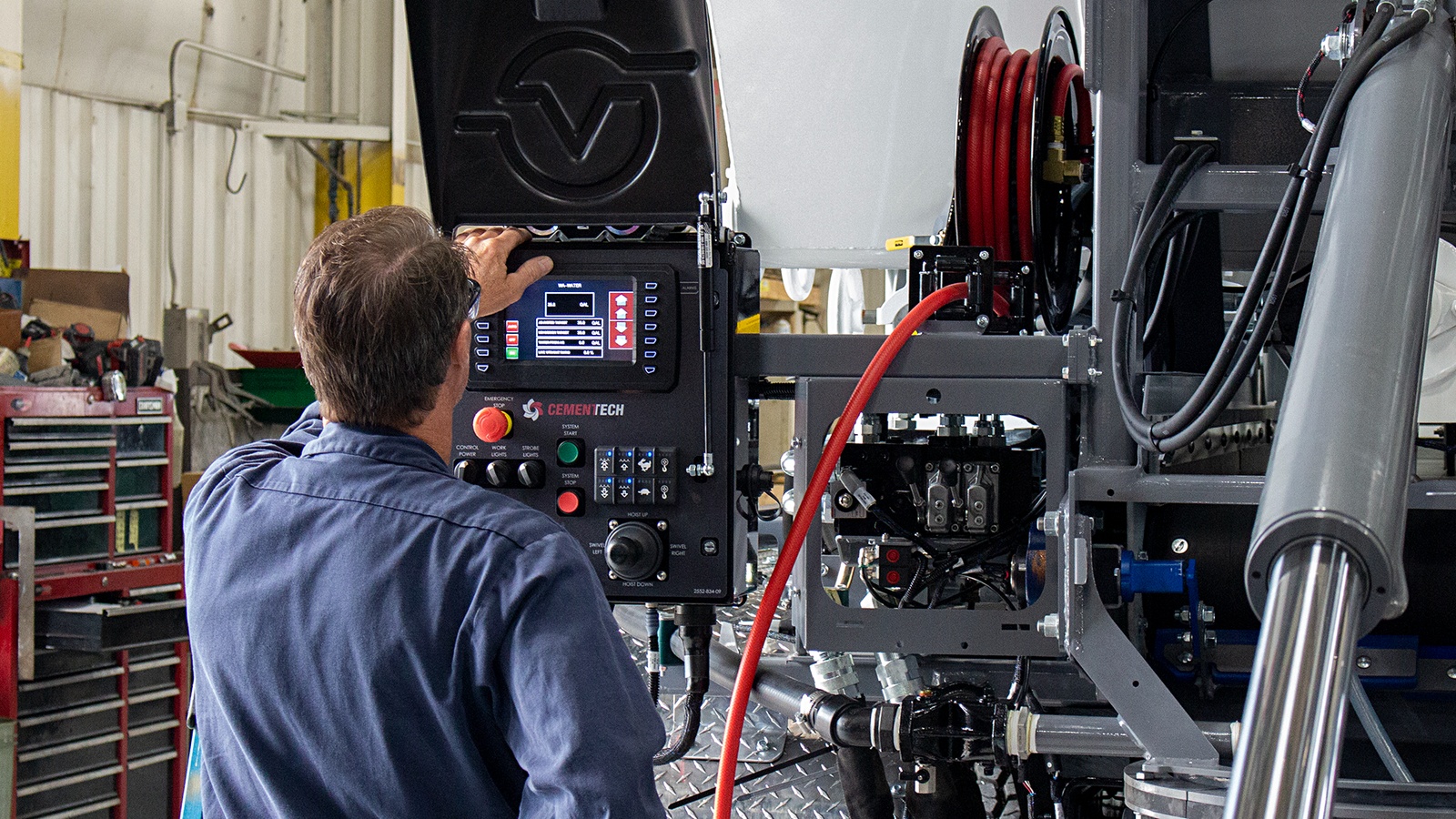

Concrete Mixer Maker Finds a Growth Formula

Even amid so much economic uncertainty, Cemen Tech is on track for a year of unprecedented growth. Leaders of the company, the world’s largest manufacturer of volumetric technology, attribute a good deal of its success to its loyal workforce.

Allegiance creator: Just what contributes to that worker loyalty? The answer may well be Cemen Tech’s unusual generosity.

- “We considered a number of new and different ways to continue to attract and retain good people,” Cemen Tech President and CEO Connor Deering said. “In September 2021, we made the decision to cover 100% of employee health insurance costs, the net effect of which is essentially our folks taking home more of the money they earn. That has really helped with retention.”

- The Indianola, Iowa–based company also raised wages across the board and began offering employees season tickets for local sports teams.

A new approach: Full health insurance coverage made a difference when it came to attracting and keeping workers, but the volumetric concrete mixer manufacturer was still hitting another roadblock when it came to employment: finding people with the right qualifications. So, it set out to solve the problem in house.

- As part of a planned facility expansion, the company is setting aside space for the new “Cemen Tech University,” an innovative answer to the question of how to develop employees with highly desired, specialized skills. Classes are tentatively set to start in January 2023.

- The company is also working with area high schools and technical schools to forge partnerships in which students work for Cemen Tech part time, while still pursuing their diplomas or degrees.

- “This way, we train applicants for immediate success on the job, helping to ensure a strong fit between the employee and the company from the start,” Deering said. “It also gives us an opportunity to teach new hires about our organizational culture. … I believe [our education efforts] will help support an educated team member who’s connected to our culture, resulting in a happier, better and more long-term employee.”

More incentives: Last March, Cemen Tech found a way to boost shift-worker attendance with a points-based rewards system.

- “We implemented an attendance bonus—if an employee stays within a certain number of points [for coming to work], they can earn an additional $90 a week,” said Cemen Tech Director of Human Resources Emily Lyons. “We have seen that help in terms of attracting and retaining employees and further incentivizing employees to achieve consistent attendance.”

- The company has also increased the referral bonus given to existing employees who bring in new hires, Lyons said.

Advice: Manufacturers looking to see similar growth to Cemen Tech, which is set to expand 65% this year, should consider implementing some of the firm’s ideas (if financially feasible). But companies should be prepared to incur some financial cost along the way.

- “Our growth has helped offset the profitability loss [from the increased benefits], but the reality is that our business is people,” Deering said. “If we don’t have people—good people—we’re not going anywhere. So, the fact that we’re little less profitable at the moment is OK, as long as we can continue to grow.”

Creators Wanted Moves the Needle in Decatur

While participants were having fun at this week’s Creators Wanted stop in Decatur, Illinois, the nationwide tour and its mobile experience were doing something, too: moving the needle on people’s perceptions of modern manufacturing.

What went on: Over the course of three days, more than 800 students from 13 area middle schools, high schools and community colleges poured into Richland Community College to learn about manufacturing careers. Also present were many educators and parents.

- Attendees “raced to the future” in the Creators Wanted mobile experience, solving various manufacturing-related challenges as they wound through the escape room.

- They heard panel talks from manufacturing leaders and team members and learned about some of the industry’s many perks, including great wages, flexible schedules, upward mobility, chances to earn and learn and more.

- Interactive activities, set up and run by manufacturers and the campaign’s recruiting partner, FactoryFix, were designed to garner interest—and display some of the real work done every day in modern manufacturing.

- This included virtual-reality paint and assembly training from Creators Wanted host sponsor Caterpillar, as well as a hazard-awareness simulator, a drink-making station and a laser-system exhibit from host sponsor ADM. Richland Community College took students on a tour through its state-of-the-art lab.

Generation inspired: Manufacturing leaders at ADM, Caterpillar and the Illinois Manufacturers’ Association, which together brought the tour to Decatur, got the chance to galvanize crowds.

- Said IMA President and CEO Mark Denzler: “Manufacturing makes the world a better place to live every day. Some of you are going to find the next cure for a disease. You’re going to build the next robot.”

- “For anyone who really is looking for a career that you can get into that is good-paying, that will provide you an opportunity to progress, consider manufacturing,” Caterpillar Group President of Resource Industries (and NAM Executive Committee member) Denise Johnson told the crowd.

- Following the event, students were indeed inspired. “It kind of changed my mind on what I want to do in the future,” one student

- “It was amazing,” said another. “I’d think about doing this for a career.”

Shoring up the shortage: The lack of skilled workers has been a pain point for manufacturers for several years now—and it’s a problem Creators Wanted aims to fix.

- “Programs like Creators Wanted are crucial in narrowing the workforce shortage in manufacturing and also showcasing the many opportunities within the manufacturing industry,” said ADM Senior Vice President of Global Operations and NAM board member Veronica Braker.

The impact: The tour stop made a splash in regional media, garnering overwhelmingly positive broadcast coverage and print mentions and placements (see here and here).

Meeting people where they are: “How do you get more young people interested in the field [of manufacturing]?” 25 News WEEK-TV anchor Erin Brown asked in a segment for the Peoria, Illinois, news station. “The answer could be more hands-on experiences with businesses like Caterpillar and ADM.”

Creators Wanted “Lends a Helping Hand” in S.C.

Last week was a milestone for the Creators Wanted Tour—it marked the first time the nationwide initiative returned to a community and got to see how perceptions of manufacturing had changed since its first visit.

Welcome back: The Creators Wanted Tour, a joint venture of the NAM and its workforce development and education partner, The Manufacturing Institute, returned to host and champion sponsor Nephron Pharmaceuticals Corporation in West Columbia, South Carolina, in the 11th stop of the roadshow, which took place Oct. 4–7.

Happy MFG Day! On MFG Day, Oct. 7, Creators Wanted campaign co-chair Lou Kennedy, president, CEO and owner of Nephron Pharmaceuticals Corporation, and her team hosted the tour stop’s premier event at its new Nephron Nitrile Glove Factory. The 426,000-square-foot facility is scheduled to open next month and will produce nitrile gloves used in hospitals and sterile rooms globally.

- The protective-glove shortage in the U.S. during the pandemic inspired Kennedy to build the factory, which is set to produce 2 million gloves a year at full capacity.

- South Carolina legislators from both sides of the political aisle were on hand for a tour of the site. House Democratic Majority Whip James Clyburn and Republican Reps. Joe Wilson and Jeff Duncan joined hundreds of local students, educators, community leaders and manufacturers to view and learn more about the campaign and its resources.

Ready for the “boom”: “There is a manufacturing boom taking place all over the country,” Majority Whip Clyburn said. “We’ve got to focus on getting these young people prepared” for manufacturing careers.

- As Rep. Wilson said, “The opportunities for manufacturing just can’t be better.”

- “401(k), great salary—average wage of 75 to 80K—clean and beautiful working conditions and hard work with a lot of fun,” Kennedy said of jobs at Nephron, while extolling opportunities at modern manufacturers across the state and in nearby communities.

- Major Creators Wanted supporters Honda and Trane Technologies also have operations in the Palmetto State, and several other campaign sponsors, including Chroma Color Corporation, are within a short distance of West Columbia.

More career guidance: Students seeking tailored advice about their professional futures got it from representatives of FactoryFix, official recruiting partner of Creators Wanted, who were on hand to meet and coach job seekers.

- South Carolina Chamber of Commerce President and CEO Bob Morgan, whose organization is a tour partner, was on site with his team to give students information on manufacturing opportunities in South Carolina.

- On Friday, Creators Wanted sponsor Autos Drive America had an exhibit showing attendees the types of vehicles being manufactured in South Carolina.

Women in manufacturing: During a “fireside chat” panel on the tour stop, Kennedy was joined by Autos Drive America President and CEO Jennifer Safavian and MI President Carolyn Lee to discuss the importance of advancing more women in manufacturing.

- “Growing up here in the deep south 20, 30 years ago, we were supposed to be teachers or … nurses; we weren’t supposed to be pharma CEOs,” Kennedy said. “And so, my goal is to help every young lady be what she wants to be, even if it’s the nontraditional career path. … If you want to be a super-genius chemist, you can do that. If you want to be a super-genius engineer, you can do that.”

- Echoed Safavian, “I think the message [of Creators Wanted] is, ‘Don’t be afraid to ask questions. Don’t be afraid to try something. For women especially, this is a terrific opportunity. … A lot of people think manufacturing is dark, dirty, dangerous. It is not. … it is the complete opposite.”

Calling all veterans: Modern manufacturing is also a natural fit for those who have been in the military, speakers told the audience during another panel discussion.

- “I started at Nephron as a senior system analyst, and throughout my career everything that I was faced with at Nephron I’d already seen in the military,” said Air Force veteran Eric Jackson, now a senior IT security analyst at Nephron. “So, I think the [military] training … is what prepared me for this job.”

The reach: The South Columbia 2022 tour stop, made possible by additional support from Dow, Honda and Nephron Pharmaceuticals, was a record breaker.

- More than 700 students from 13 schools—most located in traditionally underrepresented communities—participated in the tour stop’s events. Last year, those numbers were 500 and seven, respectively.

- This year’s West Columbia email signups—people wishing to learn more about manufacturing careers—brought Creators Wanted’s total signups to more than 520,000.

The last word: The tour stop may have been best summarized by one young student who attended the events. “Creators Wanted,” she said, “is a helping hand.”

Creators Wanted Inspires Students in Tennessee

If you’re a student or job seeker looking for tailored career guidance combined with some hands-on, immersive fun, White House, Tennessee, was the place for you to be last week.

National impact: The Creators Wanted Tour, a joint project by the NAM and MI, made its 10th national tour stop at White House Heritage High School on Sept. 27–29.

- There, more than 700 students from four schools in Tennessee’s Robertson County went through the Creators Wanted mobile immersive experience, the award-winning, manufacturing-themed escape room–like activity in which participants work together to solve challenges in a “race to the future.”

- They also got the opportunity to chat with on-site sponsor representatives from Electrolux, Schneider Electric and FactoryFix about the many rewarding, well-paying career paths available in the industry.

- Local partners, including the Robertson County Economic Development Board, the Tennessee Chamber of Commerce & Industry and the Tennessee Manufacturers Association, were also on hand to answer jobs- and manufacturing-related questions.

Calling all creators: During the Tennessee stop’s premier event, speakers underscored the need for more skilled workers to fill the millions of open manufacturing jobs in the U.S.

- “Here in Tennessee, our industry has more jobs to fill than there are people looking for them,” Tennessee Chamber of Commerce & Industry and Tennessee Manufacturers Association President and CEO Bradley Jackson said.

- Speaking from firsthand experience about the many benefits of choosing one of those jobs was Tony Fraley, a plant manager for Electrolux. “I’m living proof of the great career opportunities in the field of advanced manufacturing,” said Fraley, who started at the company “running a process that coats dishwasher racks.”

- “I grew up about two hours from here in a small town very similar to White House,” he continued. “I always liked math and science. … I hope that stories like [mine] inspire the next generation of workers to consider a career that’s not only been good to me, but also offers a strong opportunity to earn a family-sustaining wage in a high-demand field.”

The numbers: The Tennessee stop resulted in more than 52,000 email signups from people interested in learning more about manufacturing careers.

An eye-opener: Students had a great time at last week’s events—and were pleasantly surprised to learn just how many interesting options manufacturing could offer them.

- “Creators Wanted made me excited about my future,” said one student.

- Added another, “Creators Wanted made me think more about my future in manufacturing.”

The last word: It’s past time for manufacturing careers to get their due as the gratifying professions they are, according to the Creators Wanted Spotlight panelists (and manufacturing company employees).

- Manufacturing “is definitely very rewarding [from a salary standpoint] but also the lifestyle that you get to have,” said Schneider Electric Manufacturing Engineer Zoie McFarland. “I get to go boating every weekend. I get to go hiking. I travel a lot. … Also, I was able to buy a house at 25. So, I think that is one major benefit—the lifestyle [manufacturing] gives you and the benefits that come from it.”