NAM Strengthens Policy Expertise with New Leadership

Washington, D.C. – The National Association of Manufacturers announced the promotion of Charles Crain as its new vice president of domestic policy. Crain previously served as the NAM’s senior director of tax and domestic economic policy, where he led successful policy efforts on a range of tax and corporate governance issues.

In this new role, Crain leads the association’s focus on a range of priorities, including advancing competitive tax and corporate finance policies, pushing back against the regulatory onslaught facing the industry and advocating policies that strengthen manufacturers’ ability to develop lifesaving treatments. He will also bring together the expertise of the NAM’s Manufacturing Leadership Council and Innovation Research Interchange to drive the debate around the role of AI and technology in the future of manufacturing.

In addition to Crain, the lead policy experts for the association include Vice President of Domestic Policy Brandon Farris, who leads the energy, sustainability, labor and infrastructure policy portfolio; Vice President of International Policy Ken Monahan; and Chief Economist Chad Moutray. In July, Managing Vice President of Policy Chris Netram took the helm of the policy division.

“The NAM’s best-in-class policy team is made stronger with the elevation of Charles Crain. Charles has a track record of success that has benefitted manufacturers, and they will benefit even more from his leadership in this new role. As technology continues to play an increasingly critical role in manufacturing, Charles will be a leading voice in ensuring policymakers foster an environment where our industry can stay globally competitive,” said NAM President and CEO Jay Timmons. “Moreover, the integration of policy, government relations, communications, public affairs and brand strategy within the NAM ensures that manufacturers will be a driving force inside and outside the Beltway on every issue important to the industry.”

“Charles’ new role ensures that manufacturers will have an experienced advocate who can move the needle in debates on tax, health care, corporate finance, regulatory reform and technology policy. These critical issues are key to manufacturing competitiveness,” said Netram.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.91 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Creators Wanted and Union Pacific Dazzle the Twin Cities

Last week, Saint Paul College in St. Paul, Minnesota, which boasts a student body that is 65% people of color, became the 19th stop of 20 for the Creators Wanted Tour, a joint project of the NAM and the Manufacturing Institute, the workforce development and education affiliate of the NAM.

Over three days, with Union Pacific as the lead sponsor, the stop drew more than 600 visitors, from students to educators. Meanwhile, 42,000 online signups in Minnesota helped the campaign surpass 1.5 million nationwide from students and career mentors interested in modern manufacturing careers.

Twin Cities kickoff: Union Pacific Executive Vice President of Marketing and Sales Kenny Rocker gave the keynote address at the kickoff event, emphasizing the reward of manufacturing careers. He was joined by MI President and Executive Director Carolyn Lee, Saint Paul College President Dr. Dee Dee Peaslee, Minnesota Chamber of Commerce President and CEO Doug Loon and Trane Technologies Vice President of Product Management Dave Molin.

keynote address at the kickoff event, emphasizing the reward of manufacturing careers. He was joined by MI President and Executive Director Carolyn Lee, Saint Paul College President Dr. Dee Dee Peaslee, Minnesota Chamber of Commerce President and CEO Doug Loon and Trane Technologies Vice President of Product Management Dave Molin.

- “When I talk about opportunities, I’m talking about really good-paying jobs … At Union Pacific, we’re talking jobs that are … averaging over $100,000 a year, and that’s without benefits, and so you just really have an opportunity to make an impact from that perspective,” said Rocker.

- “At Trane Technologies, our vision is to boldly challenge what’s possible for a sustainable world,” added Molin. “It is the engine of our company, and we live it every day. And to do that, we need bright minds and the best minds in the world. We need diverse thinkers, we need creators, and our doors are open to everyone.”

- Notably, leaders from key government business and workforce partner organizations attended the kickoff, including the Minnesota State Advanced Manufacturing Center of Excellence, Minnesota Black Chamber of Commerce, Minnesota Parent Union and St. Paul Area Chamber, representatives from the offices of U.S. Reps. Brad Finstad (R-MN-1), Angie Craig (D-MN-2), Dean Phillips (D-MN-3), Betty McCollum (D-MN-4) and Michelle Fischbach (R-MN-7), Mayor of South St. Paul Jimmy Francis and State Reps. Jon Koznick (R), Emma Greenman (D) and Samantha Sencer-Mura (D).

Experience and exploration: Students delved deep into immersive activities, from solving manufacturing-related puzzles in the Creators Wanted mobile experience to virtually navigating a locomotive through Union Pacific’s simulators. Equally captivating was the sight of the actual railroad track, which was complemented by insightful career anecdotes from Union Pacific professionals.

- Eighty-seven percent of students surveyed reported a significantly improved view of modern manufacturing careers after completing the immersive experience.

Live Q&A sessions: The stop also offered structured opportunities for students to learn about manufacturing organizations’ support for the next generation of talent, along with the importance of mentorship and personal development in shaping successful careers.

- The first session, featuring two Union Pacific senior managers—Amy Bang, Sr. manager of diversity and inclusion, and Ken Kuwamura, Jr., manager of talent acquisition—and Saint Paul College instructors, zeroed in on the crucial roles of mentorship, diversity and passion in career selection.

- The second session, with Jake Yernberg, automotive instructor, Saint Paul College; Caitlin Bundy, manager of corporate sustainability, Union Pacific; and Preeti Subramanian, senior product manager, Trane Technologies, accentuated the pivotal role of manufacturing in tackling global challenges. Panelists pointed out the advantages of the manufacturing sector, citing competitive pay and the sector’s potential in addressing global issues, such as sustainability and climate change.

Interactive Learning: Everfi®, Ecolab and Schwan’s joined Union Pacific in bringing in representatives to give students career advice—and offer activities to spark their curiosity.

- Everfi® showcased a new digital education program, “Future Creators,” co-developed with the MI and Union Pacific, to give middle and high school students a peek into STEM careers.

- Saint Paul College also took students on a tour of its robust Trades and Technical Education program.

Beyond the Tour: The Twin Cities event is a part of Union Pacific’s overarching “Careers on Track” initiative, which aims to inspire more women and youth to pursue modern industrial careers, and the Creators Wanted campaign’s sustained drive to enhance perceptions of manufacturing careers in the United States and empower more people to create the future.

The last word: “I want all of you out here, the students, to have an opportunity to go out there and win and compete and further your careers and do well in life,” said Rocker, echoing a theme the Creators Wanted Tour has promoted since its inception: manufacturers and manufacturing care about students and their future.

Next up: The pioneering Creators Wanted Tour concludes next month, Oct. 17–21, at the Circleville Pumpkin Show in Circleville, Ohio.

NAM Leads Inaugural North American Manufacturing Conference

On Sept. 19–20, the NAM convened the inaugural North American Manufacturing Conference in Washington, D.C., along with its counterpart associations from Mexico and Canada, the Confederation of Industrial Chambers of Mexico and Canadian Manufacturers & Exporters.

What’s going on: The conference provided an opportunity for North American manufacturing executives and government representatives to share perspectives on the opportunities and challenges facing the sector across the region. At the conference, industry leaders discussed the need to:

- Ensure that North America has the affordable and reliable energy needed to support the manufacturing industry;

- Support more regional competitiveness, greater growth and the success of the United States–Mexico–Canada Agreement; and

- Address regional workforce needs in the U.S., Mexico and Canada.

Deepening ties: On Wednesday, the NAM, CONCAMIN and CME signed a memorandum of understanding that will serve as a roadmap for future cooperation between the three organizations and support close economic ties between the U.S., Mexico and Canada.

- The memorandum calls for the organizations to share information about each one’s services and activities, and to work together to shape the continent’s future manufacturing agenda.

- In addition to leaders from the NAM, CONCAMIN and CME, speakers at the event included U.S. Trade Representative Katherine Tai, ExxonMobil Senior Vice President Neil Chapman, Toyota Motor North America Executive Vice President – Product Support and Chief Quality Officer Chris Nielsen, Rep. Adrian Smith (R-NE), Bombardier Head of U.S. Strategy Tonya Sudduth, Energy Transfer Co-CEO Tom Long and Caterpillar Inc. Chief Technology Officer and Senior Vice President of Integrated Components and Solutions Division Karl Weiss.

Common principles: “Shared values, shared prosperity” was a central theme of the conference, echoing President Biden’s remarks at the U.N. General Assembly earlier this week.

- “As president of the United States, I understand the duty my country has to lead in this critical moment; to work with countries in every region linking them in common cause; to join together with partners who share a common vision of the future of the world,” President Biden said in New York on Wednesday.

- “There’s never been a greater need for us to stand together,” NAM President and CEO Jay Timmons said. “The world is caught between different political and economic systems. Our system here in North America enriches lives and lifts people up into freedom and prosperity, while other systems oppress their people and rob them of their liberty,” he continued, adding that the USMCA, of which the NAM is a longtime advocate, serves as a reminder “of what we can achieve when we work together.”

Strengthening the region: Throughout the conference, discussions focused on three components of a successful North American economy—growth, resilience and competitiveness—and the critical role manufacturers play in that system.

- “Today, we live in a new reality,” CONCAMIN President José Antonio Abugaber Andonie said. “The commercial competition with China, the pandemic, the conflict in Ukraine … [all] place us before a second great industrial transformation in North America. … Some call it nearshoring, friend-shoring, ally-shoring or reshoring. No matter the name, the truth is that this phenomenon is modifying the structure of international industrial organization. North America is the epicenter of this transformation.”

- Added CME President and CEO Dennis A. Darby: “Manufacturers are an important driver of economic development and prosperity. We are key players in the changes and challenges of the 21st century.”

A Footwear Company Strives for Circularity

Within the footwear business, Okabashi is unique. The company, based in Buford, Georgia, is not only a family-owned company focused on sustainability, but also, according to the company’s leadership, producing part of the 1% of footwear still made in the United States.

For third-generation shoemaker Sara Irvani, this choice to build a sustainable and successful business in the U.S. was made possible only thanks to constant research and development.

The backstory: Irvani’s family started the company 40 years ago, and it always tried to reduce waste, both for the positive environmental impact as well as to improve its bottom line.

- “By developing closed-loop manufacturing processes, we were able to reuse some of the materials that otherwise might have gone to waste,” said Irvani. “That helped us stay more competitive—and from there we’ve developed innovations in processes and systems and materials that build on that foundation.”

The process: Okabashi’s sustainable processes extend throughout the product lifecycle—from incorporating recycled or biological elements (like soy) that ensure products last longer to preventing disposable waste to recycling post-consumer shoes into new ones.

- “When we look at sustainability of a product, we do it holistically—we look at what it’s made of, where it’s made, how it’s made, the lifecycle, the quality—and we’ve been able to innovate and develop so that our manufacturing process doesn’t create waste,” said Irvani.

- “Without R&D, we would not only be creating the additional cost basis of throwing away all those scraps, but we would also not be able to eliminate waste that is by default landfill or ocean bound.”

The circular economy: In the traditional, linear economic model, inputs go into production, a product reaches a consumer, the consumer uses the product and eventually throws it away. In contrast, Okabashi is working to perfect a circular economic model for its products, said Irvani.

- “If you are designing for circularity, you might use renewable and recycled resources, develop them into that same product with a level of quality that lasts longer, and when the customer is ready to move on, it can be remade into something else,” said Irvani. “That’s how the loop continues. When we talk about circularity, we’re creating that virtuous cycle.”

The homegrown production: Okabashi’s R&D efforts both help it stay in the United States by keeping costs down and require domestic production to work.

- “To remake and recycle a product into something new, you need to have local production,” said Irvani. “You can’t be sending things halfway across the world to be unmade and remade and sent back. That’s why R&D locally and domestically is so important, to help produce circular systems.”

The local benefit: Irvani is quick to point out that money spent on R&D creates significant financial benefits for local communities.

- “There’s a multiplier effect for commercially oriented R&D in terms of the jobs it can create and the impact on the local economy,” said Irvani. “You get a very strong return on investment for both the company and for the community.”

The global perspective: R&D is essential for U.S. companies competing with manufacturers abroad, Irvani added.

- “For U.S. manufacturing broadly, R&D is critical to stay at the forefront of the innovation curve,” said Irvani. “Unless we’re proactively investing and developing new and better ways of doing things, we won’t be globally competitive.”

The last word: “It is imperative industry and retail move toward a circular-based economy,” said Irvani. “That’s not something that just happens or falls from the sky. Consumers are demanding it, and R&D is our pathway to that future.”

Manufacturers Step into the Industrial Metaverse

What exactly is the industrial metaverse? While the term sounds like something straight out of a science fiction movie, it’s already being used by manufacturers in the here and now. Put simply, the industrial metaverse is a collection of technologies that can create an immersive virtual or virtual/physical industrial environment.

The metaverse will contain virtual replicas of everything from complete factories down to individual components and parts, powered by evolving digital technologies like AI and cloud computing. As the metaverse develops, users will be able to access it from any internet-connected device, such as a smartphone, laptop or tablet, or using virtual reality headsets.

According to a new report released by the Manufacturing Leadership Council, the NAM’s digital transformation division, and Deloitte, 92% of manufacturing executives say they are experimenting with or implementing at least one metaverse-related use case. On average, the surveyed executives say they are running more than six.

How is it used? Manufacturers are using industrial metaverse technologies in four common areas: production, supply chain oversight, customer service and talent management.

- Production: Manufacturers are simulating key processes in order to evaluate them, creating virtual prototypes of processes or systems and creating simulated factories to optimize factory layout and setup.

- Supply chain: Other manufacturers are using the metaverse to track products and raw materials and to collaborate with suppliers.

- Customer service: Companies are also creating virtual showrooms and product demonstrations, which attendees can visit without leaving their own homes or offices.

- Talent management: Lastly, other companies are experiment with using the metaverse for immersive training, virtual plant tours and virtual recruiting and onboarding.

What are the benefits? Executives report that each of these use cases comes with significant benefits, including cost reductions. Respondents also said metaverse applications have improved employee attraction and retention.

- Immersive customer experiences and virtual aftermarket services, such as equipment service and maintenance, have also led to increased revenue, according to the survey.

The challenges: While the industrial metaverse offers many promising benefits, manufacturers are still finding some challenges, including:

- The high cost of metaverse technology and the cybersecurity protections it requires;

- A lack of employees with the right skills, along with the steep learning curve for those who must be trained; and,

- Insufficient digital infrastructure and other resources.

The solution: The report suggests that manufacturers can find success in the metaverse by building a culture of innovation, establishing leadership support and starting small by investing in a digital technology foundation.

The last word: All in all, manufacturing executives are confident that the industrial metaverse will transform their operations. Learning to understand and use the metaverse will soon be essential for companies seeking a competitive future.

Download the full report, “Exploring the Industrial Metaverse,” to learn more.

Tech Firms Squeeze More Out of AI Chips

Looking to make the most of the AI computer chips they have, technology companies are increasingly “turning to software that can squeeze more performance out of available chips and help reduce costs,” The Wall Street Journal (subscription) reports.

What’s going on: While larger firms are using hard-to-get graphics processing units to build multiple different AI models that “do things such as detect cybersecurity threats and help improve network performance,” other businesses are using central processing units to do similar tasks.

- CPUs aren’t as powerful as GPUs, but they are easier to find.

- And when “tuned with open-source software tools to get more performance out of them,” CPUs can help businesses meet their processing needs.

Boosting performance: As GPU demand continues to outpace supply, companies are using third-party software to squeeze additional performance from existing GPUs, too.

- One Israeli start-up installs optimization software on client GPUs to “automatically put idle computing power to use to gain better processing efficiency,” according to The Wall Street Journal.

- A Seattle-based startup “is betting that most businesses won’t want to deal with owning and managing an array of AI hardware … so it rents out access to processing power from cloud providers that it speeds up on customers’ behalf.”

Renting the cloud: Indeed, cloud-company giants can offer access to much-needed processing power “by renting it out as they do with computer services,” one source told the Journal.

How Novocure’s Anti-Cancer Device Extends Lives

Around 15,000 people are diagnosed every year in America with glioblastoma, a particularly aggressive form of brain cancer. At Novocure—a global oncology and medical device company with its North American flagship facility located in Portsmouth, New Hampshire—scientists and manufacturers have developed a device to revolutionize the way these tumors are treated.

The breakthrough: Novocure’s founder Yoram Palti developed an innovative treatment called Tumor Treating Fields therapy—an approach that uses electric fields to kill cancer cells while sparing healthy ones.

- For adult glioblastoma patients, the device, called Optune®, consists of wearable, portable adhesive arrays and an electric generator that can be carried in a bag.

- “Unhealthy cells and healthy cells have different properties,” said Frank Leonard, president, CNS Cancers U.S. at Novocure. “If you can create the right type of electric field, you can exert force and destroy cancer cells as they divide.”

Value added: Crucially, Tumor Treating Fields therapy is being studied together with other therapies, giving patients access to an optimal mix of treatments.

- “You get the best of both worlds with a device intervention and a drug intervention,” said Leonard. “Patients can wear this device consistently while using Temozolomide, which is the current standard of care chemotherapy agent used to treat glioblastoma.”

Low risk: Unlike drug therapies, which can present a range of adverse effects, Optune® has few side effects beyond mild-to-moderate skin irritation beneath the transducer arrays. As a result, patients can receive the treatment continuously for extended periods of time to attack cancer cells.

- “Typically, the limiting factor in treating cancer is dose-limiting toxicity—for example, you can only take one or two chemotherapies at the same time because they’re so toxic,” said Leonard.

Getting heard: The company’s device was featured in the award-winning short film “Rare Enough,” which tells the inspiring story of cancer survivor DJ Stewart and his journey in battling glioblastoma.

- Stewart is a Kansas City–based skateboarder who was first diagnosed with glioblastoma in 2019. Thanks, in part, to Tumor Treating Fields therapy, his life expectancy—once only 13 months—has been prolonged significantly. DJ now serves as a community outreach coordinator for the Head for the Cure Foundation.

Next steps: Novocure believes that Tumor Treating Fields therapy holds significant promise for other types of cancer as well. The company is developing additional wearable devices that could treat countless patients around the world.

- Lung cancer trials have shown promising results recently, and the company expects to learn more in the coming months from clinical trials involving ovarian cancer, metastases from lung cancer and pancreatic cancer.

- “We started working first in one of the rarer, yet most aggressive, forms of cancer. There are around 15,000 patients diagnosed with glioblastoma in the U.S. each year,” said Leonard. “But pre-clinical data suggests that Tumor Treating Fields can work with all different tumor types.”

A look to the future: Wearable anti-cancer devices offer an exciting new frontier in the fight against life-threatening diseases, and an important field where manufacturers can make an enormous difference.

- “In these really aggressive cancers, we still are making advances—and advanced devices that require sophisticated engineering and complex global manufacturing have a role to play,” said Leonard. “There’s a lot the manufacturing industry can do to improve the outcomes of patients, and they should be recognized for that work.”

AI Helps Buildings Go Greener

Real estate companies are turning to artificial intelligence to help cut emissions from commercial buildings, according to The Wall Street Journal (subscription).

What’s going on: While developers and builders have begun using more energy-efficient design and building methods in recent decades, and governments are introducing stricter energy-use codes for commercial spaces, “more than 80% of buildings don’t have smart systems to efficiently manage their energy use.”

- Commercial real estate manager JLL “has been making a string of investments to bring AI systems to companies looking to cut their emissions. … JLL says it expects 56% of organizations to pay a premium for sustainable spaces by 2025.”

- One of its investments is in a firm that installs electric motors and small computers into building systems to better control heating and cooling.

Why it’s important: “AI building systems learn from historical patterns and the daily habits of occupants to predict and power things on and off.”

- “For instance, software and hardware that automatically manages lights, heating and cooling can help buildings cut 20% or more of their yearly energy use.”

A caveat: Just 10–15% of buildings have systems in place to collect the data needed to make these predictions.

- As one source told the Journal, “Bad data means you can’t do any kind of schedules, rules or more sophisticated use cases around artificial intelligence. You have to have the data.”

Check it out: Speaking of data collection, the Manufacturing Leadership Council (the NAM’s digital transformation division) is hosting an event in December that will help manufacturers envision what a data-driven industry might look like by 2030. Learn more and register here.

PALIoT Takes on Supply Chain Challenges

Supply chain problems, PALIoT Solutions is coming for you.

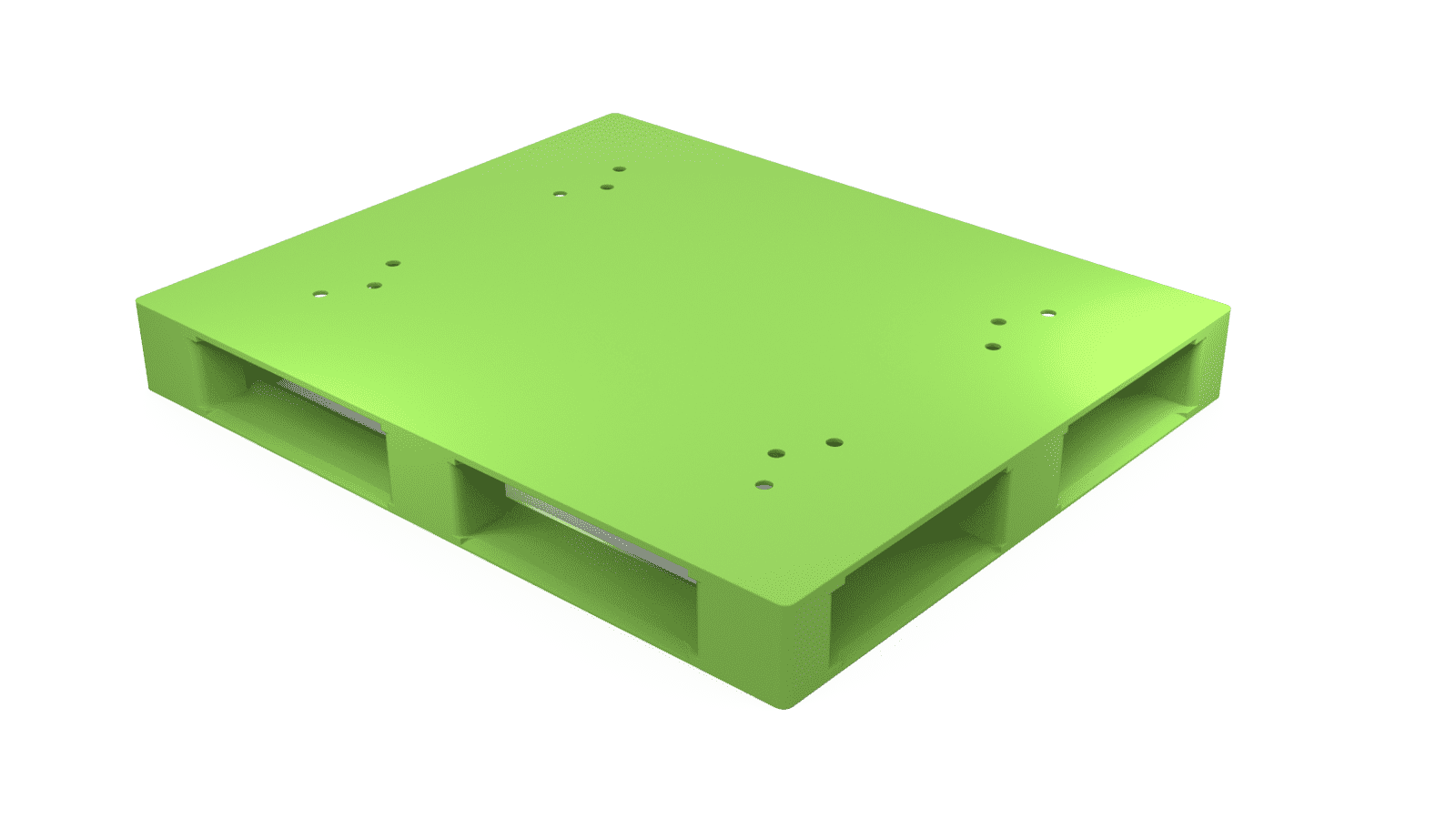

This fall, the New-York-state-based startup, whose name derives from a combination of “pallet” and “IoT,” will begin production of its smart shipping pallets. According to company leaders, these products will do nothing less than revolutionize the way food and goods are transported.

From vision to reality: PALIoT cofounders Paul Barry and Richard MacDonald envisioned pallets “whose positive impact on the environment keeps increasing as more of them are manufactured and deployed,” according to the firm’s website.

- To accomplish this feat, the pallets had to be both far lighter and more durable than typical pallets, which are made of wood and nails.

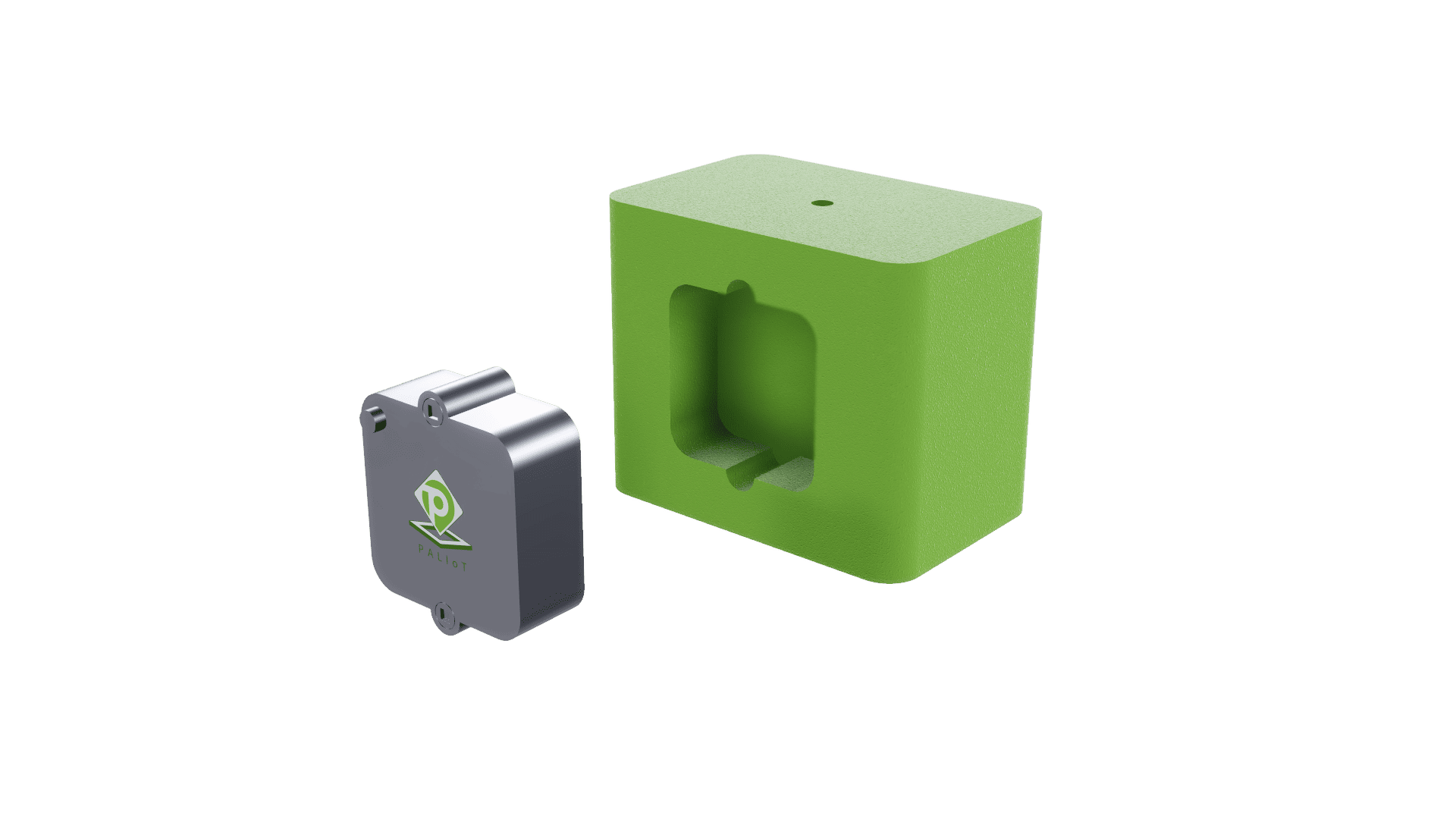

- After significant research and development, Barry and MacDonald came up with the solution: a polyurea-coated, engineered-plywood pallet that was 20 pounds lighter than its traditional peers and contained a proprietary sensor capable of instant communication with the cloud, making inventory tracking a cinch.

The “secret sauce”: “The ‘secret sauce’ is essentially a smart mesh network,” said Barry, who hails from Ireland and has an electrical engineering and investment banking background. “The PALIoT pallets in a shipment will all talk to each other, say, ‘Hey, I’m here.’ And [after shipping,] because they know they’ve been on a truck, they know they have to report all that valuable inventory and environmental data back to the cloud.”

- PALIoT, which will rent its pallets to customers using a per-pallet, pooling model (with an optional subscription service), acquired exclusive global use of the mist® Mesh Networking protocol. This ensures that communication is highly secure and battery sensitive at all times.

- The company estimates it will initially produce between 650,000 and 700,000 pallets a year in the first phase of the launch.

Savings for all: PALIoT’s groundbreaking sensors promise to save buyers both resources and money.

- “Food producers see tens of millions of dollars a year in food waste,” Barry said. With PALIoT technology, those producers will be able to track their perishable food shipments’ temperature and humidity conditions, viewing that information in the cloud so handlers can take swift action to cut down on spoilage.

- And because real-time asset protection is a PALIoT priority, the pallets will help companies cut down on theft and losses. As Barry put it, “If a pallet gets stolen, we will know where and when.”

A “smart” solution: Typical asset-embedded IoT sensors fail long before the assets themselves, making them impractical for longer-term use. Not so with PALIoT’s pallets, which can be used for a decade before they will need to be “retired and recycled,” according to Barry.

- “How can you justify having an expensive piece of hardware with a battery that needs replacing every few years?” he continued. “Using a combination of communications technologies, we’ve been able to solve the key problems of battery life and cost for large-scale asset-pooling companies.”

What’s next: Having recently relocated its manufacturing operations from Colorado to just outside Rochester, New York, PALIoT has its sights set on doing business with the dairy farms of the Northeast. It also plans to expand its manufacturing footprint across the U.S.

- “Demand is not the issue,” Barry told us. ”People just want a better solution, and we think this is it.”

PALIoT Takes on Supply Chain Challenges

Supply chain problems, PALIoT Solutions is coming for you.

This fall, the New-York-state-based startup, whose name derives from a combination of “pallet” and “IoT,” will begin production of its smart shipping pallets. According to company leaders, these products will do nothing less than revolutionize the way food and goods are transported.

From vision to reality: PALIoT cofounders Paul Barry and Richard MacDonald envisioned pallets “whose positive impact on the environment keeps increasing as more of them are manufactured and deployed,” according to the firm’s website.

- To accomplish this feat, the pallets had to be both far lighter and more durable than typical pallets, which are made of wood and nails.

- After significant research and development, Barry and MacDonald came up with the solution: a polyurea-coated, engineered-plywood pallet that was 20 pounds lighter than its traditional peers and contained a proprietary sensor capable of instant communication with the cloud, making inventory tracking a cinch.

The “secret sauce”: “The ‘secret sauce’ is essentially a smart mesh network,” said Barry, who hails from Ireland and has an electrical engineering and investment banking background. “The PALIoT pallets in a shipment will all talk to each other, say, ‘Hey, I’m here.’ And [after shipping,] because they know they’ve been on a truck, they know they have to report all that valuable inventory and environmental data back to the cloud.”

- PALIoT, which will rent its pallets to customers using a per-pallet, pooling model (with an optional subscription service), acquired exclusive global use of the mist® Mesh Networking protocol. This ensures that communication is highly secure and battery sensitive at all times.

- The company estimates it will initially produce between 650,000 and 700,000 pallets a year in the first phase of the launch.

Read the full story here.