DOE to Announce Carbon-Removal Project Winners

The Biden administration will soon announce the first grant winners of a multi-billion-dollar competition to speed up development of technology to “remove carbon dioxide from the sky,” according to E&E News’ CLIMATEWIRE (subscription).

What’s going on: The “awards for so-called direct air capture hubs could define the future of the nascent DAC industry in the United States as well as the broader CO2 removal sector, experts say.”

- The Department of Energy received more than a dozen proposals in response to the $3.5 billion DAC hub competition, which was created in 2021 as part of the historic bipartisan infrastructure legislation and seeks to increase the use of DAC technology.

- The projects expected to be announced this month could get “between $3 million and $500 million in matching funds” for efforts such as DAC undertakings capable of capturing and storing one million tons of carbon dioxide every year.

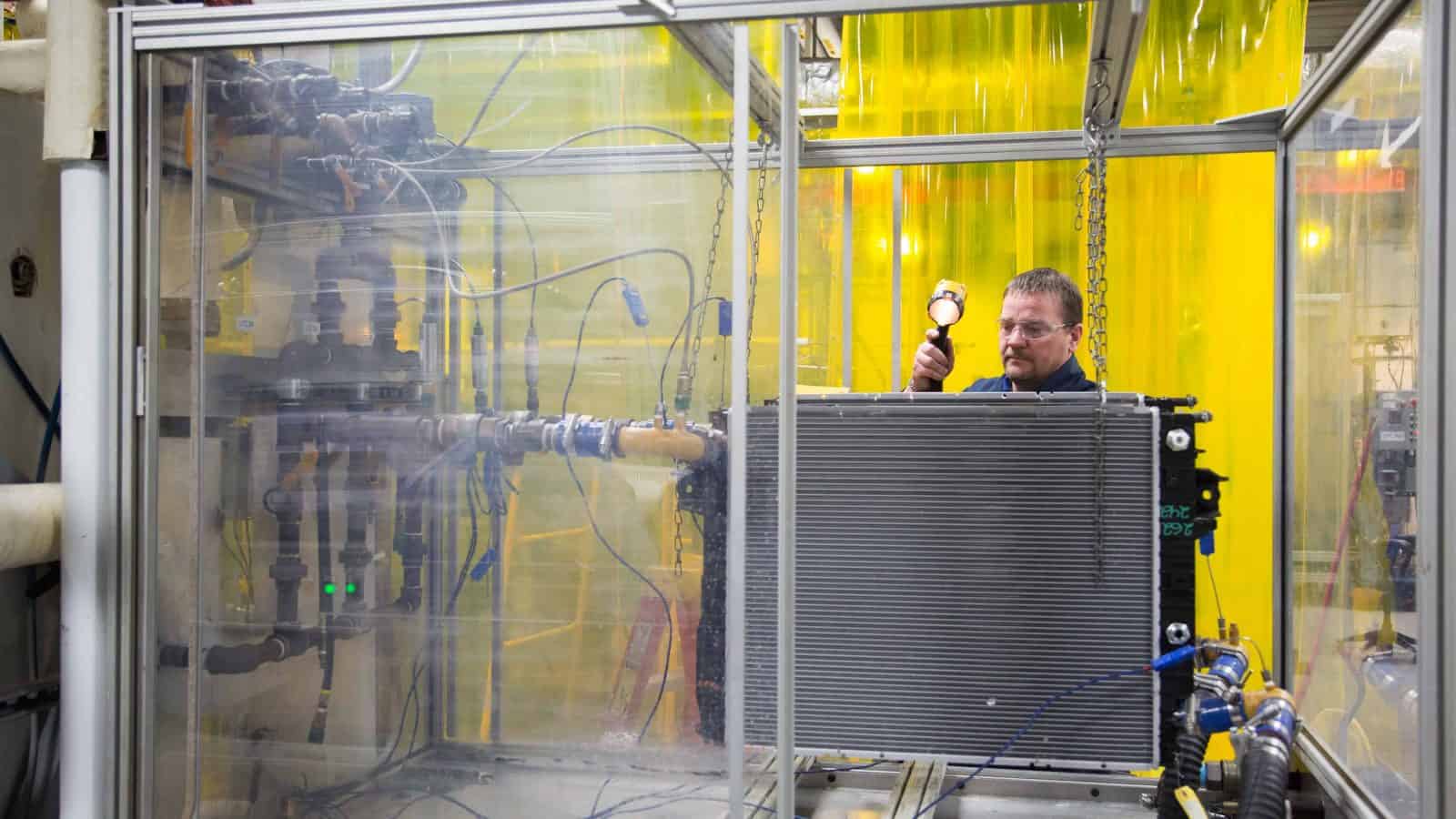

What it is: DAC plants use filters, power, piping and fans to remove carbon dioxide from the air and sequester it underground.

- Just 27 such facilities have been commissioned globally, and the largest of these can remove 4,000 tons of carbon dioxide from the atmosphere annually.

The economic challenge: “At the moment, it costs around $700 per ton for a DAC facility to remove carbon from the air, according to the industry data clearinghouse CDR. The Inflation Reduction Act, meanwhile, increased the tax incentives for DAC operators to $180 per ton for the CO2 they permanently store.”

- To bridge that cost gap, last year Congress ordered the Biden administration to start a pilot program to pay DAC firms and developers of carbon-removal technology to remove emissions from the air.

The final say: “Manufacturers view clean energy solutions—such as carbon capture and sequestration/storage technologies and hydrogen—as important parts of our country’s energy present and future,” said NAM Director of Domestic Economic Policy Brandon Farris.

- “Manufacturers are leading the charge in developing them and scaling them up for widespread use.”

Second Fusion Reaction Nets More Energy

U.S. scientists have achieved a net energy gain in a nuclear fusion reaction for a second time—this time, with a higher energy yield, according to Axios.

What’s going on: The federal Lawrence Livermore National Laboratory in California announced Sunday that in an experiment on July 30, a fusion reaction produced more energy than it consumed, and more than a similar experiment produced last December.

- The December reaction used 192 lasers to produce a net gain of 1.1 megajoules of fusion energy, enough to power an average-size home for about half an hour, according to Extreme Tech.

- The July reaction is said to have netted even more, though specific figures for it are not yet available.

Why it’s important: “Scientists have worked for decades to develop nuclear fusion as a source of effectively limitless clean energy,” Axios reports.

- However … “Scaling up the technology to support the electrical grid will require increasingly powerful lasers—and more of them,” according to Extreme Tech.

The last word: “The net gain of fusion energy—for a second time, and in a larger amount—is a tremendous milestone,” said NAM Director of Domestic Economic Policy Brandon Farris. “It is further evidence of the enormous potential of nuclear power to help us meet our energy needs and energy-security goals.”

Utilities Scramble to Get Large Transformers

U.S. power companies are finding it increasingly difficult to get the large transformers they need to move electricity long distances—and the Department of Energy should step up to help them, the Government Accountability Office said this week, according to E&E News’ ENERGYWIRE (subscription).

What’s going on: A “GAO report called on DOE to create a plan, with deadlines, to overcome growing delays and difficulties U.S. utilities are facing in getting new large power transformers that are required to move electricity across more than 160,000 miles of U.S. high-voltage lines.”

- Most of the transformers are imported from overseas, and there is still a shortage due to pandemic-related supply chain disruptions.

- In some cases, delivery times have more than doubled, and the largest of the transformers can cost up to $10 million.

Why it’s important: “Transformers are critical for the future energy mix, as they are needed to create a larger grid for increased wind and solar generation, according to analysts.”

- In 2027 the demand by North American power companies for large transformers will likely be about twice what it was in 2020, according to the DOE.

What can be done: The DOE should create a plan to get more power companies to take part in voluntary programs to loan out spare large transformers during emergencies, the GAO recommends.

- The largest of these sharing agreements, the Edison Electric Institute’s Spare Transformer Equipment Program, had 57 participating utilities as of March.

- Thirty-one utilities in 28 states have signed onto a grid program to furnish spare transformers during cyberattacks or natural disasters.

The challenges: “[S]hortages of skilled manufacturing craftsmen able to build the transformers’ complex windings are a significant challenge … [DOE] said it is working on expanding apprenticeship programs to address the issue.”

Our take: “Transformers and transmission lines are critical to meet our growing energy security needs,” said NAM Director of Domestic Economic Policy Brandon Farris.

- “The NAM will continue working with the DOE and others to ensure that current and future needs are met, including developing the next generation of the manufacturing workforce and breaking down permitting barriers to expedite the buildout of our grid.”

DOE Loosens Gas Stoves Rule

The Department of Energy is loosening proposed energy-efficiency regulations for gas cooktops after reviewing data submitted by one of the NAM’s trade association partners and a utility company, POLITICO (subscription) reports.

What’s going on: “In a notice of data availability to be published in Wednesday’s Federal Register, DOE floated less stringent efficiency requirements for gas stoves. The initial proposal called for a consumption limit of 1,204 … British thermal units, or kBtu, per year, down from the baseline estimate of 1,775 kBtu per year. But the new proposal raises those figures slightly. Now DOE is proposing a limit of 1,343 kBtu per year, down from a recalculated baseline of 1,900 kBtu per year.”

- The Association of Home Appliance Manufacturers and PG&E provided the DOE with data on cooktops with higher consumption rates, which the agency had not used in its initial efficiency testing.

- “Other comments led DOE ‘to better understand’ what features consumers want in a gas stove, including multiple high input rate burners and continuous cast-iron grates,” POLITICO reports.

Why it’s important: Manufacturers would be required to spend more than $2.5 billion to comply with the originally proposed rules, according to the DOE’s own estimates. However, consumers would save just 12.5 cents a month in energy costs.

- The mandates would have been so strict as to make 96% of gas stoves on the market noncompliant.

What Congress has done: In June the House passed the Save Our Gas Stoves Act, which would prevent the DOE from advancing its unworkable stove requirements.

What we’re doing: The NAM has held high-level discussions with policymakers on the importance of feasibility, affordability and consumer choice in rulemaking.

- To that end, in June the NAM and members of the NAM’s Council of Manufacturing Associations and Conference of State Manufacturers Associations created the Manufacturers for Sensible Regulations, which aims to combat the recent regulatory onslaught by federal agencies.

The NAM says: “Manufacturers depend on regulatory clarity and certainty,” said NAM Managing Vice President of Policy Chris Netram.

- Throughout the year, the Department of Energy has proposed an unprecedented slew of regulations, and many were aimed at home appliances. The DOE is now taking steps toward a solution that is less likely to raise production costs significantly for manufacturers, and less likely to reduce the available features, performance and affordability for consumers.”

Manufacturers: DOE Gas Stove Rules Revision Is Step in Right Direction

Washington, D.C. – Following the announcement that the U.S. Department of Energy has modified its proposed energy-efficiency rules for gas stoves to be less restrictive, National Association of Manufacturers Managing Vice President of Policy Chris Netram released the following statement:

“Manufacturers depend on regulatory clarity and certainty. Throughout the year, the Department of Energy has proposed an unprecedented slew of regulations, and many were aimed at home appliances. The DOE is now taking steps toward a solution that is less likely to raise production costs significantly for manufacturers, and less likely to reduce the available features, performance and affordability for consumers.

“Manufacturers remain committed to working with the DOE and all federal agencies to ensure that proposed rules and regulations are practical, feasible and environmentally sound without harming our ability to create well-paying jobs and investment in the United States.”

The NAM, along with members of the Manufacturers for Sensible Regulations, have been highlighting the negative impact of unbalanced regulations on manufacturers, noting the agency’s own data showed that 96% of existing gas stove models currently available would not comply.

Background: According to the NAM’s Q2 2023 Manufacturers’ Outlook Survey, more than 63% of manufacturers report spending more than 2,000 hours per year complying with federal regulations, while more than 17% of manufacturers report spending more than 10,000 hours. The NAM survey also stressed that only 67% of manufacturers are positive about their own company’s outlook, the lowest since Q3 2019. It shows the consequences of regulations: If the regulatory burden on manufacturers decreased, 65% of manufacturers would purchase more capital equipment, and more than 46% would increase compensation.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.91 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

NAM Pushes Back on New Emissions Standards

The Biden administration’s new fuel-economy standards are too aggressive and add conflicting mandates to on-the-books regulations, the NAM said Friday.

What’s going on: The Department of Transportation’s National Highway Traffic Safety Administration issued a proposal calling for a revision of current Corporate Average Fuel Economy standards for cars and light-duty trucks—to a fleet average of 58 miles per gallon by 2032.

- The draft rules are a complement to regulations released “in April that are the strictest on record and push automakers to make the majority of their sales electric vehicles,” reports Auto Dealer Today.

Why it’s problematic: “Auto manufacturers have been making historic investments to ensure that electric vehicles will have a growing place on America’s roads,” said NAM President and CEO Jay Timmons. “However, the NAM has concerns over the three different sets of standards governing light- and medium-duty vehicles. For instance, the Environmental Protection Agency’s proposed regulation on light- and medium-duty vehicles would require 67% of new manufactured vehicles to be battery electric by 2032 and is too aggressive.”

- Some of the rules that have been put forth recently by federal and state agencies conflict with one another, and some—particularly those released by the EPA—would increase the cost of both manufacturing and purchasing vehicles.

- “In addition, the federal government should not dictate the vehicle choices offered to consumers,” Timmons pointed out. “The administration should allow the market and consumers to grow the number of electric vehicles, rather than depending on a single technology to meet this goal.”

What can be done: “[T]hese regulations should be harmonized to create a single unified standard for vehicle emissions, so manufacturers do not have to navigate three often-conflicting targets, which raise costs for manufacturers and consumers,” Timmons continued.

What we’re doing: In June, the NAM and members of the NAM’s Council of Manufacturing Associations and Conference of State Manufacturing Associations launched Manufacturers for Sensible Regulations, a coalition aimed at addressing the negative effects of the multiple, often contradictory regulations being handed down by federal agencies.

Senate Moves to Onshore Uranium Production

The Senate voted overwhelmingly to create a Nuclear Fuel Security Program aimed at bolstering U.S. supplies of enriched uranium, according to the Senate Committee on Energy and Natural Resources.

What’s going on: On Thursday, the Senate voted 96–3 to include Sen. John Barrasso’s (R-WY) Nuclear Fuel Security Act amendment in next fiscal year’s National Defense Authorization Act.

- The “[a]mendment … directs the Department of Energy (DOE) to prioritize activities to increase domestic production of low-enriched uranium (LEU) for existing reactors and accelerate efforts to ensure the availability of high-assay, low-enriched uranium (HALEU) for advanced reactors,” according to the committee press release.

- The bipartisan measure was introduced in February by Sens. Barrasso, Joe Manchin (D-WV) and Jim Risch (R-ID); in May, it was passed by voice vote.

Why it’s important: Most of the advanced nuclear reactor concepts set to come online in the next few years require HALEU—and Russia is the only viable commercial supplier, according to E&E News’ ENERGYWIRE (subscription).

- “Russia now supplies 24% of our enriched uranium imports,” Sen. Barrasso said before the committee on Thursday. “We spend nearly $1 billion each year on Russian uranium. Russia uses these revenues to fund its invasion of Ukraine. Here in America, we have the resources to fuel our own reactors. My amendment authorizes the Department of Energy to take the steps necessary to expand U.S. nuclear fuel production.”

The NAM’s role: The NAM has strongly advocated for the development of nuclear energy, which will play a critical role in U.S. energy security and decarbonization efforts.

- As NAM President and CEO Jay Timmons told Congress in June, “Nuclear energy can help the U.S. generate more clean energy, stabilize our grids and improve our energy security.”

A Renewables Industry Faces Headwinds

The Biden administration is hoping offshore wind farms will provide enough power for 10 million homes by the end of this decade—but energy companies are having trouble financing the projects, according to POLITICO.

What’s going on: “Up and down the Northeast—the center of the burgeoning [wind power] industry … energy companies have struggled to finance their projects, going hat in hand to governors and utility regulators asking for more money so they can start building the turbines they have already promised to deliver.”

- Many consumers concerned about already increasing energy costs are wary of more taxpayer funds going to such projects—but without additional government funds, many current wind projects may not get built at all.

The big picture: “Offshore wind takes a combination of state and federal green lights to work. … Federal, state and local permits all have to be secured to make the projects a reality, which gives opponents numerous chances to stall or kill projects.”

- Thus far, federal regulators have approved just three offshore wind projects nationally—underlining the dire need for permitting reform, which the NAM has long called for.

- Meanwhile, “Only seven offshore wind turbines are producing power and just two of the larger projects are truly under construction,” according to POLITICO.

States struggle: Wind-power projects in New Jersey and Massachusetts are facing financial hurdles, with the costs for one project increasing 30% since approval two years ago.

- Geopolitics and the larger economy have weighed on U.S. wind power, too. “Inflation is up—the cost of steel has soared since the pandemic—interest rates are higher and the labor market is tighter. Paradoxically, the war in Ukraine made clear how important domestic energy is while at the same time driving up the costs to produce it.”

The NAM says: “Manufacturers depend on access to reliable and affordable energy, which is why the NAM strongly supports reforms that would foster transparent, streamlined and timely federal regulatory processes,” said NAM Vice President of Domestic Economic Policy Brandon Farris.

- “Our antiquated permitting system is driving up construction costs and has the potential to reduce energy security. The NAM will continue to fight for common-sense permitting reforms that expedite the development of many energy projects, including renewables.”

Incandescent-Bulb Rules to Be Fully Enforced

Following years of regulatory disputes, the incandescent lightbulb will be almost completely phased out starting this month, according to E&E News’ ENERGYWIRE (subscription).

What’s going on: “Along with prohibiting the manufacture, import and retail sales of most incandescent bulbs, [Department of Energy] rules finalized last year authorize DOE to slap penalties of $542 on companies per each violation. That could mean millions of dollars in fines for large incandescent orders.”

- DOE says the move will cut greenhouse gas emissions and lower consumers’ utility bills.

- While there is not an explicit ban on incandescent bulbs, most of them are unable to meet the efficiency requirements that were set by Congress in 2007 and will now go into full enforcement.

What it could mean: “Industry representatives say the sweep of regulations on various appliances will spike upfront costs for consumers in the market for appliances,” ENERGYWIRE reports. “Republican lawmakers on Capitol Hill argue the Biden administration is waging a back-door campaign to ban gas stoves and other appliances.”

Stricter Water Heater Standards Would Cost Manufacturers

The Department of Energy released a draft proposal late last week that would impose stricter efficiency standards on water heaters—and increase costs for manufacturers, E&E News’ ENERGYWIRE (subscription) and The Washington Examiner report.

What’s going on: On Friday night, the DOE released a 425-page plan “to mandate energy efficiency levels for new consumer water heaters, which the department defines as appliances in homes and small businesses that use ‘oil, gas or electricity to heat potable water for use outside the heater upon demand,’” according to ENERGYWIRE.

- The Biden administration says the move—which would go into effect in 2029 if approved in its current iteration—would cut carbon dioxide emissions and reduce energy use by residential water heaters, saving consumers money.

- The draft rule arrives just months after the DOE released a proposal to phase out approximately half of the gas-powered stoves on the market. The House recently approved two measures to stop “gas stove rulemaking from DOE and the Consumer Product Safety Commission,” according to ENERGYWIRE.

What it would mean: The water heater rule would force manufacturers to use heat pump technology to produce electric water heaters and condensing technology to make gas-fired water heaters—and it would spike production costs in the process, according to the Examiner.

- “The [DOE] draft outlines the potential effect on manufacturers, estimating the implementation of the updated standards could result in ‘a loss of $207.3 million to a gain of $165.5 million’ through the year 2056. The DOE estimates conversion costs would be $228.1 million,” the Examiner reports.

The NAM says: “These proposed regulations add costs to manufacturers and consumers and remove market options,” said NAM Vice President of Domestic Economic Policy Brandon Farris.

- “Manufacturers believe that regulations should allow manufacturers in America to compete in a global market—while protecting consumers. The targets proposed by the DOE fail to accomplish that goal.”