Powering America’s Nuclear Comeback

Manufacturers are hard at work on next-generation nuclear reactors and getting ready to scale up nuclear enrichment activities, but challenges lie in their way (POLITICO’s ENERGYWIRE).

What’s going on: Though it made sense at the time, the privatization of the United States Enrichment Corporation in the years following the Cold War (done due to “the anticipation that the U.S. would always have access to foreign enrichment supplies”) is now putting the American uranium enrichment market and reactor development at a disadvantage.

- This presents a problem given the U.S. ban on Russian uranium imports due to the Ukraine war.

- To shore up the American nuclear industry, the Energy Department “has started to pull startup nuclear companies into the uranium enrichment business.”

- Just this month, California-based General Matter announced that it would construct an enrichment facility in Kentucky on the site of a former U.S. government enrichment plant, saying it “can produce at a lower cost the type of enriched uranium sought out by developers of advanced nuclear reactors.”

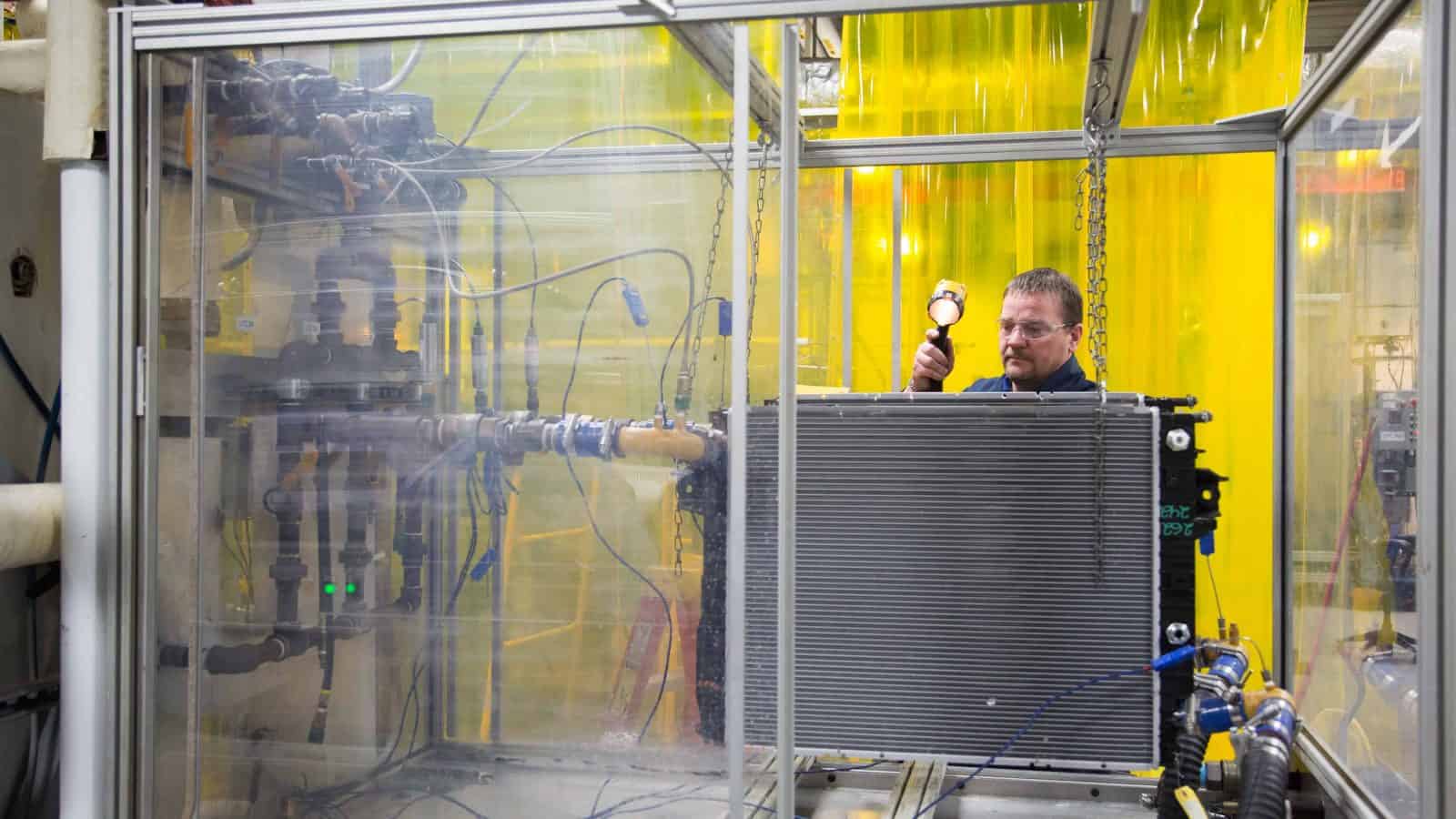

A changing tide: In 2023, the Maryland-based Centrus Energy (U.S. Enrichment’s name since 2014), made its first batch of high-assay, low-enriched uranium, or HALEU, which is the fuel needed for next-generation nuclear reactor designs.

- “With Centrus’ inaugural batch and plans to expand their centrifuge cascade, the U.S. might yet break Russia’s de facto monopoly on advanced reactor fuel.”

Challenges: Scaling up Centrus’ Ohio enrichment site will necessitate billions in investment dollars, as well as “a [high] level of sustained political backing,” according to ENERGYWIRE.

- Another hurdle: the relatively weak market signals for HALEU, said former Nuclear Regulatory Commission Chair Dale Klein, who noted “that North America doesn’t yet have any commercial reactors operating that would use HALEU. That’s a problem for the dozen-plus entities planning to build [next-generation] reactors.”

- “It is a chicken and egg,” Klein told the news outlet. “The fuel enrichers are not going to make the fuel unless they know they’ve got a market.”

Moving forward: But Centrus is ready to get to work on enrichment, it told ENERGYWIRE.

- “Our facility is already licensed. We’ve secured $2 billion in customer contracts. As soon as federal funding is awarded, we’ll pair it with private dollars and get to work,” Centrus Vice President of Corporate Communications Dan Leistikow said.

- “Centrus offers a fully American solution: proven U.S. technology, built by American workers.”

Trump Administration Relaxes State EV Charging Facility Requirements

The Trump administration is easing requirements for states’ construction of electric vehicles charging stations (POLITICO’s ENERGYWIRE, subscription).

What’s going on: “The new guidance from the Federal Highway Administration swept away Biden-era dictates that stations be built at certain intervals along highways, and removed goals both big, like uplifting disadvantaged communities, and small, like requiring plans for snow removal.”

- The changes also have the potential to get more than $2 billion National Electric Vehicle Infrastructure program funds to various projects starting in September, months after the administration halted the funding.

What it does: The new National Electric Vehicle Infrastructure program rules—which grant states 30 days to submit new EV charging facility construction plans—“give states broader latitude in how they spend their portion of federal money … [which] are allocated to states by formula.”

- States can now spend their money on light-, medium- and heavy-duty vehicle charging, and unlike in the previous administration, which required having facilities every 50 miles, will be allowed to “determine for themselves when their highway charging efforts are done.”

- Plus, by urging states to use their money “at locations where the charging site host and the company operating the chargers are the same entity,” the new regulations also direct funding to existing truck stops and gas stations, which “favors existing traditional filling stations.”

The NAM says: “Manufacturers appreciate the Department of Transportation’s updates to the NEVI program requirements to provide greater flexibility to states and businesses to get this program up and running,” said NAM Vice President of Domestic Policy Chris Phalen.

Energy Dept Kicks Off Nuclear Reactor Pilot Program

The Department of Energy announced the start of its pilot program, which will partner with 11 advanced reactor projects, aiming to bolster the nuclear energy industry (E&E News, subscription).

Big goals: The program aims to get a minimum of three reactors deployed by July 4 of next year.

The background: “The announcement comes as the Trump administration looks to reinforce domestic supply chains and expand U.S. nuclear energy capacity to 400 gigawatts by 2050.”

- “The June announcement of the program came shortly after Trump’s executive order calling for reform of the Nuclear Regulatory Commission.”

The participants: Companies involved in the program include advanced nuclear energy company Oklo—which is conducting two advanced reactor projects.

- The 10 companies in total will cover all the costs related to the test reactors, from design through construction all the way to decommissioning, according to the DOE.

The DOE says: “President Trump’s Reactor Pilot Program is a call to action,” said Deputy Secretary of Energy James P. Danly. “These companies aim to all safely achieve criticality by Independence Day, and DOE will do everything we can to support their efforts.”

The NAM says: “Nuclear energy is a safe, emissions-free component of America’s energy dominance strategy. It’s also essential for meeting additional energy needs that have arisen with the growth in data centers and the use of AI,” said NAM Vice President of Domestic Policy Chris Phalen.

- “This program will give the nuclear energy industry an important boost—to the benefit of manufacturers and all Americans.”

New Texas-to-Arizona Pipeline Planned

One of the largest midstream energy firms in the world will build a 516-mile natural gas pipeline from West Texas to Arizona (POLITICO Pro’s ENERGYWIRE, subscription).

What’s going on: The planned Desert Southwest line by Energy Transfer —a company best known for its development of the Dakota Access pipeline in the Midwest—”is slated to run along existing pipeline routes, the company said last week, and the project is expected to be completed by the end of 2029.”

- The new line is necessary to serve “population growth, high-tech industry demand and data center expansion,” Energy Transfer said in a statement.

- The Houston, Texas-based company “has a network of 140,000 miles of pipelines and related infrastructure across 44 states” and is developing a liquefied natural gas export terminal in Louisiana.

Significant interest: Arizona utilities have already announced commitments to get gas from the pipeline, which is currently slated to be three-and-a-half feet in diameter but could increase to 4 feet given the significant interest in the endeavor.

- That increase would double the expected capacity of the pipeline.

Prioritizing manufacturers in the U.S.: The new pipeline will create 5,000 new jobs, and Energy Transfer said it would be “prioritizing U.S. steel pipe manufacturers” for the project.

- In addition, the gas from this project will help supply energy to key manufacturing and AI investments being made across the Phoenix metropolitan region—including in semiconductors, automobiles, aerospace, healthcare and biosciences.

The word from Arizona: “Arizona’s economy is growing and becoming more diversified than ever, including a significant increase in advanced manufacturing,” said Arizona Public Service President and CEO Ted Geisler.

- “This new pipeline represents a long-term commitment to reliability, resilience and affordability for customers and supports the unprecedented economic momentum that makes Arizona a great place to do business.”

The NAM says: “Desert Southwest is a prime example of what can be achieved when we embrace an all-of-the-above energy strategy—one that includes harnessing our abundant natural resources,” NAM Vice President of Domestic Policy Chris Phalen said.

- “The pipeline will not only create jobs and business for U.S. manufacturers, it will also help reinforce the regional electrical grid at a critical time of explosive growth so more Americans can enjoy reliable baseload power.”

To Increase Aluminum Supply, Recycle More

To bolster domestic aluminum supply chains, the U.S. may need to simply do more of something we already do: recycle (The Wall Street Journal, subscription).

What’s going on: “U.S. primary aluminum production has dwindled over the past 25 years. Yet facilities like Hydro’s two-year-old plant in southwest Michigan have made the country a leading producer of secondary aluminum from scrap, feeding metal to brewers, builders and automakers.”

- “Recycling is the answer,” said Duncan Pitchford, who heads Norsk Hydro’s upstream aluminum business in the U.S. and is an NAM board member. “The metal is already here.”

Why it’s important: While construction of a new aluminum smelter to make primary aluminum from refined bauxite would take years and require an investment of billions of dollars, aluminum recycling plants can be built relatively quickly and inexpensively.

- They also use less energy, according to Pitchford.

The impact of tariffs: Recycling makes economic sense for the U.S. given the new 50% tariff on aluminum imports.

- “The added cost is walloping beverage companies and manufacturers … [but] [a]utomakers and other big aluminum users have yet to raise prices much in response.” according to the Journal.

- “Analysts say it is a matter of time before the stockpiles of metal that arrived in the U.S. ahead of the June increase are depleted and companies start passing on higher aluminum costs.”

The challenge: Americans are catching on to the importance of aluminum recycling, with 14 “remelt” projects announced in the U.S. since 2022. Still, “[m]ore than $1 billion worth of beverage cans were dumped in U.S. landfills just last year … A lack of sorting operations means that a lot of the aluminum in junked cars, demolition debris and old electronics winds up in landfills.”

- The U.S. also exports much of its aluminum scrap, sending about 2.4 million metric tons overseas in 2024.

The way things were: “The U.S. once dominated the aluminum business. … [and] remained the world’s top producer through 2000,” when smelters began to shutter, “squeezed” by less expensive imports and increasing energy pieces.

The electricity factor: Electricity costs make up about 40% of the price tag for the creation of new aluminum.

- For many years domestic smelters received low-cost hydropower from federal utilities, but when those arrangements ended, smelters had to begin paying market rates for their electricity.

What Hydro’s doing: Approximately 15 million pounds of scrap — including “shredded cars, old window and door frames and overhead electrical wire”— arrives at Hydro’s Michigan plant each month for recycling. (The facility does not recycle cans.)

- Much of the metal the plant takes in comes from “a sorting hub near Grand Rapids, where Hydro uses laser-induced breakdown spectroscopy technology to mechanically separate scrap by alloy.”

NAM to EPA: Power Plant Rule Repeal Is Only the First Step

The Environmental Protection Agency’s move to repeal the previous administration’s 2024 Power Plant Rule is a positive one for manufacturing in the U.S.—but to truly unleash American energy’s potential, we need permitting reform, too, the NAM told the EPA this week.

What’s going on: In June, the EPA proposed a rule to repeal the previous administration’s 2024 greenhouse gas emissions regulations for certain traditional power plants.

- “Manufacturers commend the EPA for acknowledging the unworkability of the previous administration’s rule,” NAM Vice President of Domestic Policy Chris Phalen told EPA Administrator Lee Zeldin on Tuesday.

- Repeal of the 2024 rule is a crucial start in getting “as much electricity generation online as possible,” Phalen continued. “But without comprehensive permitting reform to enable the buildout of new and modernized plants of all types in a timely manner, including traditional generation and plants using lower emissions technologies like [carbon capture and sequestration] and hydrogen, there is a serious risk we fall short of our energy generation needs.”

Why it makes sense: The NAM laid out its primary reasons for supporting the proposed rescission, which include the following:

- The requirement that some achieve a 90% carbon capture rate was arbitrary and unfeasible given that carbon capture and sequestration technology is not yet at commercial scale.

- The plant closures that would result from the rule’s implementation would threaten grid reliability.

No relief without reform: Repealing the 2024 rule keeps many traditional plants online, which is a must as the national energy appetite grows due to data center expansion, Phalen said. Still, there are further steps we must take—and soon.

- “These include consolidating the permitting processes and putting enforceable deadlines for the siting of new energy projects and their infrastructure; speeding up the approval process for transmission, distribution and electrical generation projects; enacting commonsense guardrails on judicial review to ensure a speedy process that results in definitive decisions for all projects; and committing to developing our resources to strengthen U.S. supply chains for the energy infrastructure vital to national security.”

FERC Conditionally OKs Grid Operations’ Fast-Track Requests

The federal government has agreed to fast-track some power project requests by U.S. grid operators, potentially staving off electricity shortfalls from an overloaded grid (POLITICO Pro, subscription).

What’s going on: Last week, the Federal Energy Regulatory Commission issued unanimous orders “conditionally authorizing requests from the Midcontinent Independent System Operator (MISO) and Southwest Power Pool (SPP).”

- The move follows a similar approval for an expedited interconnection process for PJM Interconnection, the largest power grid in the U.S.

- It also comes just months after FERC rejected a similar request from MISO.

Why it’s important: The MISO and SPP plans seek to get new projects online quickly as some traditional power plants are closed “and replacements are stuck awaiting studies for approval to plug into the bulk power grid.”

- Utilities have signaled that they need more generation to account for growing power appetite, much of it stemming from the rapid construction of capacity-hungry data centers.

What’s new this time: Although FERC said in May that MISO’s expedited resource adequacy study process was too broad and therefore risked worsening the “existing interconnection queue delays,” the revised proposal, submitted in June, caps at 68 the number of ERAS endeavors in coming years.

- The revised proposal also adds new eligibility requirements.

- And “projects seeking expedited grid studies must have approval of the appropriate local regulator, control the site for the project and have a contracted buyer as well as pay a $100,000 application fee and meet other conditions.”

NEPA Overhaul Measure Introduced

A bipartisan duo in Congress has introduced legislation to speed up permitting reviews under the National Environmental Policy Act while limiting legal challenges (POLITICO Pro, subscription). The NAM has called for NEPA reform for years.

What’s going on: Last Friday, House Natural Resources Committee Chairman Bruce Westerman (R-AR) and Rep. Jared Golden (D-ME) unveiled the SPEED Act to “help launch America into a future where we can effectively innovate and implement to revitalize our infrastructure, meet skyrocketing energy demands, lead the world in the AI race and work in harmony with our natural environment,” said Westerman, who told POLITICO Pro there “really seems to be momentum” in the government to make the changes outlined in the measure.

The backdrop: House Majority Leader Steve Scalise (R-LA) said last week Republican leadership plans to make bipartisan permitting reform a priority this fall.

- “Under direction from Trump’s Inauguration Day executive order, the Council on Environmental Quality has pulled back federal-wide NEPA regulations, and agencies have weakened their own NEPA rules.”

- Senate Democrats have said recently they’re willing to restart permitting reform talks with Republicans.

What the measure would do: The SPEED Act “would codify parts of a May Supreme Court ruling that limited the scope of environmental reviews” and build on 2023 NEPA reforms, including the establishment of a two-year time limit on conducting environmental impact statements. And among other actions, it would:

- Stop agencies “from evaluating impacts outside the immediate causal result of the proposed action”;

- Reduce the number of projects that can be deemed “major federal action” and thus become subject to the NEPA process;

- Set a higher bar for judicial challenges, mandating that litigants sue within 150 days and courts issue judgments within 180 days;

- “[O]nly allow parties that provided substantive comments during the public review period the opportunity to issue a legal challenge”; and

- “[L]imit a court’s ability to remand an agency decision.”

Our take: “This bill provides critically needed clarity and guardrails for manufacturers to invest and grow in America—while maintaining public input and safeguarding our environment,” said NAM Vice President of Domestic Policy Chris Phalen.

- “Energy sources of all types have for too long run into needless delays and frivolous litigation—delaying jobs for Americans and getting electrons on our grid. Manufacturers look forward to working with Chairman Westerman and Rep. Golden to advance this legislation as part of a comprehensive and bipartisan permitting reform package to drive America forward.”

Using Traditional Energy to Generate Geothermal Power

Researchers seeking new methods of generating thermal energy are now trying something new: the oil and gas industry (POLITICO’s E&E News).

What’s going on: “State research officials in North Dakota are examining two new options—pairing geothermal with active oil and gas sites and using captured carbon dioxide as a feedstock for geothermal power production.”

- The state gave the go-ahead in June for a $250,000 feasibility study looking at “whether those two new geothermal technologies could be used” there.

Why it’s happening now: President Trump signed an executive order in April, calling for the elimination of “all illegitimate impediments” to the development of geothermal projects.

- Geothermal power enjoys bipartisan support in Congress, and federal tax incentives for both geothermal and carbon capture and storage have “created an environment where companies and researchers can start to explore different methods of production,” Matt Villante, an earth scientist with the Pacific Northwest National Laboratory, told E&E News.

- In addition, the 45Q tax credit, which offers an incentive for carbon management undertakings that capture carbon dioxide, was preserved in the recent reconciliation bill.

How it works: Researchers are exploring several different methods for using captured carbon dioxide to produce geothermal energy, which is traditionally extracted “by drilling and pumping up brine from deep within the earth.”

- One method would involve injecting large amounts of carbon dioxide into the ground to push out the brine.

- “Another approach could be pushing CO2 underground to the heat source, and pumping back up the heated CO2 to power the turbines, then injected the cooled carbon dioxide back underground in a closed-loop system.”

- A third way would use hydraulic fracturing to break up “hot dry rock” using carbon dioxide.

Yes, but…Despite the support for geothermal, actual projects to harness it are thin on the ground.

- In 2023, only about 0.4% of U.S. power came from geothermal sources, according to the U.S. Energy Information Administration, as “investors … [wait] for the existing technology to become safer bets.”

The NAM says: “While geothermal represents a small portion of the energy mix now, the NAM supports efforts to invest in developing the technology so that the U.S. has more sources in its all-of-the-above energy portfolio,” said NAM Director of Energy and Resources Policy Michael Davin.

Westinghouse to Build 10 New Nuclear Reactors

Westinghouse will construct 10 large nuclear reactors in the U.S., the energy company told President Trump at a roundtable in Pennsylvania this week (CNBC).

What’s going on: “Westinghouse’s big AP1000 reactor generates enough electricity to power more than 750,000 homes, according to the company. Building 10 of these reactors would drive $75 billion of economic value across the U.S. and $6 billion in Pennsylvania,” Westinghouse interim CEO Dan Sumner said Tuesday during Sen. Dave McCormick[’s] (R-PA) inaugural Pennsylvania Energy and Innovation Summit at Carnegie Mellon University.

- The U.S. has built just two nuclear reactors in the past three decades, both Westinghouse AP1000s at Plant Vogtle in Georgia.

Presidential appearance: President Trump also announced at the summit that private companies will invest some $90 billion in Pennsylvania (CBS News).

- “We’re building a future where American workers will forge the steel, produce the energy, build the factories and really run a country like, I believe, this country has never been run before,” the president said, according to CBS. “I think we have a true golden age for America.”

Keeping energy promises: In May, President Trump issued four executive orders that seek “to quadruple nuclear power in the U.S. by 2050,” CNBC reports. “The president called for the U.S. to have 10 large nuclear reactors under construction by 2030.”

The event: The event at which the announcements were made featured panel discussions with energy and technology industry leaders, including Toby Rice, president and CEO of energy company EQT Corporation, and Amazon Web Services CEO Matt Garman.

- In June, Amazon announced a $20 billion investment in data centers in Pennsylvania, according to CBS.

Why it’s important: With the fast pace of data center construction and the rapid adoption across industries of energy-intensive generative artificial intelligence, the U.S. must expand baseload power generation capabilities, the NAM said.

- “Westinghouse’s announcement of 10 new nuclear reactors in the U.S. marks the start of a fulfillment of a promise made by President Trump,” said NAM Director of Energy and Resources Policy Michael Davin. “Nuclear energy is safe, carbon-free and available 24 hours a day, year-round. It’s a critical component of the energy future we need to keep manufacturing in the U.S. thriving.”