A Matchmaking Service for the Manufacturing Supply Chain

The NAM is a meeting place like no other, where manufacturers of all sizes and sectors gather to make the industry stronger. Recently, along with its partner CONNEX Marketplace, it invited manufacturing leaders to D.C. for high-level discussions about supply chain challenges.

The big picture: This meeting came at an exciting time for CONNEX. Formerly known as Manufacturers Marketplace, the program pivoted in 2022 to combine state-specific installations with the national platform and become a more powerful SaaS.

- Connecticut launched its own version of the CONNEX platform back in February, thanks to the support of the CBIA (a state business association and NAM partner) and the state’s chief manufacturing officer, Paul Lavoie—who discussed some early success stories at the D.C. event.

- “In the first two weeks, more than 200 companies joined, significantly more than the state’s most optimistic projections,” according to a Hartford Business Journal piece—and Lavoie told the paper he expects signups to blow past 750 in the first year.

- Meanwhile, Kentucky is also getting in on the action. The Kentucky Association of Manufacturers (also an NAM state partner) recently launched its own CONNEX Marketplace installation, which was announced by the governor. KAM CEO Frank Jemley also came to D.C. for the meeting, bringing his own success stories.

Talking the talk: The leaders in D.C. focused on how manufacturers can improve security and resiliency in the supply chain. They also discussed how local and state governments can ease supply chain challenges for businesses.

Security: As the participants observed, the key challenge is “illuminating risk” inside the supply chain, so that companies know what they’re facing.

- They discussed the many types of risks involved in supply chains, including cybersecurity, financial, business continuity, capacity and more.

- What’s next: CONNEX is working to integrate technology that will identify and highlight potential risks in a company’s specific supply chain.

Cooperation: The supply chain functions (or doesn’t) on the strength of manufacturers’ cooperation, from the largest companies to their smallest suppliers.

- Furthermore, competition is not company vs. company, but supply chain vs. supply chain, the participants agreed.

- Small manufacturers might benefit from a coach or guide to walk through the sourcing process so they understand how to remain resilient and competitive, one attendee recommended.

- What’s next: CONNEX is working on a playbook that entities such as manufacturing extension partnerships can use to help coach SMMs through the procurement process.

Progress: Executives from CONNEX reported more than 4,000 suppliers were connected to buyers in 2022, while the platform hosted 396 separate “postings” from manufacturers looking for specific parts or supplies.

The NAM will host another forum this fall where manufacturers will tackle supply chain issues. Contact NAM Senior Director of Member Business Services Anna Chongpinitchai for details.

“Mountaire Cares” Is More Than Just a Slogan

“Making a difference” might be the best description of what Mountaire Farms does. Founded in 1914, the fifth-generation family-owned chicken processing company has a long history of helping its communities thrive.

Mountaire Cares: Through its Mountaire Cares program, the company’s employees are committed to changing lives for the better.

- “The Mountaire Cares program was created to fulfill three main core pillars: how are we faithful to our people, how are we faithful to our communities and how can we look to be faithful to the future,” said Mountaire Cares Director JR LaPearl.

Meals for thousands: One of Mountaire Farms’ biggest events during the year is its Meals for Thousands program, where the company partners with local churches, food banks and nonprofit organizations to provide meals for families in need at Easter, Thanksgiving and Christmas.

- The program had humble beginnings 28 years ago, with Roger Marino, who was PR and community relations director at Mountaire, leading the group to provide 300 meal boxes at Thanksgiving. The company has distributed more than 1 million boxes since then.

- For this year’s Easter event, the company’s employees and other volunteers packed 15,000 meal boxes, each of which contained a Mountaire roaster chicken; vegetables; macaroni and cheese; mashed potatoes and gravy; and brownies—enough food to feed a family of four.

- “Our employees really enjoy being a part of this effort to give back to the community,” LaPearl said. “What I love about these events is that they bring people together to share love and kindness to one another.”

Feeding all year long: But hunger doesn’t just exist during holidays. Mountaire Farms donates chicken to local food pantries every month so they can help fill the need all year long. And they partner with groups like nonprofit organizations, little leagues, fire companies and more that use chicken to help fundraise during the year.

And that’s not all . . . Mountaire’s food programs are just one way the company gives back. It has partnered with Habitat for Humanity and several Boys & Girls Clubs on service projects, while also collaborating with local schools on renovations of playgrounds and basketball courts.

Why they do it: For LaPearl, it all starts with the company’s mantra “High Performance for a Higher Purpose,” striving to be a positive light to those around them.

- “Our people are the reason we’re able to do what we do and give back,” said LaPearl. “If it’s not volunteering, it’s the everyday work that we do that really helps to feed families here locally, around the region and around the world. It’s interesting when our employees are upset they were unable to volunteer on a particular day. I remind them that what you’re doing on a daily basis is making a major impact in the lives of people that you don’t even know because of your hard work and performance.”

- “When I have the opportunity to visit our processing plants and I see people smiling, singing in their respective cultural languages and just enjoying their job, that speaks volumes in today’s culture. I can tell they love being here. That’s the way we’re built.”

Mountaire cares about its employees: Through Mountaire Cares, the company offers leadership classes to help employees succeed in their roles and advance in their careers. It also provides scholarships to children and grandchildren of employees.

- In addition, the company built medical facilities at each of its processing plants, and recently established a chaplaincy program that offers employees guidance in times of crisis and high stress.

The last word: LaPearl has some advice for manufacturers who may want to start a program similar to Mountaire’s:

- “Clearly understand your strengths as a company and create an exceptional foundation to build off that. We weren’t able to do all of this overnight, so start small and really focus the first few years on going slow and being purposeful. And always show your employees you care.”

NAM Creates Cybersecurity Brain Trust

As manufacturers confront an ever-expanding list of cybersecurity threats, the NAM is mustering the leading cybersecurity minds in the sector to fight back. Since March 2021, it has been gathering chief information security officers from a large range of companies to discuss their shared challenges and the strategies that have worked against them.

Recently, a group of these cyber leaders met at the NAM’s D.C. headquarters to exchange their latest updates. Here is a sneak peek inside this meeting, where the future of the industry’s cyber defenses was being shaped.

On the agenda: The discussion covered both IT and OT technology and the interdependence between the two that requires a careful but not restrictive cyber strategy.

- Beyond the technology itself, the CISOs also detailed how they present their progress to their boards, including their metrics for success.

Zeroing in: Cyber training for employees was a particular focus for the group, as manufacturers work to educate their workforces about these threats.

- Though most cyber training is directed at IT personnel, there are more and more plant floor workers who also use computers and must receive security training, the CISOs noted.

- It is best to embed training into the overall asset care process, recommended one leader, so it becomes a long-term priority.

- In addition, role-based training ensures all bases are covered, including contractors, according to another CISO.

Guest speaker: The meeting also featured an appearance from a congressional adviser on cybersecurity, who detailed what policymakers are planning.

- Emily Burdick, professional staff member to the majority on the House Homeland Security Subcommittee on Cybersecurity and Infrastructure Protection, explained how the subcommittee is working to oversee the Cybersecurity and Infrastructure Security Agency’s two roles: overseeing critical infrastructure and monitoring federal networks.

Government priorities: Congress is focusing on four key priorities for the year, Burdick said. These include:

- Monitoring CISA’s soon-to-be-proposed rule on cyber-incident reporting (on track for a Notice of Proposed Rulemaking in March 2024, with the final rule expected by September 2025); this proposed rule would require covered entities to report cyber incidents within 72 hours and needs clarification around “covered entities” and the timing of incident reporting;

- Measuring CISA’s effectiveness as a sector risk management agency and as the national risk coordinator;

- Improving private-sector partnerships through the Joint Cyber Defense Collaborative and other processes; and

- Strengthening the national cyber workforce.

What they’re saying: The CISOs in attendance told the NAM how much they valued these high-level discussions.

- “While we often cross paths with fellow CISOs at trade shows and other industry events, it is important for us to gather in small groups and share what we are experiencing in an intimate, off-the-record setting so we can speak openly and honestly about challenges and potential solutions,” said Beth Schulte, CISO of Louisiana-Pacific Corporation.

- “I was able to share some tips with the other CISOs based on my experience and came away with tangible actions and takeaways to both implement immediately and research further after hearing recommendations from peers,” she continued.

Get involved: The NAM’s CISO group is working on industry benchmarks that will be shared with other manufacturers, so the industry can raise its defenses across the board. These benchmarks will help other CISOs evaluate their own practices and keep their boards and executives informed about industry standards.

- If you’d like to weigh in on your company’s activities, please take the short survey here.

How Toyota Shares Its Culture with Other Manufacturers

Why would a company give away its “secret sauce” recipe for success? In Toyota’s case, the answer’s easy: because it’s the right thing to do, according to Jamie Bonini, president of the Toyota Production System Support Center, Inc.

How it all began: The TSSC, which last year celebrated its 30th anniversary, is a nonprofit organization founded by the auto manufacturer in 1992 to help other companies improve their manufacturing processes using the proprietary Toyota Production System.

- “In the early ’90s, companies would come visit our factory in Georgetown, Kentucky, for tours and asked, ‘How do you [manufacture] in the U.S. competitively?’ We said, ‘It’s TPS.’”

- TPS is Toyota’s lean-manufacturing system, based on the Japanese philosophies of jidoka (which can be roughly translated as “automation with a human touch”) and “Just-in-Time,” which refers to producing “only what is needed for the next process in a continuous flow.”

- Toyota said yes to the growing number of requests from outside the company to share TPS principles, and soon developed an entire center devoted to TPS teaching.

The substance: TSSC, which is subsidized by Toyota, provides companies with the training needed to implement TPS principles, which help boost efficiency, product quality and workplace safety—while reducing costs and lead times.

- “TPS emphasizes the elimination of waste, continuous improvement and respect for people,” Bonini said.

The meaning of lean: TSSC has many long-term clients, some of which have been with the nonprofit for most of its three decades. The reason: TPS isn’t a one-and-done, single-size system that can be superimposed on all organizations the same way, Bonini said.

- “‘Lean’ has come to mean different things to different people,” he continued. “But this is what we mean by a Toyota production system: an organization-wide culture of highly engaged people who are solving problems and innovating to drive performance.”

- “When we work with a company, [our solution is] customized; it’s highly situational. What we’re trying to build in an organization is a culture. And to build it, it has to be nurtured, fortified. That’s why we like these longer-term engagements.”

Who’s involved: TSSC has worked with a wide range of companies in many industries, as well as with nonprofits and even governments. This year, the TSSC is working with approximately 50 companies and organizations, about 30 of which are nonprofits.

- The nonprofits are not charged for the consultations. “It’s completely free for them, but they have got to put a lot of hard work into it,” Bonini said.

- Meanwhile, the companies are charged a fee that doesn’t cover all of Toyota’s costs. Toyota donates its time, labor and transportation expenditures, according to Bonini.

The working relationship: Given the bespoke nature of TSSC’s consultations with companies, the work varies from client to client. It may consist of monthly visits, onsite consulting for specific projects or regular remote check-ins and discussions.

- Whatever the client needs from TPS, it requires the TSSC team’s touch. “We have worked with companies that have studied lean manufacturing for many years, and six or nine months in, they’ll say, ‘Wow, Jamie, TPS is very different from what I read.’ You really need to experience it. It’s like learning to swim or ride a bicycle,” said Bonini.

Future plans: TSSC isn’t slowing down after 30 years. It recently began hosting TPS-focused Toyota plant tours, and it has big plans for them.

- It offers half-day tours, because “we want to make TPS very understandable in a short time,” Bonini said. However, TSSC is “also likely to develop an enhanced, two-day tour. On the second day, [tour participants] would talk to us about their particular business and structure and get tailored advice.”

The last word: “A lot of companies look at lean operations as installing a collection of tools: visual management, daily huddles,” Bonini said. “In fact, the tools are part of the system, not the system. Our goal is to help companies understand that the really important thing is the tool users.”

How a Nearly Century-Old Textile Maker Went Digital

It’s no easy feat to transform a struggling family business into a thriving digital enterprise, but that’s exactly what Cooley Group President and CEO Dan Dwight is doing.

Change for the better: Cooley Group was formed in 1926 as a family-run textile manufacturer in Rhode Island. In 2011, Dwight, a member of the NAM Board of Directors, joined the company as president and CEO to navigate the ship through a new age of manufacturing and market demands.

- Today, the private equity-backed extrusion and textile manufacturer is the leading global maker of polymer-coated textiles. Applications range from single-use blood-pressure-cuff materials, to proprietary urethane combat raiding crafts for U.S. special forces, to liners and covers for some of the world’s largest water reservoirs.

How they did it: “As a family-run business, Cooley inherited aging equipment and an aging workforce,” said Dwight, who also serves as vice chairman of the Manufacturing Leadership Council’s Board of Governors. (The MLC is the NAM’s digital transformation arm.)

- “We not only modernized our equipment and infrastructure to compete in the digital age, but also revolutionized our culture. Hierarchies slowed us down.”

- “Digital transformation isn’t only beneficial for the advancement of our physical technologies; it’s also critical to develop a more collaborative company culture that empowers employees at all levels to take action.”

Starting small: “Digital transformation—the integration of digital technology into all facets of an organization—can seem daunting at first,” Dwight said. “But that can’t deter an organization from jumping in.”

- “I advise companies, particularly mid-sized manufacturers like Cooley Group, to approach digital transformation incrementally,” he said. “Don’t expect the cultural, institutional or technological benefits of digital transformation to manifest overnight as some mega-solution.”

- “Think strategically about the areas of your business that are the first movers. Once one aspect of the business is modernized, the digital insights and team’s enthusiasm for change will build momentum to push the remaining pieces into place.”

Gaining momentum: The transformation of this firm of 300 people is ongoing. “Ten years ago, we had trouble keeping our equipment operating for any period of time,” Dwight said. “Now everything in all our factories is digitally [Manufacturing 4.0]-driven across a single operating platform.”

- The company plans to do the pilot phase of an artificial intelligence implementation later this year.

Figuring it out: The MLC was key in Cooley Group’s remarkable transformation, according to Dwight.

- “I’m not sure we would have figured it out on our own,” he admits. “I’m an avid reader; I was born excited to build things. I read a lot about manufacturing and leadership. But even if I could have figured out M4.0 strategy, actually implementing it on the plant floor would have been difficult without the support of MLC members to share best practices and to encourage the Cooley team to embrace transformation.”

Get involved: Companies can jumpstart their own digital transformation by attending Rethink, the MLC’s premier event for manufacturing executives, in Florida on June 26–28. Check it out here.

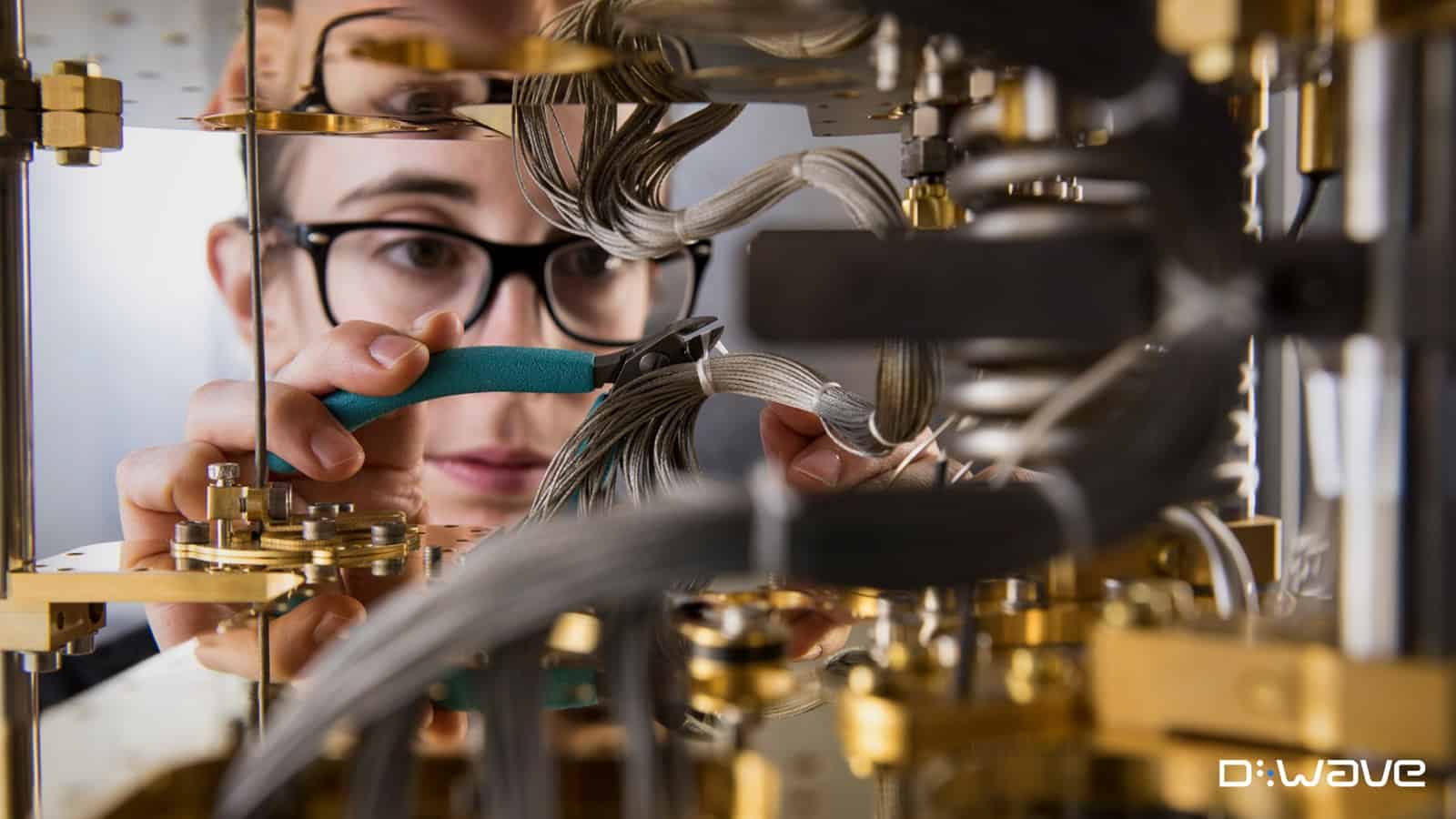

How Quantum Computing Reorganized a Pier

It might be hard to believe, but there are “more possible staff solutions than particles in the universe” for the typical factory, according to D-Wave Vice President of Quantum Business Innovation Murray Thom.

Yet thanks to quantum computing—or computers that employ the effects of quantum mechanics to operate more quickly and efficiently—D-Wave can help its customers solve this sort of knotty problem, whether they are trying to organize pallets, piers or people.

We spoke to Thom recently about the advantages of quantum as well as one of the company’s big successes, a collaboration with software company SavantX to increase the efficiency of Pier 300 at the Port of Los Angeles. Here’s what he had to say.

The future of computing is hybrid: When does it make sense to look beyond classical computing methods and add in quantum? As Thom explained, “Classical computers have to break things down into simpler steps—addition and multiplication.”

- However, a lot of logistical problems involve immense complexity. For example, let’s say you have boxes of components that must be shipped all over the country at different times. Thom puts it, “This box is going on this truck or that truck, [and that decision] affects other decision-making. It’s that cascade that makes this difficult for classical computing.”

- By contrast, quantum computers can take a huge volume of possible solutions, compare them all quickly and come up with a usable schedule.

- Marrying classical with quantum computing—called quantum-hybrid technology—provides the best of both options and delivers robust solutions, said Thom.

The Port of LA: In 2018, SavantX was hired to improve the efficiency of Pier 300, which processes millions of containers every year.

- To juggle the many factors involved—trucks, containers and cranes that load the containers—and to model their movements inside a confined space, SavantX would need a lot of computing power. That’s why it brought in D-Wave.

- SavantX modeled the whole system using a digital twin of the pier, Thom explained. The digital twin allowed SavantX to run all types of simulations, some of which would never occur in the real world.

- Quantum-hybrid technology was then used to “ingest the whole problem” and configure it all at once “like a Rubik’s cube”—simulating an impressive 100,000 cargo-handling runs to find the best algorithm.

- And thanks to D-Wave’s proprietary cloud platform, no one at SavantX had to get “a degree in quantum physics,” Thom added. Instead, “the platform let them configure a solution, while D-Wave handled the complexity.”

The solution: SavantX discovered that the key to greater efficiency was repositioning the rubber-tire gantry cranes.

- By reorganizing the trucks’ pickup times to match when the RTGs were available, and by distributing the containers more widely around the yard, SavantX greatly decreased waiting times.

- This solution resulted in “a 60% improvement in the amount of cargo they were handling, and a reduction in truck turnaround time of 12%,” Thom said.

Working with quantum: As quantum computing is still a new resource in the logistics and manufacturing industries, Thom explained to us how he works with new customers.

- First, he often talks to customers for an hour or more at the first meeting, to get a handle on how they understand the problem from the inside.

- The company’s work is “really about adapting the technology to suit the industrial challenge,” not the challenge to suit quantum computing, he explained.

- Next, D-Wave goes through “a discovery process, building out proof of concept and answering the high-level question,” Thom said. After that, its team “can build formulations and software for businesses to operate on their own systems, putting those quantum-backed applications into production.”

What’s next? D-Wave has a number of manufacturing-related projects in the works, spanning factory optimization, improvements in construction efficiency, carbon emission reductions and more. These include:

- A collaboration with ArcelorMittal to improve steel coils, and another with Johnson & Johnson to optimize the packing of pallets.

- A project with DENSO, an auto parts manufacturer, that aims to improve the safety of autonomous vehicles.

The last word: While quantum computing may sound both complicated and intimidating, “What people are delighted to find out is that it’s no more complex to use than any other technology,” Thom said.

Small Manufacturers Win Big with Digital Transformation

For small and medium-sized manufacturers, digital transformation can seem like an especially harrowing task. But smaller organizations can be uniquely positioned for success in implementing firmwide digital strategies.

Small but mighty: Just look at Graphicast, a 25-person precision metal parts company in Jaffrey, New Hampshire.

- “Because the cost of data collection and analytics is getting lower and lower, even as a small company we can collect data at a rate that gives us meaningful information we can act upon,” said Graphicast President Val Zanchuk. “For example, we created a linear programming model of our business. If we’re growing at a certain rate, I can use it to determine the most economical next steps, such as whether we should hire more people, work overtime or purchase more equipment.”

A workforce solution: Graphicast, which counts Fortune 100 companies among its clientele, has used cloud computing, AI-based systems and more to help it succeed, according to Zanchuk.

- The manufacturer is also looking into the use of collaborative robots as a potential solution to the labor force shortage.

- “When it comes to Manufacturing 4.0, we think about what our customers will be looking for from us in terms of digital collaboration,” said Zanchuk, adding that some of the business’s larger customers are “transforming at a different rate than we are.” That means it’s up to Graphicast to consider client expectations and see how best to meet them given “what’s financially and operationally feasible” for the company.

The MLC helps out: To aid in Graphicast’s digital transformation, Zanchuk joined the Manufacturing Leadership Council, the NAM’s digital transformation division.

- “The MLC is the only place I know where I can discuss broad industry trends in an open fashion, where small companies like mine and large companies like Ford or GM can all be involved in the discussion,” said Zanchuk, who serves on the MLC Board of Governors.

- “Being part of the MLC lets us know if we’re on the right track and how we can make adjustments,” he continued. “It connects us to a group of incredibly talented, intelligent and experienced people who are focused on many of the same operational challenges we face.”

Announcing the 2023 Manufacturing Leadership Award Finalists!

The Manufacturing Leadership Council—the NAM’s digital transformation division—has announced the finalists for the 2023 Manufacturing Leadership Awards, the industry’s premier awards program for achievements in digital manufacturing. You can read the complete list of finalists here.

The ceremony: The finalists will be honored at the Manufacturing Leadership Awards Gala in Marco Island, Florida, on June 28.

- Also announced at the gala will be winners for all project and individual categories, winners of the Manufacturing in 2030 Award, the Manufacturing Leader of the Year, the Small/Medium Enterprise Manufacturer of the Year and the Large Enterprise Manufacturer of the Year.

Rethink: Certain award winners will also present at Rethink, the industry’s leading event for exploring manufacturing’s digital era, which will also take place in Marco Island on June 26–28.

The categories: The awards are divided into nine project categories to recognize company achievements:

- Artificial Intelligence and Machine Learning

- Collaborative Ecosystems

- Digital Network Connectivity

- Digital Supply Chains

- Engineering and Production Technology

- Enterprise Technology Integration

- Operational Excellence

- Sustainability and the Circular Economy

- Transformational Business Cultures

Additionally, individual leaders are recognized in the Digital Transformation Leadership and Next-Generation Leadership categories.

The last word: “As more manufacturers extend digital’s reach onto the factory floor and throughout their operations, we are witnessing transformative performance improvements that would have been unthinkable just a few short years ago—and that are improving life for employees and customers alike,” said MLC Co-Founder, Vice President and Executive Director David R. Brousell.

Manufacturers Add Industry Expert Amid Fight for Permitting and Regulatory Reform

Washington, D.C. – The National Association of Manufacturers has announced Brandon Farris as its new vice president of energy and resources policy.

“Brandon joins the NAM at a pivotal time in our country and for our industry,” said NAM President and CEO Jay Timmons. “Manufacturers across the United States face regulatory challenges that affect their ability to do what they do best: transform and deploy modern technologies to protect the environment, while creating jobs and strengthening the economy. Commonsense regulatory and permitting reform, along with energy security, are needed now more than ever. Brandon’s experience and expertise will help manufacturers accomplish these critical goals.”

Before joining the NAM, Farris was the head of federal government relations for The Chemours Company, where he played an integral role in securing passage of the AIM Act, designed to phase out refrigerants that contribute to climate change. He worked closely with the NAM to help secure bipartisan ratification of the Kigali Amendment to the Montreal Protocol during the 117th Congress. Along with these and other major legislative accomplishments, he was honored as a 2022 top lobbyist by the National Institute for Lobbying & Ethics.

Previously, Farris served as assistant general counsel for Arkema as well as senior counsel for government relations for the Saudi Basic Industries Corporation. After serving in the Marine Corps Reserve, he began his career in Washington as a Bryce Harlow Foundation Fellow at the George Washington University School of Law while working on the U.S. House Agriculture Committee.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.81 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

New Survey: Manufacturers Want Increased Trade with Europe

New Regulations and Taxes Will Hurt Expansion

London, U.K. – As the National Association of Manufacturers’ Competing to Win Tour begins its second week of bolstering strategic alliances across Europe, the association released findings from its Q1 2023 Manufacturers’ Outlook Survey. The survey found that expanding trading opportunities with Europe is a top priority for manufacturers, with more than 77% of respondents supporting negotiating new agreements with European nations.

“At a time when democracy and free enterprise are under attack from forces around the world, America can provide the leadership needed to defend our values, our institutions and our way of life,” said NAM President and CEO Jay Timmons. “By advancing an ambitious trade agreement agenda, we can ensure that the U.S.—and not competitors like China—writes the rules for the global economy and trading system. That has been the focus of our conversations with government, association and business leaders across Europe over the past week.”

The survey also continues to illustrate the need for Washington to enact policies that support the sector’s competitiveness as businesses face record job openings and increased production and input costs.

“With geopolitical turmoil and a banking crisis injecting further uncertainty into the economy, policymakers must act with urgency on key tax, trade, permitting and regulatory proposals if they want to help manufacturers in America fend off a recession,” said Timmons.

Background: Manufacturers have called on Congress and the White House to address key tax, trade, and permitting policies in recent months and have pressed lawmakers to work across the aisle to move legislation. The NAM conducted the survey from Feb. 21 to March 7, 2023.

Key Findings:

- Of companies that are engaged in international trade, nearly two-thirds of manufacturers said that Europe was either a somewhat or very important market for their company. With that in mind, 77.7% would support U.S. efforts to launch market-opening trade agreement negotiations with countries in Europe.

- Nearly three-quarters of respondents (74.9%) listed attracting and retaining a quality workforce as a primary business challenge, with increased raw material prices (60.1%) and supply chain challenges (55.8%) the next biggest impediments.

- More than 90% of respondents said that higher tax burdens on manufacturing income would make it difficult for their companies to expand their workforce, invest in new equipment or expand their facilities. Similarly, 93.9% suggest that increased regulatory burdens would weaken their ability to invest in their workers, equipment or facilities.

- More than 74% of respondents said that permitting reform—which would simplify and speed up the approval process for new projects—would be helpful to their manufacturing company, allowing them to hire more workers, expand their business or increase wages and benefits.

- More than 55% of respondents said that new proposed air standards from the Environmental Protection Agency would raise their costs of compliance, with roughly one-third suggesting that it would lead to increased permitting challenges and lessen investment and facility expansion plans.

Conducted by NAM Chief Economist Chad Moutray, the Manufacturers’ Outlook Survey has surveyed the association’s membership of 14,000 manufacturers of all sizes on a quarterly basis for the past 25 years to gain insight into their economic outlook, hiring and investment decisions and business concerns.

The NAM releases these results to the public each quarter. Further information on the survey is available here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.81 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.