How to Turbocharge Your R&D Leaders’ Careers

Every manufacturing executive has talented innovation leaders in the middle ranks of his or her company—managing a lab or department, but eager to move up. How do you prepare them for the next step in leadership so they can become the executives of tomorrow?

The Innovation Research Interchange, the NAM’s innovation division, offers a program designed to fill this gap in manufacturing professionals’ career development. The Shaping Innovation Leaders program, a partnership with Northwestern University, takes place over one packed week in June every year, and gives these midlevel managers a comprehensive introduction to business strategy, accounting and finance, organizational behavior, brand management and much more.

It’s the starter pack for those seeking to advance in the manufacturing industry. If you have someone on your team who could benefit, here’s what you need to know.

Who it’s for: The course is targeted at managers who have 10–15 years of experience and usually a graduate degree (most often a Ph.D.). These managers typically have several direct reports, oversee a lab or department and handle their own budgets.

- Past participants have worked at major manufacturers and related companies of all sectors, including Mars and FM Global.

What they’ll learn: This one-week intensive residential program—this year taking place June 8–13—features classes in the morning and afternoon, and also includes lunch, dinner and evening study and networking sessions. The courses include:

- Understanding Financial Statements;

- Evaluating Financial Results and Investment Projects;

- Financial Strategy and Cost of Capital;

- Driving Profitable Growth;

- Defending Your Brand; and,

- Law for Technical Executives.

Who’s teaching: The program is taught by eminent Northwestern faculty, including award-winning professors in marketing, management and finance.

- The program’s director, Adjunct Professor of Executive Education Marian Powers, boasts a long career of developing finance textbooks and software and specializes in teaching financial reporting and analysis to executives.

Inside the classroom: Every session of the program introduces participants to skills they may not have encountered in their technical positions. To take just one example, the High-Performance Negotiation Skills session introduces these managers to the framework and tactics that high-level leaders use in handling challenges.

- The course helps participants answer essential questions, such as “How should you think differently about negotiating as part of a team? How should you think about coalition-building in deals with many parties? How can you negotiate effectively from positions of weakness as well as strength?”

- To answer these questions, participants will examine case studies from the manufacturing industry. All the program’s sessions draw on real-world, relevant examples, ensuring that participants receive a useful toolkit of strategies.

What they’re saying: “Above all, this course illustrates a framework behind the motivations of our marketing and business/finance counterparts,” said one participant.

- “We no longer have the excuse of ‘why do they do it that way!?’ but rather, we can help those functions more effectively and proactively.”

Learn more and register: To learn more about the Shaping Innovation Leaders program or to register, visit the IRI site. This year’s program is still accepting applicants.

Hydro CEO: U.S. Must Reuse More Aluminum

Aluminum is “an essential part of everything we do”—so we need to recycle more of it.

That’s the message from leading global aluminum and renewable energy company Hydro, based in Oslo, Norway, whose president and CEO, Eivind Kallevik, recently sat down with the NAM to discuss the importance of the metal to the U.S.

Ubiquitous and crucial: “Construction, automobiles, [energy and technology]—you’ll find an enormous amount of aluminum in all of that,” Kallevik told us. “Going forward, it will just become increasingly important.”

An energy imperative: The U.S. has an aging electrical grid—a matter on which the NAM has long issued a clarion call—and modernizing and expanding it to meet Americans’ energy appetite will require aluminum, and a lot of it.

- “There’s going to be a huge increase in demand for electricity, especially given [the growth in construction of] data centers,” said Kallevik.

- For vehicles to become more energy-efficient, they must be lighter, and “the best way of doing that is more aluminum.”

A workhorse: One of the metal’s best qualities is its ability to withstand nearly endless reuse, Kallevik said.

- “You can recycle it infinitely. If you sort it the right way, you will be able to take it back to exactly the same state it was in in the first place.”

- Hydro—which has operations in 17 states and employs thousands of people in the U.S.—has multiple aluminum recycling facilities throughout the country, including at sites in Pennsylvania, Indiana, Illinois, Louisiana, California and Texas.

Keep more at home: “The more [aluminum] you can keep onshore, the better it is” for manufacturing, the economy in general and national security, Kallevik continued, adding that aluminum is critical in many U.S. defense applications.

- “If the U.S. kept more scrap exports onshore, we would reduce dependence on third parties” for the metal, he said.

Policy and supply chains: Because building is a heavily energy-intensive process, “energy policy is going to be increasingly important” in the coming years, Kallevik went on.

- “To protect its industries, the U.S. needs to ensure a fair regulatory framework to ensure that everybody in a global context competes on a level playing field,” he told the NAM.

- And when it comes to shoring up domestic supplies of aluminum, “to be more self-sufficient, the short-term solution for the U.S. is recycling,” he said. “Use what’s on the ground today, and for tomorrow, build capacity.”

Komatsu Expands and Innovates in the U.S.

Komatsu is a household name in Japan, but it’s making big moves in the U.S., too.

An all-of-the-above strategy: The commercial equipment maker, whose product catalogue runs the gamut from bulldozers and log loaders to autonomous haulage systems for mines, has launched multiple new innovations in recent months.

- In March, it introduced two new wheel loader models with improved fuel efficiency, more engine power and faster speeds.

- Last fall, Komatsu announced the launch of its first commercialized truck in its Power Agnostic series, vehicles capable of running on multiple fuel types, including diesel, hydrogen fuel cells and batteries.

Expansions underway: The global manufacturing giant is also expanding. In late 2024, it announced the construction of new facilities in Mesa, Arizona, and Peoria, Illinois.

- The Mesa project, slated for completion in 2026, will triple the square footage of the company’s current operational footprint in the area. The new sales and service facility will support the company’s mining customers throughout the Southwestern U.S.

- The Peoria expansion, which will replace an existing structure built in the 1970s, “will provide a collaborative space for engineering, sales, manufacturing, management and other functions,” according to the company. It will incorporate solar panels, stormwater reclamation systems and other sustainable technologies.

- A Komatsu 980E-5SE mining truck—winner of the Makers Madness contest’s “2024 Coolest Thing Made in Illinois” award from NAM state partner the Illinois Manufacturers’ Association—will be installed permanently outside the new Peoria building, which is scheduled to be finished by the end of 2025. The truck is manufactured at the site.

All in on mining: It’s fair to say Komatsu has a special focus on mining. In September, following its acquisition of German mining equipment manufacturer GHH Group GmbH, it showcased an expanded lineup of underground mining machinery at the MINExpo tradeshow in Las Vegas.

- It also recently unveiled its Modular ecosystem, an “interoperable mine management platform” to give mining customers access to all connected operational data in one place.

In the works: At the 2025 Consumer Electronics Show in Las Vegas in January, Komatsu exhibited some exciting in-development projects, including the prototype of an electric underwater bulldozer and artwork for planned construction machinery capable of working on the moon.

- The bulldozer—currently a concept vehicle with no planned introduction data as of yet—is a driverless, remote-controlled, electric-powered vehicle. This will be the second iteration of an underwater, battery-operated bulldozer from Komatsu; the first, the D155W, rolled off conveyor belts in Japan in the 1970s.

- “We’ve found that a lot of those machines built a long time ago are still in use,” said Komatsu Chief Digital Officer Michael Gidaspow. “People need this product, so they are keeping them running. Japan has a lot of coastline and coastal infrastructure to maintain, so this kind of dozer is so important there.” The planned update utilizes the latest technology, including automated blade control and teleoperation. It is powered by batteries, whereas the original had a diesel engine, Gidaspow added.

- Komatsu’s lunar construction machinery work is part of the Artemis Program aimed at getting humans back on the moon. “Life on the moon will demand roads, housing and other infrastructure, and lunar construction machines will be indispensable for building all this,” according to the company. “Once we only dreamed of humans living on the moon. Today we are making it a growing possibility.”

MLC Announces Finalists of Manufacturing Leadership Awards

The Manufacturing Leadership Council, the NAM’s digital transformation division, has announced its list of finalists for the Manufacturing Leadership Awards—an honor given to world-class manufacturing companies and leaders who are revolutionizing the industry’s digital capabilities.

The Manufacturing Leadership Council, the NAM’s digital transformation division, has announced its list of finalists for the Manufacturing Leadership Awards—an honor given to world-class manufacturing companies and leaders who are revolutionizing the industry’s digital capabilities.

The big reveal: All finalists will be celebrated at the ML Awards gala on June 18 in San Marco Island, Florida, where the winners will be announced.

- The awards given include the Future of Manufacturing Award, the Manufacturing Leader of the Year, the Small/Medium Enterprise Manufacturer of the Year and Large Enterprise Manufacturer of the Year.

- Manufacturers can also win awards in several categories, including artificial intelligence vision and strategy, business model transformation, collaborative ecosystems and more.

- Award nominations were judged by a distinguished group of manufacturing leaders from across the industry.

- You can see a complete list of finalists here.

Rethink: Ahead of the Awards gala, the MLC will be hosting Rethink, where manufacturing leaders gather to learn best practices and make connections. The star-studded lineup includes:

- A keynote address on digital transformation from Siemens USA President and CEO Barbara Humpton;

- A talk on “How Wall Street Views Digital Transformation in Manufacturing” by Goldman Sachs Managing Director, Technology, Media and Telecommunications Group Jack Anstey;

- An inside look at Hershey’s digital factory, featuring The Hershey Company Vice President of Manufacturing and Engineering and MLC Board of Governors member Will Bonifant; and

- Numerous case studies, best practice sessions, networking opportunities and more.

The last word: “In times of business uncertainty, manufacturers find that investments in digital technology can pay off for improving efficiency and overall performance and innovation,” said MLC Founder, Vice President and Executive Director David Brousell. “In our 21st season of recognizing excellence in Manufacturing 4.0, it is remarkable to witness the innovative methodologies that manufacturers are continually developing to propel their digital transformation initiatives.”

Join us: If you’d like to learn more about Rethink or register for the conference, go here.

How Connecticut Is Strengthening the Manufacturing Supply Chain

If you are a buyer at a big manufacturing firm, you probably discover new suppliers through a mixture of Googling, networking and serendipity. But what if you could search a single database full of suppliers in your state and across the country, view their exact capabilities and certifications and then contact them directly? Or simply list your needs and have qualified suppliers respond to your post, then select the ones who meet your criteria?

You can do all that on CONNEX Marketplace, sponsored by the NAM and run by i5 Services. Think of it as manufacturers’ version of Facebook, LinkedIn or Match.com—the perfect place to find brand-new links for your supply chain. Today, the database boasts 165,000 companies of every size and sector, with more than 300 large buying organizations searching for suppliers on the platform.

One state is way out ahead in the quest to re-localize and strengthen supply chains via CONNEX, and that is, fittingly, Connecticut. We chatted with Connecticut Chief Manufacturing Officer Paul Lavoie about his big vision for the small state and the way it has reshaped national supply chains already.

Making connections: The only chief manufacturing officer in any U.S. state government, Lavoie has a simple mandate: help manufacturing grow in Connecticut.

- As a state official, however, he can’t personally introduce one company to another to help them do business. He needed an intermediary, and CONNEX was the answer.

- While all manufacturers can subscribe to CONNEX to access the national database for a fee, some states have funded state-specific instantiations of the database that in-state companies can use as well. The state governments, manufacturing extension partnerships or other associations cover the costs and help recruit more in-state firms to use the platform, enriching it for everyone.

- Lavoie saw the potential of the state-specific model, created Connecticut’s version in 2022 and began a transformation of its manufacturing sector.

Supply chain success: Today, nearly 600 Connecticut companies have built full profiles on CONNEX, out of a total of 2,504 state-based firms in the database.

- Large manufacturers and other major buyers from across the U.S. have contacted Connecticut manufacturers due to their presence in CONNEX, including Northrop Grumman, the U.S. Army and Hill Air Force Base.

- One large Connecticut company had been working with a supplier in Texas, but CONNEX showed that a similar supplier was located just a few miles away from its facility.

- That supplier now serves several large manufacturers within Connecticut and is “the poster child for shortening supply chains and growing an ecosystem,” said Lavoie.

- And lastly, another Connecticut manufacturer was forced by recent tariffs to find an inspection service within the United States, having previously used a Canadian firm. CONNEX helped the manufacturer find a company in Vermont that provided the same service.

The big guys: Thanks to the efforts of i5 Services President and CEO Alan Davis and Lavoie himself, CONNEX is building out its stable of major manufacturers.

- Several aerospace giants in Connecticut have joined, including RTX. Along with Northrop Grumman, other global companies seeking suppliers through CONNEX include Siemens, General Dynamics, PR Hoffman, Applied Materials and Medtronic.

- Big companies know they need to shorten and secure their supply chains, Lavoie told us—and CONNEX is the perfect tool to help them.

How it works: When a company joins CONNEX, the first step is to build out its profile. This involves providing information about its capabilities, factory equipment, processes, certifications, materials, industry sectors, NAICS/SIC codes, capability statements and more.

- In Connecticut, Lavoie’s office helps manufacturers complete their profiles, providing “concierge service” and even going through the process with manufacturers by phone.

- Once a company is signed up, it can start searching for and sending direct notifications to qualified suppliers or buyers.

- CONNEX also features an Exchange Center, where companies can post their RFQs, RFPs or RFIs. The average contract value of each opportunity posted in the Exchange Center is more than $1 million, and after suppliers respond to a post, they can usually expect an interview within about two weeks.

The last word: Due to the funding from Lavoie’s state office, CONNEX is “an amazing business development tool with no additional costs to Connecticut manufacturers,” he pointed out. “Not only does CONNEX help manufacturers throughout the country strengthen and shorten their supply chains, but it enables state governments and MEPs to strengthen their states’ economies.”

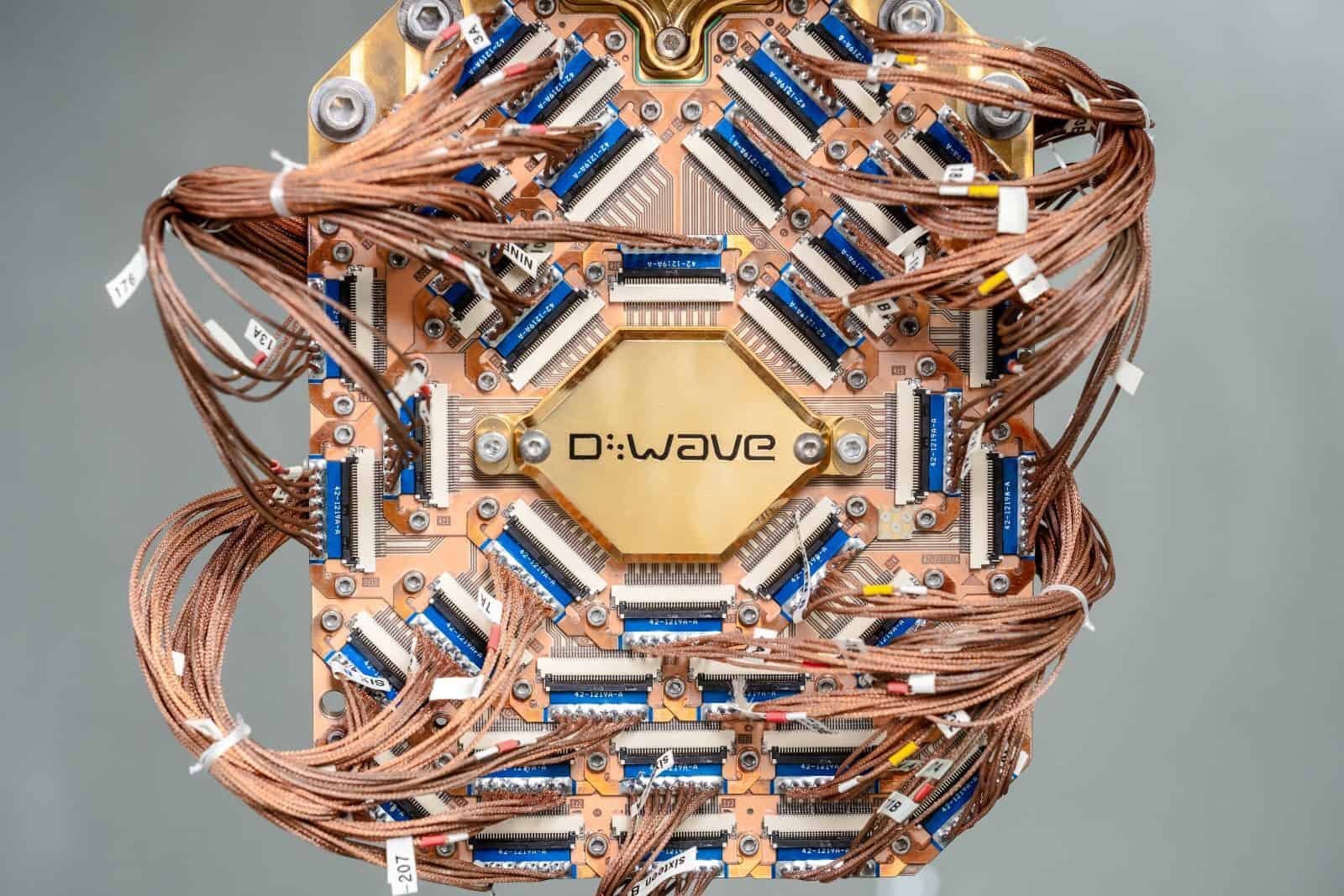

D-Wave Achieves “Quantum Supremacy”

Quantum computing firm D-Wave has achieved a singular breakthrough: it has simulated the “properties of magnetic materials,” opening up the opportunity to “invent” new materials without having to produce them physically in a lab, as D-Wave CEO Alan Baratz told Fast Company.

What it means: The achievement, first published in Science earlier this month, marks the first time a quantum computer has solved a useful, real-world problem that a classical computer couldn’t manage.

- In fact, “To simulate the property of magnetic materials on a classical computer—as the D-Wave team recently did using its quantum computer—would require nearly 1 million years and more energy than the entire world utilizes over the course of a year. D-Wave’s team did it in 20 minutes,” according to Fast Company.

Quantum vs. classical: “Rather than store information using bits represented by 0s or 1s as conventional digital computers do, quantum computers use quantum bits, or qubits, to encode information as 0s, 1s or both at the same time,” D-Wave explains on its site.

- “This superposition of states—along with the other quantum mechanical phenomena of entanglement and tunneling—enables quantum computers to manipulate enormous combinations of states at once.”

- D-Wave’s annealing quantum computer uses these capabilities to solve problems by finding the “lowest energy state” in an enormous range of possible solutions.

- “To imagine this, think of a traveler looking for the best solution by finding the lowest valley in the energy landscape that represents the problem,” as D-Wave puts it.

The possibilities are vast: Being able to simulate materials without creating and testing them in the lab offers significant opportunities for the manufacturing industry and could save companies huge amounts of time and resources. D-Wave foresees that these simulated materials could have applications in everything from “pacemakers to cellphones,” as it told Fast Company.

- “There’s no shortage of potential applications,” said D-Wave Chief Scientist Mohammad Amin.

Further innovation: Another impact of quantum computing is its potential to revolutionize blockchain technology, D-Wave told us.

- “Manufacturers are increasingly adopting blockchain technology to enhance supply chain transparency, track product origins, improve inventory management, and streamline operations. This adoption has led to increased efficiency and reduced costs,” said D-Wave Global Government Relations and Public Affairs Leader Allison Schwartz.

- “Annealing quantum computing offers a potential solution by providing a faster and more environmentally friendly alternative to manufacturers’ current mining operations using classical computers.”

Schneider Electric to Invest More Than $700 Million in U.S.

Global energy management and digital transformation giant Schneider Electric will invest more than $700 million in U.S. operations over the next two years, the company announced yesterday (The Dallas Morning News, subscription).

What’s going on: “Schneider said it intends to leverage the investment to ‘support the country’s focus on bolstering the nation’s energy infrastructure to power AI growth, boost domestic manufacturing and strengthen energy security.’”

- The investment—the largest planned single capital expenditure in Schneider Electric’s 135-plus-year history—will be used to expand manufacturing facilities across the U.S. and to boost “smart factory transformation” across Texas, Massachusetts, Missouri and Tennessee, among other states.

- The company is the latest in a string of large manufacturers to announce sizeable domestic investments. Last week, biopharmaceutical firm Johnson & Johnson said it would spend more than $55 billion in the U.S. over the next four years.

- The announcement comes less than a year after the opening of Schneider Electric’s 105,000-square-foot facility in Red Oak, Texas, to support the data center boom in the Dallas–Fort Worth area.

Where else funds will go: The money will also be used to expand a campus in El Paso, Texas, “to keep up with growing demand to increase production of switchgear and power distribution products,” and to open a Houston innovation center that will offer AI-powered automation solutions.

Our take: “Schneider Electric’s significant investment is a clear sign that manufacturing in America is moving forward—driving economic growth, innovation and job creation across the country,” NAM President and CEO Jay Timmons said in a statement quoted in the article.

- “By expanding their operations with a focus on energy security, automation and AI, Schneider Electric is not only strengthening America’s competitiveness but also creating new opportunities and powering our nation’s future.”

Manufacturing Wins: J&J Invests More Than $55 Billion

Johnson & Johnson will spend more than $55 billion on manufacturing, research and technology in the U.S. over the next four years, the biopharmaceutical company announced (Axios). These investments include a long-planned $2 billion state-of-the-art biologics facility in Wilson, North Carolina.

What’s going on: The NAM joined J&J for the groundbreaking of the 500,000-square-foot biologics manufacturing plant in Wilson on Friday.

- The White House praised the announcement and J&J’s commitment to manufacturing in America. North Carolina Gov. Josh Stein and Rep. Don Davis (D-NC) also attended the ceremony to highlight the facility’s importance to the state economy and the jobs it will bring to the state.

Other projects across the total investment will include:

- Three new advanced manufacturing sites and the expansion of several facilities in J&J’s Innovative Medicine and MedTech businesses;

- Significant spending on research-and-development infrastructure “aimed at developing lifesaving and life-changing treatments in areas such as oncology, neuroscience, immunology, cardiovascular disease and robotic surgery,” according to the company; and

- More investment aimed at speeding drug discovery and development, supporting workforce training and improving business operations.

Common goal: The Wilson site demonstrates the power of collaboration, Johnson & Johnson Executive Vice President and Chief Technical Operations & Risk Officer and NAM Board Chair Kathy Wengel said at the groundbreaking.

- “Today is a tangible example of how J&J is bringing communities, government, education and industry together to achieve the common goal of creating a future-ready workforce that is ready to tackle the toughest health challenges and achieve new breakthroughs.”

Why it’s important: The investments will strengthen not only North Carolina’s economy, but the U.S. economy as a whole, NAM President and CEO Jay Timmons said at the event.

- “Every $1 invested in manufacturing adds more than $2.60 to the economy. That’s top-of-the-line ROI for communities, neighborhoods and cities like Wilson—among the best ROIs you can get. And every new manufacturing job supports, on average, five additional jobs in other industries.”

The big picture: The new Wilson facility will generate a $3 billion impact across North Carolina in its first decade of operation.

- It will support about 5,000 jobs during construction and create more than 500 permanent positions—paying an average of $109,000 a year—in the state (WRAL News).

Certainty and predictability: These investments illustrate why policymakers must ensure that manufacturers have more certainty and predictability, not less, Timmons added.

- “Manufacturing—especially biopharmaceutical manufacturing—requires years of planning, ingenuity and investment decisions,” he said. “When there’s stability, common sense and competitive policies, companies like Johnson & Johnson can plan for the future—and plan big.”

- Timmons said that to “make more wins like this happen,” elected officials must stay focused on a comprehensive manufacturing strategy, including a “competitive tax policy, balanced regulations, prompt permitting, abundant energy and smart trade policies.”

The tax factor: J&J credits the 2017 Tax Cuts and Jobs Act with allowing it to increase its investment, according to MassDevice.

- Investments like J&J’s “are why it is critical that pro-growth provisions of the 2017 tax law be made permanent and more competitive,” Timmons wrote in a social post. “If Congress fails to act, 6 million American jobs—184,000 in North Carolina—will be wiped out. We can’t let that happen.”

- But if Congress does preserve the measures, manufacturing will win, Timmons said. “And when manufacturing wins, America wins.”

Digital Transformation Sees Explosive Growth

Manufacturers are increasing their investments in digital assets, according to a recent survey from the Manufacturing Leadership Council, the NAM’s digital transformation division.

What’s going on: Due in large part to expectations of economic growth, manufacturers plan to either maintain or boost their spending on smart factory investments, they told the MLC in the recently published results of the Smart Factories and Digital Production Survey.

- Respondents also said they are optimistic about continued digitization and adoption, with 69% expecting moderate growth and no recession.

- While 28% would call their current operations “smart” or “somewhat smart,” 76% expect to be there in the next two years.

- Awareness of AI is growing by leaps and bounds among manufacturers; some 34% said they see AI as very significant. (Last year, just 10% said the same.)

Key points: The survey’s top takeaways include the following:

- Digital transformation is changing the game: Most manufacturers—60%—see digital transformation as something that is redefining the industry.

- More manufacturers are going digital: Some 75% of manufacturers say they are at “midlevel” digital maturity, up significantly from 2024 and 2023.

- AI’s role is inevitable: Fully 80% of manufacturers fully or partially agree self-managing and self-learning facilities powered by AI and machine learning are coming.

How a Small Manufacturer Offers Big Retirement Benefits

401(k) fees are a hot topic of conversation if you are an HR leader. When Miltec UV Human Resources Director Karen McKernan was discussing 401(k)s with an old friend, she discovered that Miltec, a small manufacturer, paid much more in fees than her friend’s larger employer. She was aghast, but what could Miltec do about it? The company did not have the purchasing power of a large firm, and so its options seemed limited.

Not so fast. Soon after that conversation, McKernan started receiving emails from the NAM about its new multiple employer plan, the Manufacturers Retirement & 401(k) Savings Plan, which allows many companies to participate in one 401(k) plan. Not only does the larger number of participants lower the fees, but the plan offers administrative and compliance oversight, as well as other benefits.

After doing her research, McKernan was convinced. By mid-2022, she was working with the NAM, the plan administrator, and recordkeeper and service provider Principal to make the switch. On Nov. 1, 2022, the new plan went live for Miltec employees. Today, McKernan says, she would never go back.

The benefits: Once McKernan laid out all the advantages for Miltec’s owners and 401(k) trustees, NAM 401(k) was an “easy sell,” she told us.

- Not only did the fee reduction seem like a “no-brainer,” but the new plan would lift a considerable administrative burden that had fallen entirely on McKernan. It would also offer benefits to employees that Miltec, as a small company, could not add on its own without creating even more administrative tasks.

- Furthermore, the NAM 401(k) comes with an independent 3 (38) investment fiduciary, One Digital, which reviews the funds’ performance regularly and issues reports on a quarterly basis, ensuring low-performing funds are “watched” and subsequently removed and replaced when needed. By delegating investment decisions under this arrangement, a company significantly reduces its potential liability for poor investment decisions.

- Additionally, any plan with more than 100 participants must undergo an annual audit, which is time consuming and expensive. Under NAM 401(k), the plan coordinates and manages the audit for participating companies.

What she doesn’t miss: McKernan listed all the duties she used to perform for Miltec’s own 401(k), which have now been taken over entirely by the NAM’s plan. She doesn’t miss:

- Monitoring enrollment, which Miltec’s employees can now undertake directly on Principal’s website;

- Sending out many required annual notices;

- Compliance testing and 5500 filings (which ensures the plan meets the IRS’s requirements for retirement plans, so that employees can receive tax benefits);

- Sending out summary annual financial reports and quarterly statements; and

- Handling employees’ questions and all communications about the plan.

In contrast, McKernan now only provides information to Principal through an automated payroll report and keeps an eye on how things are going, just in case. There have been few problems, she told us, and those were fixed with alacrity by Principal and the NAM.

Implementation: The entire timeline, from learning about NAM 401(k) to finalizing the switchover, took no more than a few months, McKernan said.

- Principal oversaw the transition, with weekly check-ins, a dedicated project manager and a schedule that included clear deadlines. While transitioning 401(k) plans is “a project,” McKernan said, Principal “managed it very well, including all required communications, and finishing right on time.”

- A word of advice: “If I had to do it all over again, I would have moved the plan over on Jan. 1 instead of Nov. 1,” said McKernan. Having two different plans in one year proved to be more of a headache than she expected, as it forced Miltec to do compliance testing on both plans in 2022.

The reception: “The company’s employees and owners are very pleased with the new NAM plan,” McKernan said.

- Aside from the savings in time and money, NAM 401(k) offers a host of other features that manufacturers can customize. One new feature that has proved popular with Miltec’s employees is loans, noted McKernan.

- In addition, Miltec’s previous plan had a 12-month waiting period before employees could participate, but NAM 401(k) reduced the wait to six months—which is far more appealing to new hires, she added.

- Ultimately, Miltec’s leaders and employees understood and appreciated the logic of joining a multiple employer plan, said McKernan. “They recognize the more participants you have, the more buying power you have. They are seeing the positive results of having access to a robust fund lineup and how that translates to lower fees every time they receive a quarterly statement.”

The bottom line: “I honestly don’t see how a small manufacturing company wouldn’t benefit from joining the NAM 401(k),” said McKernan.

- “I’ve been in HR for a very long time, and when we talk to job candidates about benefits, the 401(k) plan always comes up. It’s a benefit that is necessary to attract talent, as well as help your employees meet their retirement goals,” she added.

- “I wouldn’t hesitate to recommend this plan to any small, medium or large manufacturer.”