Manufacturers Unveil Industry COVID Shared Practices

Manufacturing Leadership Council Releases COVID Operating Practices from Leading Manufacturers

Washington, D.C. – Today, the Manufacturing Leadership Council, a division of the National Association of Manufacturers, released a new collection of emerging strategies and operational practices that leading manufacturers of all sizes are implementing to keep their employees safe and facilities operating. The MLC’s “New Operational Practices to Consider in the Time of COVID-19” brings together the best shared practices within the industry to help manufacturers continue to lead the way as America moves from response to recovery and renewal.

“Manufacturers have been on the front lines throughout this crisis, and this guide leverages the experiences and real-world practices that manufacturers across America have put into place. We’re all looking to get back to some sense of normalcy, but that’s not possible unless we can protect manufacturing workers,” said NAM President and CEO Jay Timmons. “By collecting these practices, the MLC is helping all manufacturers continue to set high standards for protecting employees, families and communities, while creating products essential to our daily lives.”

Shared Practices Breakdown:

- Site Access to Mitigate Exposure

- Workstation Measures to Promote Social Distancing

- Facilities and Traffic Management

- Shift and Team Design

- Leave Policies

- Illness or Diagnosis Response

- Essential Travel Policies

- Returning Nonessential Workers

The MLC compiled and shared these practices to assist manufacturers taking steps in their facilities to meet or exceed existing guidelines from the various federal agencies while also mitigating operational and business risks that are outside the scope of such guidance.

“Since this crisis began, the NAM has been working with Vice President Pence and the Coronavirus Task Force, Centers for Disease Control and Prevention, Occupational Safety and Health Administration and others to relay real time information from our industry and to ensure manufacturers received the critical guidance they needed to operate safely,” said NAM COO Todd Boppell. “The MLC has also convened thousands of manufacturing leaders to share practices and develop new ideas for operating safely through this crisis. Manufacturers have come together to help each other and to help our country.”

This information is not meant as authoritative legal, medical or regulatory guidance or advice. It is not an exhaustive list of operational practices in the COVID-19 environment but rather represents some of the most common “best practices” communicated to the National Association of Manufacturers.

To read the full document click here.

-MLC-

The Manufacturing Leadership Council is the world’s first member-driven, business leadership network dedicated to helping senior industry executives identify the opportunities created by transformational digital technologies in the operation, organization, and leadership of manufacturing enterprises as they pursue their journeys to Manufacturing 4.0. For more information visit https://www.manufacturingleadershipcouncil.com/

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.37 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 63% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the Manufacturers or to follow us on Twitter and Facebook, please visit www.nam.org

How One Manufacturer Invented a Portable Clean Room

How do you keep health care workers safe during COVID-19? It’s one of the most crucial questions of the pandemic. One manufacturer came up with an answer: build them portable booths that mimic clean rooms.

Oldcastle BuildingEnvelope–a company that manufactures glazed products like windows, storefronts, and safety glass—has created a small glass enclosure that shields a health care worker from patients while allowing her to do her job.

The company thinks it could be a gamechanger—by decreasing health care workers’ exposure to the virus and greatly reducing their need for personal protective equipment (along with the time spent changing in and out of it).

How it works: The booth’s modular glass system is easy to clean and assemble. It features:

- Built-in gloves that allow health care workers to examine patients without exposing themselves.

- Positive air pressure to keep outside air from filtering in.

- A powerful filtration system—backed up with the company’s airtight window technologies—that keeps the air inside clean and safe.

How they built it: It was a Herculean effort—the company crammed a development process that normally takes a year into a monthlong sprint.

- On March 23, the idea was hatched.

- Four days later, OBE came up with seven potential designs, then reviewed them until they found the best one.

- Within three weeks, the company had purchased parts, treated materials, and built two working prototypes.

- Less than 29 days after the idea was first discussed, OBE manufactured its first booth.

What’s next? OBE has submitted its designs to regulatory authorities, including the FDA. Once the design is approved:

- Within two weeks, the company expects to start production of its first orders

- With more than 80 locations in the US and Canada, OBE could deploy the technology across North America.

And there’s more…The booth could even feature in the reopening of the economy. OBE has designed a second version for workers who need to be in close proximity without contact, like ticket takers at movie theaters, sports venues and airports.

Here’s another question: what’s one of the most important forces helping to save lives during the pandemic? Answer: manufacturers’ ingenuity.

A Manufacturer Provides Lighting for Temporary Hospitals

One Sunday, it was a text message; two weeks later, it was a product ready for shipment. That’s how fast Acuity Brands sprang into action, after realizing that the temporary hospitals opening around the country needed something very basic: good, reliable lighting.

Without exam lighting, doctors and nurses can’t see what they’re doing. And patients need to be able to read books and see their surroundings at night.

Acuity Brands, a maker of lighting products, answered all these different needs with one ingenious design. Its portable healthcare light stand, which meets all lighting requirements set out by the U.S. Army Corps of Engineers and the Department of Health and Human Services for alternate care sites, includes:

- A medical exam light

- A reading light for patients

- A night light for nurses

- Outlets for charging patients’ smartphones or tablets

- An IV hanger bar that eliminates the need for a separate IV pole

How it works: All of these come together in one package, which can be assembled in under five minutes and folded up for storage or redeployment in a new hotspot.

How they made it: CEO Neil Ashe encouraged employees to “think outside the box” about how the company could aid the COVID-19 response effort, says Mike Montgomery, Vice President of Applied IOT Solution Sales. Here’s what happened next:

- One Sunday afternoon, three engineers exchanged ideas by text message and began sending sketches around for a possible prototype.

- On Monday morning, the design went to the shop for construction.

- On Tuesday afternoon, a working prototype was completed.

- By Wednesday, they’d built a full working unit.

- Less than two weeks later, Acuity Brands had shipped the first 30 units to an alternate care site in Michigan—and two weeks after that, it sent an additional 1000 working units to other sites across the country.

Acuity Brands squeezed a development process that usually takes up to a year into two weeks—and its leaders are using what they learned to streamline the usual processes, making them faster and stronger for normal times.

So far, the stands are already being used in temporary hospitals in Michigan, Tennessee, and Washington, D.C. The company also has pending orders for shipments to Mexico and South America—plus 1,000 additional units in inventory ready to ship.

It wasn’t quite the speed of light, but this lighting stand moved pretty darn fast. Manufacturers like Acuity Brands are making the response to COVID-19 faster, safer, more comfortable—and better lit.

How Pfizer Came to the Rescue of the USNS Comfort

It was around 10:00 p.m. EST when Pfizer got the call. The USNS Comfort—the massive naval hospital ship stationed in New York harbor—needed an emergency order of sterile injectables. Its first COVID-19 cases were arriving on board.

The Comfort had sailed into NYC to treat non-COVID patients and relieve the burden on hospitals. But as ERs and ICUs overflowed, it had to take COVID cases as well. And the ship wasn’t prepared.

That’s when a manufacturer stepped in. Here’s what happened:

On board: 25 ICU patients arrived from a Brooklyn hospital and required immediate medical attention.

- The doctors on the Comfort needed 9 different medications to treat them, but they didn’t have any in stock.

- Most crucially, they needed the sedatives necessary for intubation, should patients need to be put on ventilators.

- So they called Pfizer.

What happened next: Though not an emergency response team, Pfizer’s Hospital Business Unit came together quickly and worked through the night. Here are a few hurdles they faced:

- Logistics: The medications had to be routed through centers in Tennessee and Wisconsin and then delivered directly to the Comfort.

- Transportation: They chartered two planes on short notice, to ensure same-day delivery.

Within 24 hours of the initial call, 4,100 units of medication arrived on the Comfort, and medical workers could treat the patients on board. Several more shipments would follow in the coming days, after the emergency had passed.

Weeks later, the Comfort left New York City’s harbor with its mission complete, thanks in no small part to a manufacturer. This is how the industry is responding to the pandemic: at short notice, at odd hours, and with a sense of duty.

A Visit to Hershey During the Pandemic

What’s it like to work in a manufacturing plant during the pandemic? The NAM’s staff photographer took a trip to the Hershey facility in Hershey, PA, to find out. Here’s what he saw.

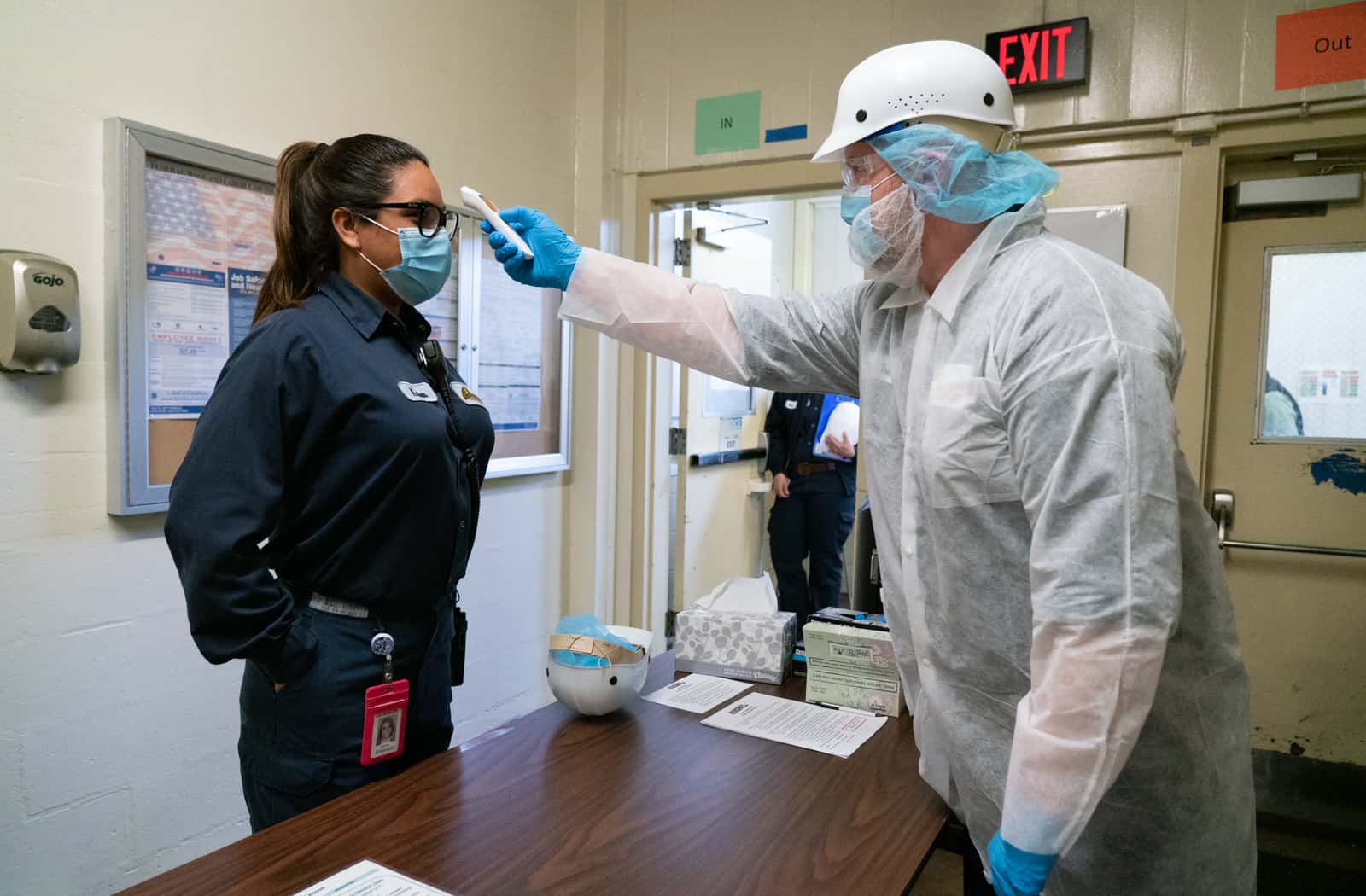

At the entrance, employees’ temperatures are checked. Either in their cars…

Or upon entering the facility. By then, workers have already put on masks.

All around the facility, workers are sanitizing equipment—from machinery to desks to keyboards. They go through this procedure multiple times a production shift.

Walk into the cafeteria, and you’ll see a new table design—yellow tape shows workers where to sit to maintain a safe social distance.

No more huddles—all meetings take place at a distance.

Below, a trainer and trainee use a two-way radio while social distancing, in order to hear each other over the noise of the machinery.

The control room has some new décor: vinyl sheets, which create clear cubicles around each worker.

Hershey’s chocolate production goes on much like before, keeping America stocked with the famous brand’s familiar treats.

But meanwhile, the company is also lending a hand—by helping to source, store and distribute medical supplies within its community. The boxes below contain sterile exam gloves for the Penn State Health System.

Because it instituted precautions early on, Hershey’s workforce has stayed healthy. As Senior Director of Manufacturing Tim Hinegardner said, “The safety of our team is our top priority and always has been. Hershey made chocolate throughout the Great Depression and two world wars, for both soldiers and civilians. We’ll persevere through this, too.”

Protolabs is Working Quickly to Produce Medical Supplies

In response to the COVID-19 pandemic, Protolabs—a digital manufacturer of custom prototypes and on-demand production parts headquartered in Maple Plain, Minnesota—has prioritized the production of medical supplies and is already providing essential products to labs, hospitals and companies across the United States.

The company has seen an influx of COVID-19 related medical components needing urgent production, including test kits, ventilators, shields, masks and respirators. Across the company’s service lines—injection molding, CNC machining, 3D printing, and sheet metal fabrication—over 4 million COVID-19 related parts have been expedited at no charge.

Combating the virus has become the company’s highest priority. “We’re honored to do our part to help fight this virus,” said Protolabs President and CEO Vicki Holt. “We’ve been working nonstop to develop components needed for critical medical supplies, such as ventilators, respirators, test kits and shields, and we put internal protocols in place to prioritize these orders ahead of all others to get critical medical supplies into the market.”

With so many manufacturers working to support the pandemic response, each is attempting to find the best way to contribute effectively. On Protolabs’ end, its proprietary software converges software and hardware platforms, automating the front-end of the manufacturing process and moving parts across a multitude of processes out the door in as little as a day.

“The manufacturing industry has really rallied to produce critical supplies, with companies quickly shifting resources to answer the call,” said Holt. “Due to the exponential growth of COVID-19 cases, the speed of response is critical for our customers and our nation. At Protolabs, we have always prided ourselves on our speed—which enables us to cut new tools and ship parts in a matter of days in order to get them to the people who need them.”

“Manufacturing heroes have been a part of our country’s history since its inception, and that tradition continues today,” said National Association of Manufacturers President and CEO Jay Timmons. “During this crisis and in the future, you can count on manufacturers to lead the way forward.”

From Medical Gowns to CDC Billboards, Cooley Group Is Making It Happen

Cooley Group, a Rhode Island manufacturer that makes engineered geomembranes, building products and commercial graphics, has taken on many roles in supporting the response to COVID-19.

As a company that already produces items like respiratory vests, blood pressure cuffs and medical bedding, Cooley was well versed in the materials needed to support patients and protect medical staff. As soon as the pandemic hit, it began working on testing and manufacturing medical gowns. Today, their facilities in South Carolina and Rhode Island are producing high-quality Level 3 and Level 4 medical gowns that protect against moderate and high risks—and those gowns are being shipped to medical professionals at a rate of approximately a million square feet per week.

“It took us about two weeks to develop the material, perform full testing and certification and roll it into what is now full-scale production,” said Cooley Group President and CEO Dan Dwight. “We’re shipping this out by the truckload.”

Cooley has also found other ways to respond to COVID-19. According to the company’s leadership, around 70 percent of the billboards in North America are printed on Cooley-produced material. Through a partnership with the Ad Council and outdoor media companies, Cooley has been donating material and services to the Centers for Disease Control and Prevention and other entities that want to use those billboards for public messaging. Currently, there are more than 50 locations around the country where CDC messaging is printed on donated Cooley material.

As with any venture, Dwight’s advice to other manufacturers seeking to make a difference is to find the best application for your organization’s existing skills and assets.

“Our view was, we needed to pick our targeted sweet spots and then put all our effort into it,” said Dwight. “What do you already do well, and how do you apply it? We prioritize innovation, so we knew we could produce something that would be new and creative. We prioritize high performance, so we wanted to focus on higher-end products that take advantage of our capabilities.”

Dwight also believes that the cooperative nature of the manufacturing industry has been helpful in weathering difficult times.

“We’ve always had a collaborative culture, and we know the benefit of sharing best practices,” said Dwight. “Now that collaboration is not about Manufacturing 4.0 or the Internet of Things—it’s about surviving a pandemic. But it’s built into the way we do things.”

“Manufacturers across the country are working tirelessly to make sure that people have the products they need,” said National Association of Manufacturers President and CEO Jay Timmons. “As we face this moment of uncertainty and challenge, manufacturers are showing again and again that we are committed to doing our part.”

Samsung Calls on its Network to Support Local Communities

As a large manufacturer with employees spread across the United States, Samsung Electronics North America is leveraging its extensive network to help local communities strengthen their responses to COVID-19. The company has already donated $4.3 million in COVID-19 relief to partners in neighborhoods where a majority of Samsung’s U.S. employees live and work. David Steel, executive vice president and head of corporate affairs for Samsung Electronics America, says that the company’s strong relationships with local communities have helped them to distribute that funding effectively—from providing technology to aid frontline workers to assisting school systems with their transition to remote learning.

“We chose to support local needs in the states with our largest workforce—we partnered with organizations that are really on the front lines in those communities, whether they’re food banks or educational organizations,” said Steel. “Our local communities are so important to us, and we wanted to help them through this time of need.”

Samsung has also expedited some of its planned contributions to support teachers and students. Solve for Tomorrow is Samsung’s annual nationwide contest designed to boost interest and proficiency in science, technology, engineering and math among public school students in grades 6-12. Samsung cancelled the final events scheduled for this spring due to COVID-19, but instead of holding the contest, the company was still able to expedite much of the $3 million in technology to the schools involved in order to help them transition to distributed learning programs.

“After 10 years of the Solve for Tomorrow contest, we’ve built close ties with a whole network of STEM education teachers in schools around the country,” said Steel. “We were able to reach out to many of them and understand their needs as they were transitioning to this new way of teaching and learning, and we were able to help with the technology and supplies that would help underserved schools make this transition.”

Samsung has also long been involved in efforts to support manufacturers and STEM education nationwide. The company was a founding sponsor of Heroes MAKE America, a Manufacturing Institute initiative that equips transitioning service members, veterans and military spouses with the skills and certifications they will need for rewarding careers in manufacturing. Samsung’s grant to the program included financial resources as well as laptops and other key technology for its training locations.

“Our philosophy is that a company thrives with its community,” said Steel. “So for us to be successful, we need our local community to be successful.”

“Manufacturers are dedicated to the health and safety of the people who work in our facilities, live in our neighborhoods and rely on us for the necessities they use every day,” said Executive Director of The Manufacturing Institute Carolyn Lee. “We are committed to supporting our employees and our communities—both now and always. Samsung’s local support is a great example of how manufacturers are rising to respond to this crisis.”

Electronics Manufacturer Sparks Inspiration in NYC

Manufacturers nationwide are answering our nation’s call and finding creative ways to support of the COVID-19 response effort—including at the epicenter of the pandemic in the United States.

Adafruit Industries, an open-source electronics hardware company based in New York City, has retooled their facilities to make two in-demand products: personal protective equipment for health care professionals and electronics for critical medical devices. Currently, the company is working with the New York City government as well as care centers like The Mount Sinai Hospital to deliver face shields, but they have also received requests for electronic components of essential medical machines, including motor controls and pressure sensors for ventilators.

In addition to the new products rolling off the assembly line, some of the items Adafruit was already developing are now being repurposed for medical needs. For example, the company produces thermal cameras and imagers the size of a finger that can determine the temperature of what they are seeing with no contact. Traditionally, these cameras are used for controls in heating, ventilation and air conditioning—but today, those sensors are being used in medical devices for contactless fever screening as part of the coronavirus defense.

Adafruit’s founder and owner Limor Fried highlighted the importance of clear communication with employees and staff—and credited Adafruit’s workers with pulling together in the face of ongoing challenges.

“I think that day-to-day consistency and clear messaging and the tools we have—masks, temperature checks, sanitation protocols—it’s just part of the job,” said Fried. “If you have really good people and trust and transparency, you can get the job done.”

Fried is also a 2019 STEP Ahead Honoree, a distinction conferred by The Manufacturing Institute—the National Association of Manufacturers’ workforce and education partner—to recognize women in science, technology, engineering and production careers who exemplify leadership within their companies. As the head of a 100 percent woman-owned business, she hopes that Adafruit’s role can help inspire young women around the country.

“There are little girls that are scared about what this pandemic is,” said Fried. “But they should know that there’s a woman-owned manufacturer working to combat this virus right in New York City.”

As manufacturers nationwide pull together to create medical equipment and deliver essential products, Fried is confident that the industry will be able to help the country overcome the pandemic.

“This is the epicenter,” said Fried. “But it’s also the epicenter of really tenacious, smart people who are going to see this through.”

“Across the country, the men and women who make things in America are delivering for their communities and their country,” said President and CEO of the National Association of Manufacturers Jay Timmons. “I could not be more proud of their incredible work or more grateful for their commitment to the cause.”

Listen: Public Health & Industrial Cleaning Practices for COVID-19

On April 1, the National Association of Manufacturers and the NAM’s Manufacturing Leadership Council hosted a phone call to discuss best practices for public health and industrial cleaning as part of the COVID-19 response. The call included remarks from Manufacturing Leadership Council Executive Director David R. Brousell; Eli Lilly and Company Chief Financial Officer Josh Smiley; and Ecolab Global Food and Beverage Division Research, Development and Engineering Food Safety and Quality Program Leader Dr. Tatiana Lorca.

Brousell discussed the importance of industrial cleaning to the overall effort against COVID-19, and led a question-and-answer session with participating manufacturers.

“We’re hopeful that the information from this call will help guide your own thinking on ways to protect and defend the people in your plants and factories and in your factory environments,” said Brousell.

Dr. Lorca emphasized there is currently no evidence COVID-19 is transmitted to humans through food or through packaging materials, but cautioned that the virus is new and still has some unknowns.

“The primary route of transmission is person to person, so the best way to protect ourselves, our employees, our families and our communities and customers is to follow standard infection control practices,” said Dr. Lorca. “The good news is that the virus is an enveloped virus, and we know that enveloped viruses are vulnerable to disinfection, which means we can use approved disinfectants to kill the coronavirus on surfaces.”

Dr. Lorca highlighted standard safety practices like properly washing hands and cleaning and disinfecting high-touch surfaces, including utensils. She explained the difference between sanitizers and disinfectants, the latter of which tend to be more effective for destroying COVID-19 on surfaces. She also encouraged manufacturers to check the U.S. Environmental Protection Agency’s publicly available list of products that are known to kill the virus when selecting a disinfectant and to follow the instructions for use posted on the product’s label.

Smiley discussed Lilly’s efforts to protect the supply chain, including the supply of insulin; to keep employees safe and productive; and to address the pandemic by developing a therapeutic antibody with pharmaceutical company AbCellera Biologics, Inc. He also spoke about Lilly’s work to support their community by conducting testing in Indianapolis and their work to keep business moving.

“We’re trying to figure out—all of us—how to keep employees safe and healthy while we carry on our business,” said Smiley. “Lilly’s mission is to make life better for people around the world, and we’ve use that as our guiding principle…Lilly is bringing the full force of our scientific and medical expertise to attack the coronavirus pandemic.”

The conversation can be accessed here.

The NAM is continuing to provide coronavirus resources for manufacturers, connecting businesses with guidance from appropriate government officials and agencies and providing updates on the state of the manufacturing industry.