The Company That Puts UV Light to Work

Did you know that several of the components in your car may have passed under high-intensity UV light prior to your purchase? You may have heard that manufacturers coat headlights with a UV protective film to keep them from getting scratched by road debris, but several other components are also manufactured using UV—including windshield borders and the protective coating on interior trim. The process is called UV “curing,” which dries coatings consistently, efficiently, durably—and without releasing harmful chemicals into the atmosphere, as other drying processes do.

The NAM got a firsthand look at this technology recently, thanks to manufacturer Miltec UV of Stevensville, Maryland. The company manufactures UV systems that cure products like optical fiber, semiconductors, prefinished hardwood floors and cars, supplying this technology across the country and around the world. NAM Director of Photography David Bohrer visited Miltec’s facility to check it out.

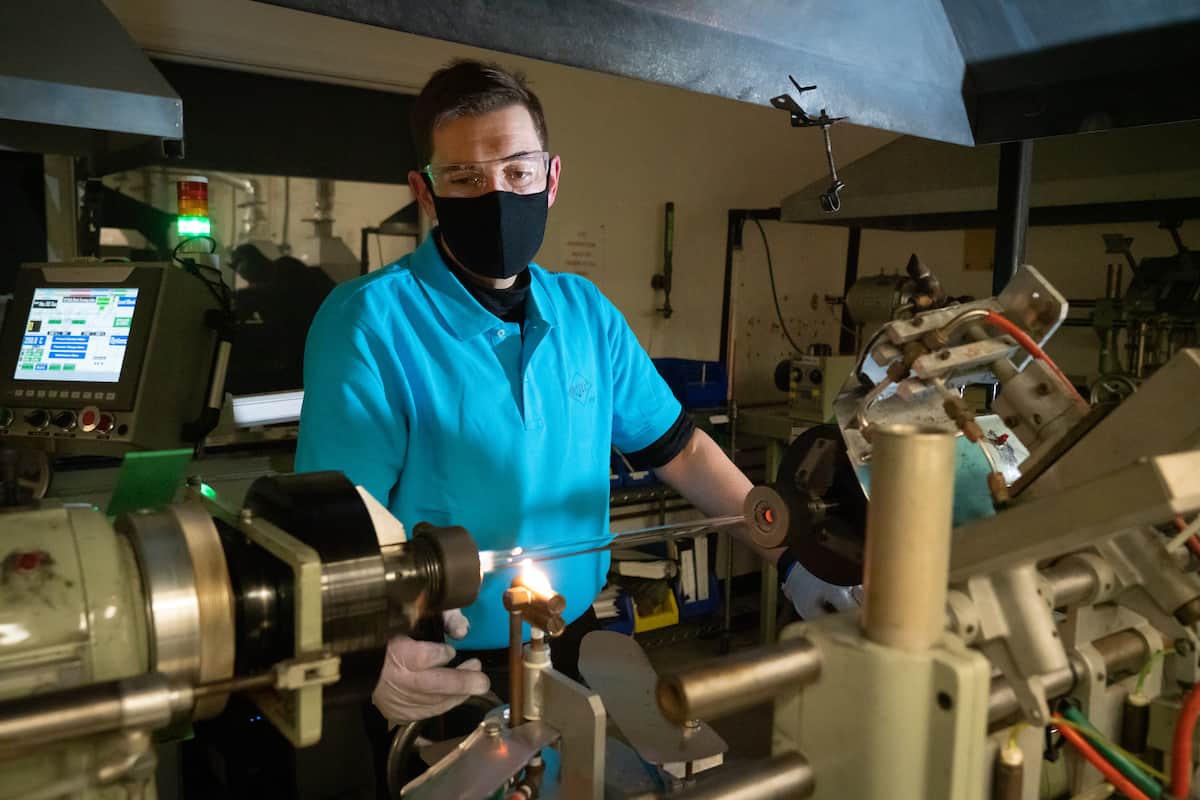

Here, an employee at the Bulb division is making a UV bulb. Miltec manufactures thousands of bulbs each year for export around the globe:

When dealing with UV technology, safety comes first. Here, an employee working in the Li-ion Battery Research and Development lab is assembling coin cell batteries in a glove box. The batteries will be used as test samples.

The set of a sci-fi movie? Nope. It’s just the testing of a 16-lamp UV curing system that produces more than 530 KW of UV power. Ultimately, the customer will use this system to cure inks and coatings on a high-speed printing press that manufactures outdoor packaging bags, such as for Miracle-Gro.

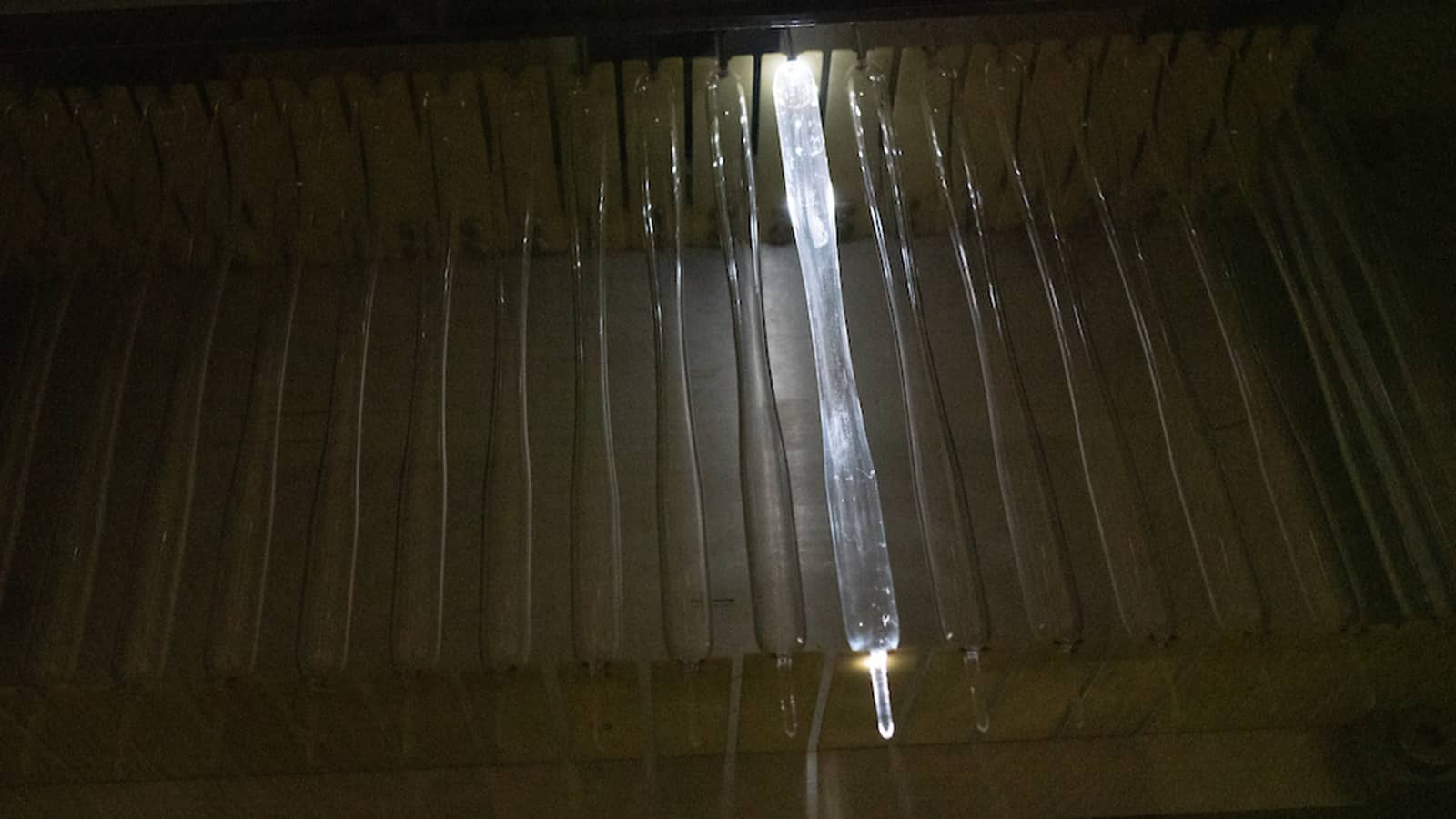

Of course, you can’t go through an entire story about UV light without a cool picture of UV light—so here it is. This is a UV bulb after it’s been filled with an inert gas, which helps it illuminate its powerful UV light.

Miltec says: “Miltec UV is proud to be a member of the NAM and extremely grateful for all of the work that the NAM does to protect the jobs of our team members that do so much to help our company grow and succeed in the international market,” said Miltec President Bob Blandford. “We are also honored and blessed to have such a dedicated manufacturing team that truly understands the importance of making products in the USA and satisfying customers with reliable and high-performance products. With the help of tax cuts, Miltec UV is doing its part by creating more jobs, increasing salaries and offering end-of-year bonuses for its employees.”

This Is What Port Congestion Looks Like

Ports in the United States have been facing serious congestion issues for almost a year, even as manufacturers work tirelessly to ensure essential products can get where they need to go. NAM Director of Photography David Bohrer recently paid a visit to the Port of Long Beach, where an influx of exports coming to the United States is causing traffic jams along the California coast.

Long Beach is one of the country’s busiest ports at the best of times, since it receives much of the trade traffic from Asia. Today, it’s mobbed by ships waiting for their turn to unload. Under normal circumstances no more than one or two ships would be temporarily anchored while awaiting a spot at the port terminals. But as of late October, that number peaked at more than 70 ships holding offshore. Just look at these lines:

Meanwhile, the port is full of shipping containers waiting to be hauled away and emptied. However, there aren’t enough workers, specialized truck chassis, or available truck drivers to handle the volume of containers:

Here is one container in transit. But once it’s unloaded, the empty container has to be stored as well—and current parking and warehousing space isn’t sufficient for the many empty containers at the port.

Recently, the Biden Administration announced an initial plan to help strengthen supply chains and reduce these blockages. Actions include extending hours of operations at the Ports of Los Angeles and Long Beach and addressing workforce shortages and negotiated shipping agreements.

- Additionally, on November 9, the White House announced details of a new Action Plan to quickly distribute newly available port funds in an effort to clear backlogs. This plan creates new flexibility in how some ports can use federal dollars to meet on-the-ground needs and sets bold new deadlines for releasing funds—including the authorization of nearly $240 million in grant funding before the end of the year.

The NAM says: “Manufacturers in America have been tirelessly working to maintain operations and provide essential products and jobs to their communities throughout the pandemic. These port backups and supply chain delays aren’t some distant, downstream issue—NAM members are facing historically high shipping costs and unheard-of delivery delays on an hourly and daily basis. We will continue to engage with policymakers to identify short-term solutions and establish long-term measures that allow for economic growth and a functional, inclusive and efficient supply chain,” said NAM Director of Infrastructure Policy Ben Siegrist.

How Eastman Strives for a Circular Plastics Economy

Eastman may be a specialty materials company, but its focus these days is expansive: the well-being of the planet and the sustainability of manufacturing practices.

“We have three main pillars,” Eastman Executive Vice President and Chief Technology & Sustainability Officer Steve Crawford told us. “How do you improve the climate? How do you care for society? And how do you eliminate waste?”

Eastman means to do all three.

Circular economy: Among Eastman’s goals for the foreseeable future is making major strides toward the creation of a circular plastics economy, a model of production and usage that emphasizes the reuse and refurbishment of plastic products over new creation.

- Eastman encourages traditional, also known as mechanical, recycling when it can be used. However, “300 million metric tons of plastic get produced in the world every year, with less than 20% collected for mechanical recycling. In the U.S., less than 10% actually gets recycled,” said Crawford, who has been with Eastman for 35 years. “Most of it ends up in landfills, incinerated or worse.”

Under construction: Eastman, which plans to make its operations carbon-neutral by 2050, is constructing what will be one of the world’s largest plastic to plastic molecular recycling facilities in Kingsport, Tennessee. It is slated for completion by the end of 2022.

- Eastman estimates that by 2025, the facility will be diverting 250 million pounds of plastic waste every year. By 2030, the company plans to make that figure 500 million.

Why it’s important: “Mechanical recycling—where you go out and take items like single-use bottles, chop, wash and re-meld them and put them back into textiles or bottles—can only really address a small portion of the plastics that are out there,” Crawford said. After a few cycles, the polymers in the products degrade and the process is no longer possible.

- Instead, Eastman uses advanced, also known as molecular or chemical, recycling. “We unzip the plastic back to its basic building blocks, then purify those building blocks to create new materials,” Crawford said. This “creates an infinite loop because that polymer can go through that process time and time again.”

Additional measures: Eastman also makes use of carbon renewal technology, in which hard-to-recycle mixed plastics are brought into the recycling stream, broken down to the molecular level and reformed into textiles and other materials. Fully 40% of the material in Eastman’s Naia Renew cellulosic fiber, in fact, comes from the plastic reclaimed through this process, Crawford said.

- The company is involved in polyester renewal technology as well. Using colored soda bottles, old carpet and a variety of other mixed plastic waste streams, Eastman creates new materials that can be used to make everything from reusable containers to electronics to eyeglass frames.

First do no harm: Before implementing any new technology, Eastman makes sure of one thing: that it has a lower greenhouse-gas footprint than the process it will replace. Said Crawford: “We fundamentally believe that solving the waste issue should not hurt the climate.”

- The company also has a long-term goal regarding emissions: it plans to reduce its greenhouse-gas output by one-third by 2030.

The policy angle: To make a real difference where plastic waste is concerned, the U.S. needs “smart” policies in place, Crawford said. Eastman’s recommendations include:

- Incentives, mandates and infrastructure investment that will increase all recycling;

- Cooperation between companies, nonprofits and local and state governments that have effective models for aggregating and collecting plastic waste; and

- Legislation to ensure the definition of recycling includes advanced-recycling techniques.

The last word: “There is no one company that’s going to be able to create the circular economy by themselves,” Crawford said. “It’s going to take partnerships across the value chain and really smart public policy. We can’t solve this issue alone.”

How BASF Uses Enhanced Reality to Help Workers Learn

The human side of digital transformation was on full display at a recent virtual plant tour of BASF Chemical Intermediates Geismar, Louisiana, facility. Hosted by the NAM’s Manufacturing Leadership Council, the tour gave participants an inside look at how the company is using Voovio’s enhanced-reality technology to transform employee training.

Who they are: BASF Chemical Intermediates, a division of German multinational chemical manufacturer BASF, makes approximately 600 distinct products sold worldwide to the chemical, plastics, agricultural and consumer goods industries, among others.

What is Voovio? The company has partnered with simulation-software maker Voovio to design a customized training solution for its employees: a virtually accessible digital replica of the BASF plant.

- Using a computer or other digital device, employees can select plant components such as valves, pumps and control panels to get a detailed view of each. These components respond and perform virtually the same way they would in real life.

- Using the software, trainees can click on any piece of equipment in any workflow to see how it fits into each process.

Why use it? BASF wanted to make worker training faster, more interactive and more self-directed so employees could learn new skills and review existing ones more quickly and easily.

Scalable training model: The tailorable Voovio software offers different training-module levels based on each worker’s experience level and skills.

- Training modules include an equipment replica, tasks to be performed and an action checklist for completing a series of tasks.

- Employees get feedback from the software as they perform each virtual procedure, letting them know whether they’ve performed a task correctly.

Real-world application: Voovio also lets companies take the training into the production facility. Using an approved digital device, employees can perform test runs at any time to ensure they’re prepared to complete a job on the ground.

The verdict: BASF has already begun to reap the benefits of the software. Since implementing Voovio, it has seen a marked increase in both worker competency and productivity.

Sign up for a virtual plant tour: Don’t miss the MLC’s upcoming tour of Johnson & Johnson’s facilities on Wednesday, Dec. 1, from 11:00 a.m. to 1:00 p.m. EST. You will see how Johnson & Johnson uses mobility tools, advanced robotics and material handling, as well as adaptive process controls to drive improvements. After the tour, stay for the panel discussion on how to scale advanced manufacturing technologies to ensure a sustainable, reliable and adaptable product supply chain. Sign up today!

One Small Manufacturer Battles Thousands of Counterfeits

If you can buy anything online, how can you make sure that what you’re buying is genuine?

That’s a problem facing consumers and manufacturers alike. According to the NAM’s research, fake and counterfeit products cost the United States $131 billion and 325,000 jobs in 2019 alone—and estimates suggest that global trade in counterfeits exceeds $500 billion per year. The explosive rise of counterfeit goods has heavily impacted manufacturers, requiring them to fight back on a range of fronts.

For Clint Todd—the chief legal officer at Nite Ize, Inc., a manufacturer of mobile, pet and key accessories, as well as hardware, lighting and other products—that challenge is very real and only getting worse.

“In 2019, we took down 75,000 counterfeit listings and websites,” said Todd. “And we’re a small business, so you can guess how large the problem is countrywide.”

Why it’s happening: First, the online nature of e-commerce makes it more difficult to ensure accountability. Many counterfeit products are purchased through third-party sellers that may or may not provide real contact information.

- In practice, many platforms have not been held liable for counterfeit products sold on their platforms by these third-party sellers, even as they facilitate their sale. That means there’s often little manufacturers can do beyond asking the platforms to remove the listing.

- Second, a large proportion of the sellers of counterfeit goods are located in China and Hong Kong, making it much more challenging for U.S. companies to bring effective lawsuits, even if they do have accurate seller contact information.

“You have this odd confluence of laws and tech development and the involvement of another country that has driven this exponential increase in counterfeits,” said Todd. “You don’t have to be a rocket scientist to see how the inability to fight the problem has been detrimental to U.S. businesses.”

How manufacturers respond: Manufacturers and others have been forced into a piecemeal strategy that includes using software tracking services to find fraudulent trademarks and images; working with third-party sites to remove listings for knockoff merchandise; bringing lawsuits against counterfeiters where possible; and coordinating with the International Trade Commission. That strategy is challenging for lots of manufacturers but is particularly hard on small and medium-sized companies that may have fewer resources yet can be devastated when their products are ripped off.

What we need: The NAM’s report, “Countering Counterfeits,” details solutions for the federal government and the private sector, including:

- Requiring e-commerce platforms to reduce the availability of counterfeits;

- Modernizing enforcement laws and tactics to keep pace with counterfeiting technology;

- Streamlining government coordination;

- Improving private-sector collaboration; and

- Empowering consumers to avoid counterfeit goods.

As Todd put it, “It’ll take a multi-stakeholder approach. It’s not just the government. It’s not just manufacturers. It’s not just the online platforms. It has to be a coordinated approach with all those stakeholders to get to the heart of the matter.”

What the NAM is doing: The NAM is leading the effort against counterfeiting and has already made significant headway with policymakers. Among its recent highlights:

- After years of NAM advocacy, the Department of Homeland Security has implemented the Synthetics Trafficking and Overdose Prevention (STOP) Act of 2018, which steps up screenings for international mail shipments—one way in which counterfeits get into the U.S.

- In late 2020, Congress also implemented several NAM recommendations, including bolstering federal oversight at U.S. ports; cracking down on scammers and other bad actors exploiting the pandemic by producing fake goods or engaging in price gouging; and allowing the FDA to seize and destroy dangerous counterfeit medical devices.

- Both the Senate and House have seen the introduction of bipartisan bills that incorporate NAM recommendations on addressing the sale of counterfeits through online platforms.

The last word: “People need to understand the scope of the problem and how pervasive it has become,” said Todd. “Everyone needs to know how often counterfeits and knockoffs are affecting U.S. companies and how expensive and difficult it is to combat the problem with the tools we have at our disposal now.”

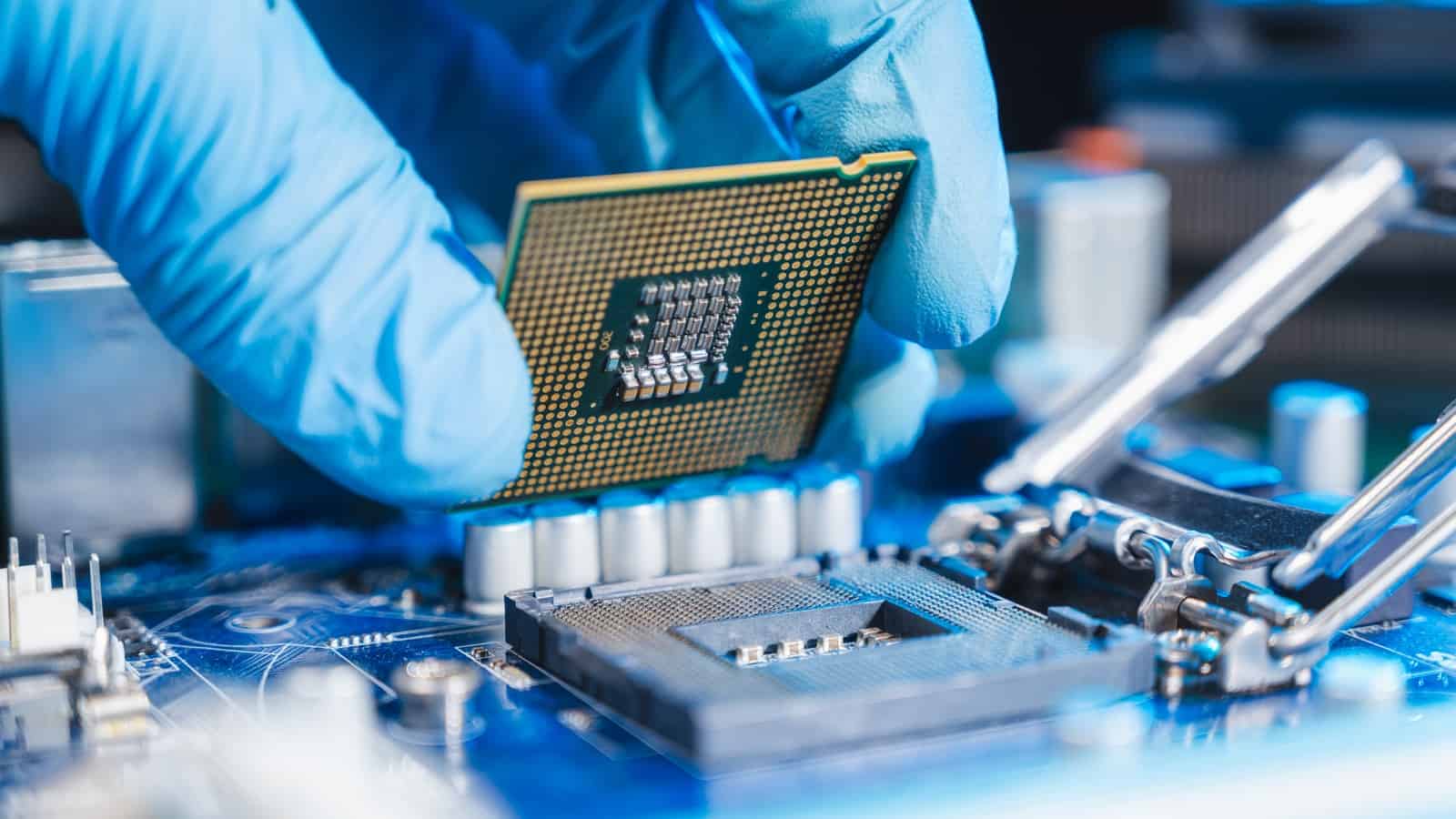

How Cloud Computing Could Help Chip Manufacturers

One small component is creating big delays in global supply chains: the ubiquitous semiconductor or chip. These components are not only essential to our phones, laptops and other electronics, but to the production process in just about every sector of the manufacturing industry. So, what would help us produce more of these desperately needed parts? According to Birlasoft Vice President and Global Business Head of Communications, Media & Technology Nitesh Mirchandani, the answer is cloud computing.

Why the shortage? As COVID-19 unfolded, millions of consumers purchased new laptops, smartphones, game consoles and other devices as they spent more time at home. This shortfall was compounded by the existing high demand for chips brought on by the growth in smart products—everything from thermostats and appliances to robot vacuum cleaners and GPS-enabled dog tags. COVID-19 also caused a wave of semiconductor factory closures that also exacerbated the problem. The result? A shortage that industry experts say could last through 2022.

Why the cloud? Cloud computing is the on-demand delivery of resources like data storage, software, networking and other services via the internet. Users either purchase a set subscription or pay by their level of usage—both cheaper and more flexible options than maintaining an on-site IT team for all needs. Cloud computing has several advantages for semiconductor manufacturers, according to Mirchandani:

- It speeds up time to market through swifter design and development. Because they can be accessed anywhere, cloud services enable teams to connect and collaborate more easily. Development cycles become quicker as teams connect better internally and with other parts of the business, including partners and suppliers.

- It enables data-driven business decisions. Thanks to the faster processing and analysis of cloud computing, manufacturers can get instant information on things like factory performance, supply disruptions or customer demand. Likewise, workers can be alerted to a machine that needs maintenance or to potential defects in materials or products.

- It provides service continuity. Internal IT teams often have limited resources. Cloud infrastructure is managed by specialists who can ensure uninterrupted service, so in-house IT teams don’t need to continuously maintain software through updates and patches.

Why it matters: Semiconductor shortages threaten to drag down the economy just as recovery is getting underway. Businesses rely on chip-enabled technologies for creating products, managing operations and maintaining the flow of goods and services. Consumers rely on them for smarter, safer homes and connections to work or school. Unless chip manufacturers can shore up production to meet demand, the ripple effect will create added distress for many sectors of the economy.

A Manufacturer Goes Lean and Wins Big

Consumer goods manufacturer Church & Dwight found that it needed to boost performance to meet customer demand. To meet this goal, it embarked on an ambitious Lean initiative at all of its 13 production facilities.

“We look at all challenges through the lens of Lean manufacturing—it’s the only way that we can operate,” said Bruno Silva, vice president of manufacturing operations.

What’s Lean? Researchers James Womack and Daniel Jones first defined the concept of Lean manufacturing as “a way to do more with less … while coming closer to providing customers exactly what they want.” Many manufacturers see mastering Lean as an essential springboard to operational initiatives like digital manufacturing and other advanced production practices.

Setting the stage: In developing its Lean program, Church & Dwight first held a weeklong leadership summit to decide on standards and expectations. The company’s leaders came up with a Lean assessment system with 16 standards and a definition for achievement at the gold, silver and bronze levels. But the essential part was ensuring frontline employees were driving improvement from the bottom up—not the other way around.

- “This is not corporate pushing it down,” said Felipe Vilhena, director of Lean manufacturing – global operations. “We help workers overcome challenges and give them the right tools to do that. We created a mindset and expectation that improvements are part of the work.”

Putting it into practice: Initially, each worker was asked to list five potential improvements at his or her site, and then go out and make them. The company provided training and support to help with these fixes, while managers kept employees fully informed of their progress according to key indicators.

- Workers formed self-directed teams and continued to seek out improvements, which they began making more and more frequently. Thanks to the trust and autonomy that employees were given, engagement and retention measurably increased at the same time.

Receiving recognition: The company’s achievements have received recognition from its peers in the industry. One of its top-performing facilities in Green River, Wyoming, earned the company a 2021 Manufacturing Leadership Award in the Operational Excellence category from the NAM’s Manufacturing Leadership Council.

The last word: “It was important to create the right expectation and mindset,” Vilhena said. “From big to small improvements, we are seeing them happen every day.”

How PTC Onshape Helps Formlabs Print the Future

The NAM’s Makers Series is an exclusive interview series featuring creators, innovators and trailblazers in the industry sharing their insights and advice. In this episode, you’ll meet Matt Lipsitz and Adam Lebovitz of Formlabs, who discuss how PTC Onshape helps Formlabs improve their 3D-printer design. Learn how PTC has helped Formlabs “try out new ideas that weren’t possible in the past.”

A Visit to Big Ass Fans

Yes, Big Ass Fans is their real name. The Kentucky-based manufacturer makes fans, evaporative coolers, and controls for industrial, agricultural, commercial, and residential use, and the eye-catching name isn’t the only thing that makes them distinctive.

NAM Director of Photograph David Bohrer recently went to the BAF facilities in Lexington, Kentucky to take a closer look.

When you arrive at the campus, a herd of yellow donkeys on the lawn serves as a reminder that this is no ordinary company.

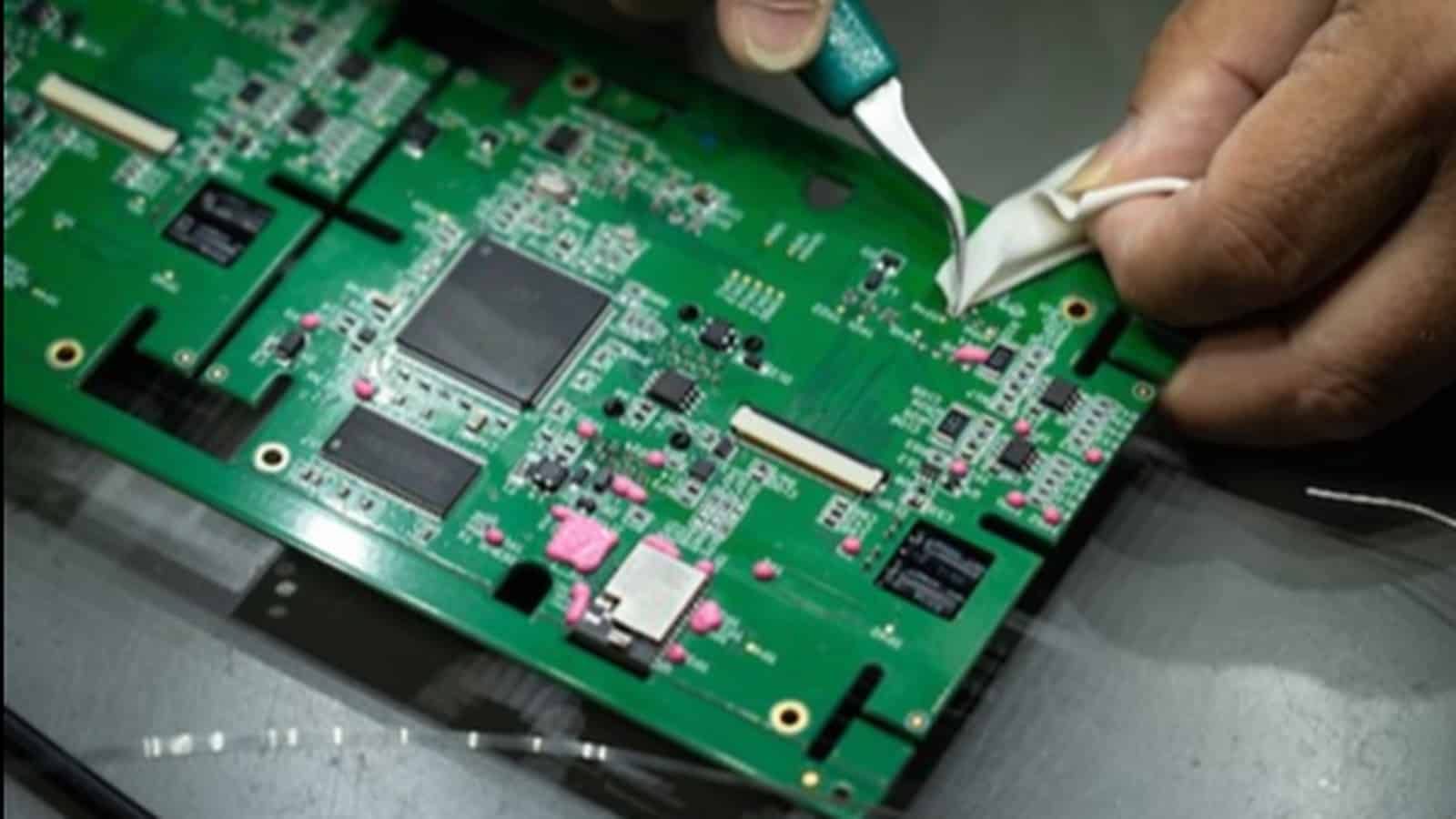

For a place called Big Ass Fans, the facility requires some very small and careful work. Here an employee gets up close with a circuit board.

Here, an employee is putting the finishing touches on the drive for a large industrial fan model.

As promised, the company does make some Big Ass Fans. Here, an employee works on the product that gives the business its name.

Hang on, maybe it’s this product?

We spoke too soon.

BAF says: “We take great pride in making products that deliver comfort to people worldwide,” said BAF Public Relations Director Alex Risen. “It means a lot as a manufacturer knowing everything we touch is going to help someone do what they do a little more comfortably.”

Nexteer Displays Advanced Manufacturing in Action

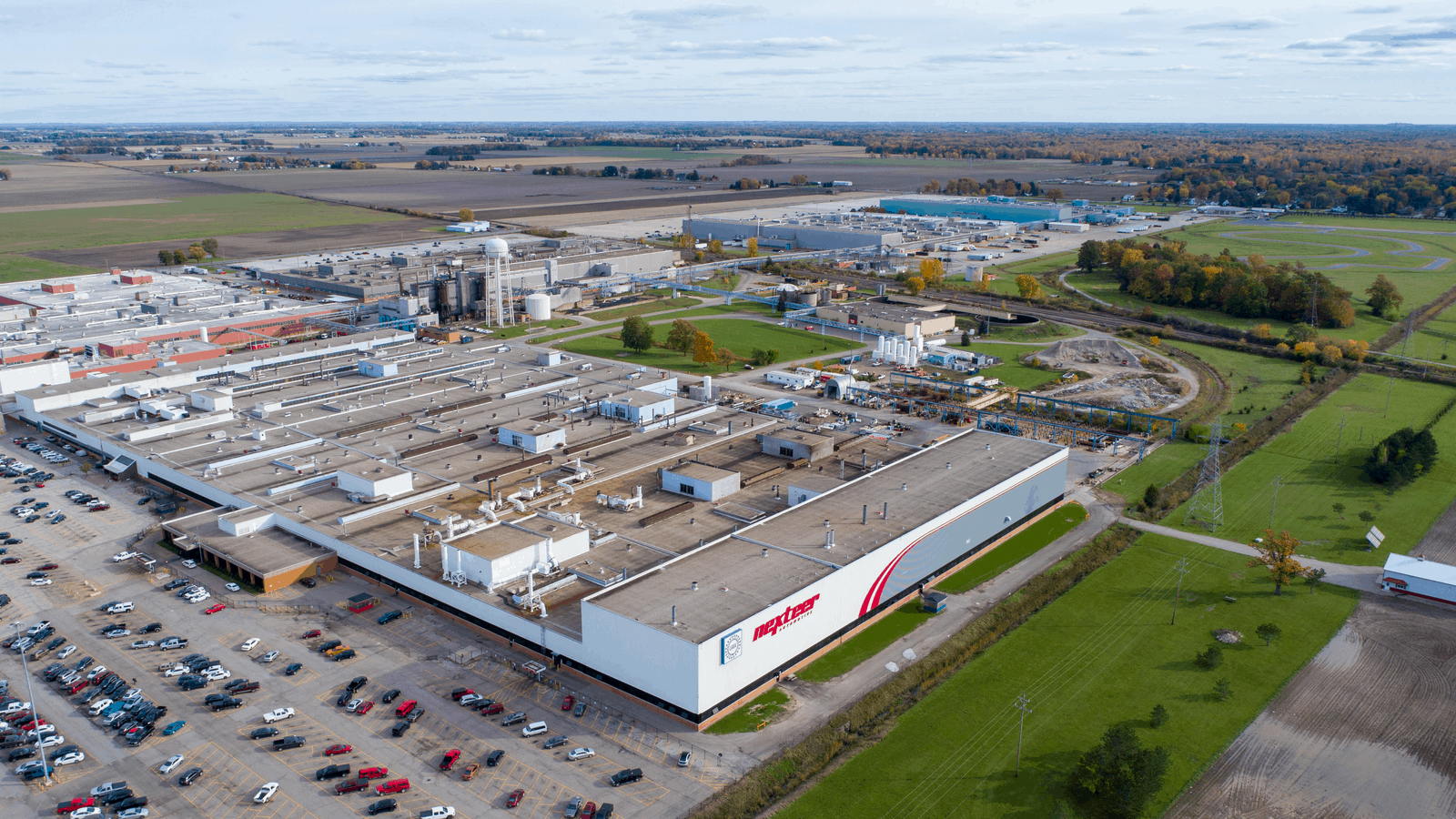

Would you like to see the latest advanced technologies exhibited and explained for your benefit, all without leaving your office? The NAM’s Manufacturing Leadership Council’s virtual plant tours provide just such an opportunity, taking you inside cutting-edge processes and complex systems at manufacturing facilities across the country. Most recently, the MLC dropped in on Nexteer Automotive, where tour participants got to see its innovative Digital Trace Manufacturing™ (DTM) System in action.

Who they are: Nexteer specializes in electric and hydraulic power steering systems, steering columns and driveline systems, as well as advanced driver assistance systems and automated driving-enabling technologies. The company serves more than 60 customers around the world, including BMW, Ford, GM, Toyota and Volkswagen.

What is DTM? Nexteer’s DTM System connects and standardizes the company’s entire operations—including thousands of data-production components in 27 manufacturing plants around the world. To showcase the system’s capabilities, Nexteer took tour participants inside its Saginaw, Michigan, site, which includes six manufacturing plants comprising 3.1 million square feet of manufacturing floor space.

Tour highlights: Participants learned about the complexities of running a large-scale automotive component manufacturing plant, as well as how Nexteer uses the DTM System to maximize efficiency.

- Nexteer team members explained how they design and program machines for data processing, showing how they determine where data will be sent and how they use barcode scanners and other methods to track components’ serial numbers.

- Participants also got a virtual walk-through of Nexteer’s tracking system, which follows material from receiving and shipping through the production line with single-box precision. They also learned how Nexteer uses its Center of Analysis to correct any issues that arise.

Why it matters: It’s one thing to have a large system collecting data, and it’s another to be able to use that data effectively. The Nexteer virtual plant tour provided participants with practical takeaways, which will help them adopt similar innovations at their own facilities—for the benefit of employees, customers and shareholders alike.

Coming soon: Don’t miss the MLC’s upcoming tour of Johnson & Johnson’s facility on Wednesday, Dec. 1, from 11:00 a.m. to 1:00 p.m. EST. You will see how Johnson & Johnson uses mobility tools, advanced robotics and material handling and adaptive process controls to improve its operations. After the tour, stay for the panel discussion on how to scale advanced manufacturing technologies to create a sustainable, reliable and adaptable product supply. Sign up here.