A Manufacturer Goes Lean and Wins Big

Consumer goods manufacturer Church & Dwight found that it needed to boost performance to meet customer demand. To meet this goal, it embarked on an ambitious Lean initiative at all of its 13 production facilities.

“We look at all challenges through the lens of Lean manufacturing—it’s the only way that we can operate,” said Bruno Silva, vice president of manufacturing operations.

What’s Lean? Researchers James Womack and Daniel Jones first defined the concept of Lean manufacturing as “a way to do more with less … while coming closer to providing customers exactly what they want.” Many manufacturers see mastering Lean as an essential springboard to operational initiatives like digital manufacturing and other advanced production practices.

Setting the stage: In developing its Lean program, Church & Dwight first held a weeklong leadership summit to decide on standards and expectations. The company’s leaders came up with a Lean assessment system with 16 standards and a definition for achievement at the gold, silver and bronze levels. But the essential part was ensuring frontline employees were driving improvement from the bottom up—not the other way around.

- “This is not corporate pushing it down,” said Felipe Vilhena, director of Lean manufacturing – global operations. “We help workers overcome challenges and give them the right tools to do that. We created a mindset and expectation that improvements are part of the work.”

Putting it into practice: Initially, each worker was asked to list five potential improvements at his or her site, and then go out and make them. The company provided training and support to help with these fixes, while managers kept employees fully informed of their progress according to key indicators.

- Workers formed self-directed teams and continued to seek out improvements, which they began making more and more frequently. Thanks to the trust and autonomy that employees were given, engagement and retention measurably increased at the same time.

Receiving recognition: The company’s achievements have received recognition from its peers in the industry. One of its top-performing facilities in Green River, Wyoming, earned the company a 2021 Manufacturing Leadership Award in the Operational Excellence category from the NAM’s Manufacturing Leadership Council.

The last word: “It was important to create the right expectation and mindset,” Vilhena said. “From big to small improvements, we are seeing them happen every day.”

How PTC Onshape Helps Formlabs Print the Future

The NAM’s Makers Series is an exclusive interview series featuring creators, innovators and trailblazers in the industry sharing their insights and advice. In this episode, you’ll meet Matt Lipsitz and Adam Lebovitz of Formlabs, who discuss how PTC Onshape helps Formlabs improve their 3D-printer design. Learn how PTC has helped Formlabs “try out new ideas that weren’t possible in the past.”

A Visit to Big Ass Fans

Yes, Big Ass Fans is their real name. The Kentucky-based manufacturer makes fans, evaporative coolers, and controls for industrial, agricultural, commercial, and residential use, and the eye-catching name isn’t the only thing that makes them distinctive.

NAM Director of Photograph David Bohrer recently went to the BAF facilities in Lexington, Kentucky to take a closer look.

When you arrive at the campus, a herd of yellow donkeys on the lawn serves as a reminder that this is no ordinary company.

For a place called Big Ass Fans, the facility requires some very small and careful work. Here an employee gets up close with a circuit board.

Here, an employee is putting the finishing touches on the drive for a large industrial fan model.

As promised, the company does make some Big Ass Fans. Here, an employee works on the product that gives the business its name.

Hang on, maybe it’s this product?

We spoke too soon.

BAF says: “We take great pride in making products that deliver comfort to people worldwide,” said BAF Public Relations Director Alex Risen. “It means a lot as a manufacturer knowing everything we touch is going to help someone do what they do a little more comfortably.”

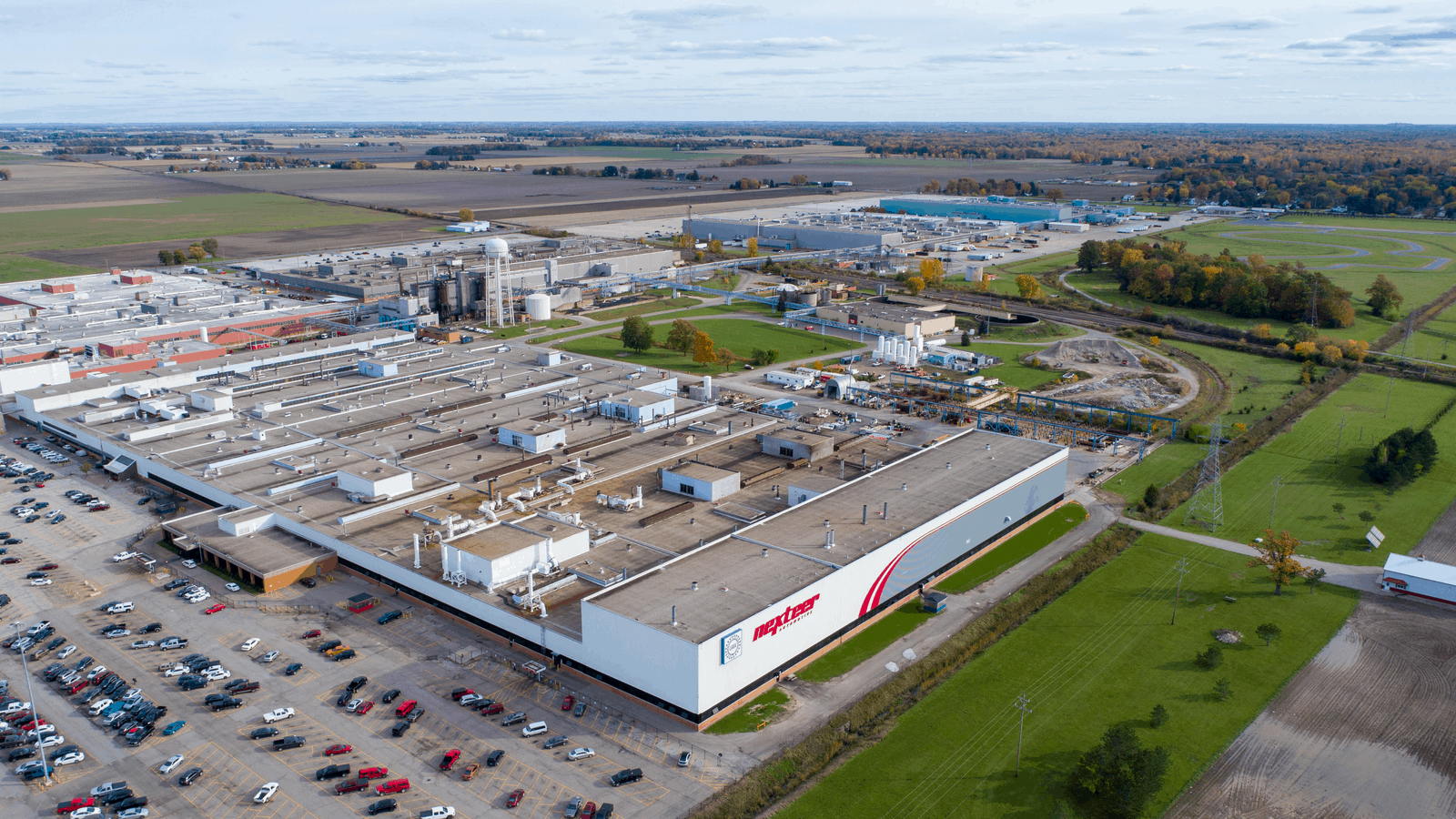

Nexteer Displays Advanced Manufacturing in Action

Would you like to see the latest advanced technologies exhibited and explained for your benefit, all without leaving your office? The NAM’s Manufacturing Leadership Council’s virtual plant tours provide just such an opportunity, taking you inside cutting-edge processes and complex systems at manufacturing facilities across the country. Most recently, the MLC dropped in on Nexteer Automotive, where tour participants got to see its innovative Digital Trace Manufacturing™ (DTM) System in action.

Who they are: Nexteer specializes in electric and hydraulic power steering systems, steering columns and driveline systems, as well as advanced driver assistance systems and automated driving-enabling technologies. The company serves more than 60 customers around the world, including BMW, Ford, GM, Toyota and Volkswagen.

What is DTM? Nexteer’s DTM System connects and standardizes the company’s entire operations—including thousands of data-production components in 27 manufacturing plants around the world. To showcase the system’s capabilities, Nexteer took tour participants inside its Saginaw, Michigan, site, which includes six manufacturing plants comprising 3.1 million square feet of manufacturing floor space.

Tour highlights: Participants learned about the complexities of running a large-scale automotive component manufacturing plant, as well as how Nexteer uses the DTM System to maximize efficiency.

- Nexteer team members explained how they design and program machines for data processing, showing how they determine where data will be sent and how they use barcode scanners and other methods to track components’ serial numbers.

- Participants also got a virtual walk-through of Nexteer’s tracking system, which follows material from receiving and shipping through the production line with single-box precision. They also learned how Nexteer uses its Center of Analysis to correct any issues that arise.

Why it matters: It’s one thing to have a large system collecting data, and it’s another to be able to use that data effectively. The Nexteer virtual plant tour provided participants with practical takeaways, which will help them adopt similar innovations at their own facilities—for the benefit of employees, customers and shareholders alike.

Coming soon: Don’t miss the MLC’s upcoming tour of Johnson & Johnson’s facility on Wednesday, Dec. 1, from 11:00 a.m. to 1:00 p.m. EST. You will see how Johnson & Johnson uses mobility tools, advanced robotics and material handling and adaptive process controls to improve its operations. After the tour, stay for the panel discussion on how to scale advanced manufacturing technologies to create a sustainable, reliable and adaptable product supply. Sign up here.

Fortune Brands Puts Sustainability Front and Center

When it comes to making strides in sustainability, Fortune Brands Home & Security knows the power of small, steady steps. The company works to improve sustainability in a wide variety of ways, from water conservation to the recycling of ocean plastics and wood. We talked to two of its leaders recently to get the inside scoop.

Mission Moen: In 2020, the company launched Mission Moen, its commitment to conserving 1 trillion gallons of water by 2030. To meet that goal, Moen has employed cutting-edge innovation, explained Fortune Brands Global Plumbing Group Chief Marketing and Innovation Officer Mark-Hans Richer.

- Its Flo by Moen, for example, is a “smart water security system” that, through a mobile app, standalone sensors, detectors and other tech, allows consumers to monitor their water usage—and detect leaks they may not even know about.

- “There is an immense amount of water that’s wasted every year in the United States … due to lack of knowledge,” said Richer. “Flo by Moen allows users to see where water use is any minute of any day.”

“The key to saving water is in small fixes,” Richer emphasized. For example, “a faucet that has a little bit more managed gallon-per-minute flow can add up over the course of its use … to some pretty substantial savings.”

Cleaning up the oceans: The second pillar of Mission Moen is the company’s commitment to cleaning up the world’s oceans—specifically, 2,000 tons of plastic that’s currently floating in them.

- “We’ve found a lot of very useful, interesting things” that can be made with ocean-recycled plastic, Richer said. These include product packaging and components in showerheads.

- “When you commit yourself to a large goal, then you start to look for ways” to meet that goal, he continued.

Recycled wood and plastic: FBHS’s dedication to conservation extends throughout the company. Recycled wood and plastic are used to create its Fiberon Balance composite decking, Fiberon President Fenton Challgren told us. It’s a complex process:

- First, there is an “intensive search … for the right plastic, which comes in bales by the truckload,” said Challgren.

- The company then must “sort the contaminants, contain them, grind them, get them into different extruders … and create a stable pellet” that can be used for the decking, he continued.

What should manufacturers learn from FBHS? Manufacturers seeking to reduce the size of their company’s environmental footprint should think of these efforts as a long-term investment, according to Challgren.

- “On the water recycling side, have a really robust filtration system,” Challgren urged. “Spend the money, get the technology. It’s a big investment, but if you’re doing any type of high-volume water usage,” it will be less expensive in the long run.

The last word: As Challgren summed it up, “The impact your company could have by going down this path … will be worth it both financially and for the greater good.”

How IPAK’s Diversity Sustained It Through COVID-19

When COVID-19 swept through Camden, New Jersey, it hit the kit and packaging manufacturer IPAK very hard. The majority of IPAK’s nearly 100 employees are women and people from underserved communities, and like many other similarly situated groups, they suffered from particularly high case rates and economic disruption. But it was the company’s long commitment to diversity, equity and inclusion that helped it get through this global disaster—and even allowed it to thrive.

We spoke to IPAK CEO Karen Primak about all the company did to safeguard its employees and serve its customers. Here’s what she told us.

Keeping employees safe: The early days of the pandemic were terrible; the company had four employees in the hospital on respirators “right from the beginning,” says Primak. But IPAK responded swiftly and comprehensively:

- IPAK created an extensive COVID-19 action plan to prepare, inform and assist employees. This included an “ambassador” program so team members had a point of contact to ask about their virus-related concerns and receive answers and resources in the five different languages that employees speak.

- The company rearranged schedules to allow workers without childcare to be home when needed. Managers spent an hour or two every morning discussing how they could accommodate everyone.

- IPAK stayed current with the latest science and data, so that it could react quickly to the fast-changing pandemic. The company instituted an evolving set of daily cleaning protocols, social distancing measures, remote work provisions, masking and face shield requirements, vaccine information sessions and regular COVID-19 testing.

All these measures allowed IPAK to remain open and continue to deliver high-quality solutions to its customers throughout the pandemic. And here’s one last impressive detail: “We didn’t furlough or lay off anyone,” said Primak. “Despite all the craziness and the disproportionate impact on our employees and revenue, we remained committed to employing our workforce during this awful time.”

The “secret weapon”: How did IPAK cultivate the flexibility and dedication necessary to get through a global pandemic?

- “Diversity, equity and inclusion have been our secret weapon,” Primak said. “If you hire people like you, all you get back is you. IPAK is equipped with a range of voices and perspectives, which helps us innovate and creatively solve problems. Our commitment to put employees first and understand their needs allowed us to come together and stay operational during such a difficult time.”

Success during upheaval: IPAK also went above and beyond for its clients, including nonprofit educational-content provider ACT, maker of the well-known college-entrance exam, whose supply chain was upended by COVID-19.

- ACT was faced with shipping disruptions, shuttered test centers, constantly changing local conditions and testing center capacity constraints. It needed an agile partner who would be able to move quickly, adjust schedules and innovate in real time.

- As a result, ACT pivoted early in the pandemic and massively expanded its contract with IPAK to include the handling of secure paper-based processing, which includes creating kits and manufacturing and distributing the ACT test.

- Amid all this disruption and change, IPAK stepped up. Its staff worked tirelessly with ACT to deliver more than 2 million college-entrance exams during the pandemic.

“We worked nights and weekends and even hand-delivered some test booklets to make sure they arrived on time,” said Primak.

A great partnership: “We were the vendor that was willing to make huge and necessary changes alongside ACT during the pandemic so that many deserving students could take the ACT and benefit from the opportunities afforded by their hard work,” Primak said.

- “IPAK asked so many questions about our organization and offered a unique process optimization perspective,” said ACT CEO Janet Godwin. “It was clear they had deep knowledge of the education marketplace and cared about our mission—not just their bottom line. IPAK knocked its first assignment out of the park, catalyzing ACT to outsource additional critical programs to IPAK.”

NAM involvement: Primak also credits the NAM’s work with Congress and the administration with helping IPAK survive and succeed. She is grateful for government programs such as the employee retention tax credits, economic injury disaster loans and Paycheck Protection Program loans, which the NAM advocated for, and said that without such help, the company “wouldn’t be here.”

The last word: “Helping people achieve success and ensure equity, access and opportunity for all” is ACT’s mission, said Primak. It’s that type of commitment to equity and inclusion that also motivates IPAK’s whole team, in good times and in pandemics.

The NAM and The Manufacturing Institute are committed to increasing diversity and inclusion in the manufacturing industry. Visit the NAM Pledge for Action page to make your own commitment today.

Hologic Supports Women’s Health via Innovation

Nilo Caravaca, Hologic’s vice president of operations for Costa Rica and Latin America, says the company has an “important purpose”: to improve and save women’s lives around the world. At the Costa Rica facility that he manages, the company manufactures diagnostic and imaging equipment that protects women’s health, such as mammography systems and bone density scanners.

In pursuit of their goal, Caravaca and his team have embraced innovative technologies as well as best practices in talent management. For their achievements in attracting, upskilling and retaining a world-class workforce, the NAM’s Manufacturing Leadership Council awarded Hologic the 2021 Manufacturer of the Year award in the small and medium enterprise category. But the company is not stopping there. Caravaca anticipates further innovations, as Hologic keeps prioritizing efficiency, safety and growth.

Here is a snapshot of Hologic’s two award-winning projects and a look at things to come.

Supply chain innovation: Almost every product made by Hologic’s Costa Rica facility serves a patient with an urgent medical issue. That means its supply chain must be incredibly resilient and reliable.

- To meet these critical needs, Hologic launched a project called “Impacting Lives Every Day,” which employed robots for moving materials and bots for automating processes, while improving operations using real-time data and analytics.

- The project has resulted in a more reliable supply chain that gets products to patients faster while improving quality and safety.

Talent management: Caravaca believes companies need to focus on people in addition to technology to make the transition to Manufacturing 4.0, the next wave of technological progress.

- To that end, his team developed a new set of talent management processes that helps attract and recruit the best employees on the market, as well as ensure they have the opportunity to perform at their highest level.

The last word: An engineer by trade, Caravaca has a simple “formula for the future” of manufacturing: “Find the right talent, fit that talent in the right position, engage it and add tenure over time.” That will allow people to grow into their roles and perform at their peaks—the best result for both the company and the employees themselves.

To learn more about the innovative technologies and processes at Hologic’s Costa Rica facility, read “Hologic’s Winning Formula” in the August 2021 issue of the Manufacturing Leadership Journal.

A Visit to Robinson Helicopter Company

What’s it like to make machines that capture the news, fight crime and train pretty much every helicopter pilot? For Robinson Helicopter Company, a manufacturer of civil helicopters, that’s just another day at work.

NAM Director of Photography David Bohrer took a trip to the Robinson facility in Torrance, California, to get an up-close look at what they do. Here’s what he saw.

Attention to detail is a core value of Robinson’s workforce. Here, two of Robinson’s employees focus on the critical work they do to make sure Robinson’s helicopters can perform successfully and safely.

The people who use Robinson’s machines are precious cargo—and so employees are careful to make sure that every piece, no matter how small, is handled correctly.

Robinson’s employees work hard on their machines—inside and out.

With a few finishing touches—like the rotor blades—this R44 Raven II will be ready for flight.

At Robinson, the work is never done. Here, a group of helicopters-in-progress wait to join the more than 13,000 helicopters that the company has already delivered worldwide.

The last word: “We are proud to be the world’s leading producer of civil helicopters and take great pride in our employees and their commitment to quality,” said Robinson President and Chairman Kurt Robinson.

How Manufacturers Are Mastering Data

When it comes to data management, most manufacturers are basically teenagers. They’ve gotten past the early stages but have yet to reach full maturity and mastery in their approach. In fact, it is often unclear what the data strategy is, who is responsible for it or even what the data is worth in the first place.

A new survey from the NAM’s Manufacturing Leadership Council shows us how manufacturers are progressing in their quest to harness the power of data—a capability that could have transformative power for many manufacturers throughout their operations. Below are some highlights.

Data collection: Most manufacturers rate their organizational data skills as just average, saying they struggle to collect the right data and interpret it.

- Fifty-eight percent of respondents said their company had just a moderate ability to collect data that is meaningful for their business needs.

Data analysis: If gathering data is a challenge, gaining insights from that data is an even bigger one.

- Seventy-five percent of respondents ranked their organization as only somewhat capable in their ability to analyze their manufacturing operations data.

- Even more worrisome, 11% of respondents said their organization was not at all capable of this type of analysis.

Applying insights: The practical application of data to create value is also a challenge for many manufacturers.

- Almost one-third said they expend greater than 80% of their efforts on gathering and organizing data—as opposed to analyzing and applying insights from it.

Other stumbling blocks: The survey revealed additional impediments to using data:

- The lack of systems available to capture the data (46%)

- Data inaccessibility (43%)

- The lack of skills to analyze data effectively (39%)

Opportunities: The good news is that even with these imperfect efforts, organizations are largely leveraging the data they do have to make informed decisions.

- Forty-eight percent said their organization makes data-driven decisions frequently, while 18% said they make data-driven decisions constantly.

The bottom line: Seventy-five percent of respondents said data mastery will be essential for future competitiveness. Indeed, data mastery is crucial to the industry’s transition into Manufacturing 4.0—the next big wave of industrial innovation—and the MLC will be tracking the industry’s progress closely.

To see more insights from the latest MLC M4.0 Data Mastery Survey, read “Growing Pains” in the August 2021 issue of the Manufacturing Leadership Journal.

How Manufacturers Are Dealing with Delta

As the COVID-19 pandemic keeps changing, plenty of manufacturers are looking for answers on how to protect their employees. To help clarify where we stand and what comes next, the NAM hosted a town hall on the strategies manufacturers are deploying to keep workplaces safe as well the vaccine policies some companies are implementing in response to the delta variant.

Who participated: Moderated by NAM Vice President of Infrastructure, Innovation and Human Resources Policy Robyn Boerstling, the webinar featured Dr. Michael Ybarra of the Pharmaceutical Manufacturing Association (PhRMA); NAM Senior Vice President, General Counsel & Corporate Secretary Linda Kelly; Senior Director of Global Compensation & Mobility R.J. Corning of Whirlpool Corporation; and Vice President and Chief Communications Officer Shannon Lapierre of Stanley Black & Decker.

The vaccination deal: Dr. Ybarra gave a rundown of the current state-of-play in the pandemic, detailing the various kinds of vaccines—protein-based, viral vector, and mRNA—and laying out which vaccines have been approved for use in the U.S. (Johnson & Johnson, Pfizer and Moderna). He explained the reasons why variants are occurring, and the possible need for booster shots as the effectiveness of vaccines wanes and variants create further challenges.

- Who’s at risk: “It’s still the unvaccinated,” said Dr. Ybarra. “It’s people who are young and think they’re invincible and don’t need the vaccine, and people who maybe just got one dose of the vaccine and didn’t complete their series. That’s the super high risk.”

- Masks on: “Even if you’re vaccinated, you should wear a mask indoors,” said Dr. Ybarra. “You don’t want to stress test the vaccine.”

- An important reminder: Ybarra noted a “humbling reality”: that almost all of the current COVID-19 deaths are among unvaccinated people.

“The best thing you can do right now is get the vaccine if you’re not vaccinated,” said Dr. Ybarra. “It’ll provide protection against the worst impacts of COVID-19. And if you’re in that high stress environment of being indoors with people whom you don’t know are vaccinated, it’s important to wear a mask because it will provide that extra layer of protection.”

An NAM policy rundown: Kelly provided an overview of the NAM’s policies and explained its phased approach to a vaccine mandate for all employees.

- A vaccine mandate: In July, the NAM made a decision to require all NAM employees to be vaccinated or to seek accommodations for medical or religious reasons by September 20.

- A NAM, a plan: “This decision was not taken lightly,” said Kelly. “We talked about it for a long time, we worked through a lot of issues, we sought outside legal advice on it. But we saw it as the next evolution on our ongoing workplace safety posture during the pandemic.”

- Good feedback: “As we have been rolling this out…we’ve actually heard from a number of employees who have thanked us, because the policy has made them feel safer about being in the office,” said Kelly.

- Useful advice: “No matter what you’re doing on your vaccine policies, you need to have your HR, your legal team, and your communications team working very closely together,” she added.

Cases in point: Corning and Lapierre discussed the actions they have taken at Whirlpool and Stanley Black & Decker to prioritize employee health and safety.

- Masking up: Both Whirlpool and Stanley Black & Decker have responded to the increase in cases by re-imposing mask mandates.

- Incentivizing vaccines: While vaccines are not yet mandatory for employees, Whirlpool is focused on making it easy for people to be vaccinated—in particular by holding large onsite vaccination clinics where possible. It is also providing $250 to people who get vaccinated. Stanley Black & Decker has sent its chief medical officer and local doctors to facilities where vaccine uptake is low to answer questions and provide encouragement. The company has also set up on-site vaccine clinics where possible.

- Collecting data: Whirlpool is working to collect data from its employees to better understand who is getting vaccinated, and to gather information on any breakthrough infections. Stanley Black & Decker, meanwhile, surveyed its employees early on in order to gauge interest in vaccinations so it could target its efforts appropriately. Both are taking care to protect their workers’ confidentiality.

The last word: “We’re not going to have all the answers, but we can help guide people in the right direction and help them make the best choices for their circumstances,” said Boerstling.