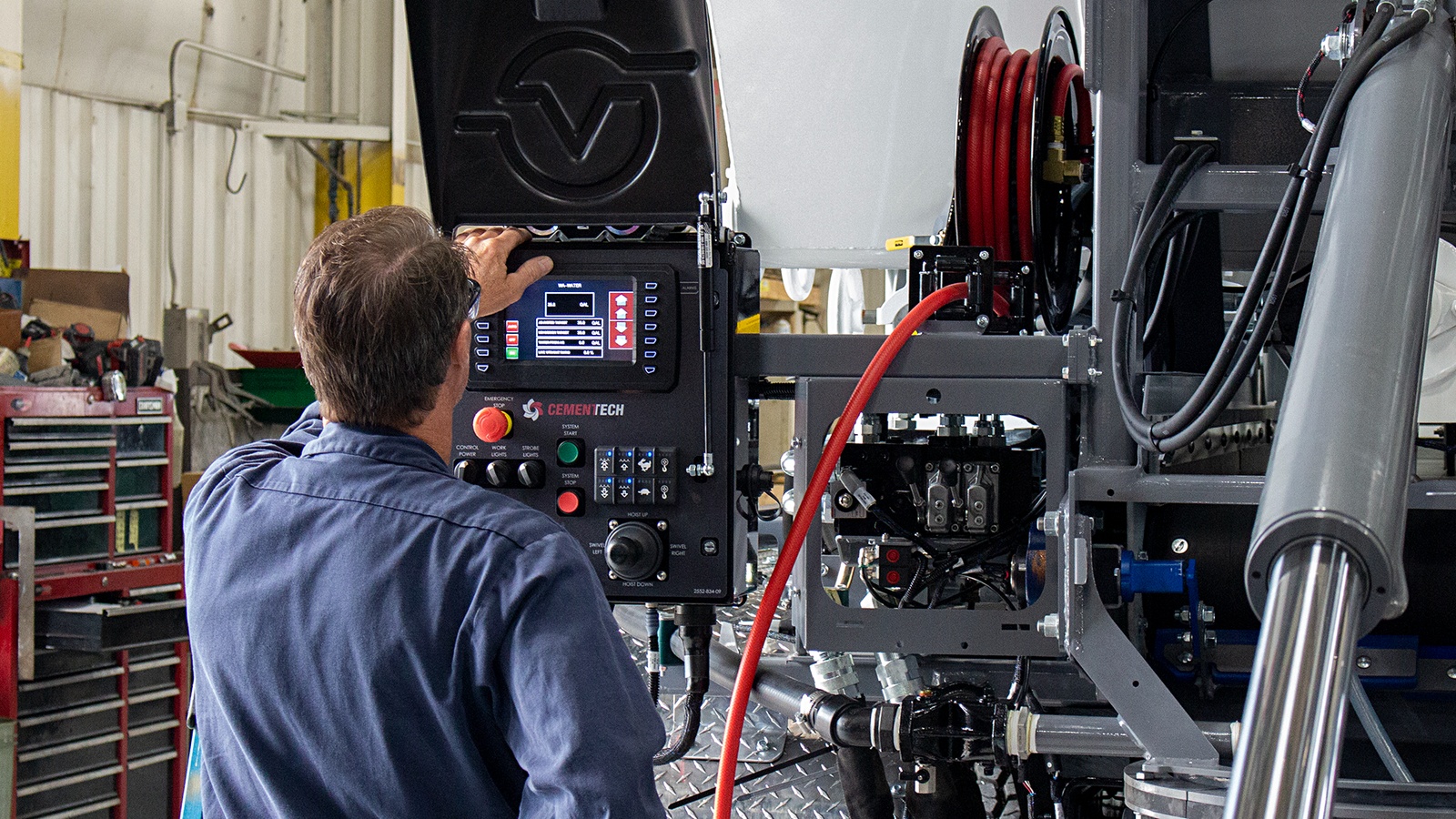

Concrete Mixer Maker Finds a Growth Formula

Even amid so much economic uncertainty, Cemen Tech is on track for a year of unprecedented growth. Leaders of the company, the world’s largest manufacturer of volumetric technology, attribute a good deal of its success to its loyal workforce.

Allegiance creator: Just what contributes to that worker loyalty? The answer may well be Cemen Tech’s unusual generosity.

- “We considered a number of new and different ways to continue to attract and retain good people,” Cemen Tech President and CEO Connor Deering said. “In September 2021, we made the decision to cover 100% of employee health insurance costs, the net effect of which is essentially our folks taking home more of the money they earn. That has really helped with retention.”

- The Indianola, Iowa–based company also raised wages across the board and began offering employees season tickets for local sports teams.

A new approach: Full health insurance coverage made a difference when it came to attracting and keeping workers, but the volumetric concrete mixer manufacturer was still hitting another roadblock when it came to employment: finding people with the right qualifications. So, it set out to solve the problem in house.

- As part of a planned facility expansion, the company is setting aside space for the new “Cemen Tech University,” an innovative answer to the question of how to develop employees with highly desired, specialized skills. Classes are tentatively set to start in January 2023.

- The company is also working with area high schools and technical schools to forge partnerships in which students work for Cemen Tech part time, while still pursuing their diplomas or degrees.

- “This way, we train applicants for immediate success on the job, helping to ensure a strong fit between the employee and the company from the start,” Deering said. “It also gives us an opportunity to teach new hires about our organizational culture. … I believe [our education efforts] will help support an educated team member who’s connected to our culture, resulting in a happier, better and more long-term employee.”

More incentives: Last March, Cemen Tech found a way to boost shift-worker attendance with a points-based rewards system.

- “We implemented an attendance bonus—if an employee stays within a certain number of points [for coming to work], they can earn an additional $90 a week,” said Cemen Tech Director of Human Resources Emily Lyons. “We have seen that help in terms of attracting and retaining employees and further incentivizing employees to achieve consistent attendance.”

- The company has also increased the referral bonus given to existing employees who bring in new hires, Lyons said.

Advice: Manufacturers looking to see similar growth to Cemen Tech, which is set to expand 65% this year, should consider implementing some of the firm’s ideas (if financially feasible). But companies should be prepared to incur some financial cost along the way.

- “Our growth has helped offset the profitability loss [from the increased benefits], but the reality is that our business is people,” Deering said. “If we don’t have people—good people—we’re not going anywhere. So, the fact that we’re little less profitable at the moment is OK, as long as we can continue to grow.”

Manufacturers Renew Call for Action on Immigration

NAM CEO says broken system is harming manufacturers’ competitiveness

Washington, D.C. – National Association of Manufacturers President and CEO Jay Timmons addressed the Minnesota Chamber of Commerce’s Manufacturers’ Summit today, where he made another call for policymakers to act on immigration, saying it is time to “fix this problem now.” Timmons called on Congress to act in the year-end government funding bill. His remarks come as the NAM rereleased its immigration proposal “A Way Forward.”

Excerpts from Timmons’ speech:

“First and foremost, this is a humanitarian issue. We see it play out in tragic ways—including family separations at the border and confusion as families seek to reunite following a harrowing journey.”

“But as manufacturing and business leaders, we also know there are serious economic consequences. Research and development—the cornerstone of innovation and our industry’s success—depends on access to the best and brightest from across the world.”

“The broken immigration status quo is also preventing us from growing our talent pool, leaving jobs unfilled. There are around six job seekers for every 10 job openings in the U.S., and our population growth is slowing. Last year, the U.S. population grew at its slowest rate ever.”

“Last year’s infrastructure law and this year’s CHIPS and Science Act prove that Congress can still get bipartisan things done—and immigration should be next on the list, whether it’s one bill or multiple bills. We would absolutely support a long-term, comprehensive legislative fix that addresses all of these issues, but we also want to be realists. We have a workforce crisis that needs to be addressed now, so let’s take action where we can. We want to focus on the art of the possible. One approach would be to address some of these issues in the year-end government funding bill.”

First released in 2019 and updated to reflect current challenges, the NAM’s “A Way Forward” proposal identifies seven core areas of action for Congress and the administration to take:

- Strengthen border security through physical infrastructure and best-in-class technology.

- Prioritize America’s workforce needs through reforms to the legal immigration system.

- Reform nonimmigrant visas and temporary worker programs to reflect employer needs, including a fund to support STEM programs so that we can reduce the need for these types of visas in the future.

- Provide a permanent and compassionate solution for populations facing uncertainty, including the Dreamers, who were brought here as children and know no other home.

- Reform asylum and refugee programs for a more orderly and humane system, including asylum standards consistent with our values.

- Fix the problem of the unauthorized population with a firm reset, requiring an orderly process of review, including financial penalties for those who seek to become legal and deportation for those who choose to stay in the shadows.

- Strengthen the rule of law so that it is respected and followed by all, with a focus on gang violence and also on requiring localities to cooperate to advance the enforcement of immigration priorities.

View “A Way Forward” in full here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org

New NAM Board Members to Bolster Manufacturing Competitiveness

The NAM is constantly working to support and strengthen the men and women who make things in America. That mission is upheld by outstanding members of the NAM Board of Directors and their commitment to promoting the industry’s competitiveness on the global stage—a goal laid out in the NAM’s “Competing to Win” agenda.

Welcoming new faces: A number of new members have been elected to the board and will begin their two-year terms in January. They come from many sectors of the industry and companies both large and small, holding an array of leadership roles and boasting a wide range of experience. All of them are dedicated to ensuring that manufacturers in the U.S. have the tools they need to prosper.

The new members include the following:

- Edward Blair, president, Lutron Electronics Co., Inc.

- Sara Beth Burton, senior vice president, global supply chain, Hallmark Cards, Inc.

- Richard Cammarano, president and chief executive officer, Tech-Etch, Incorporated

- Karl Ehemann, vice president, global manufacturing and quality, Corning Incorporated

- Ed Elkins, executive vice president and chief marketing officer, Norfolk Southern Corporation

- Cynthia Farrer, senior vice president, global operations and integrated supply chain, Allegion plc

- Aimee Gregg, vice president and general manager, containerboard and recycling, International Paper

- John Hartner, founder, Digital Industrialist LLC

- Christopher Kastner, president and chief executive officer, Huntington Ingalls Industries

- Ram Krishnan, executive vice president and chief operating officer, Emerson

- Reece Kurtenbach, chief executive officer and president, Daktronics, Inc.

- Rose Lee, president and chief executive officer, Cornerstone Building Brands

- Thomas Long, co-chief executive officer, Energy Transfer LP

- Michael McGarry, chairman and chief executive officer, PPG

- Lori Miles-Olund, president, Miles Fiberglass & Composites, Inc.

- Christopher Perkins, president North America and senior vice president Taste & Beyond North America, Firmenich, Inc.

- Kimberly Ryan, president and chief executive officer, Hillenbrand, Inc.

- Karin Shanahan, executive vice president, global product development and supply, Bristol-Myers Squibb Company

- Matt Shields, senior vice president, global animal health manufacturing, Merck & Co., Inc.

- Sachin Shivaram, chief executive officer, Wisconsin Aluminum Foundry

- Shruti Singhal, chief executive officer, Chroma Color Corporation

- Mark Smucker, president and chief executive officer, The J.M. Smucker Company

- Matt Wood, national industry leader, commercial products practice, FORVIS

- Brent Yeagy, president and chief executive officer, Wabash

- Renée Zemljak, executive vice president, midstream, marketing & fundamentals, Ovintiv USA Inc.

What we’re saying: “The diverse backgrounds of our new board members, and their varied experience across many manufacturing sectors, make their counsel invaluable to the NAM in its efforts to bolster the industry’s competitiveness,” said NAM Chief of Staff Alyssa Shooshan. “We are counting on their insights and dedication to help steer manufacturers through this turbulent time and into a position of even greater strength.”

Manufacturers Help Hurricane-Hit Communities

Hurricane Ian’s devastating landfall in Florida Wednesday afternoon marked the second significant storm to hit the U.S. and territories in less than two weeks. But as is usually the case when catastrophe strikes, manufacturers are already among those leading the charge to help the communities affected.

Manufacturers mobilize: In Puerto Rico, where approximately one-third of all residents remain without power following Hurricane Fiona Sept. 18, manufacturers including Dow, UPS, Coca-Cola, Ecolab and Toyota are funding product donations across the island through NAM partners Good360 and SBP.

What’s happening: These NAM partner organizations are providing on-the-ground updates and working to get products where they’re needed most. Items of greatest need include:

- Solar-powered power generators;

- Nonperishable foods and ready-to-eat meals;

- Mold remediation products;

- Oxygen tanks;

- Hygiene kits and supplies;

- Drinking water;

- New clothing; and

- School supplies.

Meanwhile, the work is just beginning in Florida to respond to Hurricane Ian, with anticipated items including drinking water, nonperishable foods, hygiene kits, tarps, blankets and mold remediation products.

NAM in action: The NAM’s Emergency Response Committee is an employee-led, volunteer group that works year-round with nonprofit partners, including Good360, SBP and Project HOPE, to provide NAM members with disaster-preparedness resources and training.

- These resources, which include e-learning modules, fact sheets and webinars, enable manufacturers to support their employees ahead of, during and in the aftermath of disasters.

- The NAM’s ERC also helps manufacturers activate to aid their communities when disaster strikes—and it works to identify and highlight members that are leading this critical work.

Be prepared: In a webinar sponsored by the NAM’s ERC, Amanda Gallina, SBP community engagement manager, and Matt Woodruff, vice president of public and government affairs for Texas-based tank barge operator Kirby Corporation, gave their suggestions for hurricane preparation.

For businesses: Woodruff provided some commonsense advice for employers:

- Have a plan: Have a hurricane-preparedness plan and ensure that all employees understand it—before hurricane season starts.

- Make a list: Create a checklist of tasks that must be done during the season, starting with the first day.

- Set up: Create and offer remote work sites for affected communities and employees.

- Support: Provide support to the families of employees who live in disaster-hit areas.

The last word: “The NAM stands ready to provide resources and support for its manufacturing members and the communities in which they operate in all conditions,” said NAM Director of Member and Board Relations Isabelle Powell.

- “We urge members to contact their membership directors with questions on how to better prepare their team or support people in their communities.”

For more information on manufacturer disaster preparedness or to be added to the NAM’s ERC mailing list, please email [email protected].

How to Get the Most Out of R&D

How should companies design R&D teams and processes to create the best possible results? That’s the challenge that Babson College Professor of Innovation Management Gina O’Connor addressed in her talk at the Innovation Research Interchange’s annual conference back in June. The IRI is a division of the NAM that advances the field of innovation management by creating contemporary practices—in R&D and many other areas.

A common problem: In an extensive research project at Babson College, O’Connor worked with experts from Goodyear, Synthomer and Diageo to study companies and decipher best R&D practices. She noticed a recurring theme: R&D professionals were being used by companies to solve urgent technical issues rather than to discover and invent.

- “In many organizations R&D has this feeling of being an order taker and of having to solve problems that are finely tuned and narrowly scoped,” said O’Connor. “That erodes confidence—and eroded confidence reduces empowerment.”

Empowerment and autonomy: O’Connor described empowerment as the authority to determine which projects and initiatives to take on and what problems to tackle. Meanwhile, autonomy refers to the authority to make final decisions.

- So, what do R&D professionals need? According to O’Connor, most want a moderate amount of empowerment, but not complete control over what to do.

- “We want to make sure that there’s organizational commitment somewhere associated with what we are doing, but we don’t just want to be told what to do,” as she put it.

So, what works? O’Connor explained that organizations with structureless R&D systems often had erratic decision making, sudden disruptions and unexpected changes in direction that left employees feeling powerless.

- Similarly, organizations with R&D processes that were too formal were also alienating to employees, who felt there wasn’t any room for flexibility or discussion.

- In contrast, the best systems included strong project leaders, consistent back and forth between the R&D group and organizational leadership, constructive communication, clearly outlined goals and trust in employees.

A last piece of advice: Training and developing project leaders is among the most essential steps in achieving successful R&D, said O’Connor.

- “What you need to be doing as a team leader every day is checking in with every member of your team, seeing what they need, where they are, what has happened,” said O’Connor. “It has to be an interactive, interpersonal kind of a thing.”

Learn more: Head on over to the IRI website to check out more of its programs and events.

A Summer Reading List for Innovative Manufacturers

Heading to the beach? Take along the Manufacturing Leadership Council’s summer reading list to catch up on today’s top trends in digital manufacturing while you catch some rays. With these articles, you’ll discover new ideas, technologies and best practices to give your company a competitive edge.

Workforce: Leading the Way to Workforce Optimization. As digitization changes employees’ expectations of their employers, manufacturers must adapt. Examples include options for remote work, interactive training, agile and rapid collaboration platforms, career development, work-life balance and more.

Industrial automation: Camozzi’s Autonomous Vision. Successful autonomous manufacturing will depend on the fundamental relationship between humans and machines, says Camozzi Group CEO Lodovico Camozzi, whose company makes industrial machinery. In a recent interview with the MLC, Camozzi shared his view of manufacturing’s autonomous future, including:

- How advanced additive manufacturing approaches promise new production paradigms;

- The importance of collaboration in driving innovation and excellence; and,

- Why the industry must maintain a human focus in today’s digital world.

Cybersecurity: Ransomware Attacks Increasingly Targeting Manufacturers. Think your business is safe from hackers? Think again. Ransomware attacks against manufacturers are on the rise. All businesses should be on guard against cyber extortion, advises Peter Vescuso, vice president of marketing for industrial cybersecurity provider Dragos and a member of the MLC.

Supply chain: How Manufacturers Can Navigate Supply Chain Challenges.

As global supply chain woes, worker shortages and wage inflation challenges intensify, manufacturers everywhere want to know the best way to navigate them. In this article, a panel of industry experts shares top tips to sustainably and profitably overcome current obstacles.

Artificial Intelligence: AI Roadmap: How Manufacturers Can Amplify Intelligence with Artificial Intelligence. Artificial intelligence offers manufacturers a host of benefits, including better visibility into supply chains, insights from predictive analytics and the ability to quickly respond to unexpected changes in demand. A six-step road map can help manufacturers looking to integrate AI into their businesses.

5G: 5G Will Help Unlock M4.0’s Potential. 5G technology offers speed and capacity advantages to manufacturing companies. According to the MLC’s recent Transformative Technologies survey, 26% of manufacturers have already invested in 5G technology. More than half expect to invest or are considering investing in the technology over the next two years to take advantage of 5G’s benefits.

Sustainability: Overcoming Roadblocks to Advance Sustainability Programs.

The manufacturing industry is expected to improve its sustainability and keep leading the fight against climate change. However, making green changes to processes and procedures can be costly. To get the most bang out of their sustainability investments, manufacturers should focus on data-driven initiatives and indicators.

Looking for more digital manufacturing insights? Browse the Manufacturing Leadership Journal for additional information on technology, organizational structure and leadership in manufacturing’s digital era.

Illinois Manufacturers’ Association Wins Inaugural COSMA Leadership Award

San Diego, California – For their work to attract and maintain the manufacturing workforce, the Illinois Manufacturers’ Association won the 2022 Leadership Award from the Conference of State Manufacturers Associations. COSMA members also serve as the NAM’s official state partners and drive manufacturers’ priorities on state issues, mobilize local communities and help move federal policy from the ground up in all 50 states and Puerto Rico.

“I am so pleased to present the inaugural COSMA Leadership Award to the Illinois Manufacturers’ Association,” said Kris Johnson, president of the Association of Washington Business and chair of COSMA. “These are challenging times, but manufacturers in America have demonstrated once again, as they have throughout our nation’s history, that they are equal to the challenge. All manufacturers should be proud of the role they have played in navigating the pandemic, and the Illinois Manufacturers’ Association should be especially proud of the innovative ways it has helped its members address the workforce challenges we have all faced. Congratulations to my friend Mark Denzler and his talented team.”

The association’s recent achievements included its $7 million Manufacturing Jobs Campaign aimed at attracting students, veterans, communities of color, women, ex-offenders and other individuals to the manufacturing sector. They were also asked by Governor JB Pritzker to co-chair the state’s Equipment Task Force during the pandemic and appointed by Chicago Mayor Lori Lightfoot to lead the B2B Recovery Group that included manufacturing, transportation and warehousing, construction and utilities companies in the state.

“Mark is more than an inspirational colleague and true friend. He is an amazing representative for Illinois’ manufacturing workers on the national stage,” said NAM President and CEO Jay Timmons. “At a time when there are more than 800,000 open jobs in our industry, we need the efforts of groups like the IMA to help us find that next generation of talent and strengthen manufacturing competitiveness so that we can continue to lead our economy and our country toward a better future.”

In this inaugural year, the COSMA Leadership Award drew many extraordinary applications, each demonstrating how manufacturing associations across the country are rising to meet workforce and supply chain challenges in new and innovative ways.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.8 million men and women, contributes $2.77 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

What Manufacturing Leaders Learned at Rethink 2022

Manufacturers flocked to Florida this summer to discuss the cultures, skills and technologies necessary for digital transformation at the 2022 Rethink Summit, the signature event of the NAM’s Manufacturing Leadership Council. The MLC is the world’s first member-driven, global business leadership network dedicated to senior executives in the manufacturing industry.

The big event: The first in-person Rethink since 2019, this year’s summit drew the largest crowd since the annual event began 18 years ago.

- The conference in Marco Island, Florida, hosted some of the most innovative leaders and teams in the industry, from companies such as Pfizer, Intel, Dow, Saint-Gobain and many more.

- Participants learned about real-world advances and shared best practices in supply chain resilience, effective business cultures, machine learning, business ecosystems and more—as explained by industry experts who put these innovations into practice themselves.

The panels: Here is a quick sample from the array of manufacturing expertise on offer.

- A Pfizer case study: Pfizer Vice President of Digital Manufacturing Mike Tomasco explained how Pfizer Global Supply transformed itself from a digitally siloed operation to a world-class digital powerhouse.

- Bridging the digital divide: A panel of leaders—including Graphicast President Val Zanchuk, BTE Technologies President and NAM SMM Board Chair Chuck Wetherington and Intel Senior Director of Industrial Innovation Irene Petrick—discussed how small and medium-sized manufacturers can keep up with the digital transformation occurring throughout the industry.

- Reaching the next generation: A panel of young manufacturing leaders from Dow, Cooley Group and Saint-Gobain North America discussed what young people are looking for in manufacturing jobs, including interdisciplinary teams and lots of communications up and down the organization levels.

A week of manufacturing: The Rethink Summit was only one highlight of a week of manufacturing events put on by the MLC. The roster of events also included the MLC’s Council Day and the ML Awards Gala.

- Council Day offers MLC members the opportunity to chart the agenda for the MLC’s next year, thus influencing how the whole industry thinks about and plans for digital innovation.

- The Awards Gala spotlights companies and individuals doing incredible work to advance M4.0. The black-tie event honored leaders and companies in 11 project categories, plus the Manufacturers of the Year and Manufacturing Leader of the Year.

- This year, the MLC named Pfizer CEO Dr. Albert Bourla the Manufacturing Leader of the Year, for Pfizer’s extraordinary and ongoing contributions in fighting the COVID-19 pandemic.

The last word: “[T]he fundamental shift in our economy to doing business digitally in all industries, including manufacturing, not only continues but is gaining greater speed and urgency,” said MLC Co-Founder David R. Brousell during an address at Rethink.

Join us next year: Keep up to date with the MLC by visiting the website and stay tuned for Rethink 2023!

Manufacturing Leadership Council Recognizes Pfizer CEO

The Manufacturing Leadership Council—a division of the NAM that helps manufacturers leverage digital transformation—named Pfizer CEO Dr. Albert Bourla the 2022 Manufacturing Leader of the Year at the 18th annual Manufacturing Leadership Awards Gala.

The details: The ML Awards are the U.S. manufacturing industry’s biggest stage for recognizing excellence in digital manufacturing. Since the program’s founding in 2005, more than 1,000 high-performing projects and individual leaders have been honored with an award. Winners represent companies of varying sizes in a wide array of industries.

The big award: The Manufacturing Leader of the Year award was presented to Bourla for Pfizer’s extraordinary and ongoing contributions in fighting the COVID-19 pandemic.

- “Manufacturing in America today is stronger thanks to the leadership of Dr. Bourla and his team at Pfizer, including our Executive Committee member Mike McDermott,” said NAM President and CEO Jay Timmons. “Albert and Mike’s passion and dedication to defeating COVID-19 set an example for thousands of companies as our industry navigated and responded to the evolving pandemic, and their leadership and innovation will make us better prepared to respond to the next crisis.”

Other honorees: Awards were given to companies that excelled in various categories of manufacturing, including Protolabs for collaborative ecosystems, AB InBev for digital network connectivity and operational excellence, Dow for digital supply chains, General Motors for engineering and production technology, Flex and Johnson & Johnson for enterprise integration technology, AUO Corporation for sustainability and ALOM Technologies for transformative cultures.

Manufacturers of the Year: Protolabs was named the Small/Medium Enterprise Manufacturer of the Year, and AB InBev was named the Large Enterprise Manufacturer of the Year.

The last word: “Manufacturers continue to be the driving force for global economic recovery and pandemic response as they establish innovative ways to problem-solve in an increasingly complex environment,” said MLC Co-Founder, Vice President and Executive Director David R. Brousell. “Those recognized tonight have helped establish a roadmap for the future of the sector and highlight the importance of Manufacturing 4.0.”

Case Studies for Success in the Factory

There’s nothing quite like a real-world test run to determine whether a new technology is right for your business. That’s where Rethink, the annual summit of the NAM’s Manufacturing Leadership Council, comes in.

The world’s leading event on Manufacturing 4.0, Rethink boasts an agenda packed with case studies to help manufacturing leaders see exactly how various digital technologies might help them improve their operational quality and efficiency.

The featured case studies coming to Rethink include the following:

- The Expanding Reach of Collaborative Robots: Examine practical applications for collaborative robots in manufacturing. Discover the benefits already being realized from the use of robots and identify ways to maximize the benefits.

- Extracting Insights from Plant Floor Data: See firsthand how to use data to monitor equipment performance, predict conditions and take preemptive action to avoid downtime. Gain practical takeaways on how to leverage data for bottom-line benefits.

- How AR/VR Can Empower Frontline Workers: Take a deep dive into one company’s advanced deployment of augmented and virtual reality technologies. Explore how these technologies helped transform operational activities and empower frontline workers.

- Fostering Data Literacy: The What, Why and How: Learn how to manage and analyze data from all aspects of your operations and use it effectively to improve decision making. Gain an understanding of the emerging discipline of data literacy as a way to overcome business culture hurdles.

How to participate: The Rethink summit takes place June 27–29 in Marco Island, Florida.

- In addition to case studies, the agenda will include inspirational keynote speeches, thought-provoking panel discussions and hands-on think tanks.

- More than 300 top-level executives and their teams attend each year.

- Participants include professionals in operations, IT, supply chain, engineering, C-level management, HR and more.

Click here to browse the agenda and to register.