ABB: Motoring Toward Greater Energy Efficiency

Jesse Henson wants you to think of motors the way you think of lightbulbs.

Most people recognize the energy and cost savings to be had by switching from incandescent bulbs to LED light sources. In the same way, they should see the advantages of swapping out anachronistic, clunky motors for newer alternatives, said Henson, president of ABB’s NEMA Motors Division.

“You’ve [still] got the old incandescent lightbulbs out there—which are your motors—that need to be replaced with newer technology,” Henson told the NAM.

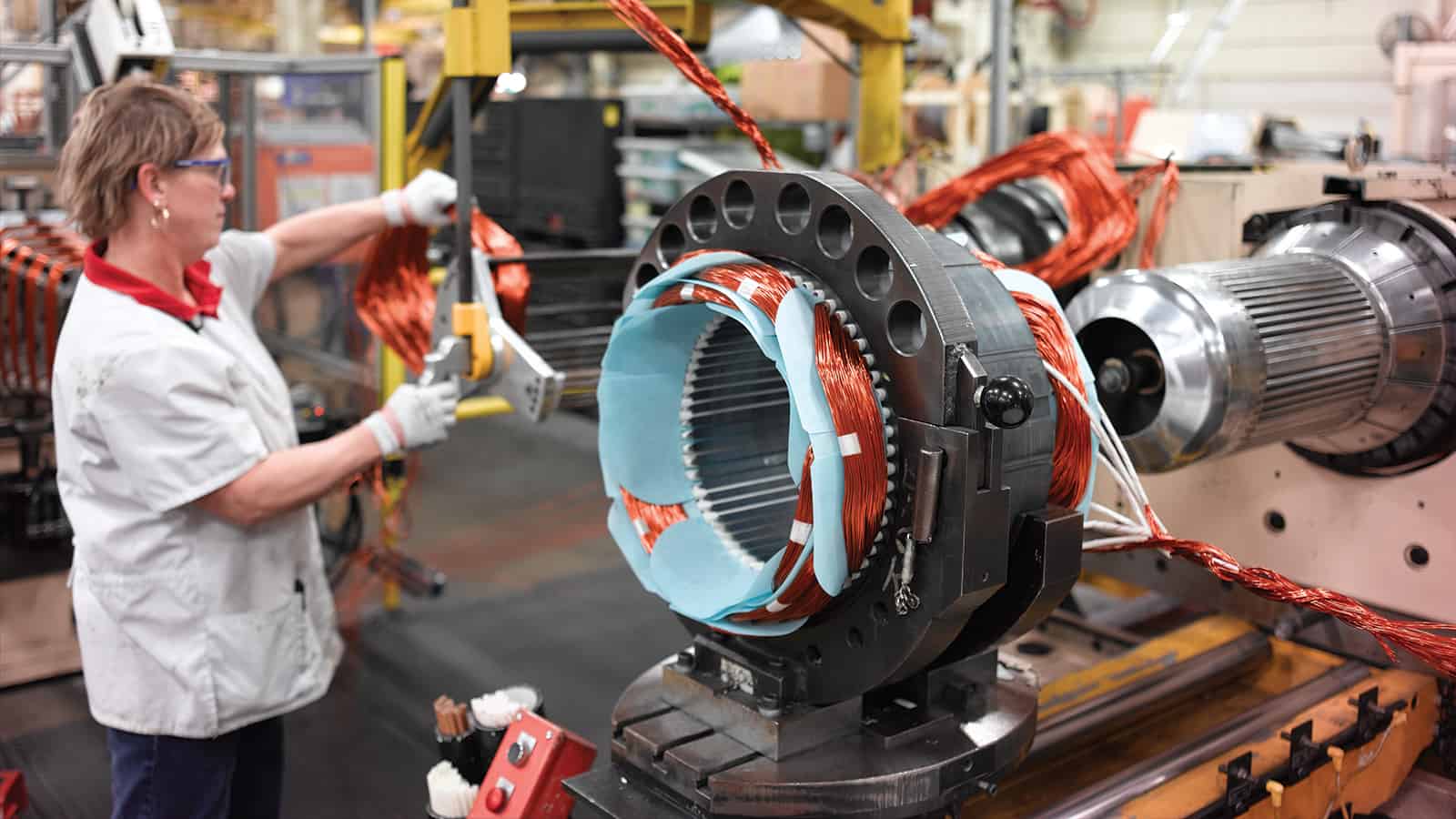

Not too different from 1921: The humble motor, which Henson says has “really not changed much in over 100 years,” is ubiquitous in manufacturing. Motors are found in factories in fans, pumps, compressors and more, powering everything from systemwide HVAC systems to individual power tools. But new technology could make them much more efficient and environmentally friendly—and save manufacturers a lot of money in the process.

Motor movement: ABB is working to change the way motors are used across the manufacturing sector, where they account for the lion’s share of expended electricity—approximately 70%, according to the U.S. Department of Energy.

- A sizable portion of that electricity is wasted because the motors using it are running constantly, consuming energy even when no task is being performed, Henson noted. That’s a costly reality for manufacturers.

Use only what is needed: ABB’s variable speed drives address this problem, allowing manufacturers to tailor a motor’s speed to the job it is doing. “That’s how you save energy,” Henson said.

- Adding a drive to a motor-driven system typically reduces power consumption by 25%, according to ABB.

- However, most companies aren’t getting that level of efficiency—just a quarter of motors in use today have such energy-saving drives, Henson noted.

No rare-earths needed: Of particular importance at a time of global supply-chain disruption is the fact that ABB motors achieve higher levels of efficiency without using rare-earth magnets.

- ABB’s EC Titanium motor, for example, does not use rare earths. Instead, it employs synchronous reluctance (the conversion of electrical energy to mechanical) technology and ferrite magnets for an even higher level of efficiency.

Easy savings: In fact, just by adding the EC Titanium motor drive to a fan array with 50 motors, one ABB manufacturing customer that already used drives cut its electricity consumption in half.

- The company slashed its annual energy bill from $20,000 to $10,000, according to Henson.

The last word: “We want to continue embracing sustainability . . . today and into the future,” said Henson. “These motors and drives are truly a game-changer in our marketplace today.”