AlloSource Honors Tissue Donors, Heals the Living

The supply chain of biotechnology company AlloSource looks a bit different from the supply chains of other manufacturers—mostly because it hinges on the donation of human tissue.

A different kind of manufacturing: For nearly three decades, Colorado-based AlloSource has transformed donated human tissue from deceased individuals into transplantable products, or “allografts,” that surgeons can use to heal living patients.

- “Something that distinguishes AlloSource among manufacturers is [that] our base materials come from donated human tissue, which makes manufacturing very complex,” said AlloSource Chief Operating Officer Dean Elliott.

- “Donors vary in age, size and many other factors, so a lot of planning takes place to ensure the gift of tissue donation is fully maximized. Each allograft takes a different amount of time to create through a variety of unique processes.”

- Common tissue recovered for donation includes skin to treat burn victims and bones and ligaments for use in orthopedic procedures to restore mobility.

Meeting a need: AlloSource, which today is one of the largest providers of allografts in the world, was founded in 1994 by three organ procurement organizations “out of a need for expertise in transforming deceased human donor tissue into transplantable products,” Elliott said.

- Today AlloSource produces approximately 200 different types of allografts, which are used in surgeries ranging from spinal fusion to shoulder rotator-cuff repair.

- In 2021, the company used tissue from nearly 8,000 unique donors to place more than 200,000 allografts in all 50 states and in 25 countries.

How it works: Following the passing of a donor, a local tissue-recovery agency has just 24 hours to recover the tissue to be made into allografts.

- “One of the miraculous things that happens when someone dies is their cells stay alive—and as long as the tissue is recovered and sent quickly, AlloSource can preserve the tissue while keeping the cells viable,” Elliott said.

Always innovating: AlloSource has made great strides in its field over the past few decades. The company recently patented a method of decellularizing skin, a process that lowers the risk that an allograft will be rejected by a recipient. The method was developed by its R&D and engineering teams.

- This method “keeps our in-house cleanroom usage at a minimum while allowing for a higher volume of processing so that we have enough allografts available to help more patients,” Elliott said.

Meaningful work: At a time of record-high job openings, the biotech organization has a high level of employee retention—thanks to “our unique mission,” Elliott said.

- “We offer competitive pay and benefits and the opportunity to grow in an evolving medical field,” Elliott said. “But we also look for people who are driven by a mission of helping others—and that culture is ingrained in our day-to-day operations.”

WTO TRIPS Decision Jeopardizes Pandemic Response, Manufacturing Competitiveness

Washington, D.C. – Following a decision by the World Trade Organization to lift intellectual property protections for COVID-19 products, National Association of Manufacturers President and CEO Jay Timmons released the following statement:

“This damaging decision will undermine American innovation, competitiveness and technology leadership—weakening manufacturing in America and threatening the jobs of manufacturing workers. Even worse, the agreement could exacerbate the supply chain and logistical hurdles that represent the biggest current challenges to global efforts to ensure access to critical COVID-19 products.

“It is alarming and disappointing that the United States would join other countries to give away manufacturers’ innovations to our commercial rivals. Our industry has been on the front lines of efforts to fight COVID-19—developing, manufacturing and distributing vaccines and other essential products needed to save lives and strengthen our economy. American innovation has been at the heart of the manufacturing response to the pandemic and will be just as critical for our ability to lead the world and respond to future global health crises.

“Manufacturers have been vocal supporters of effective solutions at the WTO that leverage trade to fight the pandemic—but this waiver is not one of them. Manufacturers call on the Biden administration to reverse course on this decision and take immediate action to protect this vital technology, American workers and global health.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.7 million men and women, contributes $2.71 trillion to the U.S. economy annually and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

“The Right Thing to Do”: Toyota Provides Overnight Child Care

For parents who work the night shift, the prospects for high-quality child care are usually dim. Not so for those who work at one of Toyota’s major U.S. manufacturing sites, however.

Toyota North America has been providing onsite, 24-hour-a-day care for employees’ children at its largest global site, in Georgetown, Kentucky, since 1993, and at its Princeton, Indiana, facility since 2003. The company subsidizes care to ensure affordability for all employees.

Not just a retention tool: “I’ve been asked, ‘Is this just a retention tool?’” said Toyota Group Manager for People and Property Services Myriah Sweeney, who oversees the auto manufacturer’s Family Care Services division, which includes child care. “The answer is no. Our employees take care of us, and we take care of them.”

- This was especially true during the COVID-19 pandemic lockdowns, when nearly one in five working-age adults left the labor force to care for children.

- Toyota’s care center stayed open and even offered in-person learning “pods” for school-age children.

The Toyota family: Employer-provided child care—particularly of the Toyota type, which is open overnight and on Saturdays and managed by the award-winning Bright Horizons Family Solutions Inc.—is a highly prized benefit.

- “We hear from families all the time, ‘This is part of the reason I stay here,’” said Sweeney, who counts herself among that contingent. “We actually have some employees now that were kids in our center that we helped raise and are now teachers or are working at Toyota. It creates a sense of family.”

- Toyota’s child care benefit has “touched approximately 10% of the workforce” over the past five years, Sweeney said.

How it works: Toyota’s two care facilities, which “are open pretty much anytime Toyota is open,” cater to children as young as six weeks.

- There are pick-up and drop-off points for local school bus routes, and center employees feed breakfast to early morning arrivals and dinner to overnight and late-stay attendees.

- Care-center teachers also help with homework and get kids safely on and off buses.

Additional benefits: The vehicle maker’s Family Care Services extend beyond children to include tutoring and pet care company discounts, counseling services and informational help for employees who act as caregivers outside of work.

- Toyota also gives every team member 15 days a year of “emergency backup care,” a company-subsidized program that allows employees to have vetted, qualified care providers come to their houses to look after elderly relatives or children “when things go haywire—the water main breaks or a babysitter calls in sick,” Sweeney said.

Next up: Toyota plans to expand the child care capacity at its Indiana plant, to the tune of an additional 75 to 80 spots, Sweeney said.

- The company is also working with architectural firms in Mississippi to design a child care facility for its factory in that state, which is located in an area with few child care centers.

The last word: Toyota’s interest in providing employees with support goes beyond wanting to maintain its workforce.

- “We try to encompass everything that anybody would possibly need and help them with that,” Sweeney said. “It’s just the right thing to do.”

Manufacturers Support Relief Efforts in Ukraine

Project HOPE, a nonprofit the NAM is working with on humanitarian relief, is ensuring that some of the most vulnerable victims of the war in Ukraine receive care and support.

What’s happening: The U.S.-based international nonprofit, which has aid teams on the ground in Ukraine and in neighboring Poland, Moldova and Romania, recently delivered the following in Ukraine:

- Twenty-two pallets of medicines;

- Eight Interagency Emergency Health Kits, each one containing enough essential medicine to serve a population of 10,000 people for more than three months; and

- Forty-five Essential Health Packs, each of which comes with a minimum of 800 courses of treatment, including over-the-counter and prescription medication, antibiotics, anti-inflammatories and anti-parasitics.

Project HOPE is helping deliver crucial medicines to pediatric oncology patients at the University Children’s Hospital in Krakow, which the organization has supported for nearly 50 years. And manufacturers are helping its efforts.

- Pharmaceutical company Eli Lilly send a shipment of its diabetes treatments to Ukraine earlier this month. Lilly will continue to provide medications, including oncology and COVID-19 treatments, to the country.

- Manufacturers have donated thousands of dollars through Project HOPE, both directly and through the NAM’s partnership page. As of this writing, donations through the partnership are at more than $11,000.

Other efforts: Project HOPE has partnered with nongovernmental organizations in and around Ukraine to provide food as well as medicine and technical support to health facilities treating refugees, displaced persons and others affected by the war.

How you can help: Those who wish to donate to Project HOPE may do so here.

- To get more information on what the NAM is doing to help, or to share how your company is contributing to the relief effort, please contact the NAM at [email protected].

Read more: Many manufacturers are making a difference on the ground in Ukraine. Read our stories about Sukup Manufacturing and Greene Tweed.

The above photo, which runs courtesy of Project HOPE, shows oncology patient Tamara, 5, and her mother Mikhaila at the University Children’s Hospital in Krakow. Tamara and Mikhaila fled the war in Ukraine and are seeking safety in Poland.

Nurturing the Next Generation of Manufacturers: Vermeer’s Child Care Center

In 2012, Vermeer management realized it had been hearing the same refrain from team members for some time: There was a shortage of available, high-quality child care in the Pella, Iowa, area, and it was complicating parents’ work schedules.

Workers’ challenges are the company’s challenges: Rather than respond with a collective shrug, the company recognized there was a problem—and it vowed to find a solution.

- “Especially with early morning shifts, you heard a lot about people leaving their children at a neighbor because parents had to be at work before the bus came or school started,” Vice President of Operations Mindi Vanden Bosch, a third-generation Vermeer family member, recalled.

- “We put a task force together and brainstormed. Over the next year and a half, we built the Yellow Iron Academy, Vermeer’s early childhood education center. Every answer from employees since has been, ‘It’s been a game-changer.’”

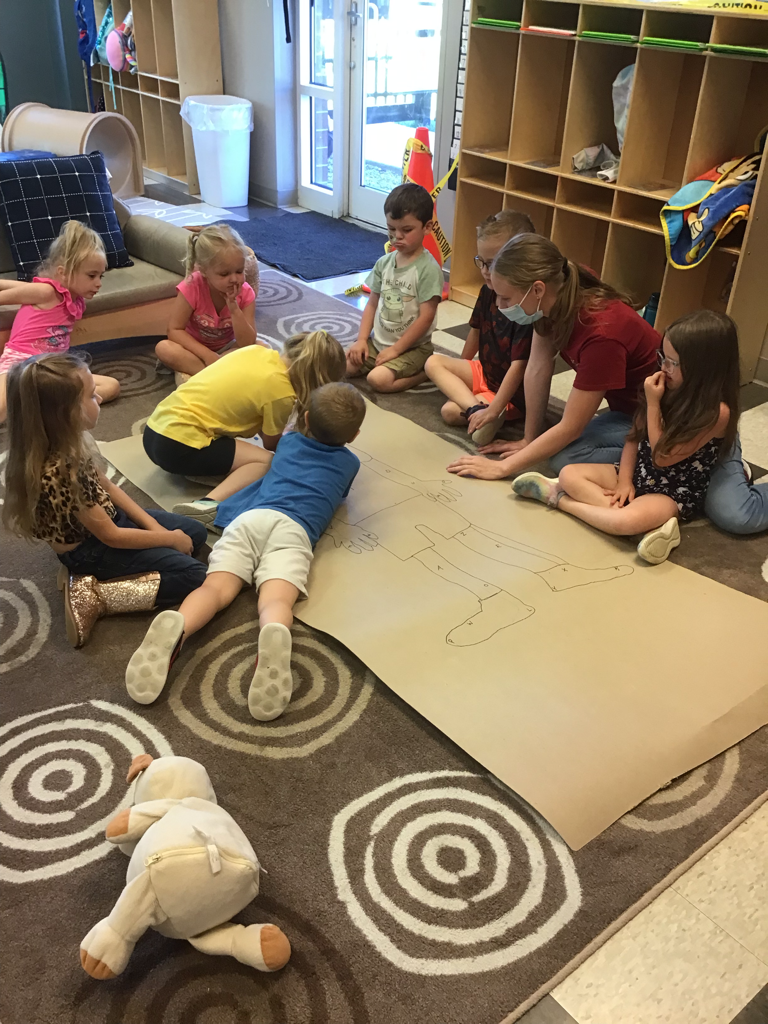

Not just care, but education, too: The Yellow Iron Academy, which gets its name from the company’s yellow products, isn’t just a nod at child care. With day-to-day operations run by award-winning third-party child care services provider Bright Horizons, it is a full-fledged center led by qualified professionals, and it aims to ready children for academia—and eventually, careers.

- “We’ve had teachers say, ‘Wow, these Yellow Iron kids are coming in with a strong readiness to learn,” said Vermeer Vice President of Human Resources Kate Guess, whose own children attended the center. “Yellow Iron Academy is taking the first steps to encourage kids to consider STEM careers like those in manufacturing,” Guess said.

- During Engineering Week, Vermeer professionals come in and talk to the center’s older kids about their jobs as engineers. The kids take regular field trips “across the road” to Vermeer’s facilities to see its museum, equipment and Global Pavilion. “It’s a place where they get excited about all the disciplines of STEM,” Guess said.

Meeting a community’s need: The center, which remained open throughout the COVID-19 pandemic, has achieved its intended goal of providing parents with top-of-the-line supervision and education while alleviating worry about having to cobble together care solutions for the next shift.

- Yellow Iron Academy isn’t just for Vermeer kids, though. While Vermeer team members and others with a connection to the company (grandparents, for example) receive discounted care rates, the center “is for the whole community,” Vanden Bosch said. “There is a need for child care in the area and across the entire state.”

- Out of the approximately 130 kids at Yellow Iron Academy, about 75 have Vermeer connections, Guess added.

Filling in school gaps: One of the most appreciated aspects of Yellow Iron Academy is its offering of before and after care, or programs prior to and following the school day.

- The center opens at 5:30 a.m. and is a pick-up and drop-off point on local school bus routes, so Vermeer team members don’t have to worry about school transportation for their children.

Other Vermeer team member benefits: Vermeer offers its team members several other differentiated, highly sought-after benefits. These include an onsite health care clinic and pharmacy, where both doctor visits and prescriptions are more cost effective than they are elsewhere, and a chaplaincy program.

- Both team members and their dependents are eligible to use the clinic and the pharmacy (features Vermeer has offered for 25 years) and many do.

- Vermeer has multiple chaplains across the company’s locations. These chaplains are available 24 hours a day, seven days a week to “support the emotional needs of the team,” Vanden Bosch said. “It is without question one of the things our team members most value.”

Child care advice for other manufacturers: “Child care is hard right now,” Vanden Bosch said. “Businesses have to go into it with the belief that it’s an investment in the workforce of today and tomorrow, knowing that there will likely be some costs they won’t recoup. But it’s one of the most viable ways to create a workforce.”

Manufacturers Lead with Their Hearts in Ukraine Aid

Manufacturers have been eager to help those affected by the humanitarian crisis in Ukraine, with many even lending a hand on the ground.

What manufacturers have been doing: They’ve raised millions of dollars through their own charities and funding vehicles, donated parts of their own profits, provided free legal support and phone calls to Ukraine, given medications and food, coordinated the shipping of relief supplies and more.

- Some manufacturers with operations in Ukraine have helped employees and their families flee the country and find temporary homes elsewhere in Europe.

Shared values: “Manufacturers have a proud history of standing firm in support of democracy, and we stand with the Ukrainian people,” NAM President and CEO Jay Timmons said recently, following the unanimous vote by the NAM Board of Directors to denounce Russia’s invasion of Ukraine.

Partnering to help: To help the people of Ukraine, the NAM’s Emergency Response Committee has partnered with Project HOPE and is engaging with other members who are donating through this and other channels.

- These efforts are providing channels for manufacturers to support efforts on the ground. For example, advanced materials manufacturer Greene Tweed recently donated $25,000 through the NAM–Project HOPE partnership.

- Project HOPE, an international health care and disaster relief organization, has emergency response teams in both Ukraine and neighboring countries that are giving health and humanitarian assistance to refugees and internally displaced persons.

- The ERC is a volunteer-led group that works to provide resources and information to manufacturing leaders before, during and after crises, both domestic and international. In addition to its partnership with Project HOPE, the ERC is also working with domestic partner Good360 on Ukraine relief.

The NAM says: “Manufacturers are truly at the forefront of aid efforts to Ukraine,” said NAM Senior Director of International Trade and Regulatory Affairs Ryan Ong. “Collectively, they’ve raised tens of millions of dollars for food, shelter, medicine, health care and more for the people of Ukraine. They’ve stepped up to help those in need, just as they do as a group in any time of crisis or hardship.”

Those wishing to donate to Project HOPE can do so here. To get more information about NAM efforts or share what your company is doing, contact the ERC at [email protected].

NAM Honors Nephron CEO Lou Kennedy for Extraordinary Commitment to Manufacturing in America

Scottsdale, AZ –– The National Association of Manufacturers today honored NAM board member and Nephron Pharmaceuticals CEO and Owner Lou Kennedy with the Manufacturing Icon Award during the NAM’s spring board meeting in Scottsdale, Arizona. The award recognizes leaders who inspire Americans to promote, perpetuate and preserve manufacturing in America.

“Lou Kennedy embodies the spirit of manufacturing, possessing a fearless commitment to solving some of our nation’s and the world’s most pressing challenges,” said NAM President and CEO Jay Timmons. “With trademark enthusiasm, Lou inspires those around her and brings together people from all sorts of backgrounds around a common purpose. In channeling her drive and dedication toward the NAM and The Manufacturing Institute’s Creators Wanted campaign, she is changing lives not just in South Carolina but across America. Her support has been game changing, and her passion for building the manufacturing workforce has helped us see our own vision for Creators Wanted more clearly. We’re honored to present this award to Lou in recognition of her exceptional leadership.”

Kennedy serves as co-chair of Creators Wanted. Last year, Nephron Pharmaceuticals hosted the Creators Wanted Tour Live in West Columbia, South Carolina.

The NAM and the MI’s “Creators Wanted” campaign is a member-driven initiative to inspire, educate and empower more Americans to pursue careers in modern manufacturing and to shift perceptions about careers in the industry. The campaign supports MI initiatives for students, women, veterans and other underrepresented communities and features a first-of-its-kind mobile experience and tour. It seeks to cut the skills gap by 600,000 workers by 2025 and increase the number of students enrolling in technical schools, vocational schools and apprenticeships by 25%. The campaign also seeks to increase the percentage of parents who would encourage their children to pursue a career in modern manufacturing to 50% from 27%.

In 2019, Kennedy was named a STEP Ahead Award Honoree. The MI’s STEP Ahead Awards honor women in science, technology, engineering and production careers who have demonstrated excellence and leadership across all levels of the manufacturing industry. Kennedy continues to work with the MI to help increase women’s representation in manufacturing and support the next generation of female talent.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.5 million men and women, contributes $2.57 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

Vaccine Myth Buster: Nephron’s Michaela Almgren Gets to Work

Michaela Almgren already has two jobs, but in recent months, she’s found herself appointed to a third: COVID-19-vaccine information hub.

A foot in each world: A pharmacist by training, Almgren divides her time between the University of South Carolina’s College of Pharmacy, where she is an assistant professor in the Department of Clinical Pharmacy and Outcomes Sciences, and Nephron Pharmaceuticals, where she is clinical adviser and pharmacy student internship director.

- Owing to her impressive background in drug formulation and analytical method development as a hospital pharmacist, as well as her skills as a lecturer, Almgren has also become a sort of de facto conspiracy-theory debunker when it comes to COVID-19 vaccination.

A go-to for facts: In recent months, in her capacity as both a professor and a Nephron employee, Almgren has given lectures and presentations about COVID-19, its variants and the vaccines—and she’s had significant follow-up questions from audience members. So many, in fact, that colleagues and others she has met teaching and at manufacturing gatherings have come to see her as a voice of reason capable of cutting through the noise.

- “A lot of people just fall into this misinformation mill” about the vaccine, Almgren said. “Typing in something like ‘Dangerous COVID-19 vaccine’ will give you this feed of articles, but it doesn’t mean the vaccine is dangerous.… That’s just how these [search engines] work.”

Convincing and calm: Almgren has been the impetus for the vaccination of several employees at Nephron, which has a 100% vaccination rate.

- “They’d say, ‘Thank you for talking with me. I was unsure about the vaccine, and it made me nervous, but talking with you made me feel that it was OK.’”

Fact vs. fiction: Almgren shared some of the top vaccine-related myths she’s successfully debunked during presentations and other conversations.

- “They have long-term side effects.” Fact: “This is where I talk about how these [vaccine] components don’t stay in your body more than 72 hours. The idea is just to elicit an immune response, and then it’s gone. And think about it on a global scale. If it was so deadly and terrible, by now we would see millions of people dropping dead or getting really sick” as a direct result.

- “They were rushed to market.” Fact: “When you actually look at how the clinical trial was defined, it was very similar to any other clinical trials for other vaccines. No shortcuts were taken. They just compressed the studies and ran them simultaneously.”

- “They’re not safe for kids.” Fact: “As a parent, I can totally understand why people would be concerned” about the vaccine for children, Almgren said. “But the clinical trial is out there, released and published in terms of how Pfizer did it. The data is clear showing the efficacy is there, and the side effects are minimal. If you have no issue with the polio vaccine or the tetanus shot, why is COVID-19 any different?”

- “Natural immunity is better.” Fact: “Natural immunity can be further boosted with the vaccine, and it wanes more than vaccine-induced immunity,” Almgren said. People who have had COVID-19 and get vaccinated “have an even stronger [immune] response.”

The last word: Check out the NAM and The Manufacturing Institute’s This Is Our Shot initiative to find out how you can protect yourself and the people you care about from COVID-19.

Supreme Court Reviews Stay of Vaccine Mandate

The Supreme Court is reviewing state and business led efforts to block two of President Biden’s signature vaccine mandate policies according to The Washington Post.

The policies: “One measure requires large private companies to implement a requirement for employees to either be vaccinated for COVID-19 or mask and be tested weekly. The second applies to health-care workers at facilities that receive certain federal funding. Together, the cases test a signature aspect of the White House’s response to the pandemic that has killed more than 800,000 people in the United States.”

The challenges: All of the court action on the cases so far has revolved around whether the rules should be stayed while the courts review the legality of the rules. Lower courts have been divided over the policies. After the administration announced the rule for private companies, the U.S. Court of Appeals for the 5th Circuit blocked its enforcement. Shortly after that, A panel of the U.S. Court of Appeals for the 6th Circuit lifted the stay, and said the rules could go into effect. A similar split occurred around the healthcare mandate, with one court saying the rules could go forward and another court blocking them.

The Supreme issue: According to NAM Senior Vice President and General Counsel Linda Kelly, while the Supreme Court is considering only whether the policies should be stayed or allowed to go into effect while lower courts hear legal challenges to the provisions, the arguments covered several pivotal issues that go to the underlying merits of the challengers’ case. Throughout the two-hour oral argument, the Justices and advocates sparred over whether federal agencies (v. Congress or the States) have the authority to impose the mandates, whether the mandates are overbroad and should instead target only certain high-risk workplaces, the extent to which vaccines are “necessary” (i.e., whether other mitigation measures would adequately protect workers), and whether the pandemic constitutes an emergency allowing the government to bypass notice and comment rulemaking. We expect the Court to issue a decision within the next few days.

Get vaxxed: Getting vaccinated is still important in order to protect yourself and the people around you. Check out the This Is Our Shot – a collaboration between NAM and The Manufacturing Institute – for tools and information.

Manufacturers Share Commitment to Vaccination

Requirements Must Be Structured in a Way That Does Not Negatively Impact the Operations of Manufacturers

Washington, D.C. – Following President Biden’s speech on new measures to combat COVID-19, National Association of Manufacturers President and CEO Jay Timmons released this statement:

“Americans can be grateful to President Trump for ‘Operation Warp Speed’ that enabled the United States to develop the lifesaving vaccines against COVID-19 and to President Biden for his continued focus on getting Americans vaccinated. We share their steadfast focus, and manufacturers have led the way in promoting the lifesaving COVID-19 vaccines. They are safe and effective vaccines made for us, by people like us—manufacturers in America.

“We look forward to working with the administration to ensure any vaccine requirements are structured in a way that does not negatively impact the operations of manufacturers that have been leading through the pandemic to keep Americans safe. It is important that undue compliance costs do not burden manufacturers, large and small alike.

“Getting all eligible Americans vaccinated will, first and foremost, reduce hospitalizations and save lives. But it is also an economic imperative in that our recovery and quality of life depend on our ability to end this pandemic. This is why the NAM and The Manufacturing Institute continue equipping manufacturers of all sizes with resources to promote vaccination through our ‘This Is Our Shot’ project.”

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12.3 million men and women, contributes $2.35 trillion to the U.S. economy annually and has the largest economic multiplier of any major sector and accounts for 58% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org