The Company That Puts UV Light to Work

Did you know that several of the components in your car may have passed under high-intensity UV light prior to your purchase? You may have heard that manufacturers coat headlights with a UV protective film to keep them from getting scratched by road debris, but several other components are also manufactured using UV—including windshield borders and the protective coating on interior trim. The process is called UV “curing,” which dries coatings consistently, efficiently, durably—and without releasing harmful chemicals into the atmosphere, as other drying processes do.

The NAM got a firsthand look at this technology recently, thanks to manufacturer Miltec UV of Stevensville, Maryland. The company manufactures UV systems that cure products like optical fiber, semiconductors, prefinished hardwood floors and cars, supplying this technology across the country and around the world. NAM Director of Photography David Bohrer visited Miltec’s facility to check it out.

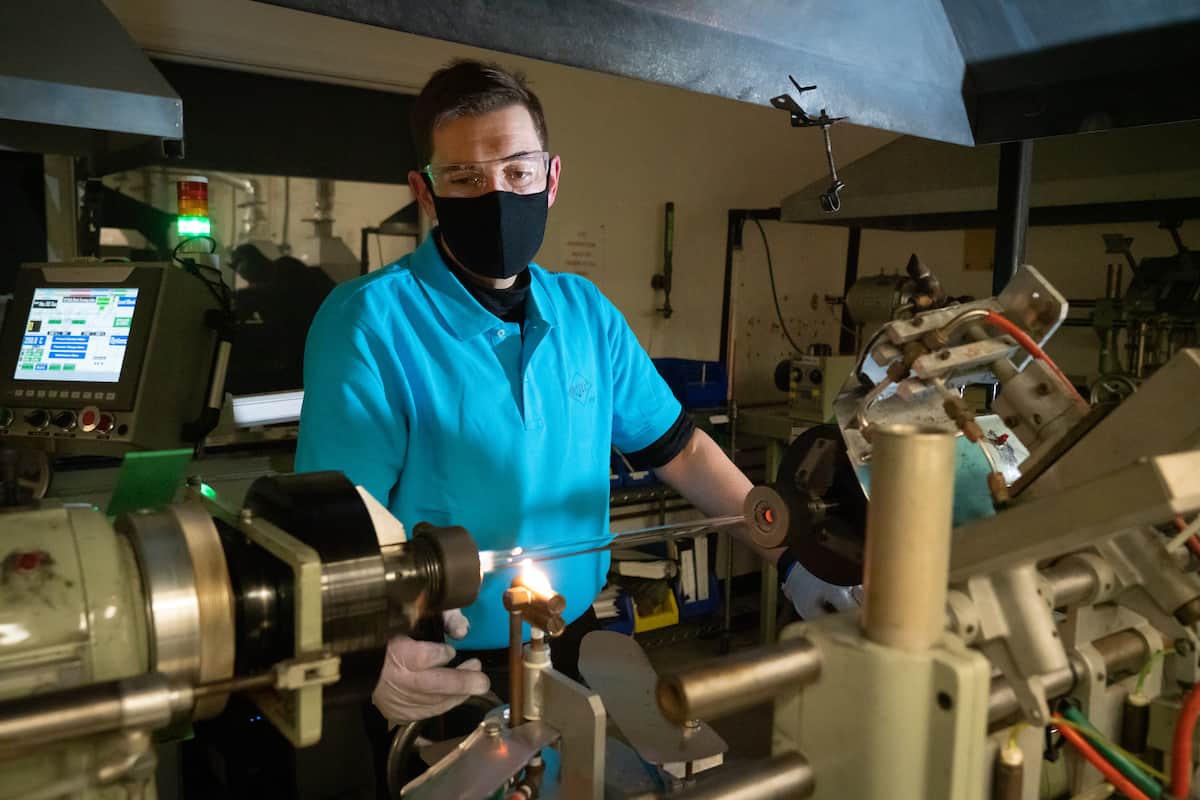

Here, an employee at the Bulb division is making a UV bulb. Miltec manufactures thousands of bulbs each year for export around the globe:

When dealing with UV technology, safety comes first. Here, an employee working in the Li-ion Battery Research and Development lab is assembling coin cell batteries in a glove box. The batteries will be used as test samples.

The set of a sci-fi movie? Nope. It’s just the testing of a 16-lamp UV curing system that produces more than 530 KW of UV power. Ultimately, the customer will use this system to cure inks and coatings on a high-speed printing press that manufactures outdoor packaging bags, such as for Miracle-Gro.

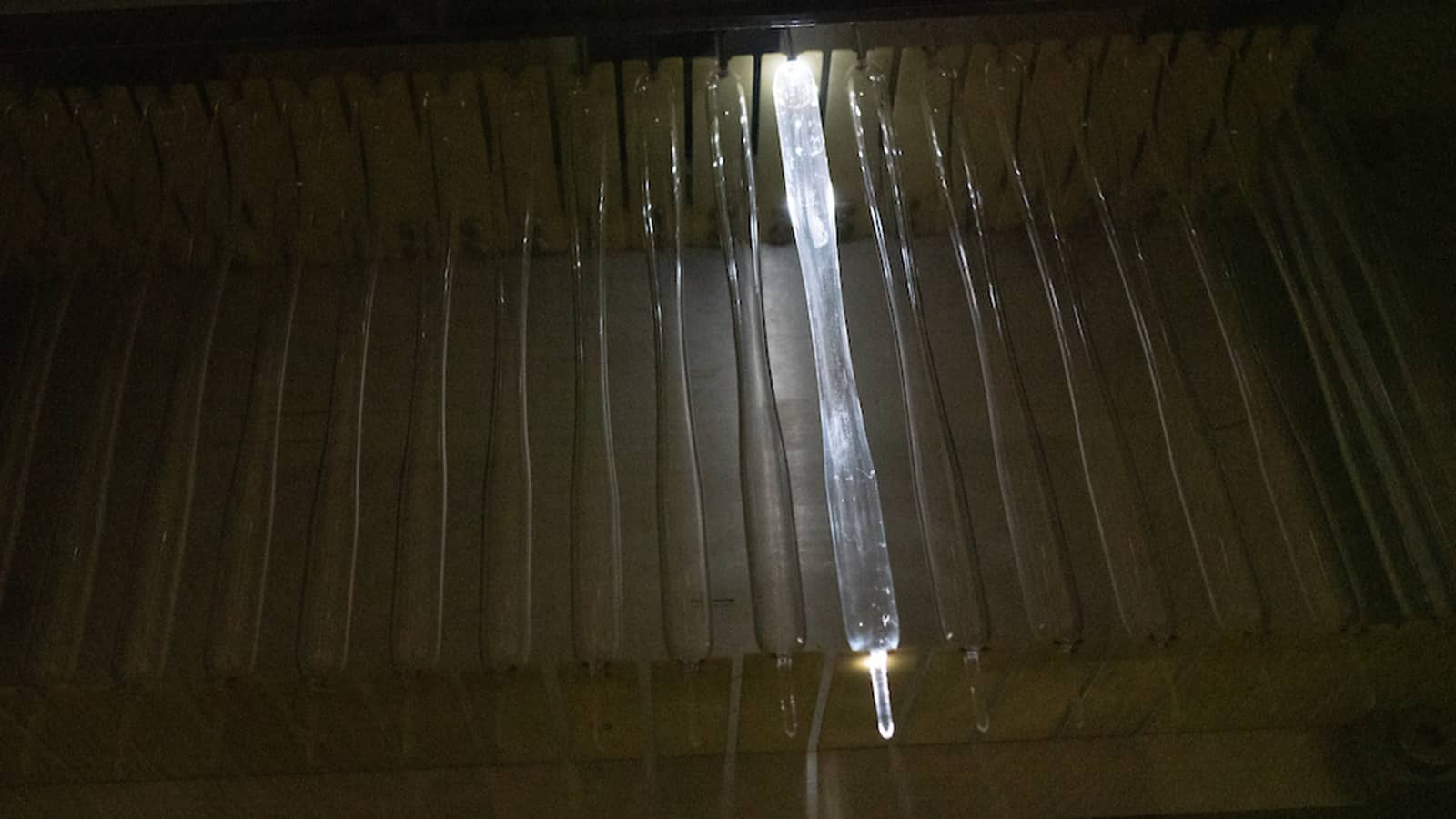

Of course, you can’t go through an entire story about UV light without a cool picture of UV light—so here it is. This is a UV bulb after it’s been filled with an inert gas, which helps it illuminate its powerful UV light.

Miltec says: “Miltec UV is proud to be a member of the NAM and extremely grateful for all of the work that the NAM does to protect the jobs of our team members that do so much to help our company grow and succeed in the international market,” said Miltec President Bob Blandford. “We are also honored and blessed to have such a dedicated manufacturing team that truly understands the importance of making products in the USA and satisfying customers with reliable and high-performance products. With the help of tax cuts, Miltec UV is doing its part by creating more jobs, increasing salaries and offering end-of-year bonuses for its employees.”