Manufacturers Launch Seven-Figure Ad Campaign Opposing Biden Administration’s March-In Proposal

Washington, D.C. – The National Association of Manufacturers has launched a seven-figure television and digital advertising campaign opposing the Biden Administration’s new proposal that would allow the government to march in and seize the rights to groundbreaking innovations developed by manufacturers.

“This radical new proposal is a major threat to manufacturers in America and counter to the president’s goals of growing the sector,” said NAM President and CEO Jay Timmons. “Empowering the government to march in and seize the rights to private-sector patents and technologies threatens American innovation and R&D, putting millions of well-paying manufacturing jobs at risk. Policymakers must protect manufacturers’ intellectual property rights and stop this government overreach.”

To view the latest television ad, click here.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.75 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

NAM Announces New Board Leadership

Seasoned Executives Take Helm at NAM as Policymakers Debate Competitiveness Issues for Manufacturing Industry

Washington, D.C. – The National Association of Manufacturers announced its Board of Directors has elected Johnson & Johnson Executive Vice President and Chief Technical Operations and Risk Officer Kathy Wengel as board chair and Rockwell Automation Chairman and CEO Blake Moret as vice chair.

“Building on the solid foundation left by Immediate Past Chair Jim Fitterling, chair and CEO of Dow, the NAM enters 2024 with continued successful results for our members, strong financial growth and forward momentum with Kathy as chair and Blake as vice chair. Their companies are at the forefront of modern manufacturing, representing the future of what our industry can accomplish,” said NAM President and CEO Jay Timmons. “Over the past often turbulent and unpredictable years, they both have used their platforms to champion our industry and help secure landmark legislation. In addition to being a strong global voice on supply chain reliability and manufacturing for the future, Kathy is a committed force for bringing more diversity into the industry through her support of the Manufacturing Institute’s Women MAKE America Initiative, in addition to her service on the MI Board.

“Blake represents some of the most exciting, high-tech elements of manufacturing, as a leader in the industrial automation and digital innovation space. His commitment to building the next-generation manufacturing workforce was evident when he worked to bring the NAM and MI’s Creators Wanted campaign to Rockwell’s Automation Fair in Chicago. Kathy and Blake’s counsel has been instrumental in shaping the NAM’s policy agenda and elevating the values that make America exceptional and keep manufacturing strong: free enterprise, competitiveness, individual liberty and equal opportunity.”

“The NAM is best in class for its ability to address important challenges facing the manufacturing industry—from bolstering supply chains to harnessing the power of new technology,” said Wengel. “It is a true privilege to take on this new responsibility as NAM board chair. As the association looks to the future, we will seize opportunities to advance policies that foster growth, promote sustainability and ensure the readiness and diversity of the modern workforce.”

“As our industry looks to the future, manufacturing plays a critical role in solving some of the greatest challenges facing society and is at the vital core of the American economy,” said Moret. “It is an honor to represent manufacturing across America as board vice chair of the NAM. I look forward to working with this influential and well-respected association to move our industry forward.”

Wengel serves on the Board of Directors of the MI, the workforce development and education affiliate of the NAM, and has been instrumental in bringing more women into manufacturing through the MI’s Women MAKE America Initiative. Moret has worked closely with Creators Wanted, the industry’s largest campaign to build the workforce of tomorrow and is a past chair of the MI.

The two leaders take on their new roles at a time when manufacturers are confronting growing regulatory hurdles from Washington, D.C., geopolitical instability and policy uncertainty; answering significant questions about the role of advanced technologies, such as artificial intelligence; and working to ramp up implementation of historic legislation like the Bipartisan Infrastructure Law and the CHIPS and Science Act.

The NAM Board of Directors guides the association’s leadership in policy advocacy, legal action, operational excellence, workforce development and news and insights. More than 200 manufacturing leaders serve on the NAM Board, helping advance an agenda that enhances manufacturing competitiveness and the industry’s ability to improve lives in the United States and around the world.

The new board leadership was elected at the September meeting of the NAM Board of Directors.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.85 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

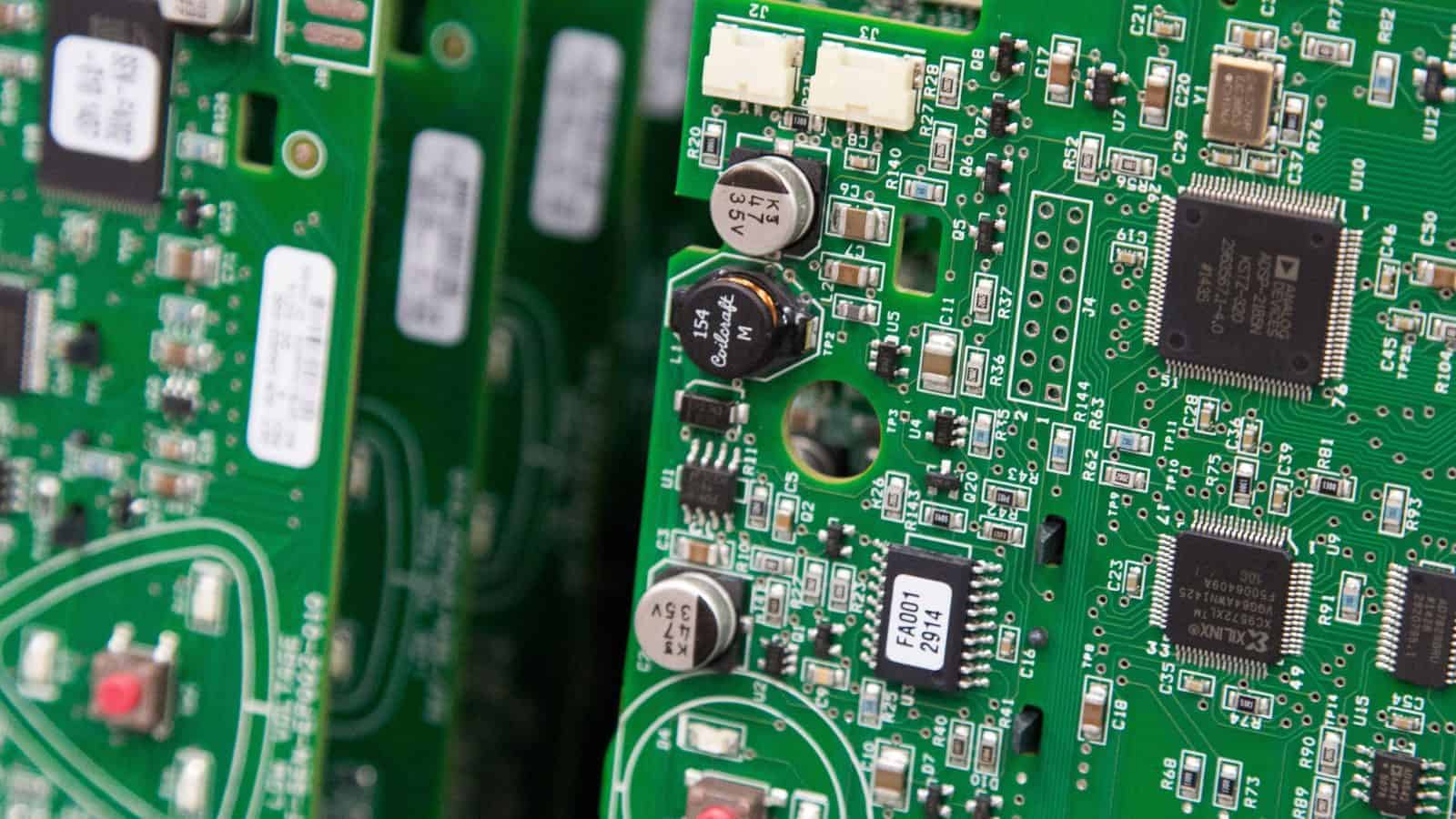

New Study: “Right-to-Repair” Stifles Innovation, Threatens Consumer Safety

Washington, D.C. – The National Association of Manufacturers released a new study, “The Economic Downsides of Right-to-Repair,” which highlights the cost to the environment, consumer safety and manufacturing innovation of providing unfettered access to complex software and components in manufactured goods. The study analyzes the wide range of unintended and potentially harmful consequences of “right-to-repair” legislation.

The study finds that instituting “right-to-repair” polices directly counteracts many federal laws put in place to protect both manufactures and consumers. The study states that, “bypassing the proper channels for repair will come at a steep cost to quality, performance, consumer safety, the environment and the broader U.S. economy.”

Notably, “right-to-repair” policies could seriously disrupt original equipment manufacturers’ supply chains, which would leave many consumers—especially in rural communities—without a reliable and efficient place to get a repair. “This could increase costs for customers significantly, as delays in placing equipment back in service directly affect a business’s bottom line,” the study warns. The study further highlights an Environmental Protection Agency estimate that more than 500,000 tons of excess emissions have entered the atmosphere since 2009 due to operators disabling or modifying emission controls in vehicles across multiple industries.

“For decades, manufacturing innovation has created new products and technologies that improve modern life,” said NAM Managing Vice President of Policy Chris Netram. “Unfortunately, so called ‘right-to-repair’ policies would threaten these programs, resulting in harm to the environment and putting American’s data and safety at risk.”

Background: In 2021, President Joe Biden signed an executive order encouraging the Federal Trade Commission to enact policies limiting OEMs’ ability to prevent nonauthorized entities from performing certain repairs. The NAM submitted comments to the FTC, calling “right-to-repair” legislation a, “solution in search of a problem.” As of 2023, New York, Minnesota and Colorado have enacted “right-to-repair” legislation, and 23 other states have also considered legislation that would force manufacturers to provide direct access to replacement parts, grant unfettered access to the central processor and further limit their ability to constrain what consumers can do with their product.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.91 trillion to the U.S. economy annually and accounts for 53% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

How Manufacturing Leaders Are Bolstering Their Cyber Defenses

Cybersecurity threats are increasing, while budgets are getting tighter—so what are C-suites doing about it? The NAM, in partnership with PwC, recently conducted a survey of cyber leaders at manufacturing companies to reveal how they think about their operational security and where they aim to make progress.

Why they do it: When asked why their companies are reinforcing the security of their operational technology, cyber leaders showed that they are thinking deeply about their firms’ long-term development.

- Nearly 50% of respondents said they aimed to defend against ransomware—a smart response, given that 2022 saw almost double the number of ransomware attacks on industrial environments as 2021. Worse yet, 70% of those attacks targeted manufacturers.

- The second most popular answer, however, was the companies’ own internal roadmaps outlining their priorities and technology requirements. This shows how integrated cyber defenses are into companies’ long-term plans; they know that as their operations grow more sophisticated and complex, their cyber defenses have to do so as well.

- Last, cyber leaders also cited the evolution of “Manufacturing 4.0,” as they recognize that the rising sophistication of factories and “smart” technology increases attack surfaces and vectors, therefore requiring smarter and more extensive cybersecurity.

Another positive sign: One of the key indicators of success for cyber leaders is whether their IT teams—which traditionally handle cyber defenses—are in sync with their teams handling operational technology.

- On that score, the survey had good news: more than 30% of respondents said those teams were fully integrated at their companies, and almost 40% said they were partially integrated.

Reporting back: A cyber chief needs to keep the rest of the C-suite and the board informed, but not overwhelmed. So what do they tell other company leaders?

- Nearly 80% of respondents said they give updates on what you might expect: the deployment of technical controls or countermeasures to attacks, as well as progress in implementing their roadmaps.

- About 50% of respondents also said they give updates on security audits, and almost 40% provide reports on compliance with regulations.

In their own words: Several CISOs who reviewed these findings for the NAM explained the reasoning in greater detail:

- One CISO said that “getting into quantitative discussion with boards around risk is hard, so the easier route is to do implementation updates, which provide measurable results.”

- Another CISO said “it’s better to share about what is being done, including patches and roadmaps [than overloading boards with background information].”

Get involved: Are you interested in finding out firsthand how companies handle real cyber challenges? Tell your CISO about the Manufacturing Cybersecurity Advisory Council, a group of CISOs from around the industry who gather every other month for a confidential discussion moderated by the NAM’s COO, Todd Boppell.

- The meetings feature guest speakers, feedback on important issues and discussions of current trends, with a focus on how CISOs at large manufacturers should handle threats throughout the supply chain.

Weigh in: If you’d like to share your company’s own approach to operational technology security, you can take the NAM and PwC’s survey yourself!

Further reading: Lastly, check out PwC’s list of tips for companies looking to beef up their cyber defenses.

NAM Study: U.S. Pharmaceutical Manufacturing Strength Requires Commitment to R&D, Innovative Regulatory Environment

Washington, D.C. – The National Association of Manufacturers released a new study, “Creating Cures, Saving Lives,” which demonstrates the urgency of strengthening U.S. pharmaceutical manufacturing amid policy threats to the sector’s innovative, global leadership.

“Creating Cures, Saving Lives” analyzes the sector’s contributions to the broader economy and its commitment to R&D that drives the development of lifesaving treatments, such as advancements in therapeutics that fight cancer. The study further examines the ways that federal price controls on the sector, such as those contained in the Inflation Reduction Act, could jeopardize these treatments. The study comes at a critical time, as the Centers for Medicare & Medicaid Services recently announced the first tranche of treatments that will be subject to price controls.

“Pharmaceutical manufacturers are a major contributor to the U.S. economy, employ millions of Americans and drive innovation. The industry’s investments in R&D have led to lifesaving treatments and therapies that have improved the quality of life for all Americans,” said NAM Chief Economist Chad Moutray. “This study explores the negative implications of price control policies on pharmaceutical leadership, putting American jobs and innovation in the health care system at risk.”

“Creating Cures, Saving Lives” includes seven key findings on the importance of the pharmaceutical and medical manufacturing industry and the implications of price controls on the sector:

- The pharmaceutical manufacturing industry is a major contributor to the U.S. economy, and its impact is growing.

- The industry accounted for $355 billion in value-added output to the U.S. economy in 2021. The direct contribution from the industry of $192 billion is up 24% from just two years ago. The pharmaceutical sector was already an economically vital sector before the pandemic, and it has become increasingly more important in its aftermath.

- The pharmaceutical manufacturing industry fuels other sectors of the economy, supporting nearly 1.5 million jobs in America.

- The industry directly employs an estimated 291,000 workers in the United States, an increase of nearly 9% in the past 24 months. One job in the pharmaceutical manufacturing industry helps support 4.1 other jobs in the overall workforce.

- Industry employees are highly productive.

- Industry employees produce $1.2 million in output per employee. This is nearly six times more than the U.S. economy’s average output per employee ($208,084).

- A successful pharmaceutical ecosystem requires strong private-sector investment.

- The pharmaceutical industry invests 16.6% of its sales back into R&D. Indeed, the U.S. pharmaceutical industry invests nearly 3.5 times more in R&D as a percentage of sales than the average U.S. industry.

- The pharmaceutical manufacturing industry pays high wages and benefits to American workers.

- Annual average labor income per worker in the pharmaceutical manufacturing industry is more than $184,000. This figure is higher than some of the highest-paying industries in the country.

- The industry creates valuable STEM jobs.

- While roughly 6.6% of the U.S. workforce has a STEM occupation, some 25% of all jobs in pharmaceutical and medicine manufacturing are STEM-related. The pharmaceutical manufacturing sector employs more than four times the percentage of STEM workers employed in the overall workforce.

- Price control policies, like those in the IRA, may hurt U.S. pharmaceutical leadership.

- Price controls may deter advancements in health care by reducing investments in R&D, negatively impacting the nation’s economic prosperity.

-NAM-

The National Association of Manufacturers is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs nearly 13 million men and women, contributes $2.91 trillion to the U.S. economy annually and accounts for 55% of private-sector research and development. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States. For more information about the NAM or to follow us on Twitter and Facebook, please visit www.nam.org.

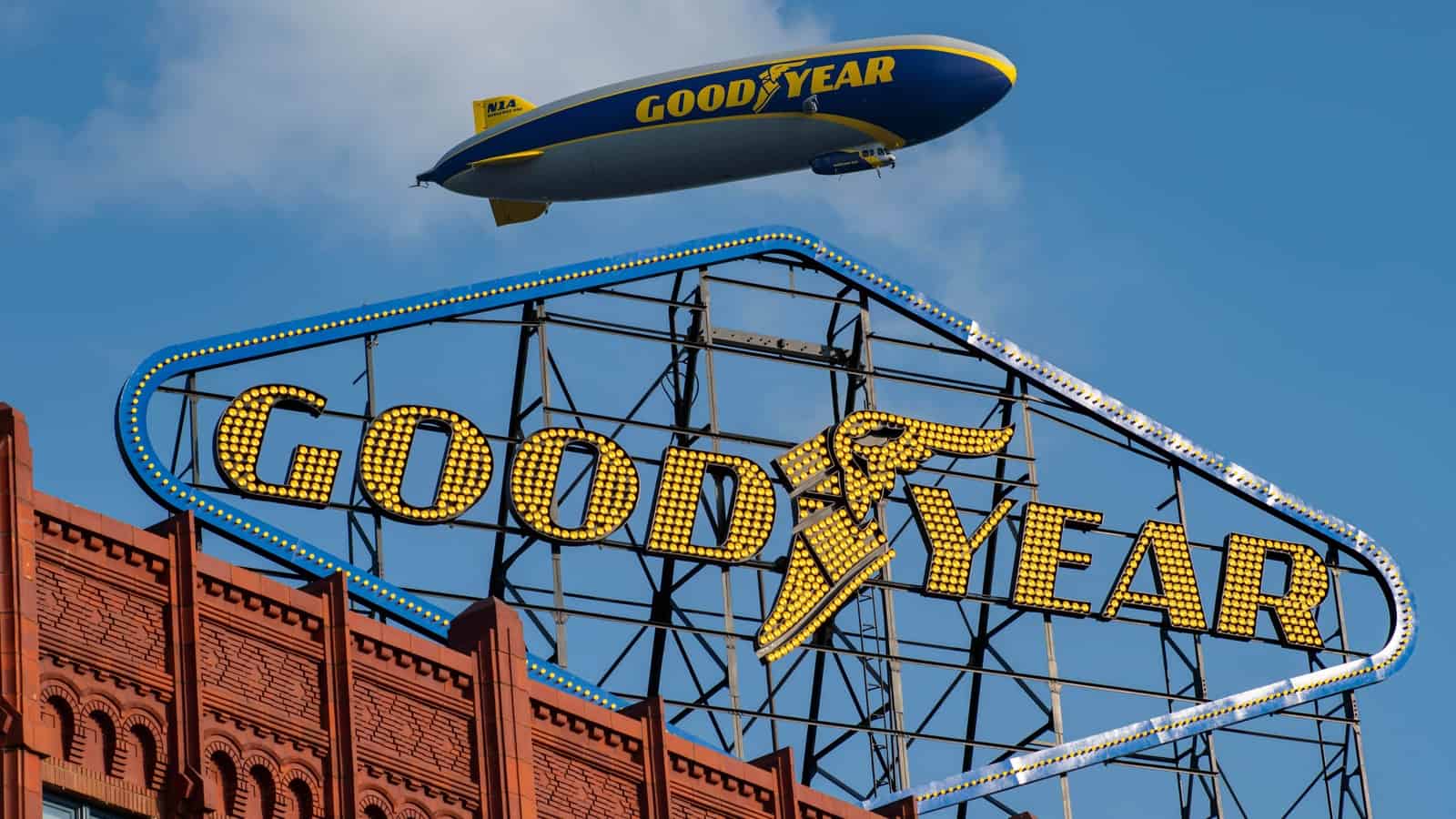

How Goodyear and Akron Thrive Together

This year, one of the most recognizable brands in America turned 125. Goodyear, the manufacturer of tires for everything from cars to planes to lunar rovers, celebrated its anniversary in style, including by flying the famous blimps over its hometown of Akron, Ohio.

The company’s deep ties to Akron have been apparent throughout its more than a century in business. We spoke to Senior Vice President and Chief Communications Officer Laura Duda recently about that history and what other manufacturers can learn from it.

The beginning: Goodyear was founded in 1898, when F.A. “Frank” Seiberling purchased two empty factories in Akron’s then-small downtown, Duda told us.

- The company brought thousands of jobs to the neighborhood known as Middlebury and is still operating there more than a century later, having built its new headquarters on Innovation Way in 2014, just blocks away from its previous headquarters.

- The company also built its largest innovation center in Akron around the same time, as well as one of its three airship bases. Its Akron facilities also include a plant that produces racing tires, a test track that helps the company develop and bring innovative products to market and much more—all in the place it first called home.

Growing together: In addition to creating and keeping jobs in Akron, Goodyear prides itself on its contributions to the expansion of the city throughout the company’s history, Duda said.

- Seiberling himself developed a neighborhood called Goodyear Heights, which offered affordable housing to the company’s workers and remains a beloved historic district today.

- Meanwhile, the city’s first municipal bus system was constructed to bring the company’s workers downtown to the factory, and Goodyear’s early leaders created the surrounding county’s public parks.

- “It’s not possible to separate the history of Akron from the history of Goodyear,” Duda concluded.

Recruiting locally: Ever since its founding, Goodyear has always prioritized local recruitment, said Duda, and worked to set employees up for long, productive tenures at the company.

- In 1913, Goodyear’s first CEO, Paul Litchfield, set up an early in-house training program called the “flying squadron,” which helped associates learn new skills and advance in their careers. Today, the descendant of that

program is known as “Sales Squad,” Duda said, and serves to “attract talent to and kickstart the company.”

program is known as “Sales Squad,” Duda said, and serves to “attract talent to and kickstart the company.” - This program recruits recent college graduates for full-time positions across the country, using a 10-week training program designed to prepare candidates for a career at Goodyear by providing experiences within the company’s retail, sales, manufacturing and product development departments.

- Goodyear also offers developmental programs throughout the company, via a learning center that provides both in-person and take-home training resources.

- Lastly, the company collaborates with STEM programs in schools both in the Akron area and around the country, sending its engineers out to tell students about Goodyear’s many rewarding career paths.

Still giving back: Today, Akron is a well-established city with significant infrastructure, and Goodyear is still contributing to the city’s future.

- “It’s unusual to find an area of community support where Goodyear is not engaged,” said Duda. “We focus on building ‘safe, smart and sustainable communities.” The company’s “safe” pillar includes a partnership with Akron’s Children’s Hospital to provide car seats to parents who can’t afford them and bike helmets to older children. “Smart” projects include efforts to promote STEM careers among underrepresented students at Akron Public Schools.

- Meanwhile, Goodyear’s focus on sustainability has led it to support the development of the region’s Ohio & Erie Canalway Towpath Trail, along with green space throughout the region.

Blimps: We couldn’t have an interview with Goodyear without asking about the blimps, of course.

- Yes, Duda has ridden in them, she told us, and the experience is “as great as you would expect.”

- Akron also takes great pride in the blimps, which can be a major draw at charity auctions, to which the company often donates rides. A ride for two on a blimp “goes for more money than you might anticipate,” said Duda.

The last word: While it is hard to replicate the sort of community ties and goodwill built up over more than a century, Duda has some advice for manufacturing companies looking ahead to the next 125 years. Not only will they find local leaders very receptive to outreach, she advised, but an enormous amount gets accomplished at local associations and chambers of commerce.

- Just as importantly, manufacturers should know that “your employees want this [level of community engagement],” Duda said. “We hear from top talent that we are recruiting that it is important to them, as well as from our current employees. From a talent perspective, this is something everyone should consider.”

For more on Goodyear’s history, innovations and future plans, check out the company’s engrossing documentary made for the anniversary: 125 Years in Motion.

Inside the MI’s Pathbreaking Workforce Summit

The best minds tackling manufacturers’ workforce challenges gathered in Atlanta last week to discuss hiring, retention, training and more. The Manufacturing Institute’s workforce summit convened almost 300 manufacturers, partners from education and training groups, philanthropy leaders and representatives from community-based organizations to share insights and brainstorm solutions.

The economic backdrop: Amid a persistently tight labor market, manufacturers are looking for immediate and long-term solutions to attraction and retention challenges.

- Chad Moutray, director of the MI’s Center for Manufacturing Research, provided the larger economic context for attendees, saying that “it’s not hard to be bullish about manufacturing. There continues to be signs of resilience in the sector despite a multitude of challenges.”

- “However, it exacerbates workforce issues, which remain the top concern of manufacturers, especially in a solid labor market,” he added.

Energizing connections: The MI was focused on helping participants learn from each other and form lasting and productive bonds.

- Organizations including the Georgia Association of Manufacturers, Siemens Foundation and River Parishes Community College sent leaders to facilitate conversations and share insights, while the generous support of WestRock, the Arconic Foundation and many others made the event possible.

- In breakout sessions, MI experts analyzed the key challenges facing manufacturers and shared proven workforce solutions like high school internships, female mentorship programs and regional sector partnerships.

Fresh insights: The two-day event was brimming with new ideas and fresh perspectives—too many to list in one article. Here is a brief sampling of the topics covered:

- People: The speakers highlighted manufacturers’ work to create positive company culture, prioritize flexibility and address issues like the shortage of child care. Maj. Gen. Kris Belanger also shared the importance of tapping into military talent pools like the U.S. Army Reserve. Programs like the MI’s Heroes MAKE America are making these important connections.

- Skills: To meet their needs for skilled workers, manufacturers are working with the MI, economic development boards and educational institutions to train the current and next generations of manufacturing employees. Workshop sessions showcased solutions from the MI’s FAME USA program, second chance hiring initiative and student engagement.

- Processes: Conversations in the popular “Brewing Solutions” rooms focused on ways manufacturers and workforce partners could tap into hidden populations, create attractive working environments and address policy barriers that restrict the adoption of innovative solutions.

Fearing you missed out? Don’t worry! There are plenty of ways you can plug into the cutting-edge work of the MI, the NAM’s workforce development and education affiliate.

- Get updates directly from the MI on the latest workforce insights and receive information about registering for the 2024 Workforce Summit.

- Join us as a sponsor for the 2024 Women MAKE Awards in Washington, D.C., on April 18 to support female manufacturing leaders and network with manufacturers and other workforce partners.

- Want more labor data and insights? Sign up for the MI’s comprehensive Workforce in Focus newsletter to stay up to date on the latest workforce trends.

The last word: “The MI’s unique positioning as both an insightful expert of emerging trends within the industry and an effective implementer of proven workforce solutions drives innovative problem-solving,” said MI President and Executive Director Carolyn Lee. “As we face structural workforce shortages, convenings like the MI’s Workforce Summit will continue to be crucial to build the types of partnerships and share important insights needed to ensure the readiness of the manufacturing workforce.”

How Manufacturers Can Unlock the Power of Data

Manufacturers are using data to improve everything from their supply chains to their workplace culture—and more. Data can lead the way to new innovations, new business models and even new revenue streams. Yet, many manufacturing executives say they are not scaling data-driven use cases successfully, meaning that much of the information they do collect is going to waste.

So how can companies get the most out of their data and ensure they aren’t losing out on key insights?

A unique event hosted by the Manufacturing Leadership Council, the NAM’s digital transformation division, aims to answer these questions and more. “Manufacturing in 2030: The Coming Data Value Revolution,” which will be held on Dec. 6–7 in Nashville, Tennessee, will explore the ways manufacturers can unlock value from their data to boost productivity, value and competitiveness.

On the agenda: This event will have three key areas of focus:

- Data value: Attendees will learn what the future holds for data monetization, data ecosystems and data-driven innovation.

- People and process: They will also hear about the future workforce, including emerging and evolving job roles, data-driven leadership and data culture.

- Technology and data: And lastly, they will peek into a future where artificial intelligence, data visualizations and the industrial metaverse are part of our everyday manufacturing world.

M2030 agenda highlights: The presenters will also share practical insights that participants can put into action right away.

- In “Capturing Intelligence for Business Model Innovation,” IDC’s Bob Parker will examine digital maturity and the future of enterprise intelligence. Parker will explain how to create new business models through enhanced customer experience, as well as how to capture and leverage economies of intelligence.

- In “The Rise of Data Ecosystems,” John Dyck of the Clean Energy Smart Manufacturing Innovation Institute will deliver a practical explanation of Manufacturing-X, Gaia-X and Catena-X as well as their goals and challenges. Dyck will discuss trends driving data-sharing initiatives as well as related technical and governance issues.

- In “Building Great Supply Chain Visibility by 2030,” Supply Chain Insights’ Lora Cecere will address why 80% of the data being generated from supply chains isn’t being used well enough. Cecere will also explore how data can be used to create more resilient supply chains by 2030.

The bottom line: Advanced technologies are only part of the digital transformation story. Manufacturers who want to get ahead need to understand data’s role and value, not to mention how people, process, technology and even data itself will evolve by 2030.

Sign up: Registration is open for Manufacturing in 2030: The Coming Data Value Revolution. Click here to learn more.

How Manufacturers Can Unlock the Power of Data

Manufacturers are using data to improve everything from their supply chains to their workplace culture—and more. Data can lead the way to new innovations, new business models and even new revenue streams. Yet, many manufacturing executives say they are not scaling data-driven use cases successfully, meaning that much of the information they do collect is going to waste.

So how can companies get the most out of their data and ensure they aren’t losing out on key insights?

A unique event hosted by the Manufacturing Leadership Council, the NAM’s digital transformation division, aims to answer these questions and more. “Manufacturing in 2030: The Coming Data Value Revolution,” which will be held on Dec. 6–7 in Nashville, Tennessee, will explore the ways manufacturers can unlock value from their data to boost productivity, value and competitiveness.

On the agenda: This event will have three key areas of focus:

- Data value: Attendees will learn what the future holds for data monetization, data ecosystems and data-driven innovation.

- People and process: They will also hear about the future workforce, including emerging and evolving job roles, data-driven leadership and data culture.

- Technology and data: And lastly, they will peek into a future where artificial intelligence, data visualizations and the industrial metaverse are part of our everyday manufacturing world.

M2030 agenda highlights: The presenters will also share practical insights that participants can put into action right away.

- In “Capturing Intelligence for Business Model Innovation,” IDC’s Bob Parker will examine digital maturity and the future of enterprise intelligence. Parker will explain how to create new business models through enhanced customer experience, as well as how to capture and leverage economies of intelligence.

- In “The Rise of Data Ecosystems,” John Dyck of the Clean Energy Smart Manufacturing Innovation Institute will deliver a practical explanation of Manufacturing-X, Gaia-X and Catena-X as well as their goals and challenges. Dyck will discuss trends driving data-sharing initiatives as well as related technical and governance issues.

- In “Building Great Supply Chain Visibility by 2030,” Supply Chain Insights’ Lora Cecere will address why 80% of the data being generated from supply chains isn’t being used well enough. Cecere will also explore how data can be used to create more resilient supply chains by 2030.

The bottom line: Advanced technologies are only part of the digital transformation story. Manufacturers who want to get ahead need to understand data’s role and value, not to mention how people, process, technology and even data itself will evolve by 2030.

Sign up: Registration is open for Manufacturing in 2030: The Coming Data Value Revolution. Click here to learn more.

NAM Sets the Policy Agenda for Manufacturing in the U.S.

The NAM is the voice of the manufacturing industry in the United States, speaking out on issues that matter to the men and women who make things in America. As times change, new issues arise, and to stay up to date with the needs of its members, the NAM updates its policy position documents accordingly.

That process—now underway for 2023—takes place with our member companies every four years under the guidance of the NAM Board of Directors. Here’s what you need to know.

The timeline: Proposed changes have been distributed from the NAM policy teams to the respective policy committees, and members have until Oct. 31 to provide their feedback.

- Shortly after Oct. 31, NAM policy committees will convene to consider the proposed changes and any subsequent suggested edits. If needed, working groups will be organized to consider new or revised language on specific issues.

The result: The NAM policy committees will recommend new policy language to the NAM Board based on their engagement with member companies.

- At the February 2024 board meeting, the NAM Board will finalize and approve the policy positions that will guide the NAM for the next four years.

How to participate: Member companies can choose which policy committees they serve on, so as the policy update process commences, companies should contact their membership directors to ensure they are aware of the various policies and committees that may be most important to their own businesses.

The last word: “Our member companies are at the center of this policy update process,” said NAM Managing Vice President of Policy Chris Netram. “The NAM fights every day for a policy agenda that supports manufacturing growth, and this is a critical opportunity for manufacturers across the country to have their say on the issues that matter to them.”