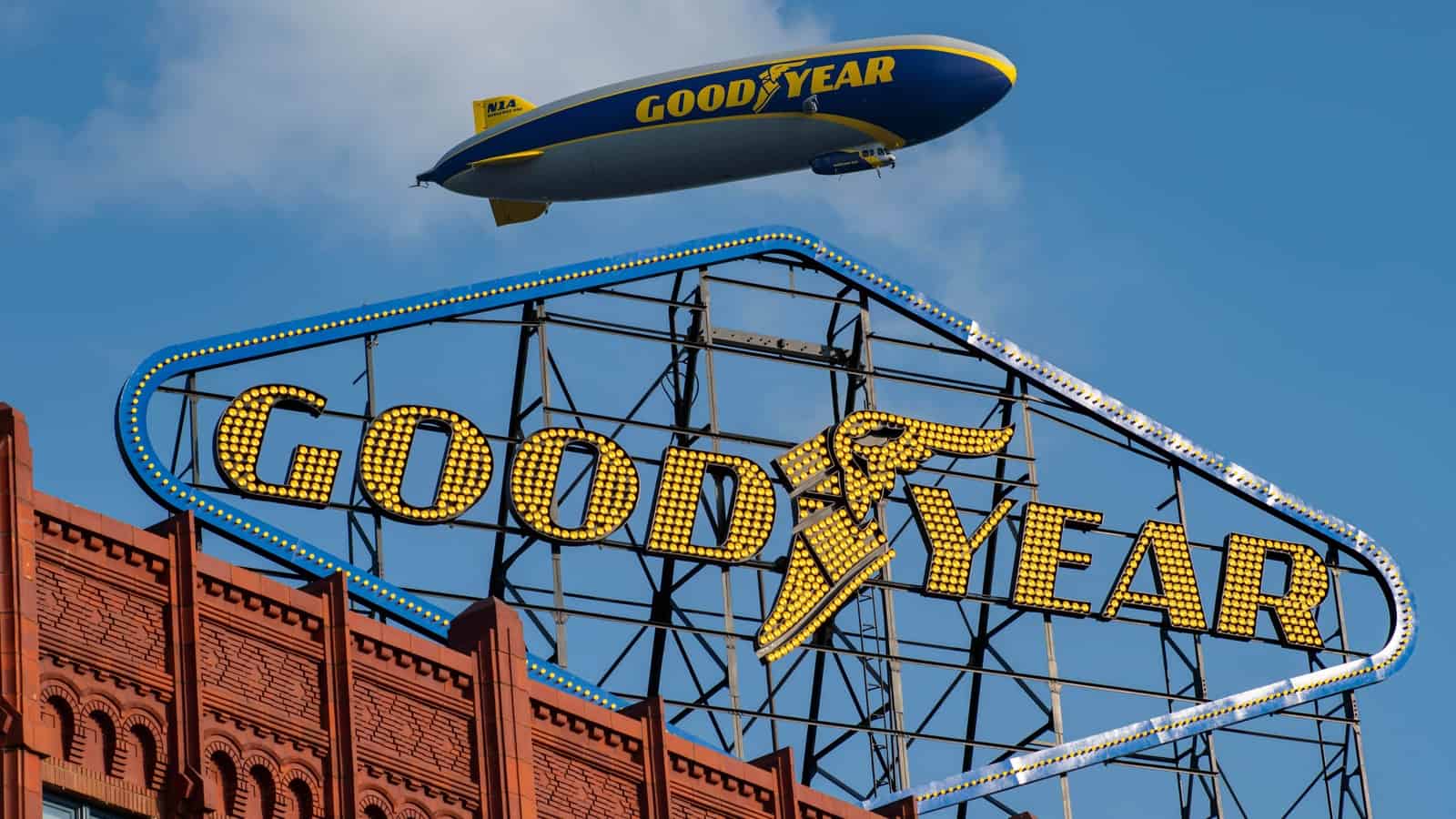

How Goodyear and Akron Thrive Together

This year, one of the most recognizable brands in America turned 125. Goodyear, the manufacturer of tires for everything from cars to planes to lunar rovers, celebrated its anniversary in style, including by flying the famous blimps over its hometown of Akron, Ohio.

The company’s deep ties to Akron have been apparent throughout its more than a century in business. We spoke to Senior Vice President and Chief Communications Officer Laura Duda recently about that history and what other manufacturers can learn from it.

The beginning: Goodyear was founded in 1898, when F.A. “Frank” Seiberling purchased two empty factories in Akron’s then-small downtown, Duda told us.

- The company brought thousands of jobs to the neighborhood known as Middlebury and is still operating there more than a century later, having built its new headquarters on Innovation Way in 2014, just blocks away from its previous headquarters.

- The company also built its largest innovation center in Akron around the same time, as well as one of its three airship bases. Its Akron facilities also include a plant that produces racing tires, a test track that helps the company develop and bring innovative products to market and much more—all in the place it first called home.

Growing together: In addition to creating and keeping jobs in Akron, Goodyear prides itself on its contributions to the expansion of the city throughout the company’s history, Duda said.

- Seiberling himself developed a neighborhood called Goodyear Heights, which offered affordable housing to the company’s workers and remains a beloved historic district today.

- Meanwhile, the city’s first municipal bus system was constructed to bring the company’s workers downtown to the factory, and Goodyear’s early leaders created the surrounding county’s public parks.

- “It’s not possible to separate the history of Akron from the history of Goodyear,” Duda concluded.

Recruiting locally: Ever since its founding, Goodyear has always prioritized local recruitment, said Duda, and worked to set employees up for long, productive tenures at the company.

- In 1913, Goodyear’s first CEO, Paul Litchfield, set up an early in-house training program called the “flying squadron,” which helped associates learn new skills and advance in their careers. Today, the descendant of that

program is known as “Sales Squad,” Duda said, and serves to “attract talent to and kickstart the company.”

program is known as “Sales Squad,” Duda said, and serves to “attract talent to and kickstart the company.” - This program recruits recent college graduates for full-time positions across the country, using a 10-week training program designed to prepare candidates for a career at Goodyear by providing experiences within the company’s retail, sales, manufacturing and product development departments.

- Goodyear also offers developmental programs throughout the company, via a learning center that provides both in-person and take-home training resources.

- Lastly, the company collaborates with STEM programs in schools both in the Akron area and around the country, sending its engineers out to tell students about Goodyear’s many rewarding career paths.

Still giving back: Today, Akron is a well-established city with significant infrastructure, and Goodyear is still contributing to the city’s future.

- “It’s unusual to find an area of community support where Goodyear is not engaged,” said Duda. “We focus on building ‘safe, smart and sustainable communities.” The company’s “safe” pillar includes a partnership with Akron’s Children’s Hospital to provide car seats to parents who can’t afford them and bike helmets to older children. “Smart” projects include efforts to promote STEM careers among underrepresented students at Akron Public Schools.

- Meanwhile, Goodyear’s focus on sustainability has led it to support the development of the region’s Ohio & Erie Canalway Towpath Trail, along with green space throughout the region.

Blimps: We couldn’t have an interview with Goodyear without asking about the blimps, of course.

- Yes, Duda has ridden in them, she told us, and the experience is “as great as you would expect.”

- Akron also takes great pride in the blimps, which can be a major draw at charity auctions, to which the company often donates rides. A ride for two on a blimp “goes for more money than you might anticipate,” said Duda.

The last word: While it is hard to replicate the sort of community ties and goodwill built up over more than a century, Duda has some advice for manufacturing companies looking ahead to the next 125 years. Not only will they find local leaders very receptive to outreach, she advised, but an enormous amount gets accomplished at local associations and chambers of commerce.

- Just as importantly, manufacturers should know that “your employees want this [level of community engagement],” Duda said. “We hear from top talent that we are recruiting that it is important to them, as well as from our current employees. From a talent perspective, this is something everyone should consider.”

For more on Goodyear’s history, innovations and future plans, check out the company’s engrossing documentary made for the anniversary: 125 Years in Motion.

Inside the MI’s Pathbreaking Workforce Summit

The best minds tackling manufacturers’ workforce challenges gathered in Atlanta last week to discuss hiring, retention, training and more. The Manufacturing Institute’s workforce summit convened almost 300 manufacturers, partners from education and training groups, philanthropy leaders and representatives from community-based organizations to share insights and brainstorm solutions.

The economic backdrop: Amid a persistently tight labor market, manufacturers are looking for immediate and long-term solutions to attraction and retention challenges.

- Chad Moutray, director of the MI’s Center for Manufacturing Research, provided the larger economic context for attendees, saying that “it’s not hard to be bullish about manufacturing. There continues to be signs of resilience in the sector despite a multitude of challenges.”

- “However, it exacerbates workforce issues, which remain the top concern of manufacturers, especially in a solid labor market,” he added.

Energizing connections: The MI was focused on helping participants learn from each other and form lasting and productive bonds.

- Organizations including the Georgia Association of Manufacturers, Siemens Foundation and River Parishes Community College sent leaders to facilitate conversations and share insights, while the generous support of WestRock, the Arconic Foundation and many others made the event possible.

- In breakout sessions, MI experts analyzed the key challenges facing manufacturers and shared proven workforce solutions like high school internships, female mentorship programs and regional sector partnerships.

Fresh insights: The two-day event was brimming with new ideas and fresh perspectives—too many to list in one article. Here is a brief sampling of the topics covered:

- People: The speakers highlighted manufacturers’ work to create positive company culture, prioritize flexibility and address issues like the shortage of child care. Maj. Gen. Kris Belanger also shared the importance of tapping into military talent pools like the U.S. Army Reserve. Programs like the MI’s Heroes MAKE America are making these important connections.

- Skills: To meet their needs for skilled workers, manufacturers are working with the MI, economic development boards and educational institutions to train the current and next generations of manufacturing employees. Workshop sessions showcased solutions from the MI’s FAME USA program, second chance hiring initiative and student engagement.

- Processes: Conversations in the popular “Brewing Solutions” rooms focused on ways manufacturers and workforce partners could tap into hidden populations, create attractive working environments and address policy barriers that restrict the adoption of innovative solutions.

Fearing you missed out? Don’t worry! There are plenty of ways you can plug into the cutting-edge work of the MI, the NAM’s workforce development and education affiliate.

- Get updates directly from the MI on the latest workforce insights and receive information about registering for the 2024 Workforce Summit.

- Join us as a sponsor for the 2024 Women MAKE Awards in Washington, D.C., on April 18 to support female manufacturing leaders and network with manufacturers and other workforce partners.

- Want more labor data and insights? Sign up for the MI’s comprehensive Workforce in Focus newsletter to stay up to date on the latest workforce trends.

The last word: “The MI’s unique positioning as both an insightful expert of emerging trends within the industry and an effective implementer of proven workforce solutions drives innovative problem-solving,” said MI President and Executive Director Carolyn Lee. “As we face structural workforce shortages, convenings like the MI’s Workforce Summit will continue to be crucial to build the types of partnerships and share important insights needed to ensure the readiness of the manufacturing workforce.”

How Manufacturers Can Unlock the Power of Data

Manufacturers are using data to improve everything from their supply chains to their workplace culture—and more. Data can lead the way to new innovations, new business models and even new revenue streams. Yet, many manufacturing executives say they are not scaling data-driven use cases successfully, meaning that much of the information they do collect is going to waste.

So how can companies get the most out of their data and ensure they aren’t losing out on key insights?

A unique event hosted by the Manufacturing Leadership Council, the NAM’s digital transformation division, aims to answer these questions and more. “Manufacturing in 2030: The Coming Data Value Revolution,” which will be held on Dec. 6–7 in Nashville, Tennessee, will explore the ways manufacturers can unlock value from their data to boost productivity, value and competitiveness.

On the agenda: This event will have three key areas of focus:

- Data value: Attendees will learn what the future holds for data monetization, data ecosystems and data-driven innovation.

- People and process: They will also hear about the future workforce, including emerging and evolving job roles, data-driven leadership and data culture.

- Technology and data: And lastly, they will peek into a future where artificial intelligence, data visualizations and the industrial metaverse are part of our everyday manufacturing world.

M2030 agenda highlights: The presenters will also share practical insights that participants can put into action right away.

- In “Capturing Intelligence for Business Model Innovation,” IDC’s Bob Parker will examine digital maturity and the future of enterprise intelligence. Parker will explain how to create new business models through enhanced customer experience, as well as how to capture and leverage economies of intelligence.

- In “The Rise of Data Ecosystems,” John Dyck of the Clean Energy Smart Manufacturing Innovation Institute will deliver a practical explanation of Manufacturing-X, Gaia-X and Catena-X as well as their goals and challenges. Dyck will discuss trends driving data-sharing initiatives as well as related technical and governance issues.

- In “Building Great Supply Chain Visibility by 2030,” Supply Chain Insights’ Lora Cecere will address why 80% of the data being generated from supply chains isn’t being used well enough. Cecere will also explore how data can be used to create more resilient supply chains by 2030.

The bottom line: Advanced technologies are only part of the digital transformation story. Manufacturers who want to get ahead need to understand data’s role and value, not to mention how people, process, technology and even data itself will evolve by 2030.

Sign up: Registration is open for Manufacturing in 2030: The Coming Data Value Revolution. Click here to learn more.

How Manufacturers Can Unlock the Power of Data

Manufacturers are using data to improve everything from their supply chains to their workplace culture—and more. Data can lead the way to new innovations, new business models and even new revenue streams. Yet, many manufacturing executives say they are not scaling data-driven use cases successfully, meaning that much of the information they do collect is going to waste.

So how can companies get the most out of their data and ensure they aren’t losing out on key insights?

A unique event hosted by the Manufacturing Leadership Council, the NAM’s digital transformation division, aims to answer these questions and more. “Manufacturing in 2030: The Coming Data Value Revolution,” which will be held on Dec. 6–7 in Nashville, Tennessee, will explore the ways manufacturers can unlock value from their data to boost productivity, value and competitiveness.

On the agenda: This event will have three key areas of focus:

- Data value: Attendees will learn what the future holds for data monetization, data ecosystems and data-driven innovation.

- People and process: They will also hear about the future workforce, including emerging and evolving job roles, data-driven leadership and data culture.

- Technology and data: And lastly, they will peek into a future where artificial intelligence, data visualizations and the industrial metaverse are part of our everyday manufacturing world.

M2030 agenda highlights: The presenters will also share practical insights that participants can put into action right away.

- In “Capturing Intelligence for Business Model Innovation,” IDC’s Bob Parker will examine digital maturity and the future of enterprise intelligence. Parker will explain how to create new business models through enhanced customer experience, as well as how to capture and leverage economies of intelligence.

- In “The Rise of Data Ecosystems,” John Dyck of the Clean Energy Smart Manufacturing Innovation Institute will deliver a practical explanation of Manufacturing-X, Gaia-X and Catena-X as well as their goals and challenges. Dyck will discuss trends driving data-sharing initiatives as well as related technical and governance issues.

- In “Building Great Supply Chain Visibility by 2030,” Supply Chain Insights’ Lora Cecere will address why 80% of the data being generated from supply chains isn’t being used well enough. Cecere will also explore how data can be used to create more resilient supply chains by 2030.

The bottom line: Advanced technologies are only part of the digital transformation story. Manufacturers who want to get ahead need to understand data’s role and value, not to mention how people, process, technology and even data itself will evolve by 2030.

Sign up: Registration is open for Manufacturing in 2030: The Coming Data Value Revolution. Click here to learn more.

NAM Sets the Policy Agenda for Manufacturing in the U.S.

The NAM is the voice of the manufacturing industry in the United States, speaking out on issues that matter to the men and women who make things in America. As times change, new issues arise, and to stay up to date with the needs of its members, the NAM updates its policy position documents accordingly.

That process—now underway for 2023—takes place with our member companies every four years under the guidance of the NAM Board of Directors. Here’s what you need to know.

The timeline: Proposed changes have been distributed from the NAM policy teams to the respective policy committees, and members have until Oct. 31 to provide their feedback.

- Shortly after Oct. 31, NAM policy committees will convene to consider the proposed changes and any subsequent suggested edits. If needed, working groups will be organized to consider new or revised language on specific issues.

The result: The NAM policy committees will recommend new policy language to the NAM Board based on their engagement with member companies.

- At the February 2024 board meeting, the NAM Board will finalize and approve the policy positions that will guide the NAM for the next four years.

How to participate: Member companies can choose which policy committees they serve on, so as the policy update process commences, companies should contact their membership directors to ensure they are aware of the various policies and committees that may be most important to their own businesses.

The last word: “Our member companies are at the center of this policy update process,” said NAM Managing Vice President of Policy Chris Netram. “The NAM fights every day for a policy agenda that supports manufacturing growth, and this is a critical opportunity for manufacturers across the country to have their say on the issues that matter to them.”

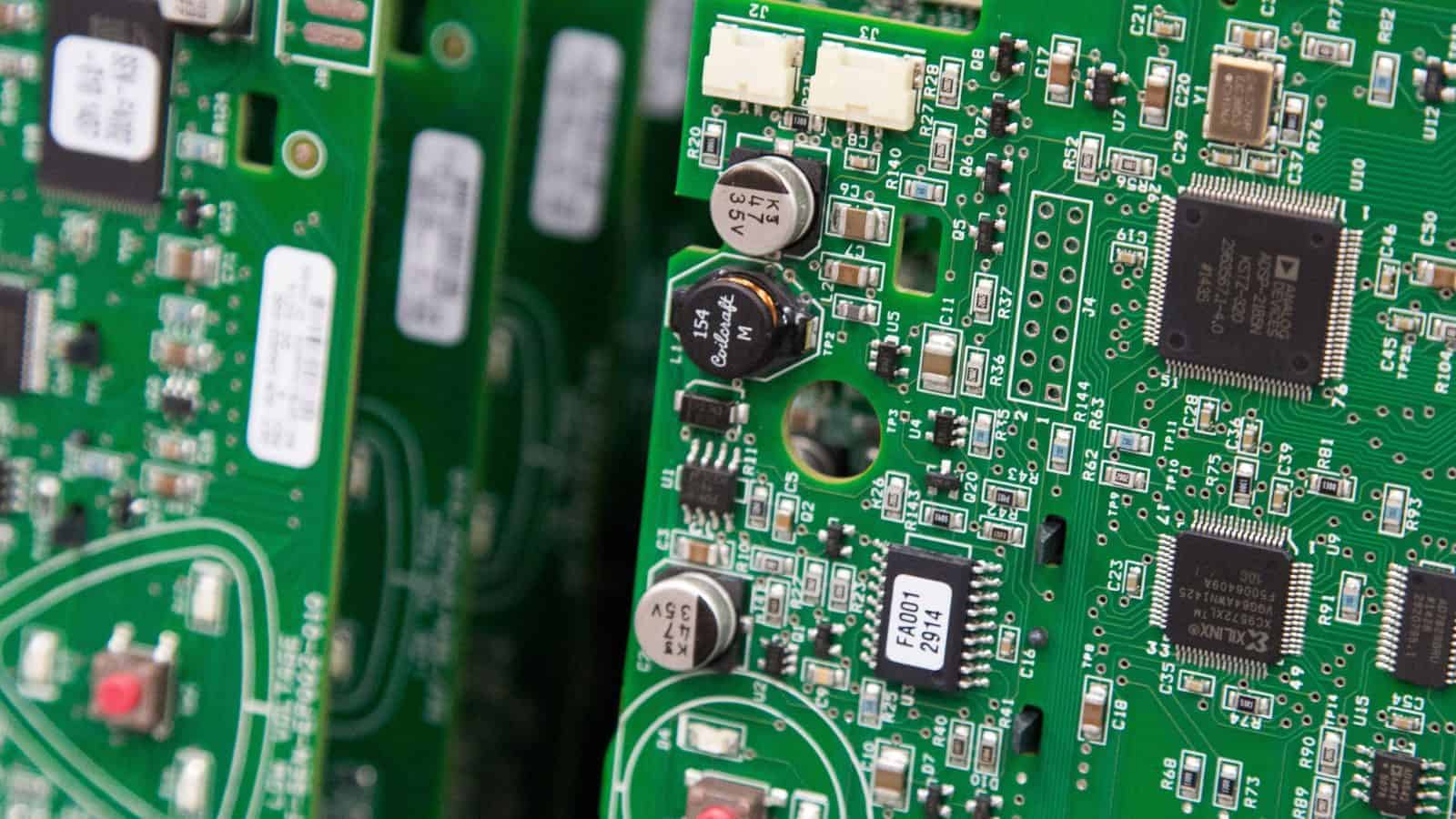

NAM Works with FCC on Cybersecurity Labeling Program

A proposed cybersecurity-labeling program for Internet of Things devices is a good idea for manufacturers and consumers alike—but it should be undertaken in the right way, the NAM recently told the Federal Communications Commission.

What’s going on: “The cybersecurity certification and labeling program—which is still in its proposal stage—is called Cyber Trust Mark and would be voluntary,” Government Technology reports.

- Participating companies would be able to utilize the cybersecurity label to signify that their products “meet certain cybersecurity criteria like ‘unique and strong default passwords, data protection, software updates and incident detection capabilities,’ and other features identified by the National Institute of Standards and Technology.”

What we’re saying: It is imperative that the FCC—which would oversee the initiative—keep manufacturers involved at all stages of development, NAM Vice President of Domestic Policy Charles Crain told the commission late last week.

- “To drive robust participation in the program and enhance cybersecurity protections for consumers, the NAM respectfully encourages the FCC to work closely with industry to finalize criteria and procedures that remain voluntary but, when implemented, prove workable for manufacturers and trusted by consumers,” he said.

What should be done: There are six main actions the FCC should take to ensure the success of the program, Crain said.

- Collaborate with manufacturers as the program is being developed.

- Keep participation in the program voluntary.

- Ensure that the process of qualifying for and receiving a Cyber Trust Mark is “trusted, practical and flexible.”

- Make program criteria reflective of the varying degrees of risk that different products pose to consumers.

- Institute a legal safe harbor protecting manufacturers from liability.

- Educate consumers about the program and how they can protect themselves from cybersecurity threats.

The last word: “Manufacturers of IoT devices continue to take steps to enhance the cybersecurity measures implemented within these devices in order to secure them against threats and ensure that consumers are protected to the maximum extent possible,” Crain added.

- “The FCC’s proposed labeling program is thus an exciting opportunity for companies to show the progress they have made in this important arena, and for the industry to cohere around a set of practical, implementable best practices to protect the American people.”

NAM Works with FCC on Cybersecurity Labeling Program

A proposed cybersecurity-labeling program for Internet of Things devices is a good idea for manufacturers and consumers alike—but it should be undertaken in the right way, the NAM recently told the Federal Communications Commission.

What’s going on: “The cybersecurity certification and labeling program—which is still in its proposal stage—is called Cyber Trust Mark and would be voluntary,” Government Technology reports.

- Participating companies would be able to utilize the cybersecurity label to signify that their products “meet certain cybersecurity criteria like ‘unique and strong default passwords, data protection, software updates and incident detection capabilities,’ and other features identified by the National Institute of Standards and Technology.”

What we’re saying: It is imperative that the FCC—which would oversee the initiative—keep manufacturers involved at all stages of development, NAM Vice President of Domestic Policy Charles Crain told the commission late last week.

- “To drive robust participation in the program and enhance cybersecurity protections for consumers, the NAM respectfully encourages the FCC to work closely with industry to finalize criteria and procedures that remain voluntary but, when implemented, prove workable for manufacturers and trusted by consumers,” he said.

What should be done: There are six main actions the FCC should take to ensure the success of the program, Crain said.

- Collaborate with manufacturers as the program is being developed.

- Keep participation in the program voluntary.

- Ensure that process of qualifying for and receiving a Cyber Trust Mark is “trusted, practical and flexible.”

- Make program criteria reflective of the varying degrees of risk that different products pose to consumers.

- Institute a legal safe harbor protecting manufacturers from liability.

- Educate consumers about the program and how they can protect themselves from cybersecurity threats.

The last word: “Manufacturers of IoT devices continue to take steps to enhance the cybersecurity measures implemented within these devices in order to secure them against threats and ensure that consumers are protected to the maximum extent possible,” Crain added.

- “The FCC’s proposed labeling program is thus an exciting opportunity for companies to show the progress they have made in this important arena, and for the industry to cohere around a set of practical, implementable best practices to protect the American people.”

Manufacturing Leadership Awards Kick Off 20th Season

For two decades, the Manufacturing Leadership Awards have recognized outstanding manufacturing companies and their leaders for their groundbreaking use of advanced manufacturing technology. What started out in 2005 as a modest 50-person gathering in New Orleans has evolved into one of the industry’s most exciting celebrations.

This past June, the Manufacturing Leadership Awards Gala honored an impressive 163 projects and leaders, in front of an electrified crowd of 450 guests. The program’s growth is a testament to the momentum of Manufacturing 4.0 technologies and their success in creating performance improvements and boosting competitiveness.

With more manufacturers adopting digital and data-driven methods every day, there is still much to celebrate. The program’s 20th season is now open for nominations, with expectations running high for another amazing show in 2024.

A proud heritage: Past winners from the Manufacturing Leadership Awards include companies and leaders from nearly every industry, from 10-person shops to multinational enterprises, located all around the world.

- Each entry is reviewed by a judging panel made up of industry experts with extensive experience in technology transformation. The top-scoring projects are selected as category finalists, and the category winners are revealed at the awards gala.

- Finalists and winners report that the awards have helped them gain new customers, boosted employee morale and team camaraderie and encouraged their executive leadership to continue investing in digital technology initiatives.

- Since the program’s inception, more than 1,000 leaders and projects have been honored for their achievements.

A wide range of candidates: The awards program welcomes submissions from small and medium-sized enterprises, as judges look for the overall level of impact that projects have had on a company’s operations—not the dollar amount of their investments.

- If technology has measurably helped a company improve its operational performance, upskill employees or enter new business markets, those projects are excellent candidates for award nominations.

The categories: Over the years, the awards have encompassed an evolving list of categories, currently at nine for projects and two for individuals.

- Project categories include AI and Machine Learning, Collaborative Ecosystems, Digital Network Connectivity, Digital Supply Chains, Engineering and Production Leadership, Enterprise Integration and Technology, Operational Excellence, Sustainability and the Circular Economy, and Transformational Business Cultures.

- Individual categories include Digital Transformation Leadership, for established manufacturing operations executives who lead Manufacturing 4.0 initiatives, and Next-Generation Leadership, for up-and-coming operations leaders aged 30 or younger.

Get involved: All manufacturers in any location and of any organizational size are eligible and encouraged to apply. Program details, rules and instructions for how to submit a nomination are available on the MLC website. Entries are due Jan. 17, 2024.

NAM to Congress: Advance R&D Tax Fix Now

To restore a U.S. tax landscape that promotes manufacturing competitiveness, Congress should act quickly in advancing bicameral, bipartisan legislation that would ensure the tax code once again supports innovation.

That was the message from the NAM and several manufacturers to lawmakers last week.

What’s going on: The NAM and company leadership from manufacturers Westminster Tool and Brewer Science visited Capitol Hill last week to brief legislators on a harmful change to the tax treatment of research and development.

- The briefing was held by the NAM-led R&D Coalition in cooperation with the offices of Reps. John Larson (D-CT) and Ron Estes (R-KS) and Sens. Maggie Hassan (D-NH) and Todd Young (R-IN).

- Larson and Estes introduced the American Innovation and R&D Competitiveness Act in the House, while Sens. Hassan and Young introduced the American Innovation and Jobs Act in the Senate. These are the measures manufacturers are urging legislators to pass.

Why it matters: “We paid $26,679 per full-time employee in additional federal tax this past year” because of the change, Westminster Tool Chief Financial Officer Colby Coombs told lawmakers at the briefing.

- “This increased federal tax on R&D forced us to cancel a major aviation contract that would have added … new jobs in our community and forgo a significant capital investment. Without fixing this issue, in 2023, we expect an additional tax bill of almost $18,000 per employee,” he continued.

- Added Brewer Science Government Programs Director Doyle Edwards: “We have lost IP to China in the past, and fight[ing] that in the courts is a no-win situation. So the only way to win is to out-invent them. And that’s what we invest our money to do. However, with [the tax change] … we’re allowing China to actually catch up.”

The background: For nearly seven decades, manufacturers could deduct their R&D expenses fully in the year in which the costs were incurred. However, since the change last year, businesses must instead deduct these expenses over a period of years, making R&D more costly.

Legislative fix: To protect manufacturers’ R&D, jobs and competitiveness, Congress should move immediately on bipartisan legislation to restore R&D expensing.

- “R&D is the lifeblood of advanced technology development for our company, for our industry, but really for the nation,” Edwards continued. “And so our message is, we need your help. We need your leadership to resolve this policy issue.”

Take action: Learn more about what the NAM is doing to advocate for sound tax policy at our R&D action center.

A Footwear Company Strives for Circularity

Within the footwear business, Okabashi is unique. The company, based in Buford, Georgia, is not only a family-owned company focused on sustainability, but also, according to the company’s leadership, producing part of the 1% of footwear still made in the United States.

For third-generation shoemaker Sara Irvani, this choice to build a sustainable and successful business in the U.S. was made possible only thanks to constant research and development.

The backstory: Irvani’s family started the company 40 years ago, and it always tried to reduce waste, both for the positive environmental impact as well as to improve its bottom line.

- “By developing closed-loop manufacturing processes, we were able to reuse some of the materials that otherwise might have gone to waste,” said Irvani. “That helped us stay more competitive—and from there we’ve developed innovations in processes and systems and materials that build on that foundation.”

The process: Okabashi’s sustainable processes extend throughout the product lifecycle—from incorporating recycled or biological elements (like soy) that ensure products last longer to preventing disposable waste to recycling post-consumer shoes into new ones.

- “When we look at sustainability of a product, we do it holistically—we look at what it’s made of, where it’s made, how it’s made, the lifecycle, the quality—and we’ve been able to innovate and develop so that our manufacturing process doesn’t create waste,” said Irvani.

- “Without R&D, we would not only be creating the additional cost basis of throwing away all those scraps, but we would also not be able to eliminate waste that is by default landfill or ocean bound.”

The circular economy: In the traditional, linear economic model, inputs go into production, a product reaches a consumer, the consumer uses the product and eventually throws it away. In contrast, Okabashi is working to perfect a circular economic model for its products, said Irvani.

- “If you are designing for circularity, you might use renewable and recycled resources, develop them into that same product with a level of quality that lasts longer, and when the customer is ready to move on, it can be remade into something else,” said Irvani. “That’s how the loop continues. When we talk about circularity, we’re creating that virtuous cycle.”

The homegrown production: Okabashi’s R&D efforts both help it stay in the United States by keeping costs down and require domestic production to work.

- “To remake and recycle a product into something new, you need to have local production,” said Irvani. “You can’t be sending things halfway across the world to be unmade and remade and sent back. That’s why R&D locally and domestically is so important, to help produce circular systems.”

The local benefit: Irvani is quick to point out that money spent on R&D creates significant financial benefits for local communities.

- “There’s a multiplier effect for commercially oriented R&D in terms of the jobs it can create and the impact on the local economy,” said Irvani. “You get a very strong return on investment for both the company and for the community.”

The global perspective: R&D is essential for U.S. companies competing with manufacturers abroad, Irvani added.

- “For U.S. manufacturing broadly, R&D is critical to stay at the forefront of the innovation curve,” said Irvani. “Unless we’re proactively investing and developing new and better ways of doing things, we won’t be globally competitive.”

The last word: “It is imperative industry and retail move toward a circular-based economy,” said Irvani. “That’s not something that just happens or falls from the sky. Consumers are demanding it, and R&D is our pathway to that future.”